Objectives:

- Design and build all the mechanical part of the robot. Sphere Shell, Spare Mechanical Parts, Downloads

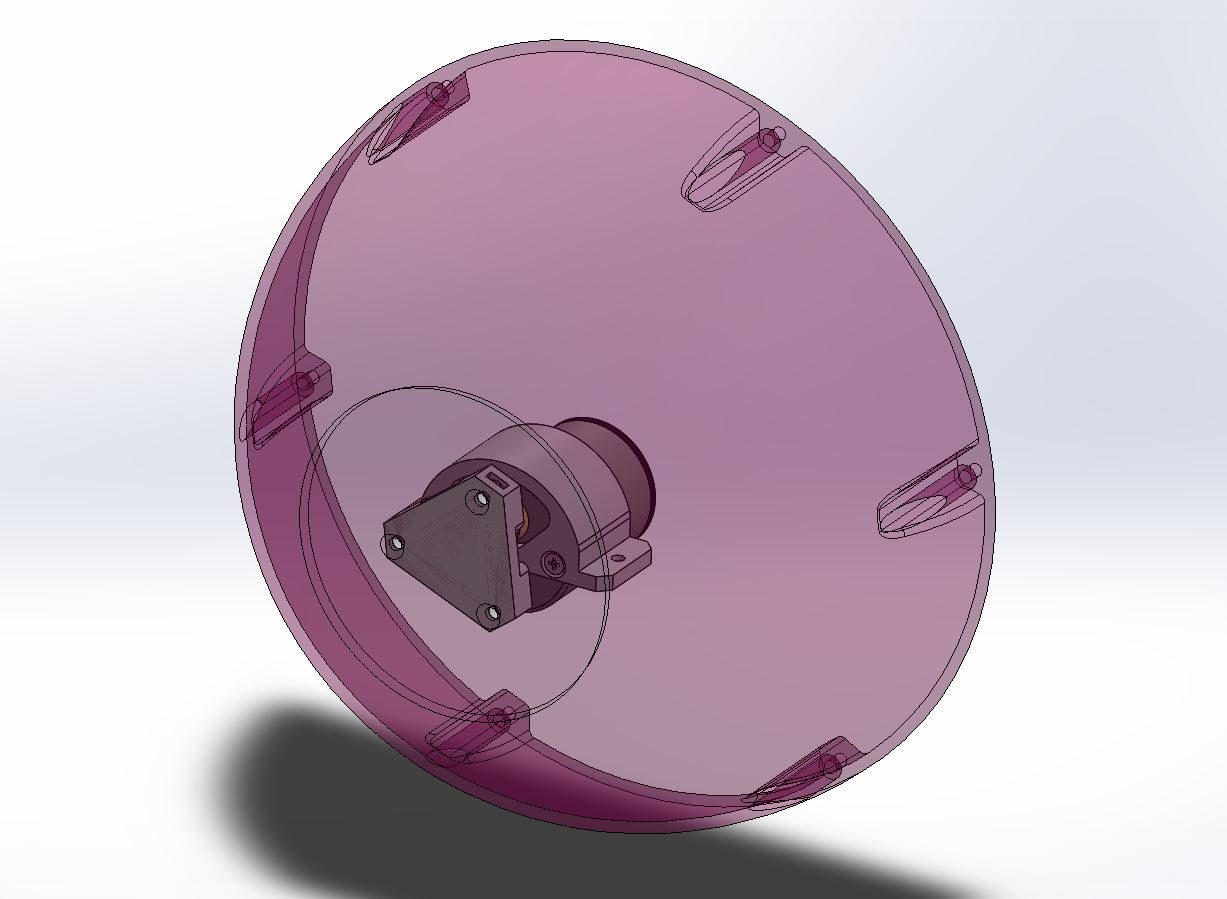

The Shell

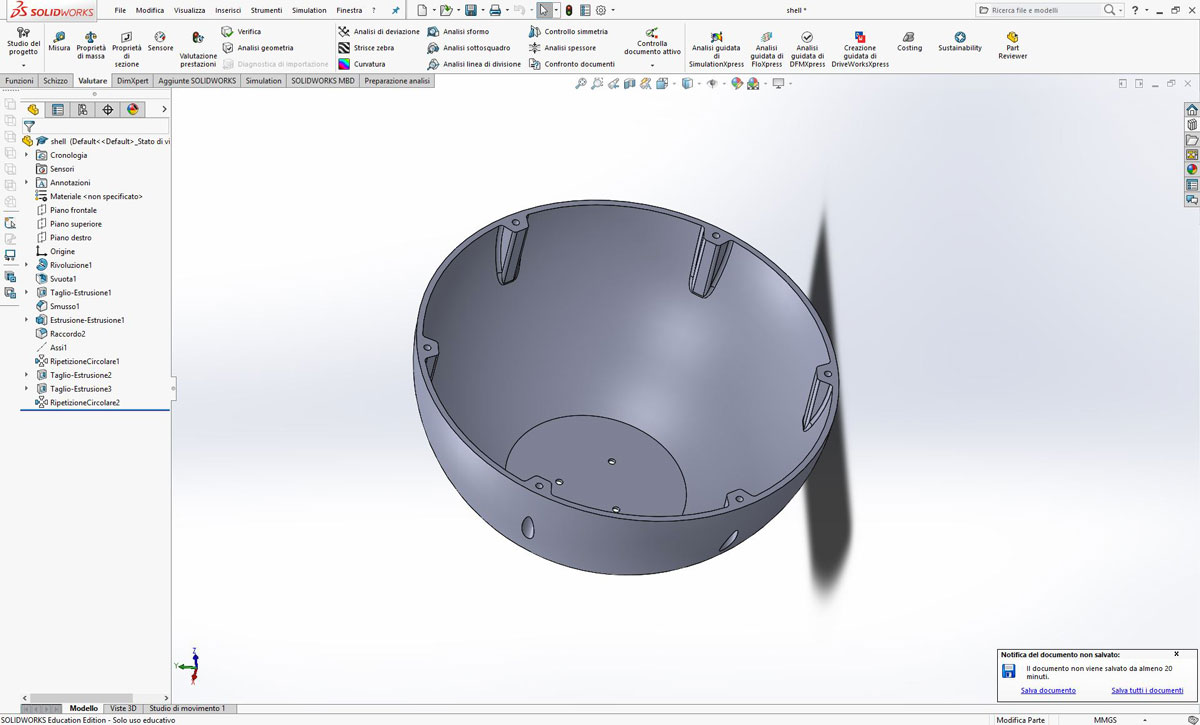

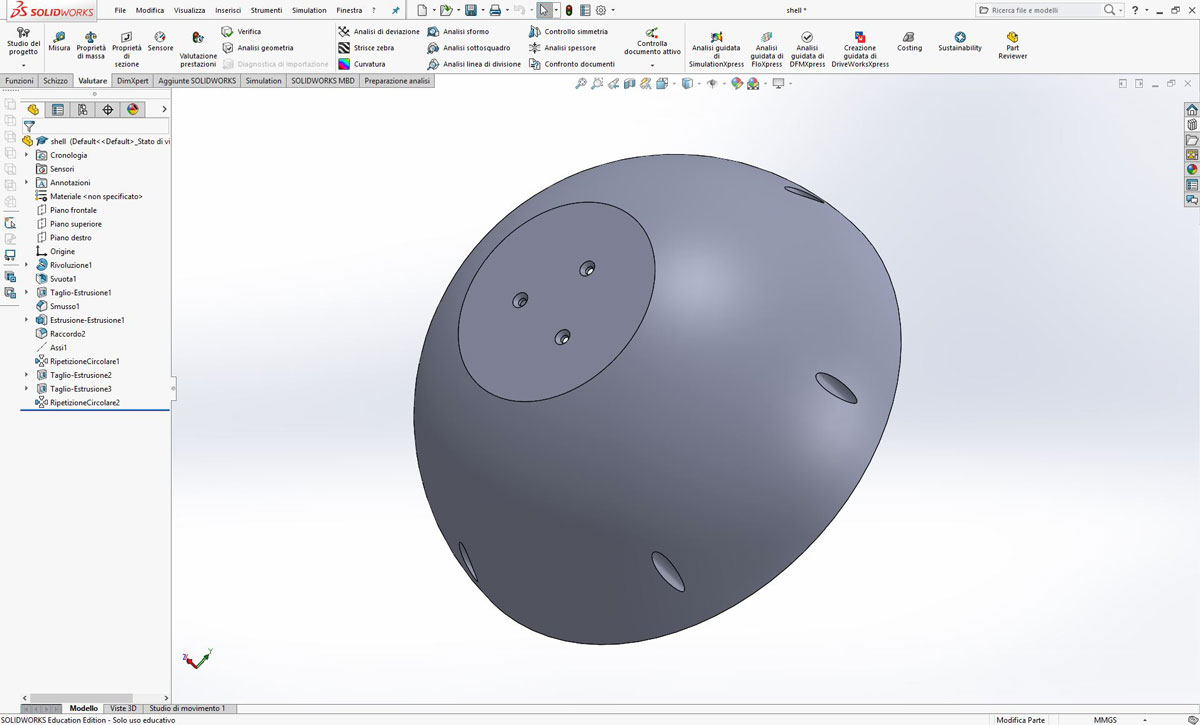

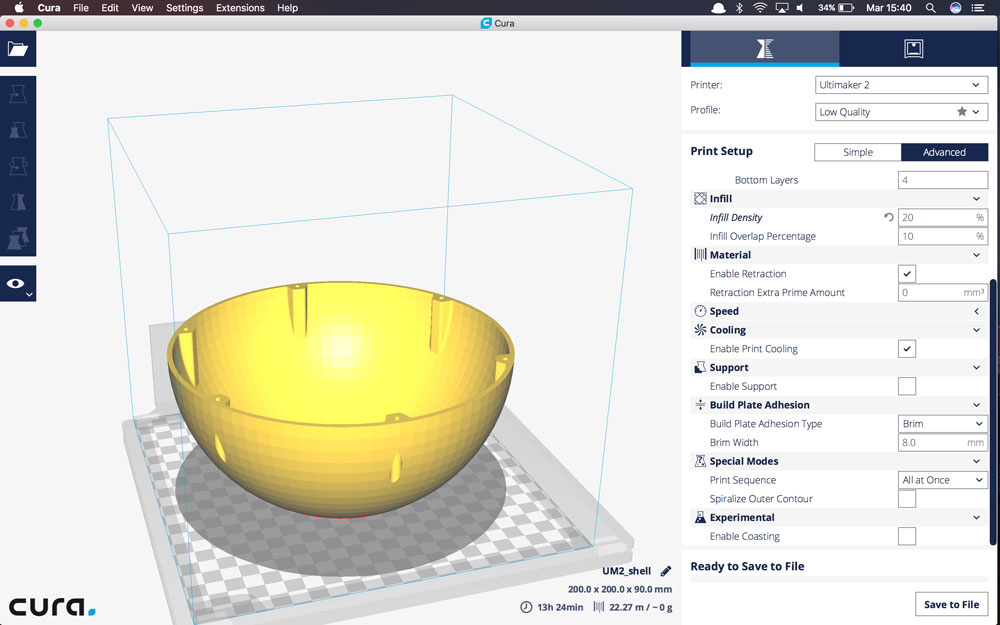

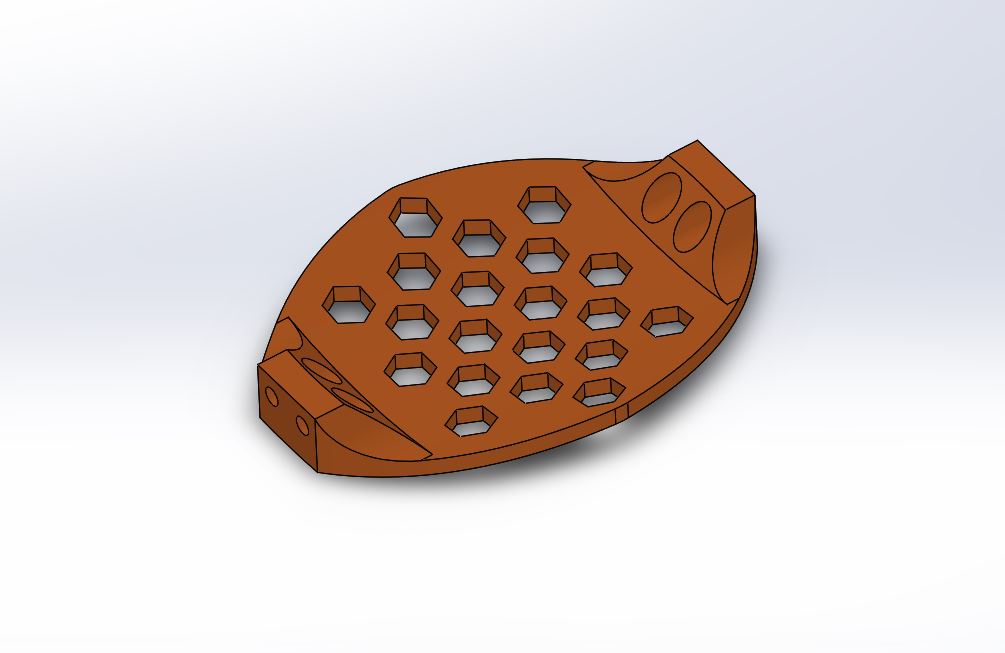

My personal goal was to build the robot as small as possible but to keep the price down and use as much as possible hardware we already have in the lab ( fablabs inventory ) i had to rethink about the dimensions. On the other hand i was limited in size by the 3D printer bed size so i designed the sphere having 200mm diameter which perfectly fit the Ultimaker 2 bed.

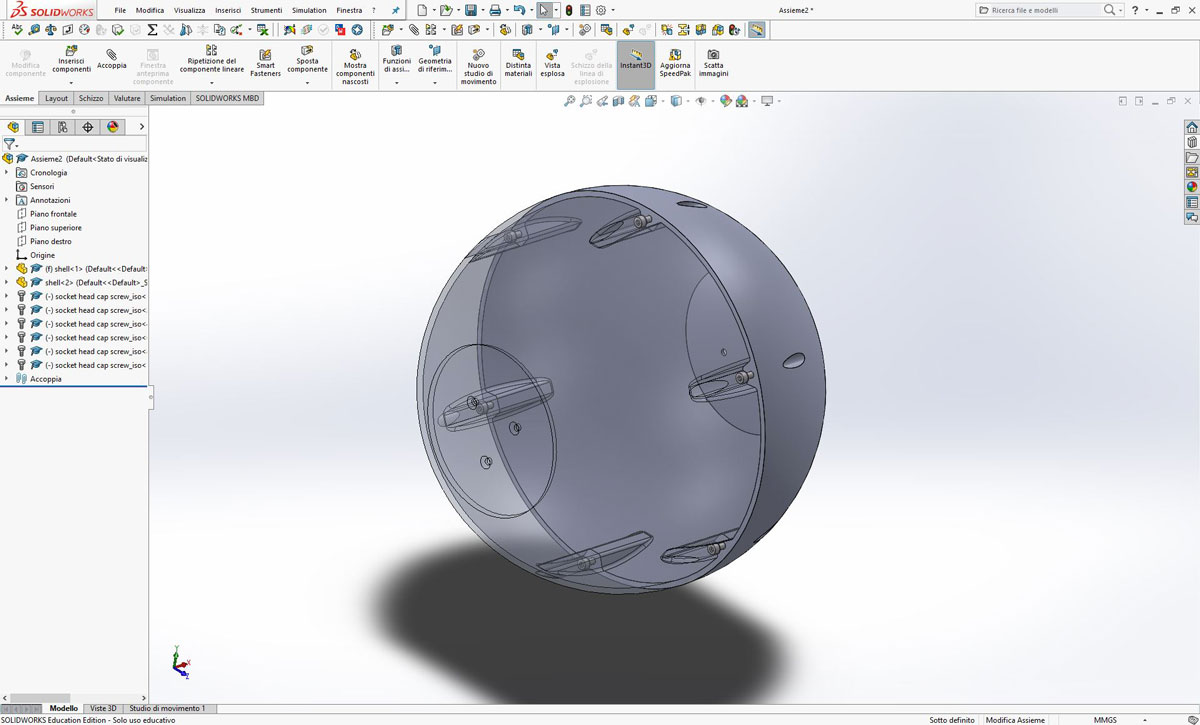

The robot is composed by two half sphere kept together with six screws.

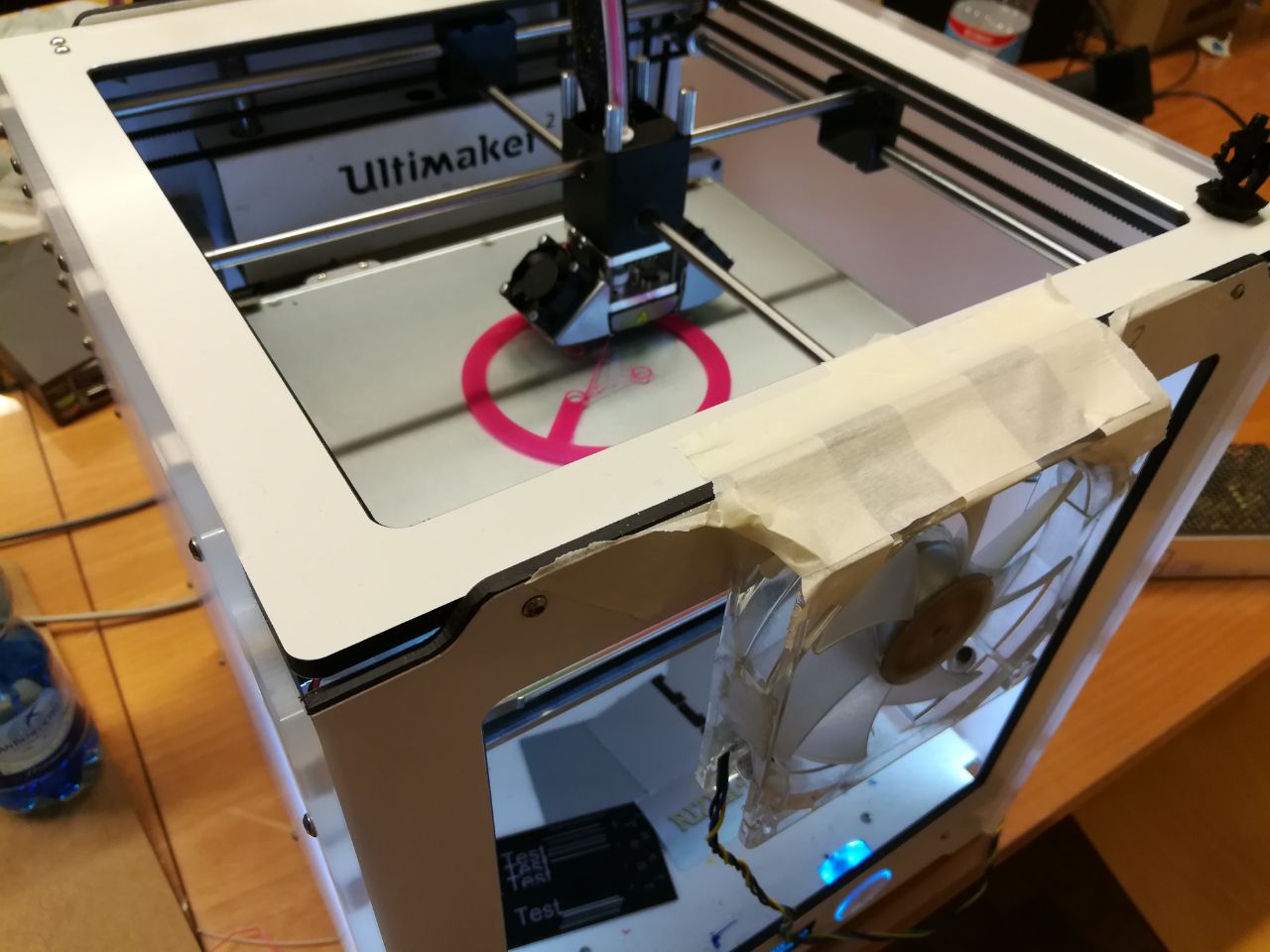

I exported from Solidworks the STL version of the shell model and i opened it with Cura, the Ultimaker 2 software. I had previous experience in printing > 45° overhangs and i knew that having a strong cooling is essential to get a good surface finish so i installed on the top front side of the printer a 120mm computer fan connected directly to a 12v source.

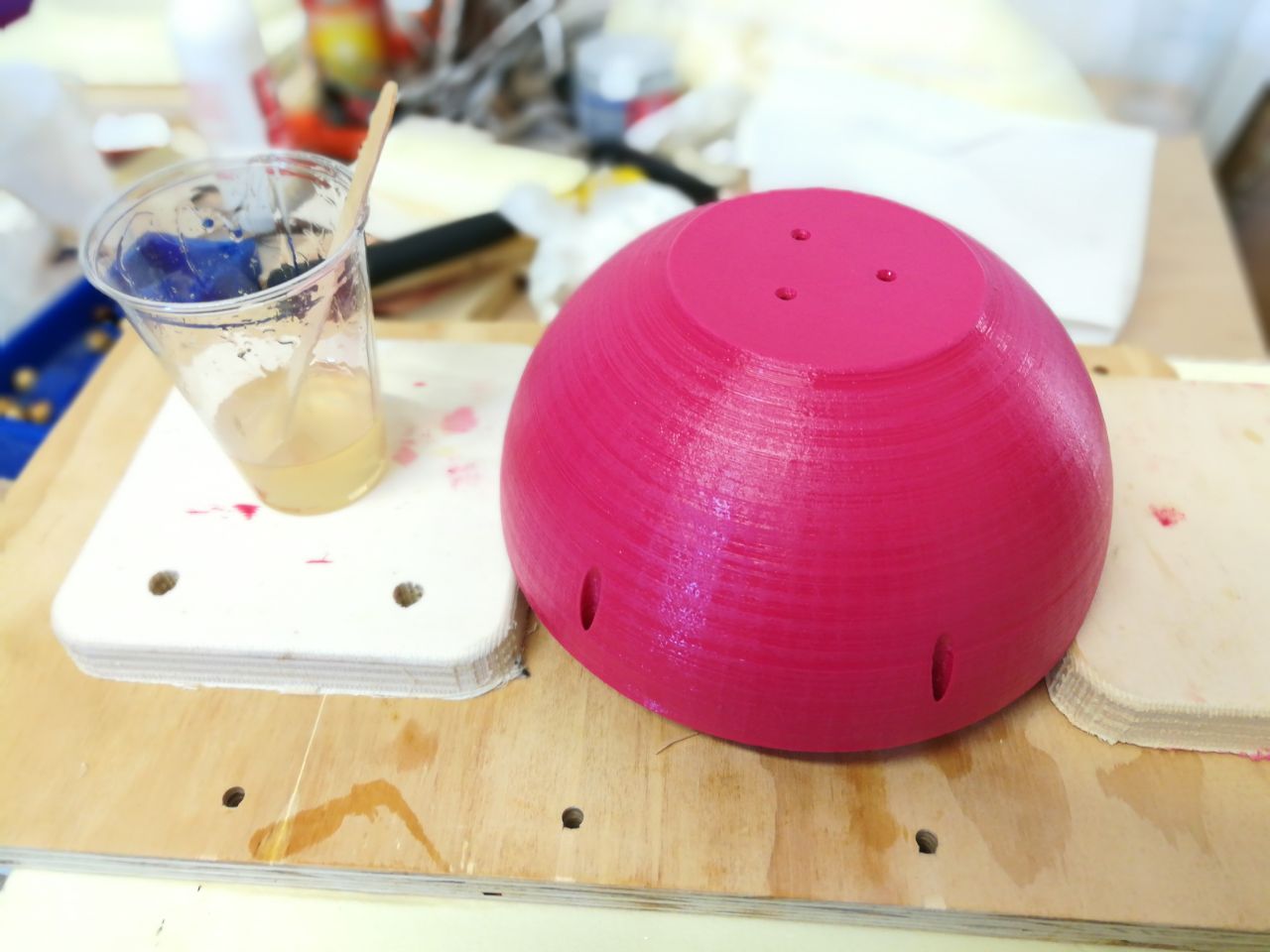

The magenta filament i used is branded 3D Prima and it’s PLA.

I printed the other half sphere with a custom built delta we have in our lab and the filament i used is from an italian company MAKE SHAPE , PLA 1.75mm diameter.

The settings i used are:

- Layer height: 0.25mm

- Infill: 20%

- Print Temperature: 215° C

- HeatBed Temperature: 60° C

After i sanded the ball and i coated it with epoxy resin to give additional strenght.

To give some “grip” to the shell i used a special rubber spray called Plasti Dip --> Plasti Dip Website

The last step was to melt inside the plastic M3 threaded inserts. To do so i used the tip of the soldering iron, heated at 160°C, to push the threaded insert inside the plastic holes.

I repeated the same process for the other half of the shell.

Spare mechanical parts

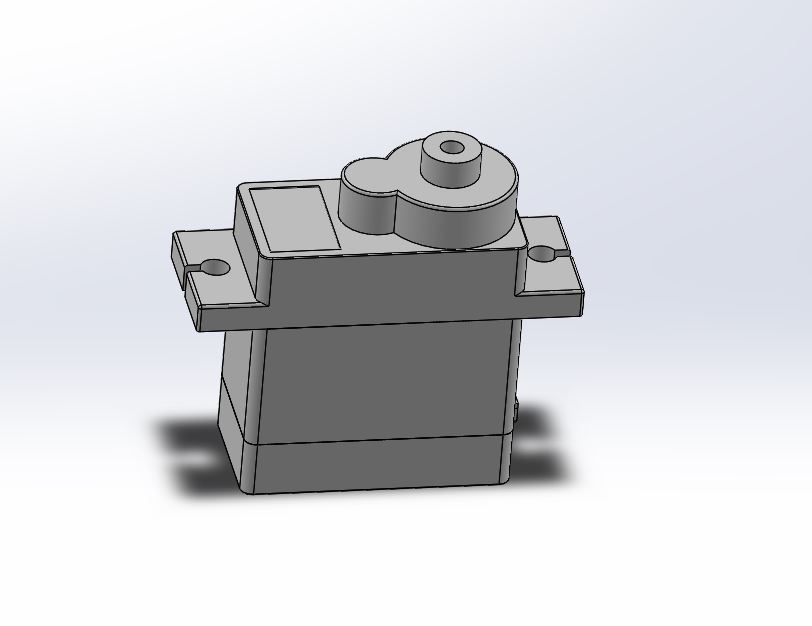

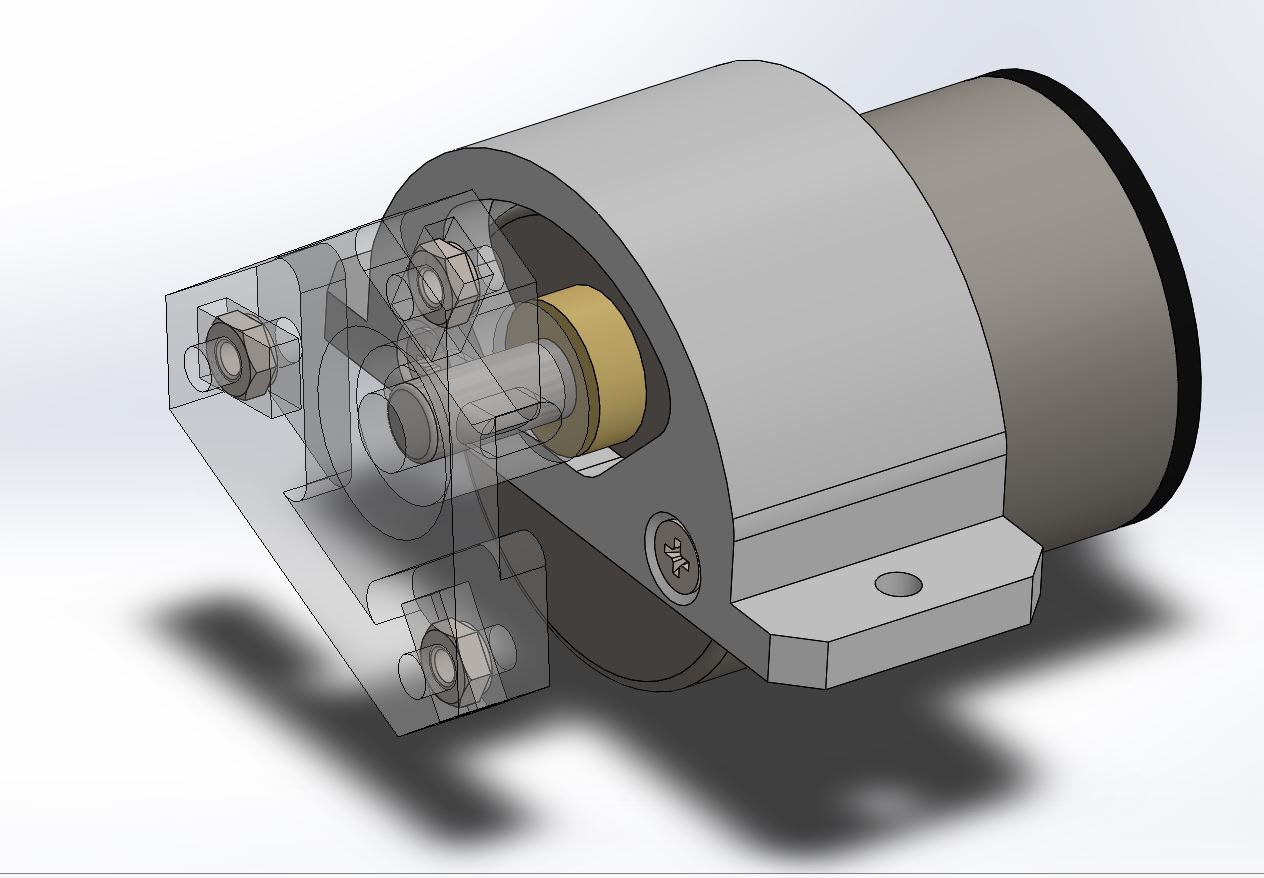

The first step was to design all the commercial parts i used like the Servo motor and the DC motors.

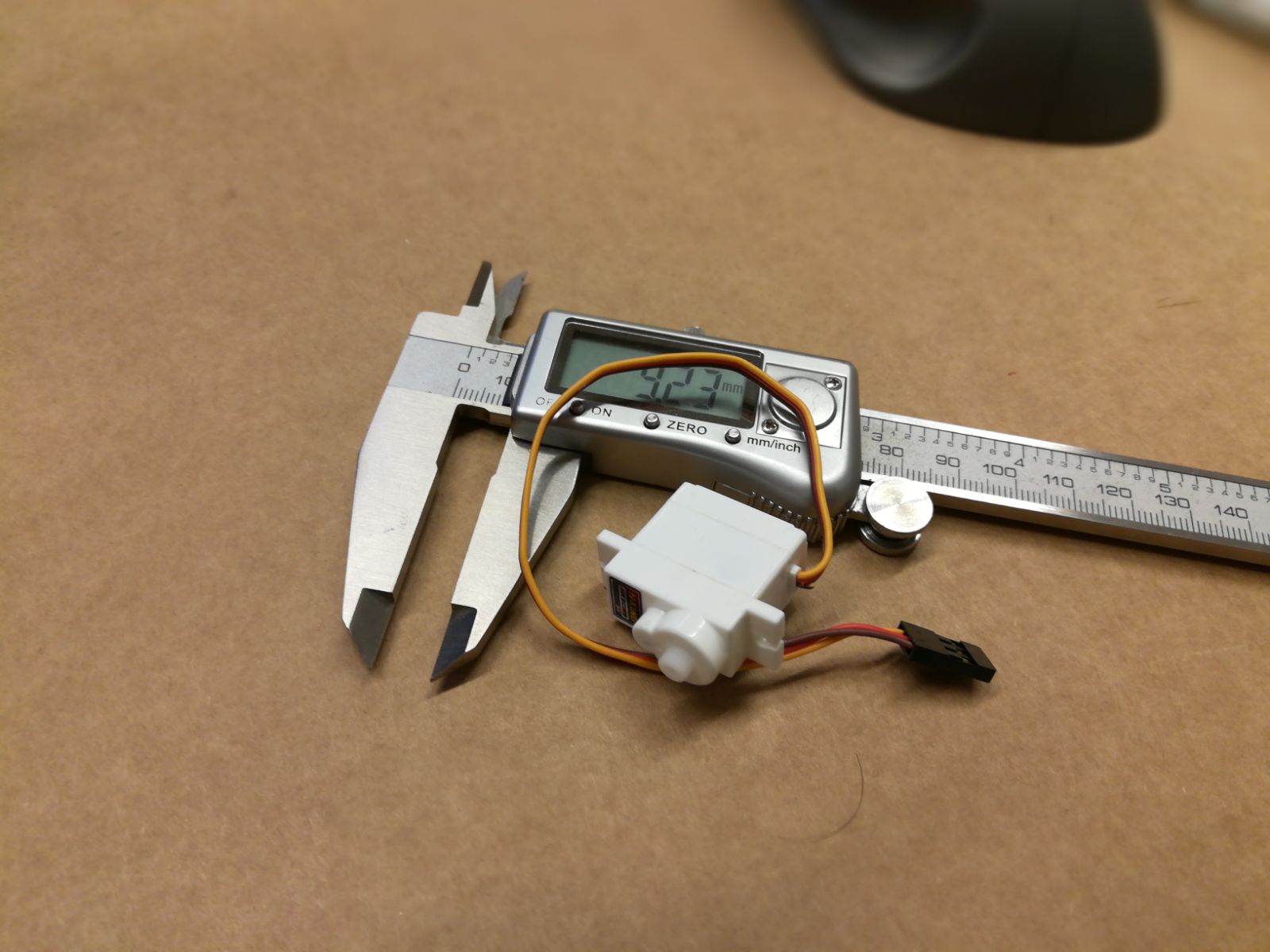

Servo motors are Hobby King HK SCM9.

Product Page

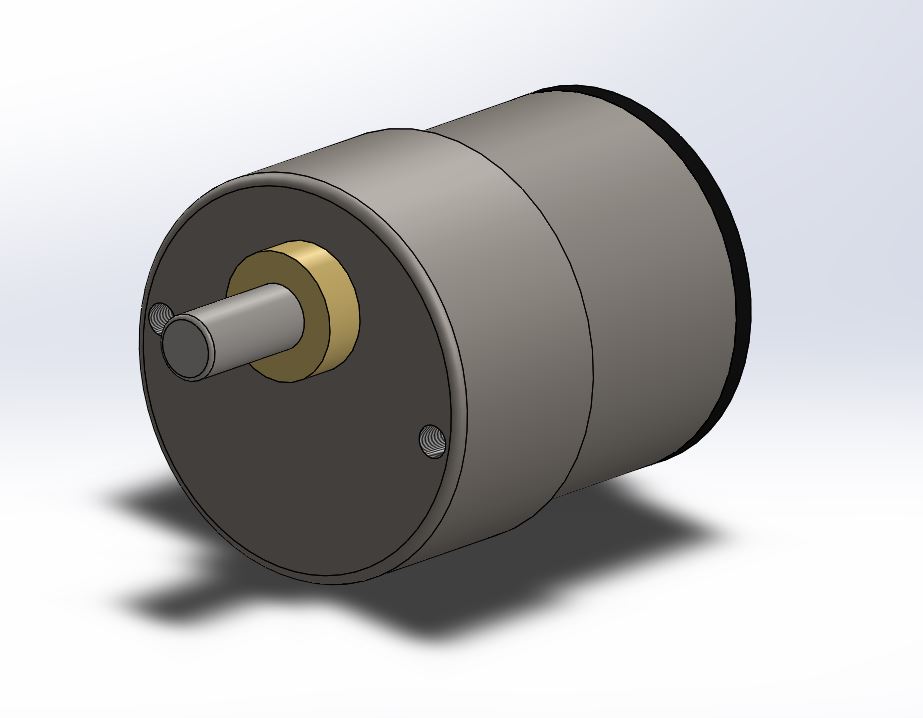

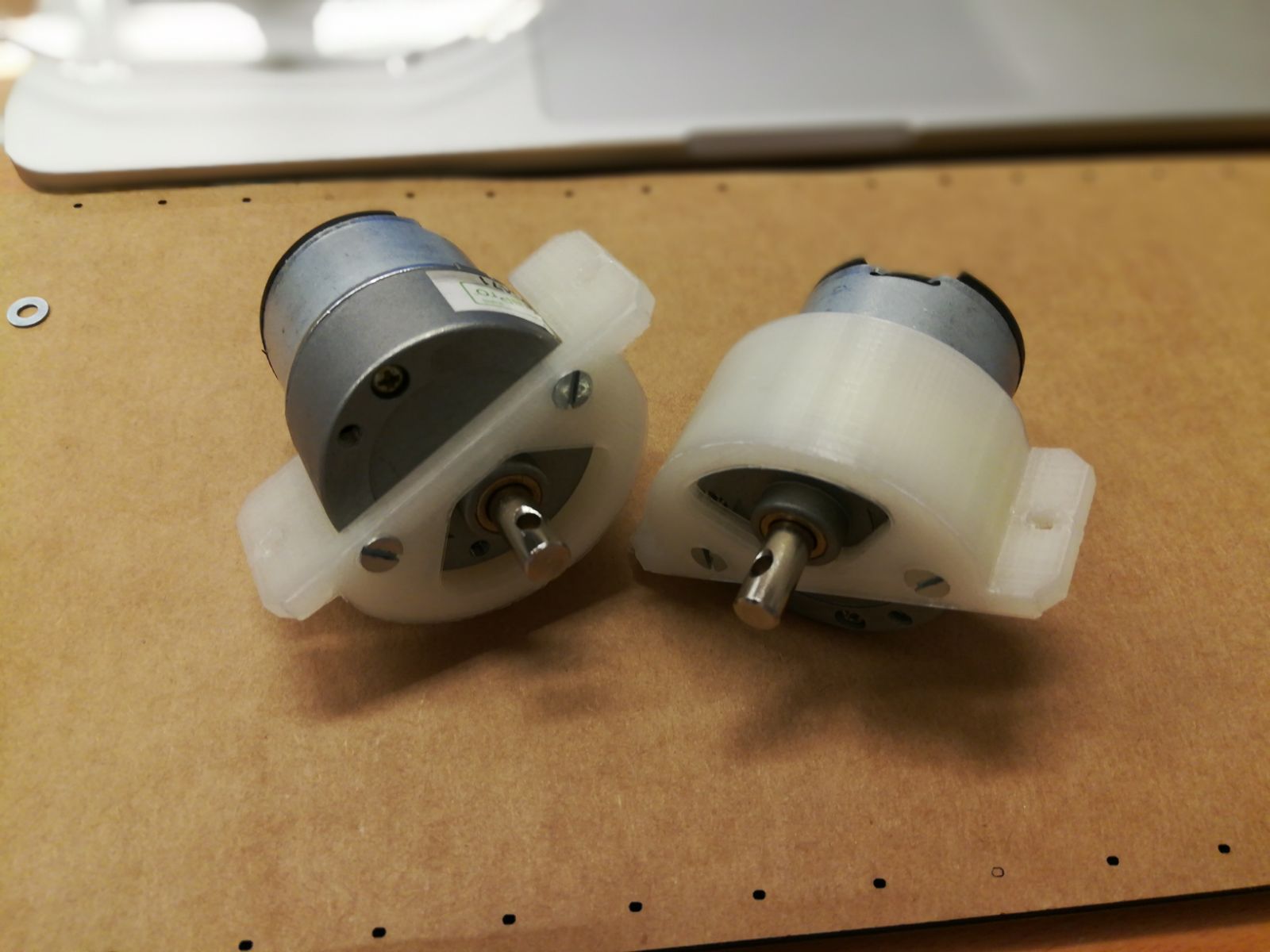

And the DC motors are Jameco 253471 Product Page

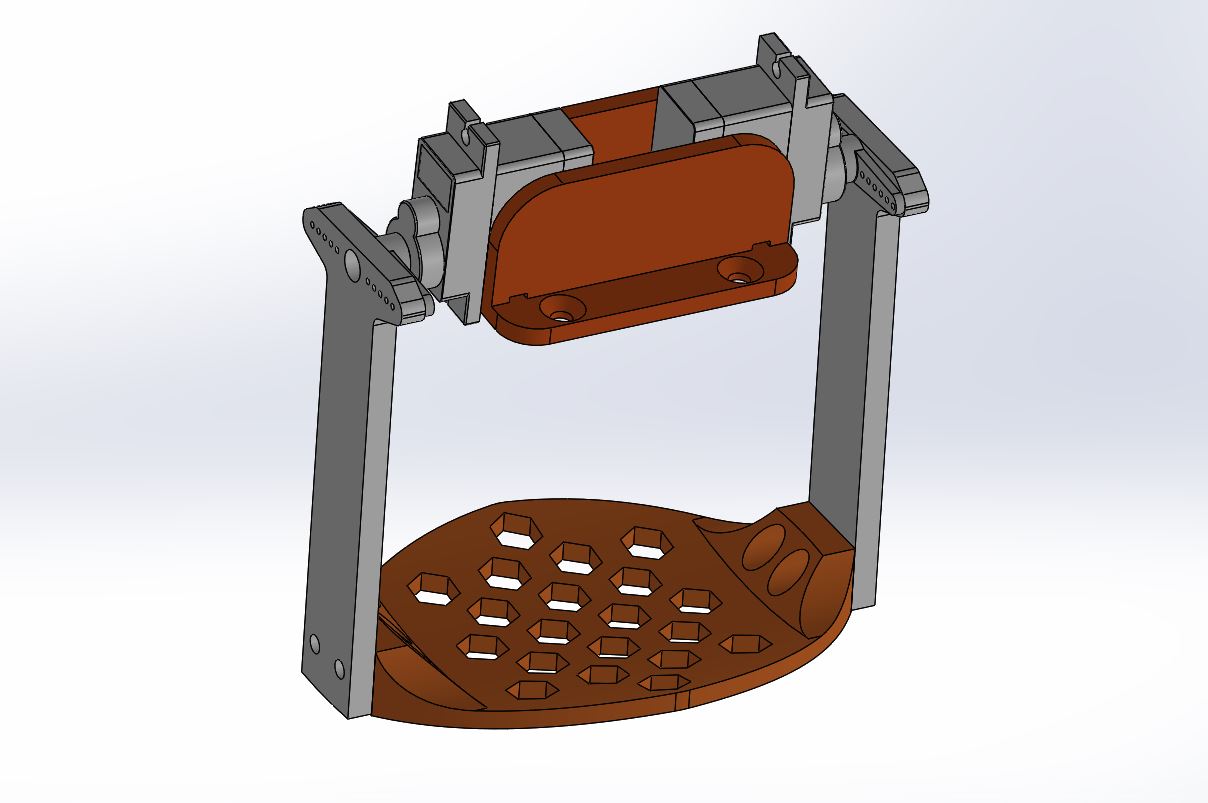

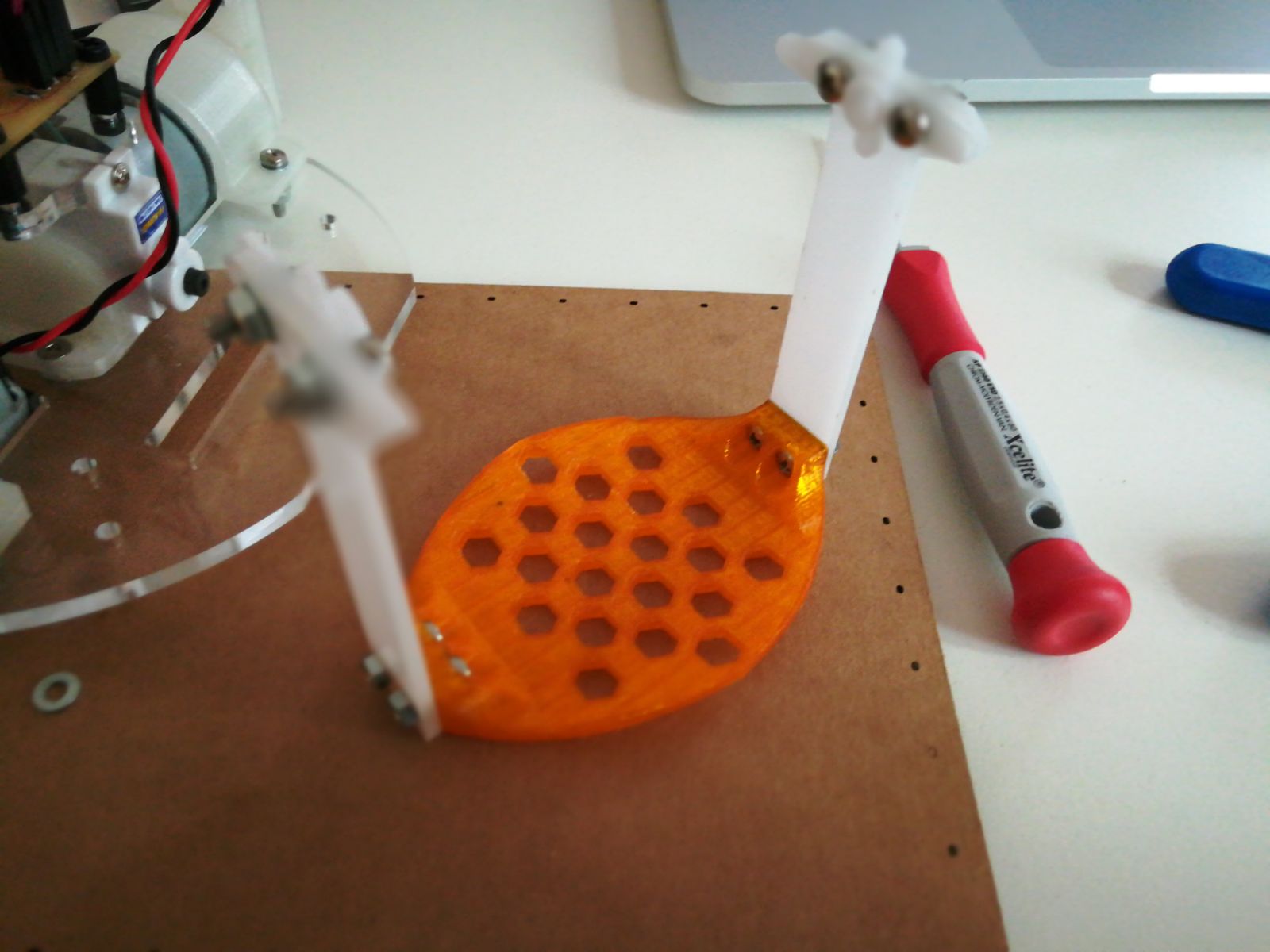

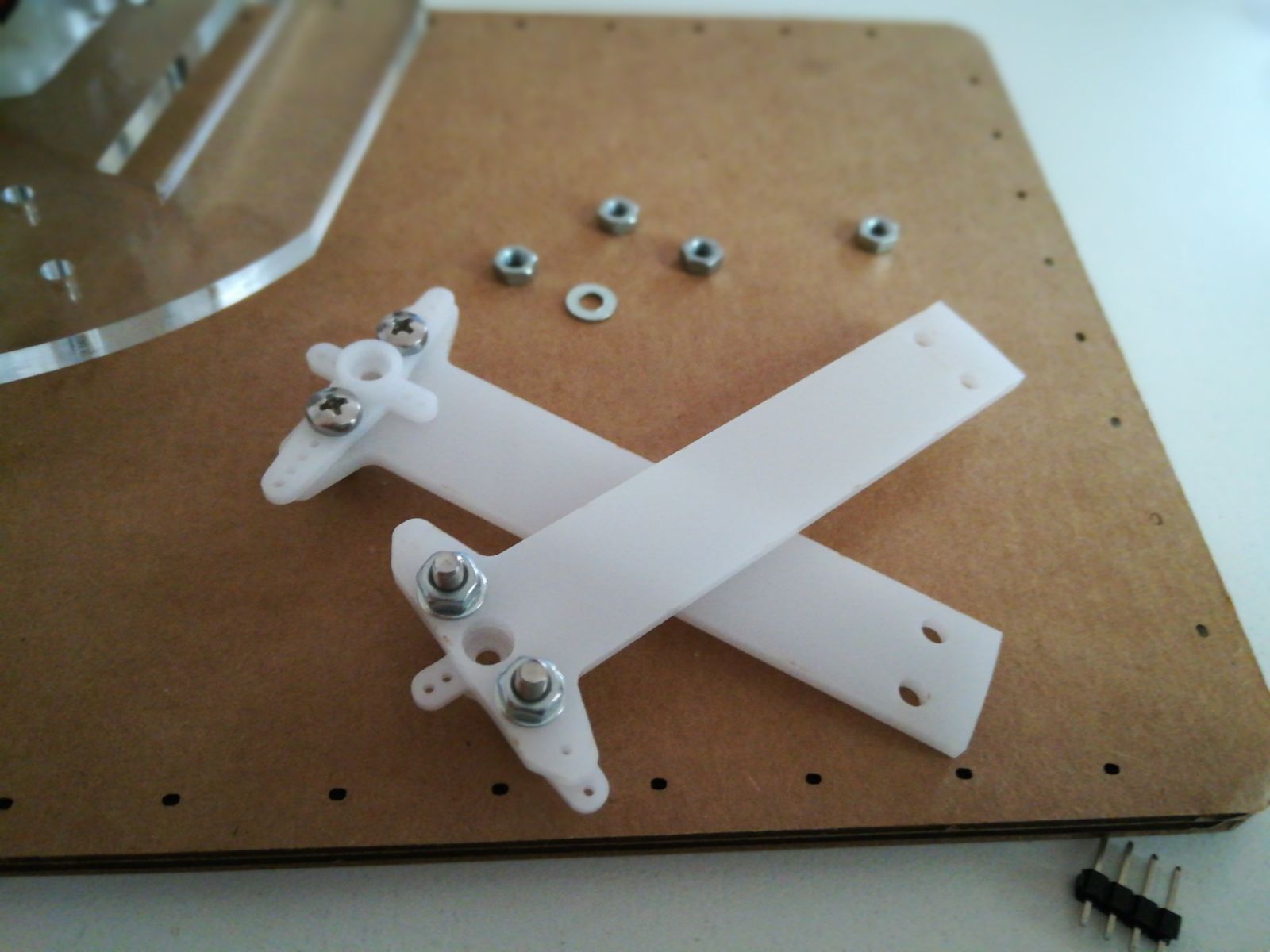

After i designed the pendulum plate that will hold the battery back below the main platform.

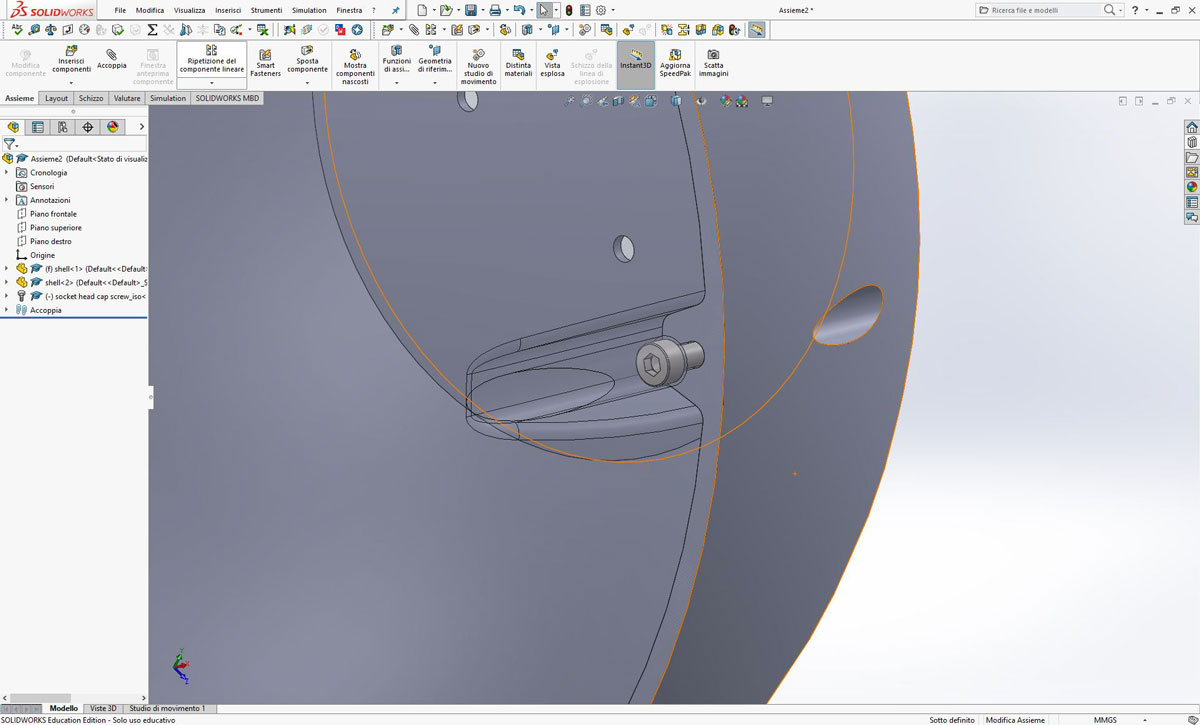

The plate is connected to the servo with two acrylic pieces i cutted using the laser cutter.

At the beginning i tried to glue the acrylic to the servo arms using super glue but just using a small pressure the bond broke so i decided to put 2 screws to hold everything.

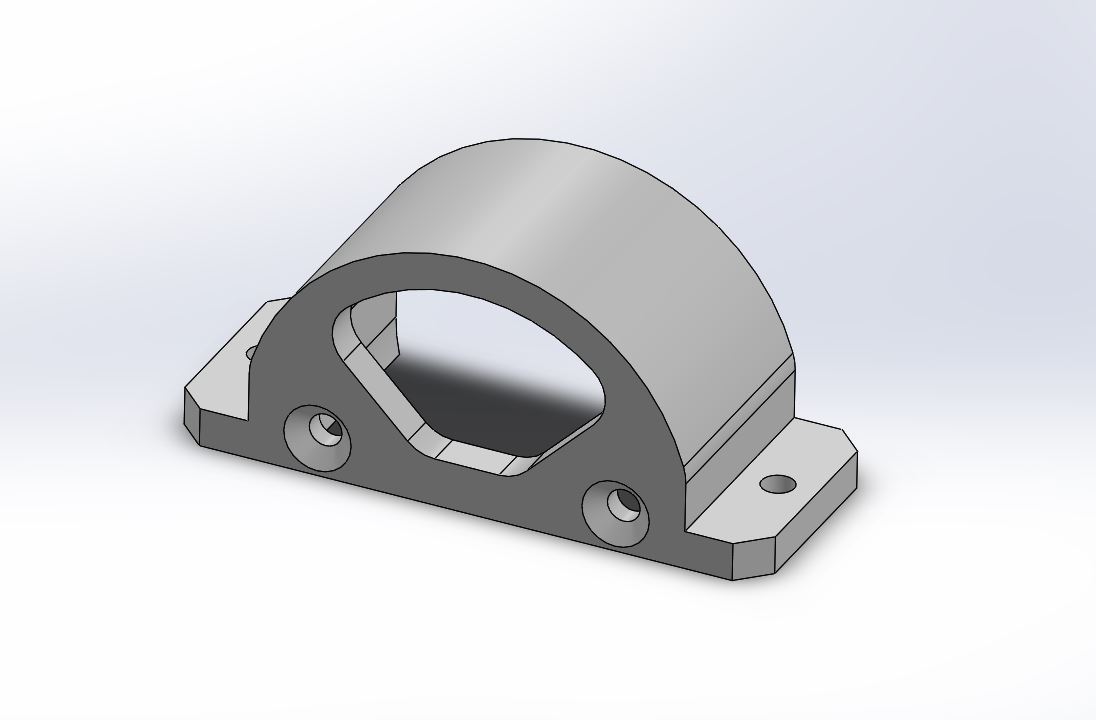

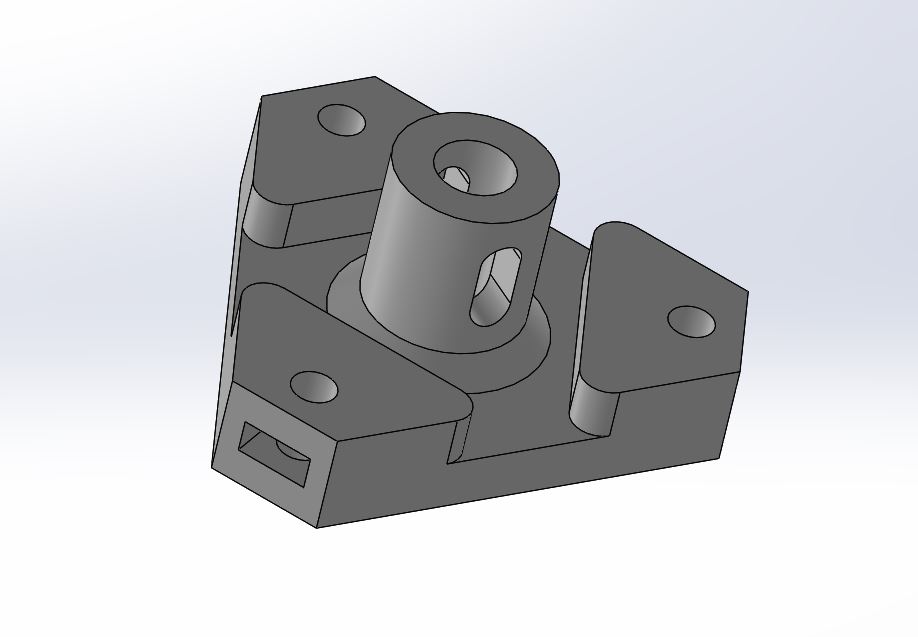

The last part i designed is the piece that connect the motor shaft to the outer shell of the robot. The part have three pockets that hold an hex bolt so i can screw from outside the shell to the part.

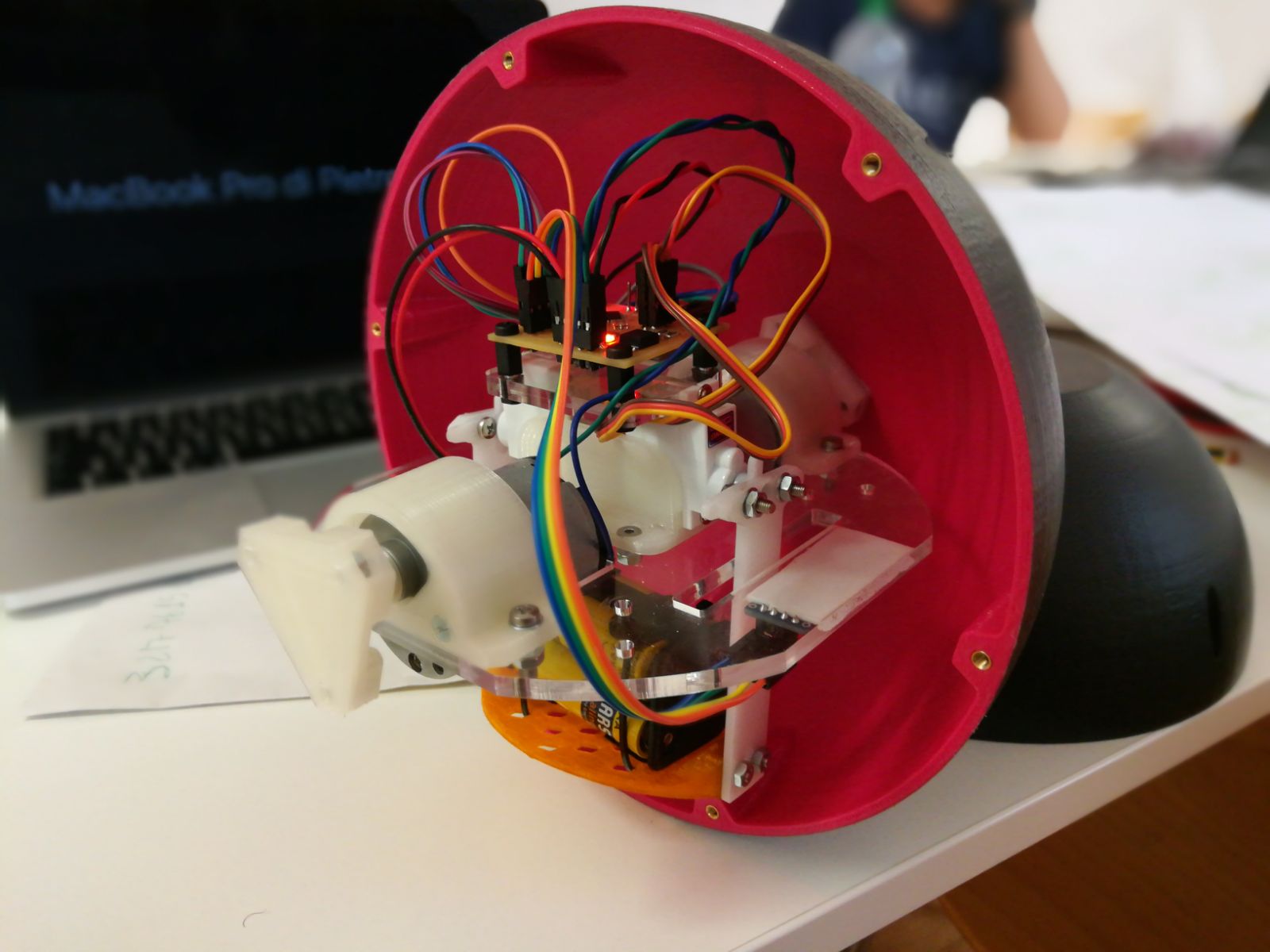

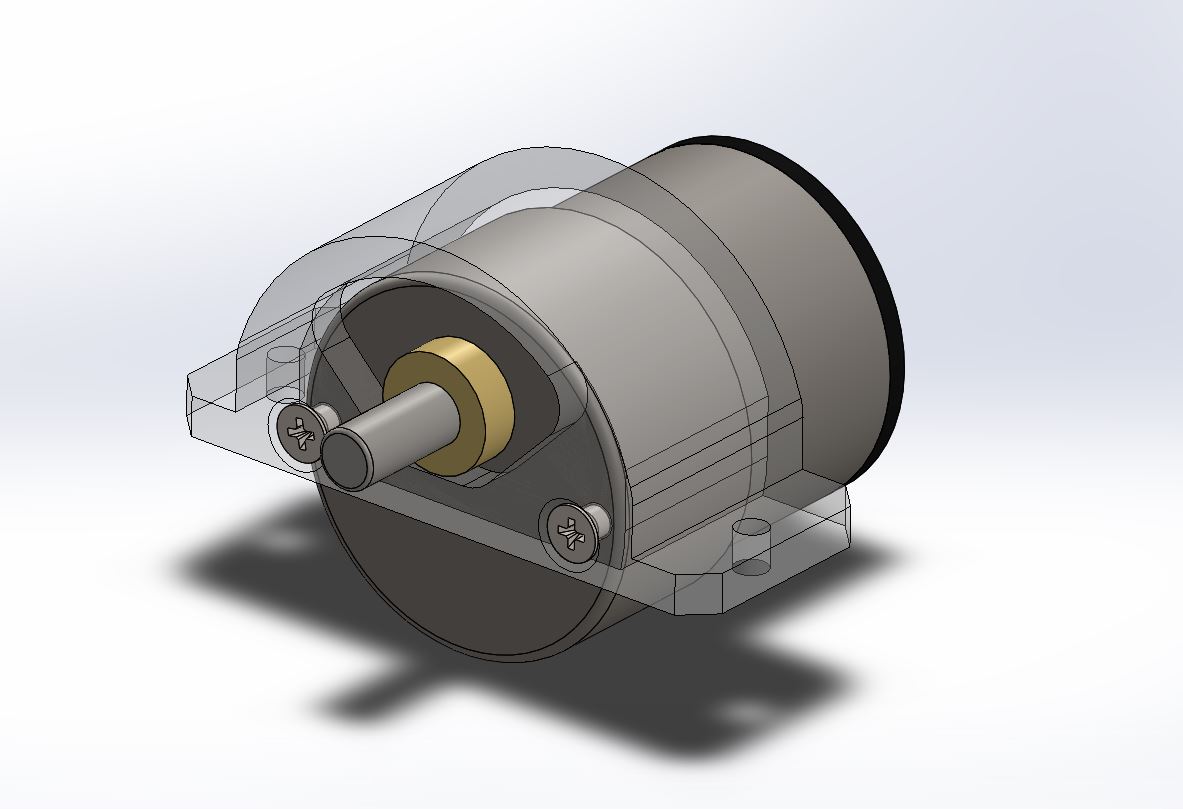

Below all the parts assembled. ( messy cables : [ )