Objectives:

- Read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using.

- Design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it. Post Processing, Composites

- Downloads

3D Model

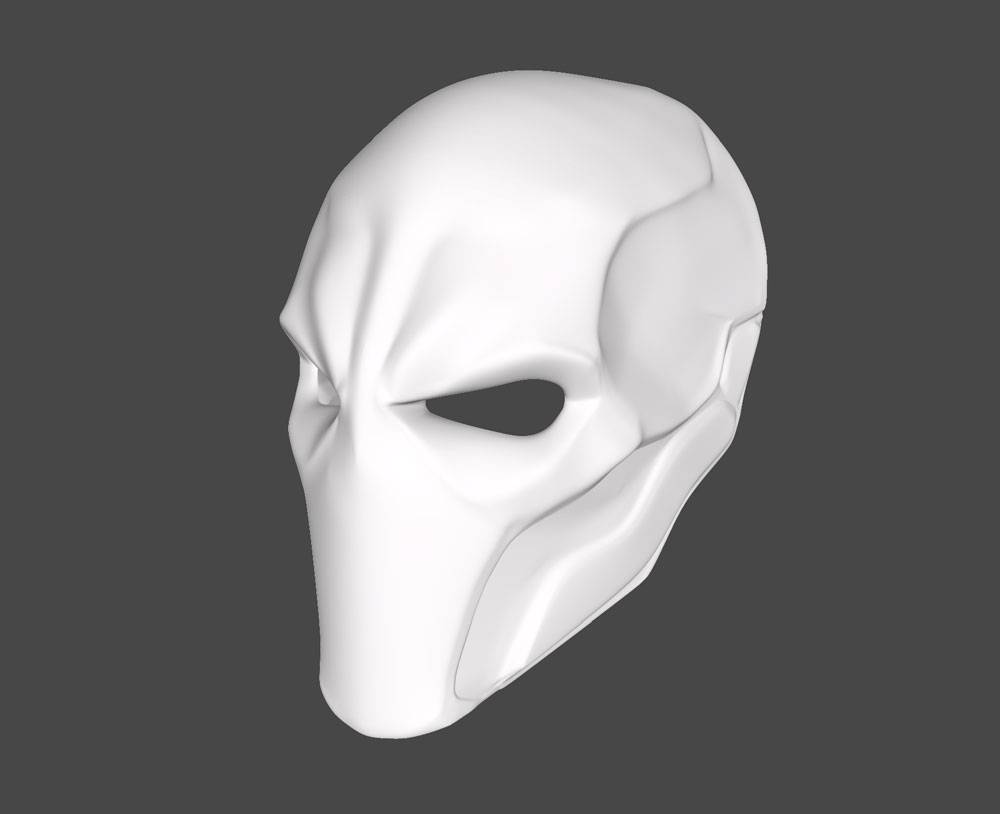

The assignment of the week was to build a mold and use it to make something with composites materials. I decided to focus on the composite part rather than the 3D modelling part so i downloaded a 3d model from thingiverse. The model i choose is a mask from the comic DeadPool, in particular the Deathstroke’s mask.

http://www.thingiverse.com/thing:2265132

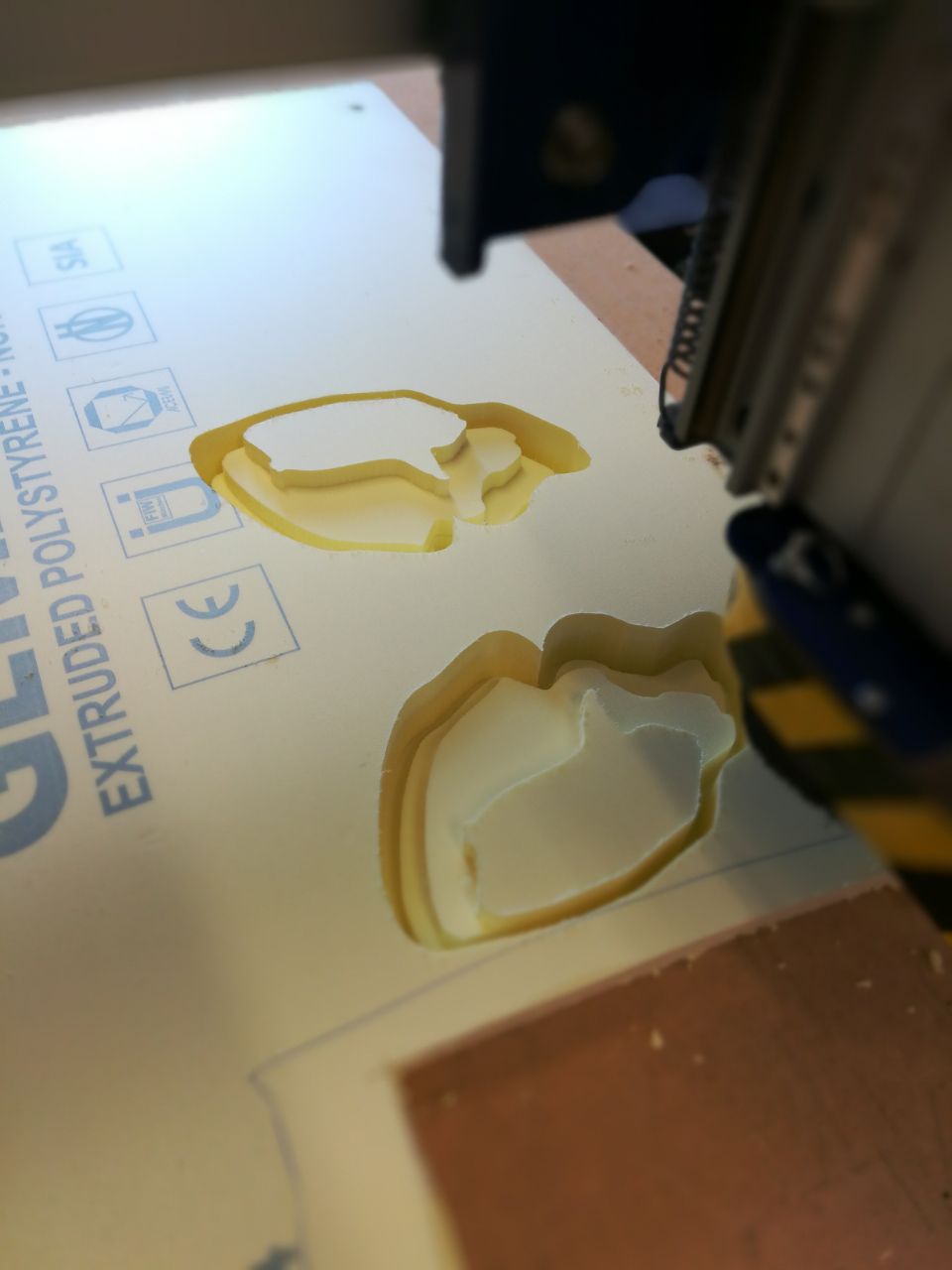

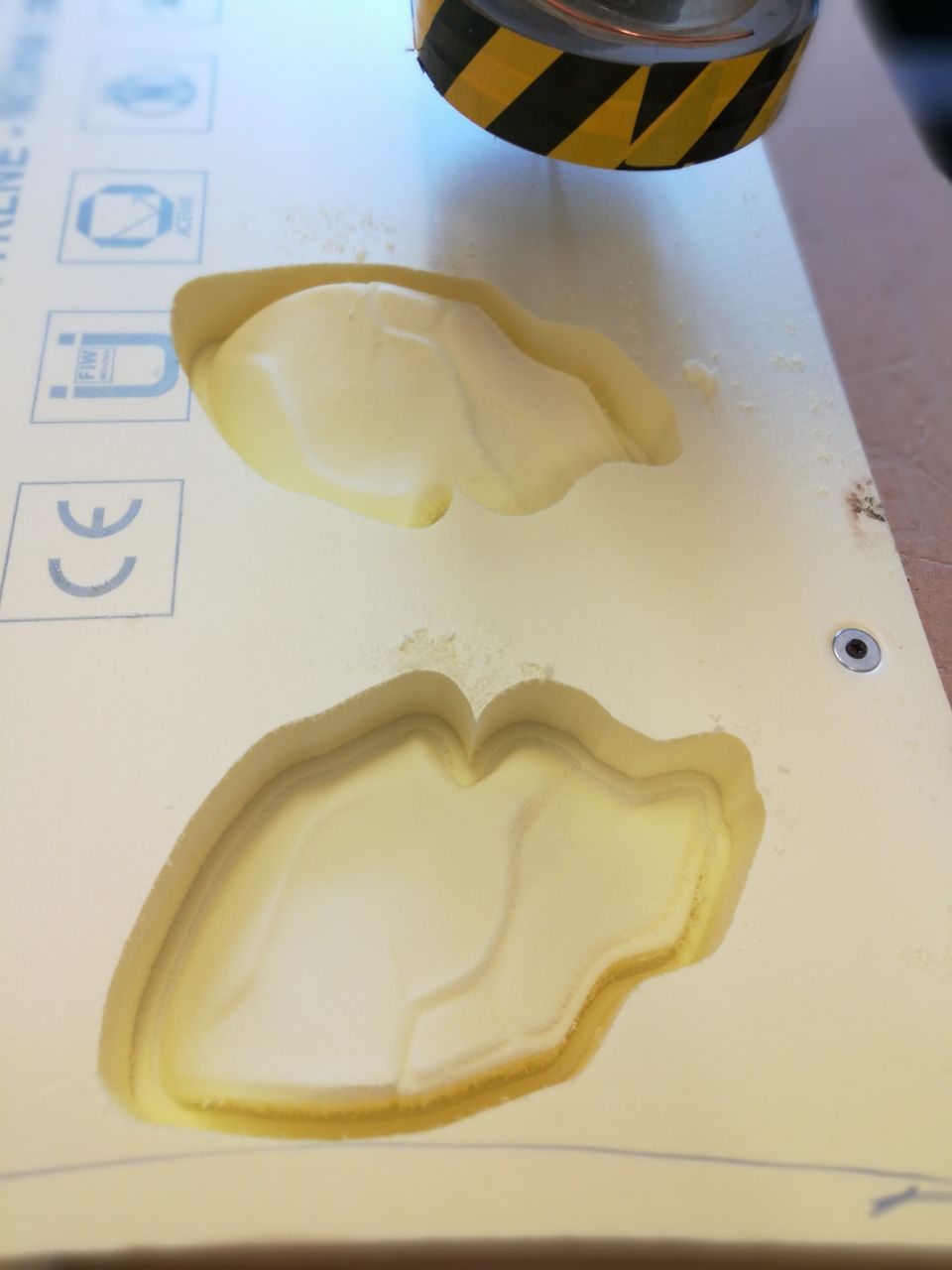

To fit the foam sheets we have ( 40 mm thick ) i had to cut the model in 4 parts.

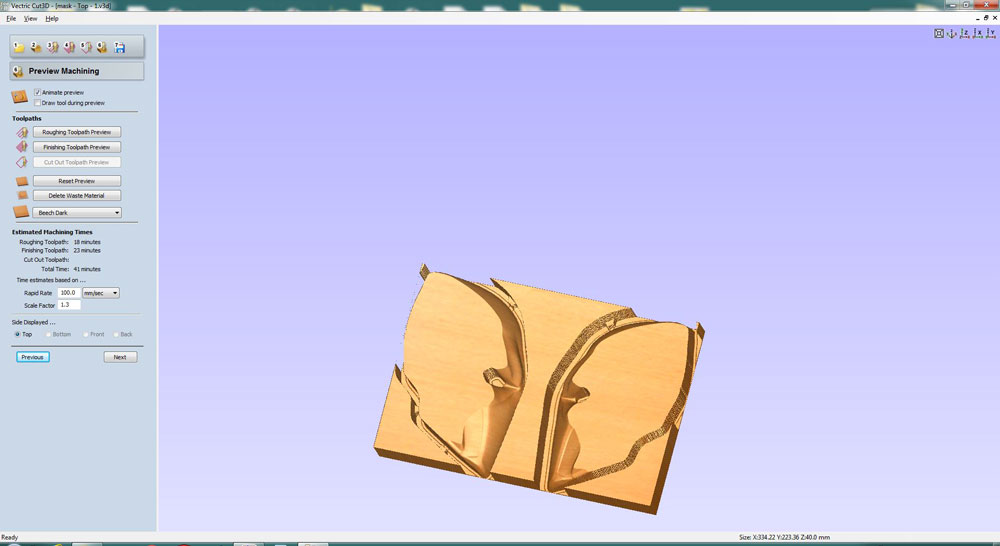

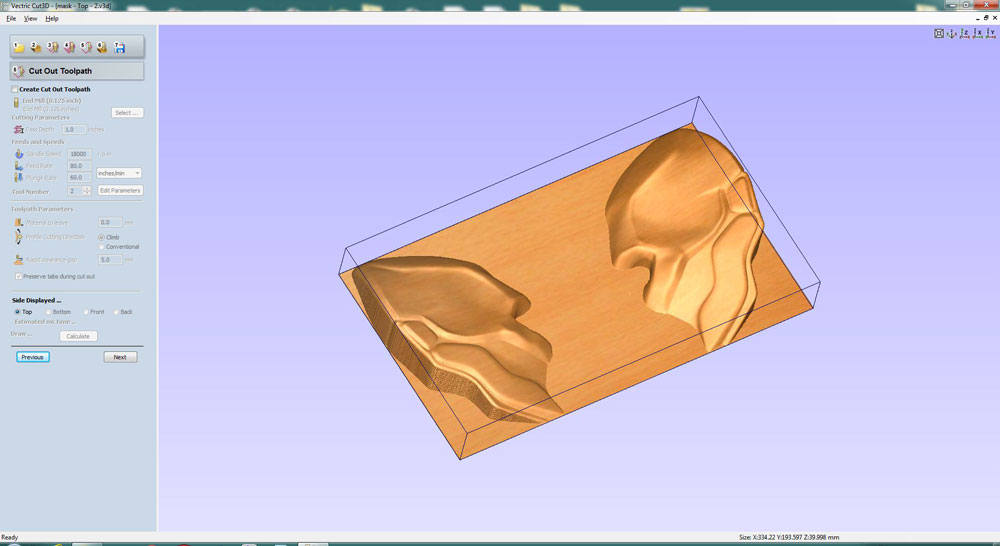

I used Autodesk Meshmixer to cut it in half and Cut3D to slice it again in 2 parts so i had the 2 middle slices in a file and the 2 outer slices in another file.

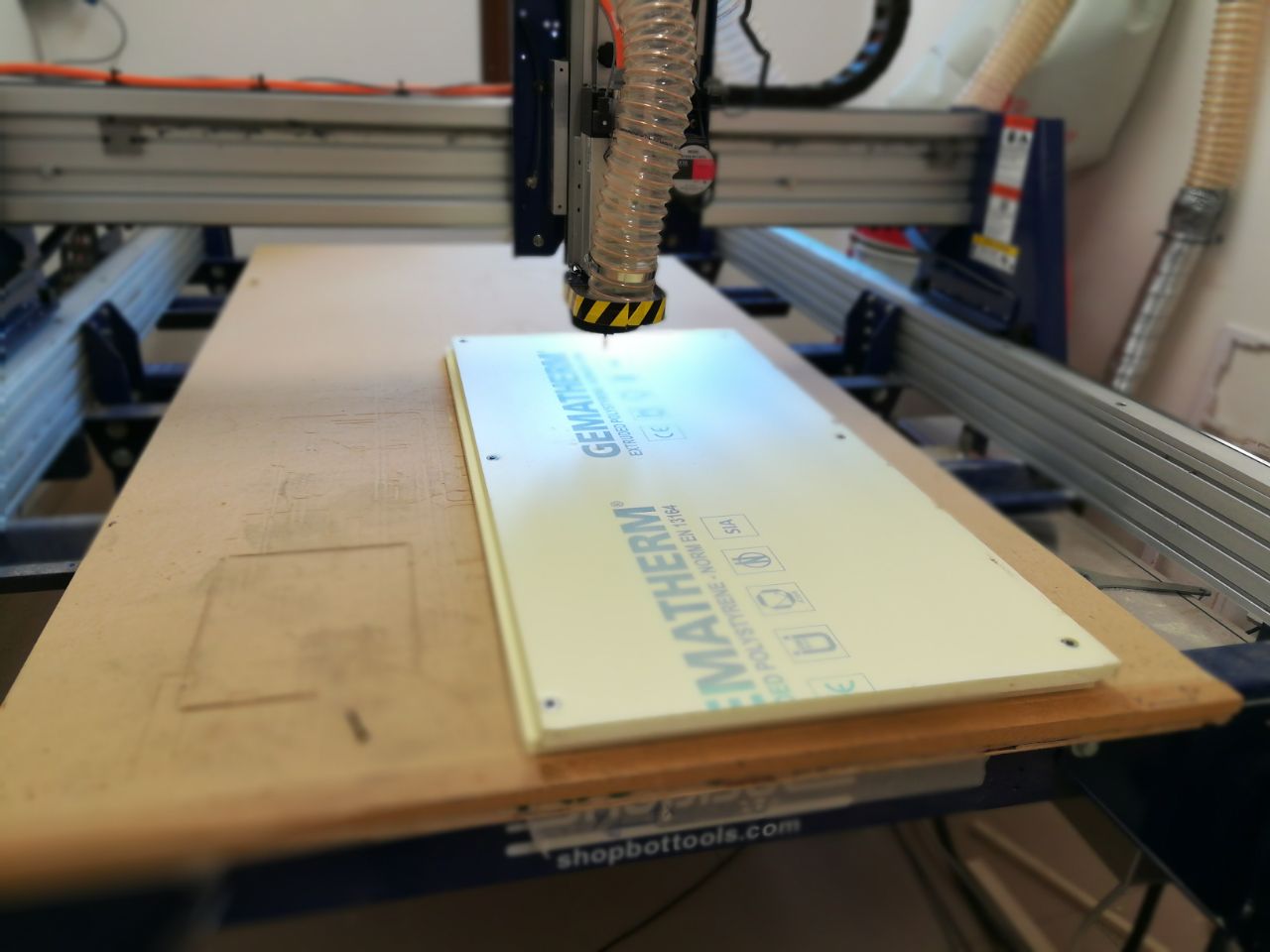

To mill the foam i used 1/4 flat end mill to generate the rough toolpath and 1/8 ball nose to mill the finishing toolpath.

The settings i used are very different from the one we use with plywood or OSB, we did a pass depth of 1.5cm at 200 inch/min.

Post Processing

I glued all the 4 parts together with Vinavil and left it dry for 1 hour.

I finished the surface, first with medium sandpaper and after with fine sandpaper.

Next i applied 2 coats of epoxy resin to fill the foam small holes and make it waterproof.

Next i applied 2 coats of epoxy resin to fill the foam small holes and make it waterproof.

After i covered the model with 3 coats of polyvinyl alcohol which is specifically used to easily detach the composite from the mold. I left dry each coat for 2 hours.

Composites

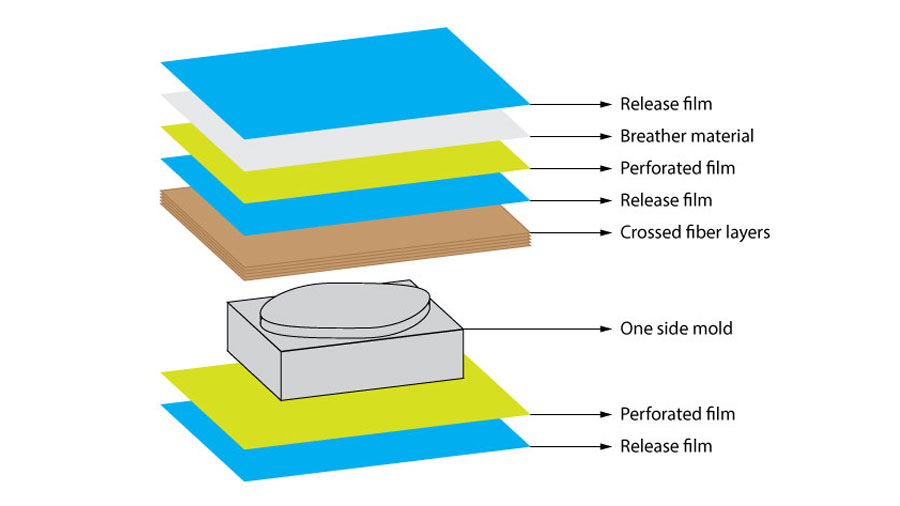

Before starting the whole process i cutted all the thing i’d need later, like the release film, the perforated film and the breather.

I also cut small slices of linen fiber which i’ll use later.

I mixed the epoxy resin with the hardener and started to apply the linen fiber slices to the mold. The process was really hard and i didn’t had the chance to take photos during it because i couldn’t touch the phone while having the gloves full of resin :D.

I assembled the “sandwich” i created before following the scheme below.

Next i placed the model with all the materials on top inside the vacuum bag and used the vacuum cleaner to create suction.

The day after i opened the vacuum bag and removed the release materials.

To remove the composite from the mold i used hot water ( as the polyvinyl alcohol suggested ) but it didn’t come out as easy as expected. At some point i had to make a little cut in the composite to remove it easier.

conclusions

Honestly i cared more about not damaging the foam mold rather than pulling the composite material without damage because the finishing of the composite wasn’t really good.

That way i can use the mold another time.

I think to have a better result, next time, i’ll use way more polyvinyl alcohol, maybe 10 coats so that i can put everything in warm water and let the PVA dissolve.

Another thing to consider is the thickness of the linen fiber maybe to have a better result the fiber have to be thinner or maybe sliced into smaller stripes.

If everything listed above does not produce a better result than the other way is to make the female and male mold and press the composite between the two.