W14 - composites

Mission & initial concepts

Assignment

Design and fabricate a 3D mold and produce a fiber composite part in it

Materials

- Fiber : Lino

- Wood

- Film or plastic packaging

- Epoxy resin (POX BAK 1206)

- Vasilin

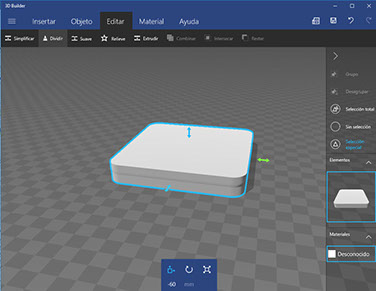

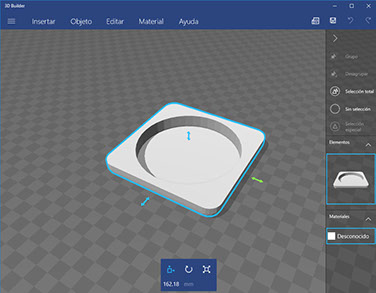

Software design

- 3D Building

INTRODUCTION

I do not smoke, however allways thinking in my house, i have a lot of friends that does. So my intention is to recreate some ashtray that i could use at home. Probably the material is not the best one but i will learn in the process.

Design Process

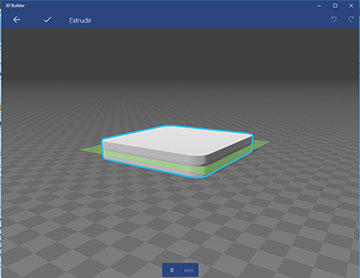

For the assignment of the week I design an ashtray, and use the software 3D modelling. My first initiative was to print in 3D but because a personal problem (health illness) i couldnt have the time to print it, so at finally i use wood for the same idea.

However i documented my process.

Final materials (wood i used for the design)

PACKAGING

Next i used package tape (plastic packaging) in order to protect the mold and use over it some vasilin.

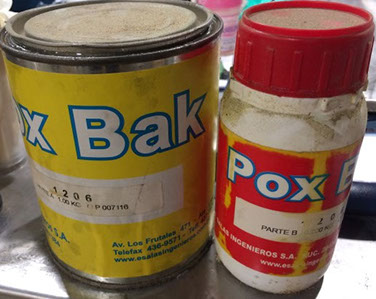

USED RESINE

POX BAK 1206

It is a resine of multiple uses, combined with its partner at normal teperature give excelents mechanical properties

Recomended Relationship of the mix:

Pox Bak 1206 : 100

Partner B: 20

Time of use: 20 to 30 minutes at 26C

Time of being hard : 45 minutes at 26C, it can be unmolded after 4 hours at least. The total hardeness can be obtained after 36 hours

I made Make a mix of pox bak

- 1: Red one

- 5: Yellow one

Based on the information of the brand i used it to my mold and left for 3 days

FINAL RESULT

The final product look not so good as expected, because i didnt left it in a saved area and also the plastic i used to give it pressure was unsecure, so most of the lino did not mix well.