Moulding and casting

Introduction

What is moulding ?

Molding is the process of manufacturing by shaping liquid or pliable raw materials using a mold or matrix, which have been made using a pattern or model of final object. But, Casting is a manufacturing process in which a molten metal is injected or poured into a mold to form an object of the desired shape

What is cast?

An object made by pouring molten metal or other material into a mould.

A mold is the negative or hollow cavity produced around a sculpted piece for use in creating multiples of that piece. A cast is the positive or reproduction of the original piece of sculpture created by pouring casting material into a pre formed mold.

Design

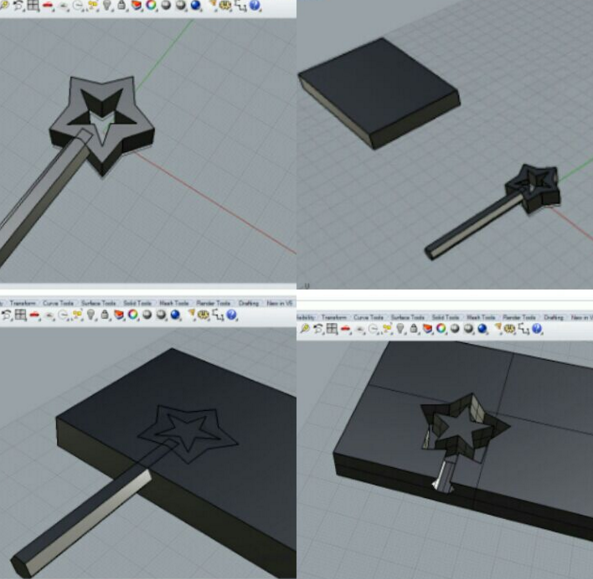

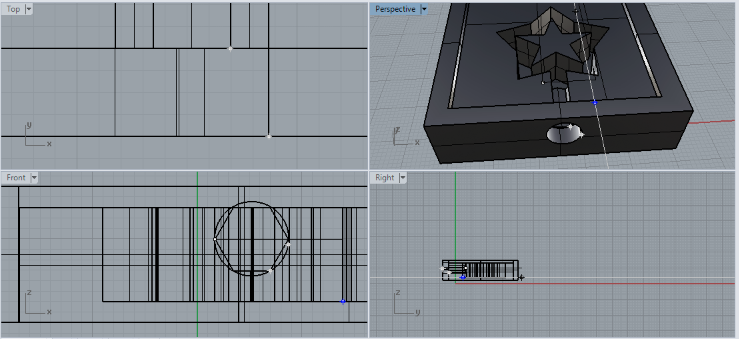

I used rhino for designing my mould,planned to make a pencil top

these are the various process of designing the mould,what i did was that just drew a star shape by using hexagonal tool and as a outline made bigger star with same method then extruded it

Measured the dimension of the pencil with vernier caliper and made a 3d model so as to subtract the exact size so that it will fit on to pencil top tight

We need to pour the solution to the mold, so i need a hollow of my design for the same i subtracted the design from a cube

This is how it looks when an additional pocket to prevent overflow of the solution just in case

I have to arrange the hole such a way that can easily remove the pencil after setting the rubber without breaking the mould

Making

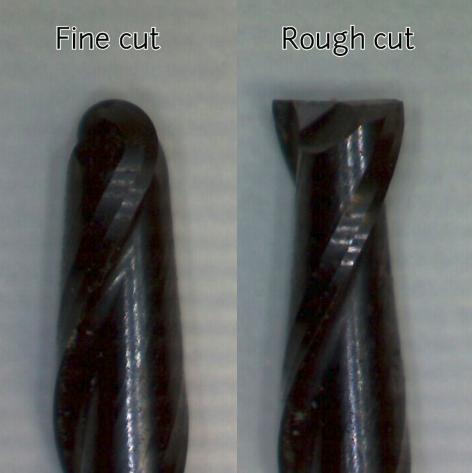

Exported the design file as ".stl" so that i can load it in fab modules, i am going to mill in the wax using Modela MDX-20 there are two types of bits used that is 1/8 rough cut and 1/8 fine cut first the material is carved with rough cut then after finishing it we have change the bit and it will give finishiing to the mould,this is the microscopic image of the both bit tips:-

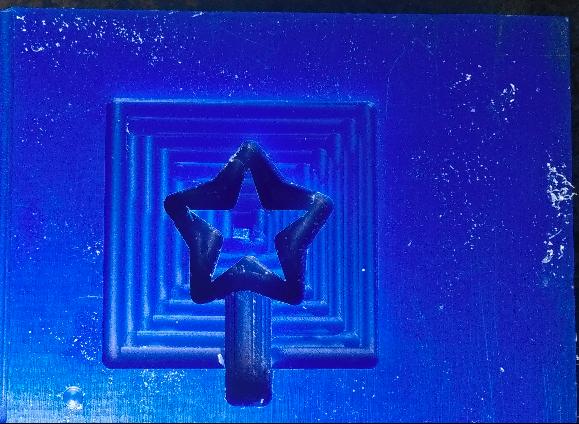

once everything is done ,start milling

Final mould i obtained after the milling

Material

What is Sorta clear?

Translucent silicone rubbers which cure at room temperature with negligible shrinkage and feature high tensile and tear strength. Materials such as urethane, epoxy or polyester resins can be cast into SORTA-Clear® silicone without application of a release agent.

I have made everything ready and took liquid rubber solution A and B then mixed it in a plastic bowl to equal (1A:1B) propotion

also added a single drop of yellow colour pigment to the solution while mixing and carefully poured to the mould after completely oozed the solution out meanwhile inserted the pencil to the mould and using a wooded stick made sure that its properly set ,since its viscous liquid there is higher chance for getting ai bubble inside.

after finished the process i left my mould for about 5 hours to set properly and using a penknife gently removed the cast out of the wax mould.

As seen in the image it went well, using a paper knife i removed the extra rubber on my design

Pitfalls

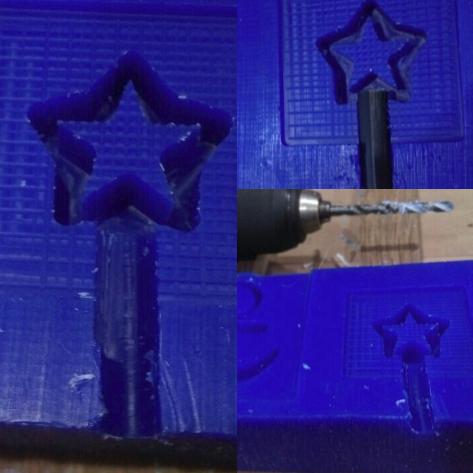

Meanwhile i have made a mistake, eventhough i gave the holes in the edge whille designing i have zeroed X and Y axes in modela a bit upside the edge so i had to drill the hole for keeping part of my pencil inside ,somehow managed and everything went well.

You can download Files here.