About my board

For this week's assignment I experienced with designing and programing a board which operate a project called Tiny CNC the Mini 3-Axes CNC v0.29 by MakerBlock. I hope this experience will provide me a backround for my final project later development.

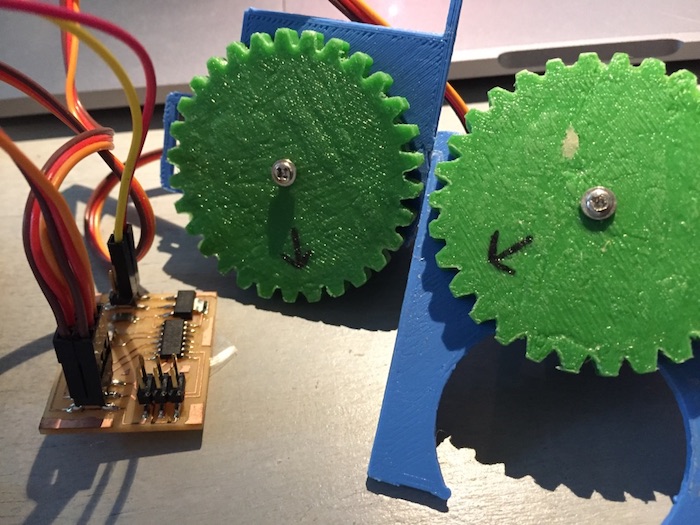

The tiny CNC device with X, Y and Z axes, includes three micro Servo motors and some 3D printable plastic parts you can download from the linked above Thingiverse page. I deal with only the X and Y axes. Handling with programing a microcontroller board to move a point on two axes by rotating the Servos.

Experiencing with Arduino

After assembling the prehead TinyCNC device I followed the instructions I found on this page.

Working process:

- wiring the Servos to the Arduino board.

- downloading these files.

- opening the MiniCNC code (located inside the MiniCNC folder) on Arduino IDE.

- checking my wiring compatible with the code.

- uploading the code to the Arduino board

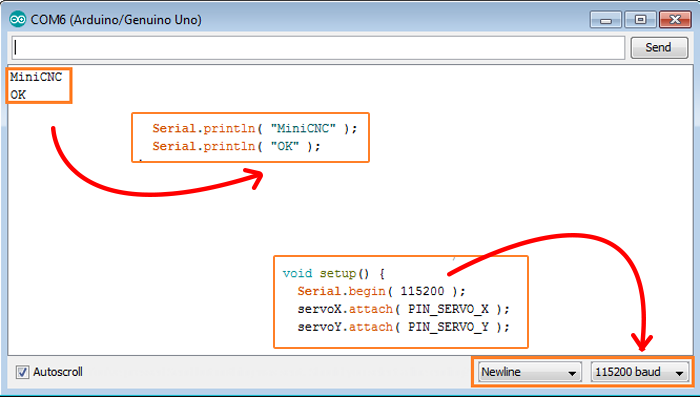

- opening the serial monitor, matching the baund definition to the code and receiving an answer.

- typing a coordinate making the ‘header’ moving on the X axis following by the Y axis.

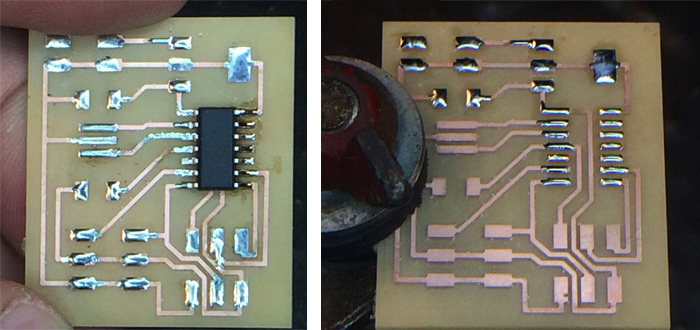

Fabricating my own board

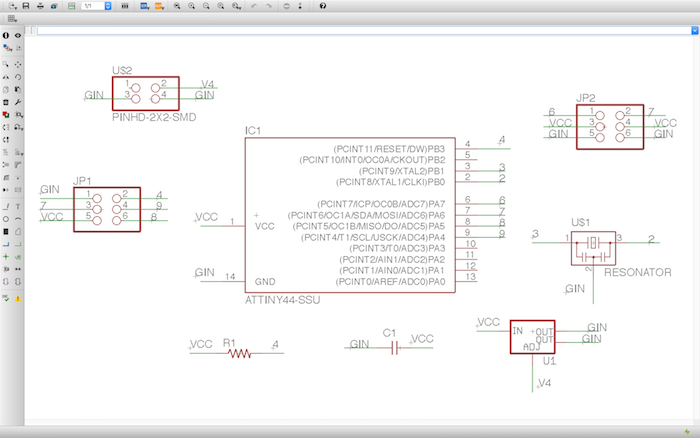

After succeeded with programing an arduino and operating the TinyCNC I turn to designing my own board. I based my design on the Hello Servo board For a better understanding about the structure of the board and the use of the regulator I turn to compare between the microcontroller and the servo motor operating voltage through their datasheet:

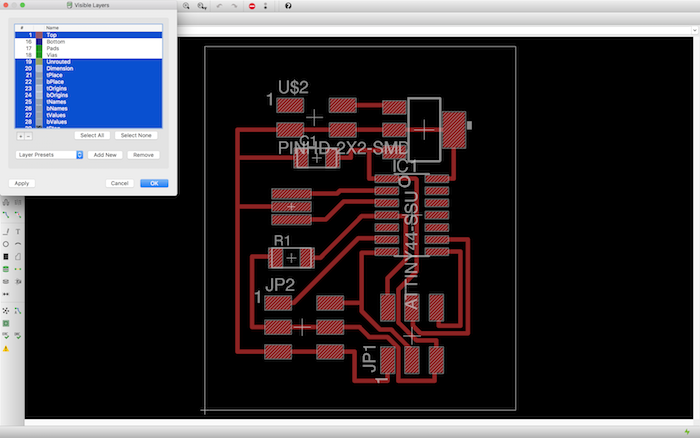

working process through Eagle:

- redesigning the Hello Servo board schematic

- Adding component to the schematic

- Naming, labeling and linking the component

- Placing the components over the brd

- Tracing+Design rules

The board's BOM:

- 1x ATtiny44

- 2x 2x3 pin header

- 1x 20MHz resonator

- 1x 2x2 pin heade

- 1x 10kΩ resistor

- 1x 22uf capacitor

- 1x regulator IC2 5V 1A

The board's files:

download SCH download BRDMilling with Othermill & Stuffing

Setting parameter over Otherplan and the stages to complete:

- The current tool, when changing the tool test for the Z facto

- Material: kind, size and placement

- Plans: File to upload and placement

- Milling tools:

- 1/32in for surface cleaning

- 1/64in for traces milling

- 1/32in for cutout

Otherplan alerts you if there are areas which needs a smaller tool.

Programing the Board

After completing the assignment of week eight, embedded programing, the programing went smoothly. I downloaded the files from the lecture page:

Then I located them inside a pre made folder on my computer. I navigate over the terminal to the folder and ran the make -f filename and the make -f filename program-usbtiny commands. After burning the program on my board I wired both of the servos motors and connected the board to Arduino Uno as my power supply. After completing wiring I supplied power to the Arduino Uno and it worked!!

Editing the code

Over the datasheet of the servo I found explanation about what ‘ms’ stand for. I’ve wanted to create a sketch for the TinyCNC that will draw a square. First I located both X and Y axes over point 0,0 (-90° to the left). Then I moved the X axes all length that the servo unable (90° to the right). After I moved the Y axes the full length (90° to the right). For the third side I moved the Y axes back to point 0 (-90° to the left) and at last the X axes back to point 0 (-90° to the left).

download c.file download make.file