Composites

The assigment divided in three parts for this week, they are:

- Read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using

- Design and fabricate a 3D mold (~ft2)

- Produce a fiber composite part in it

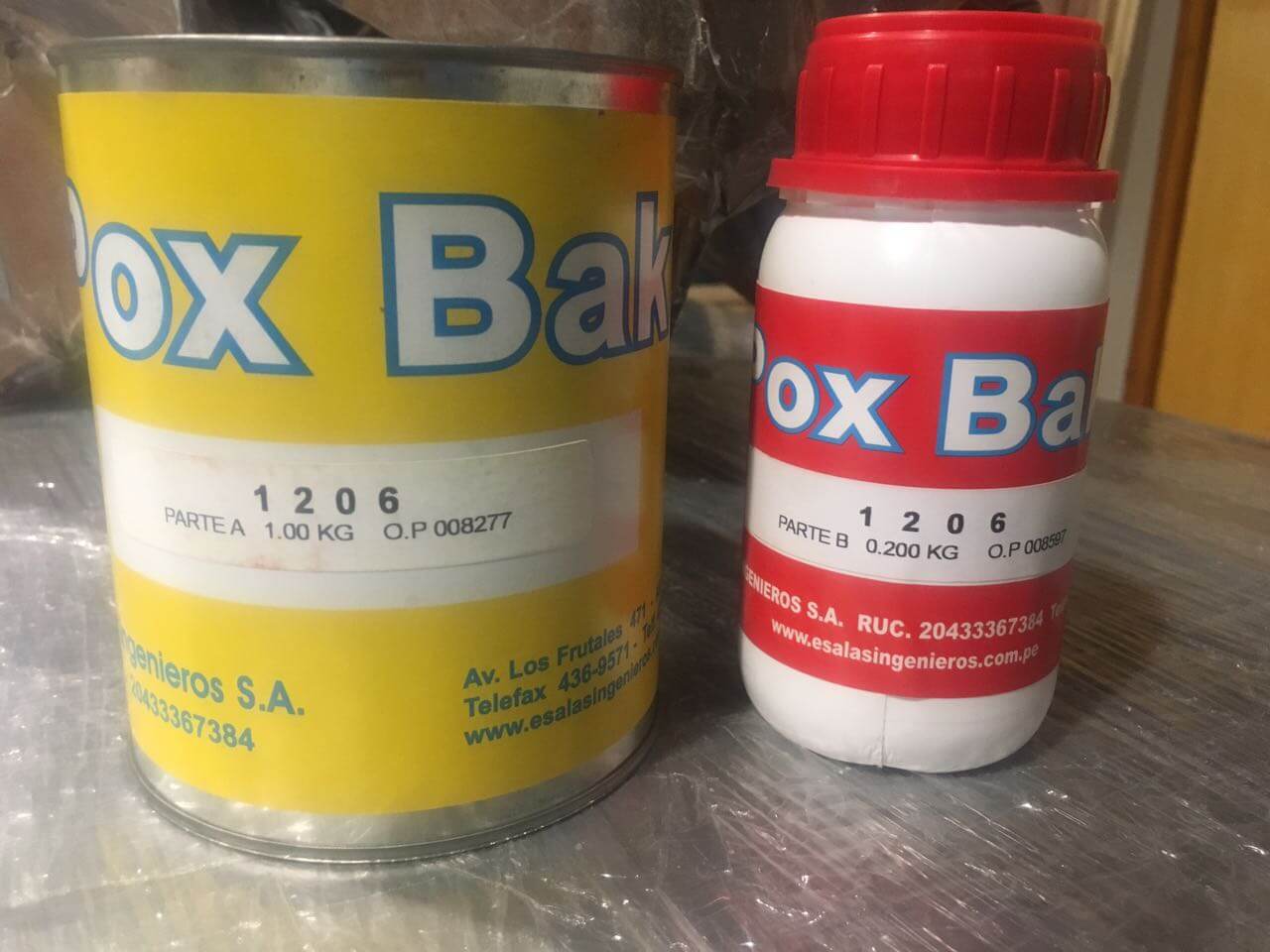

Material safety data sheet (MSDS) and technical data sheet (TDS)

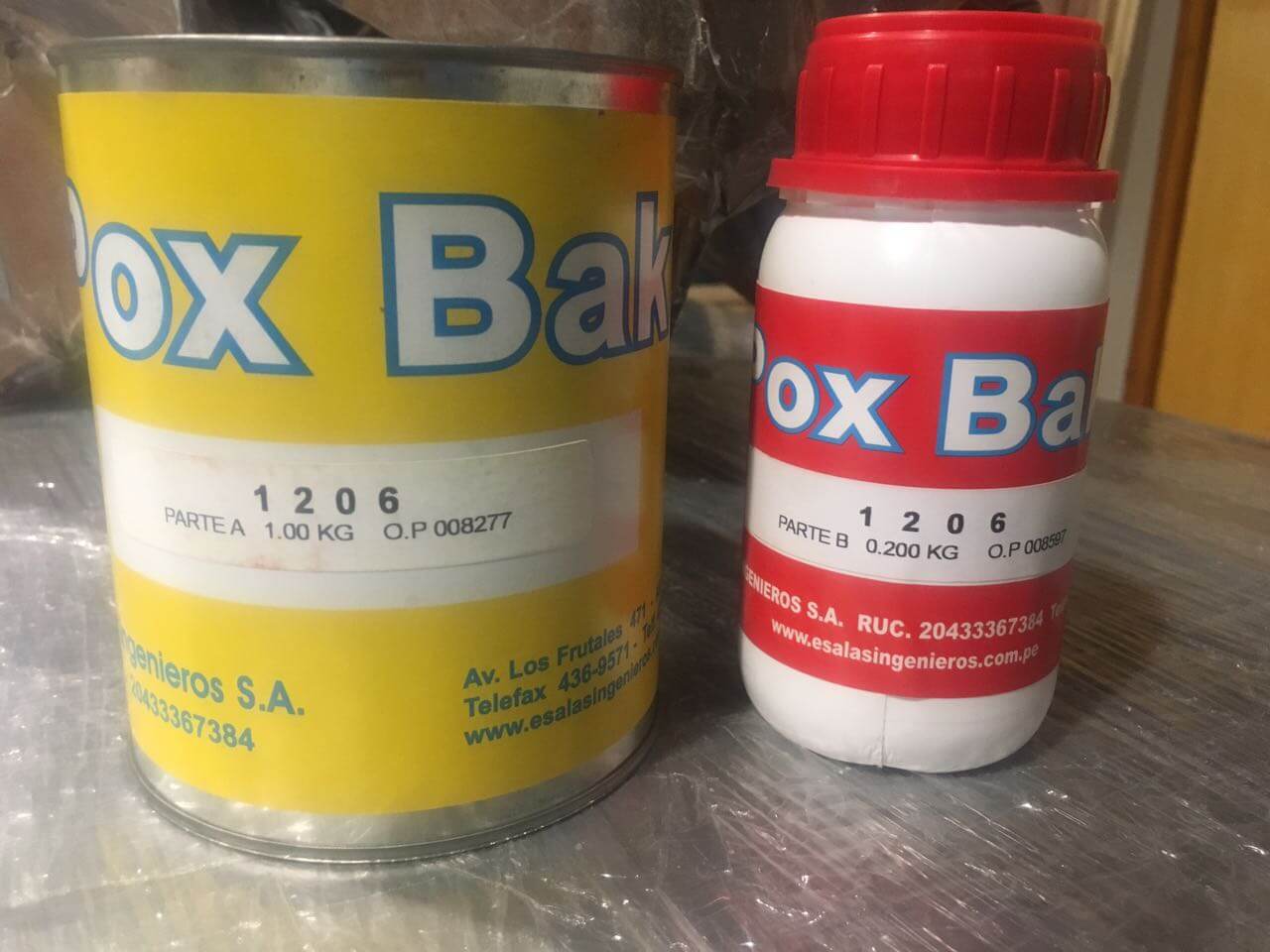

The kit has two elements: resin (A) and a catalyst (B). They should mix in a proportion of 5 to 1. To prepare we do the next steps

- Part (A) should mixed for two minutes

- Put part (B) in the mixe

- Mix both elements for five minutes until to homogenize

- After homogeneize we must wait for three minutes

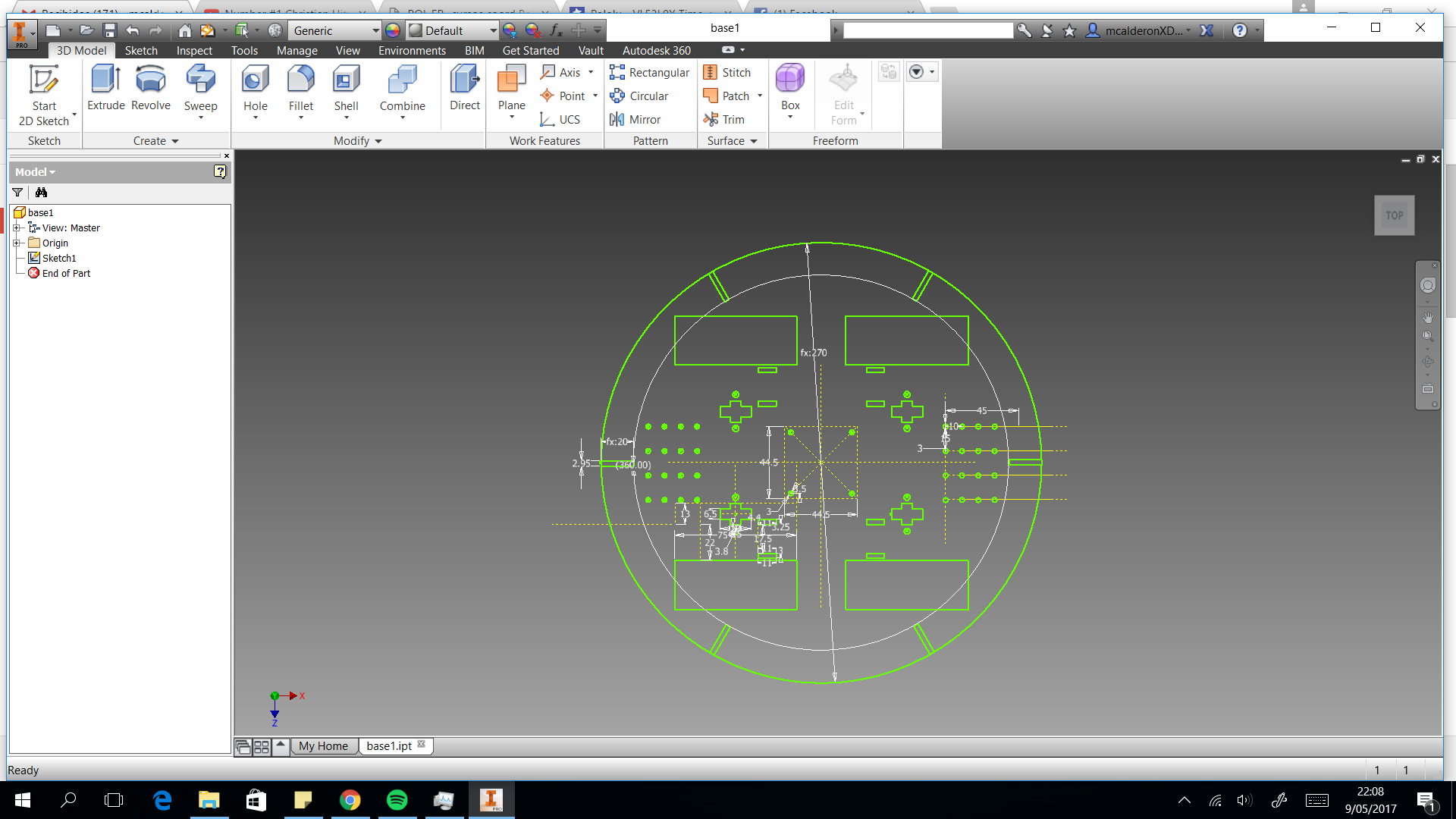

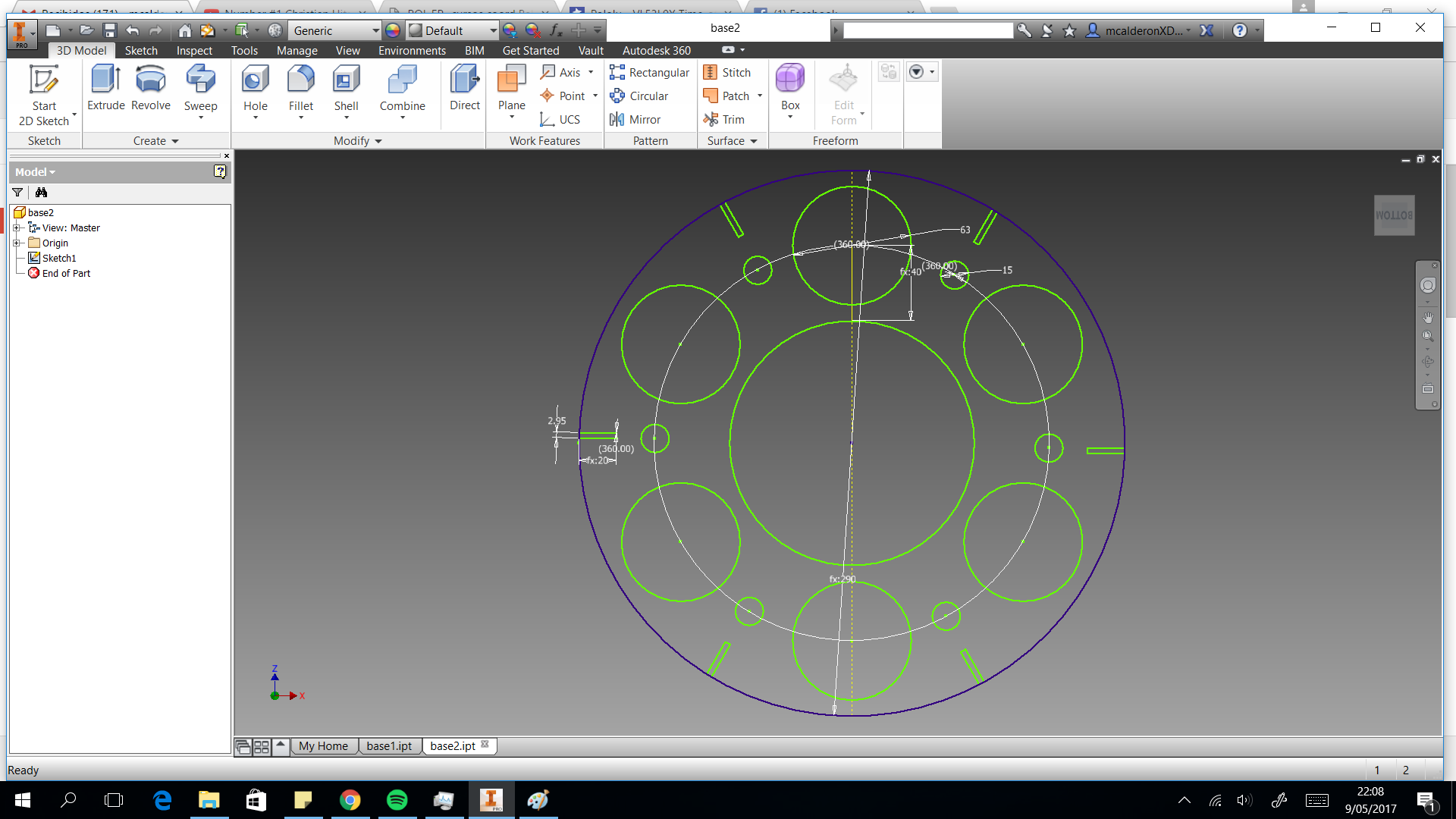

Design the Object

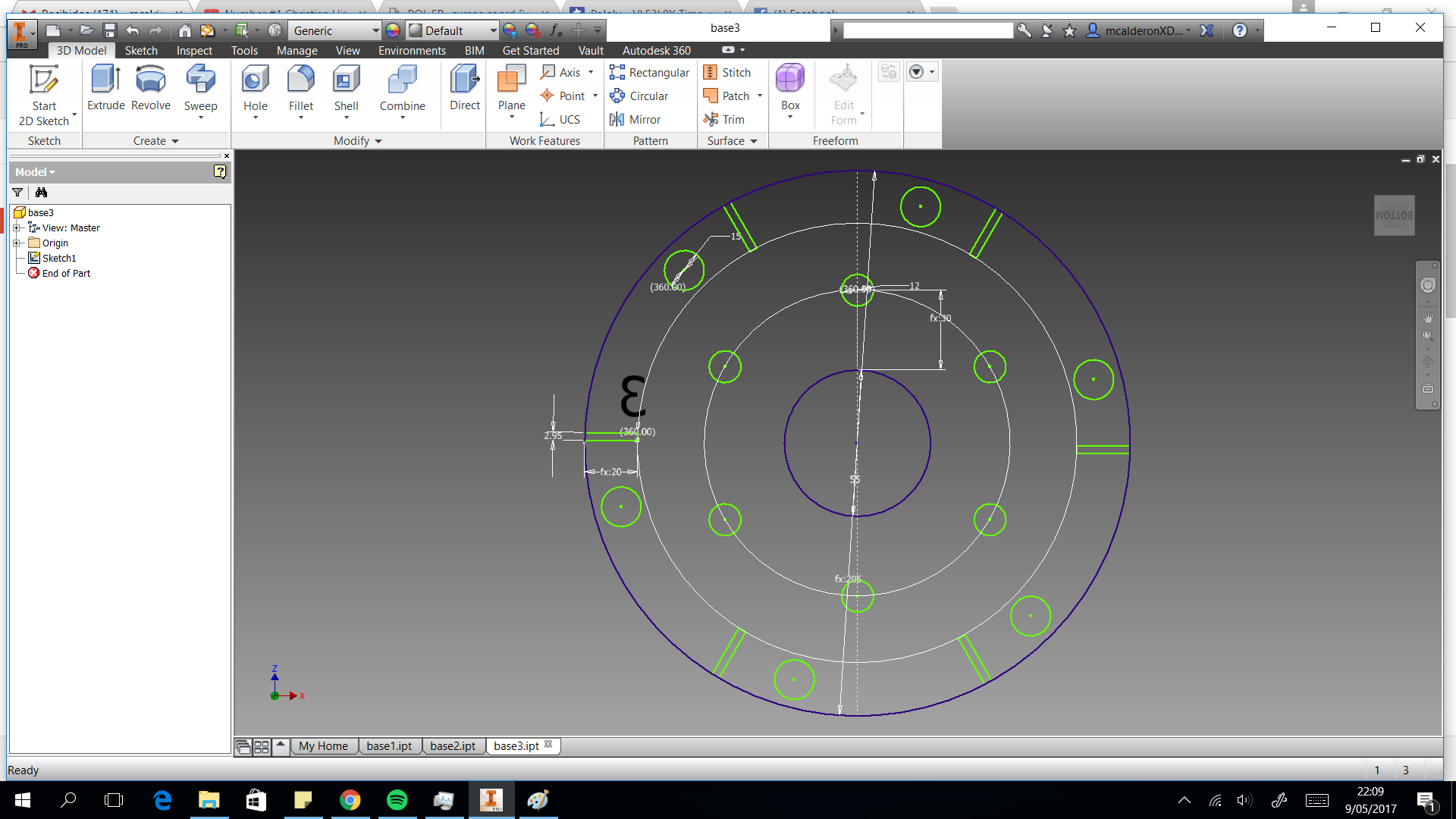

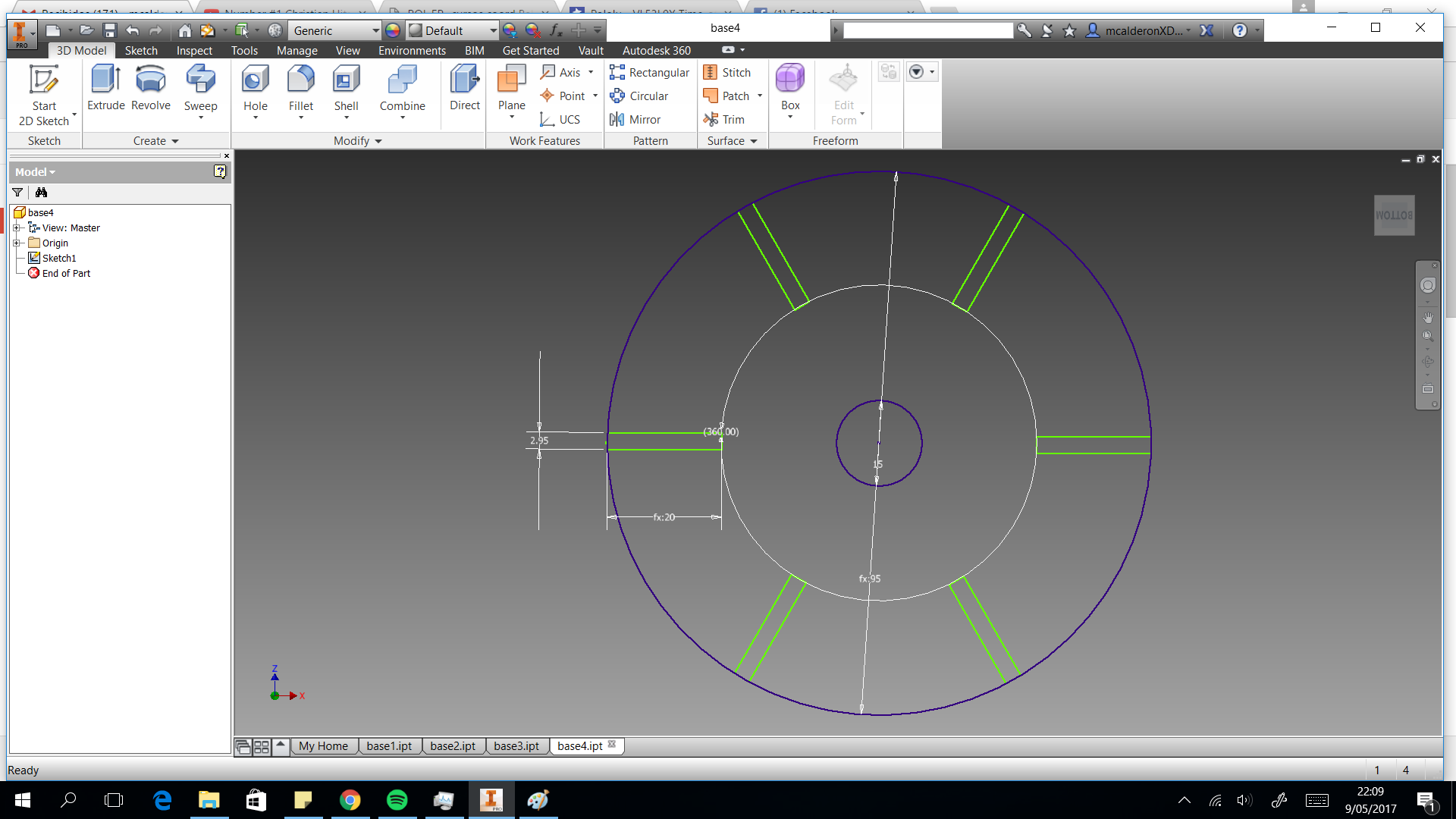

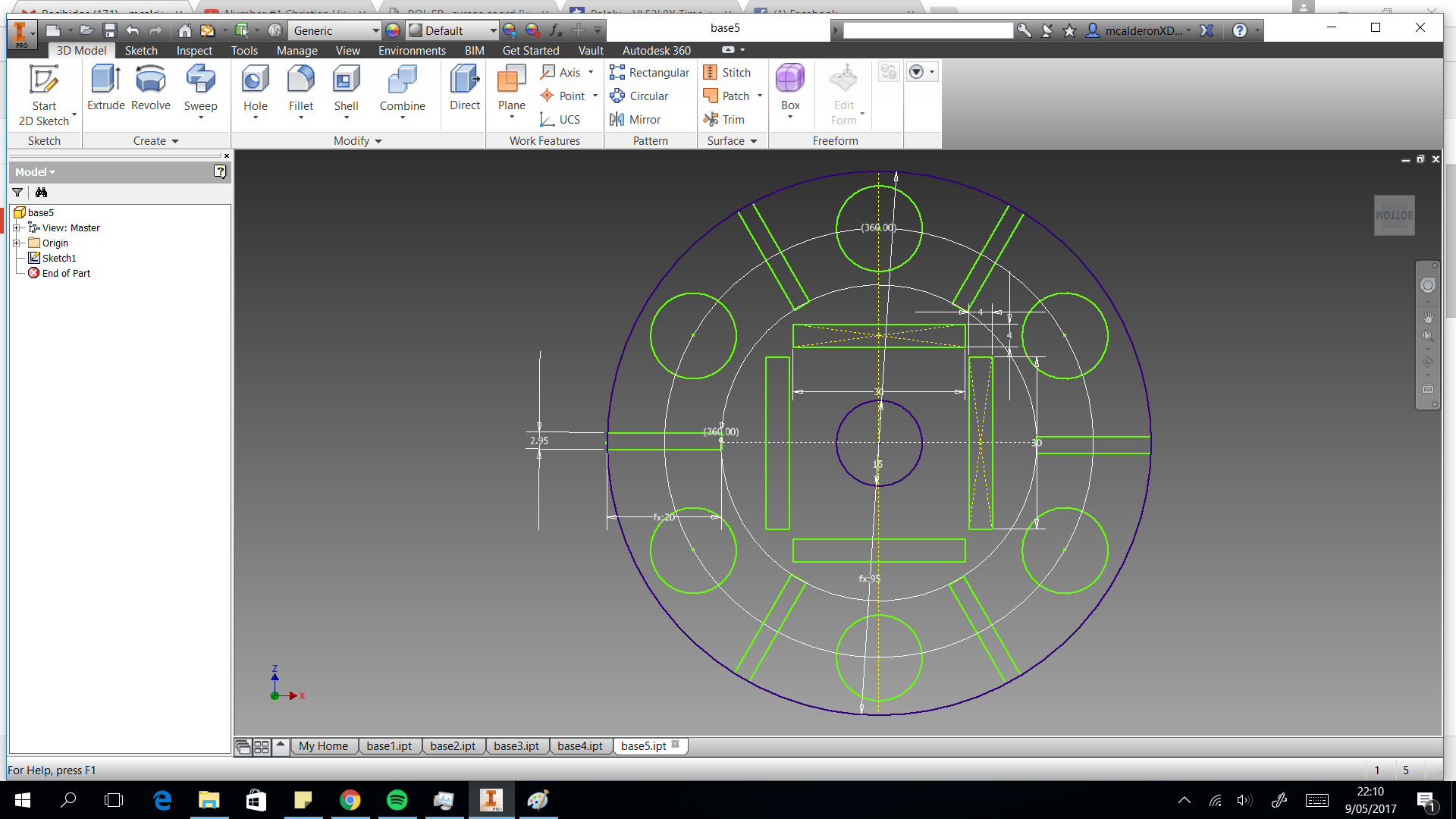

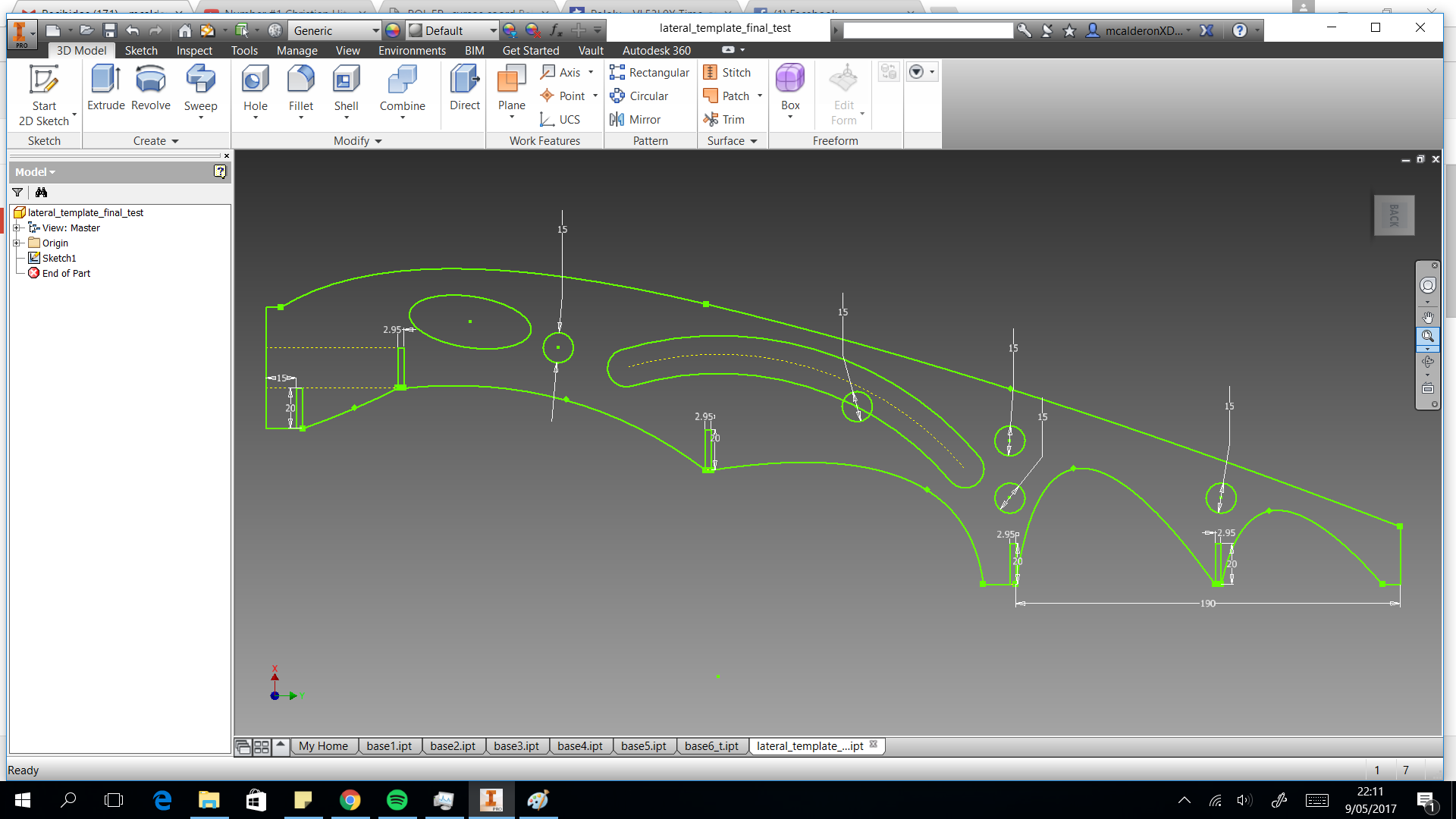

I decided to create the shell of structure like egg. This structure composes by five levels where each one can fixed with a support part. The challenge here is to keep the surface curve.

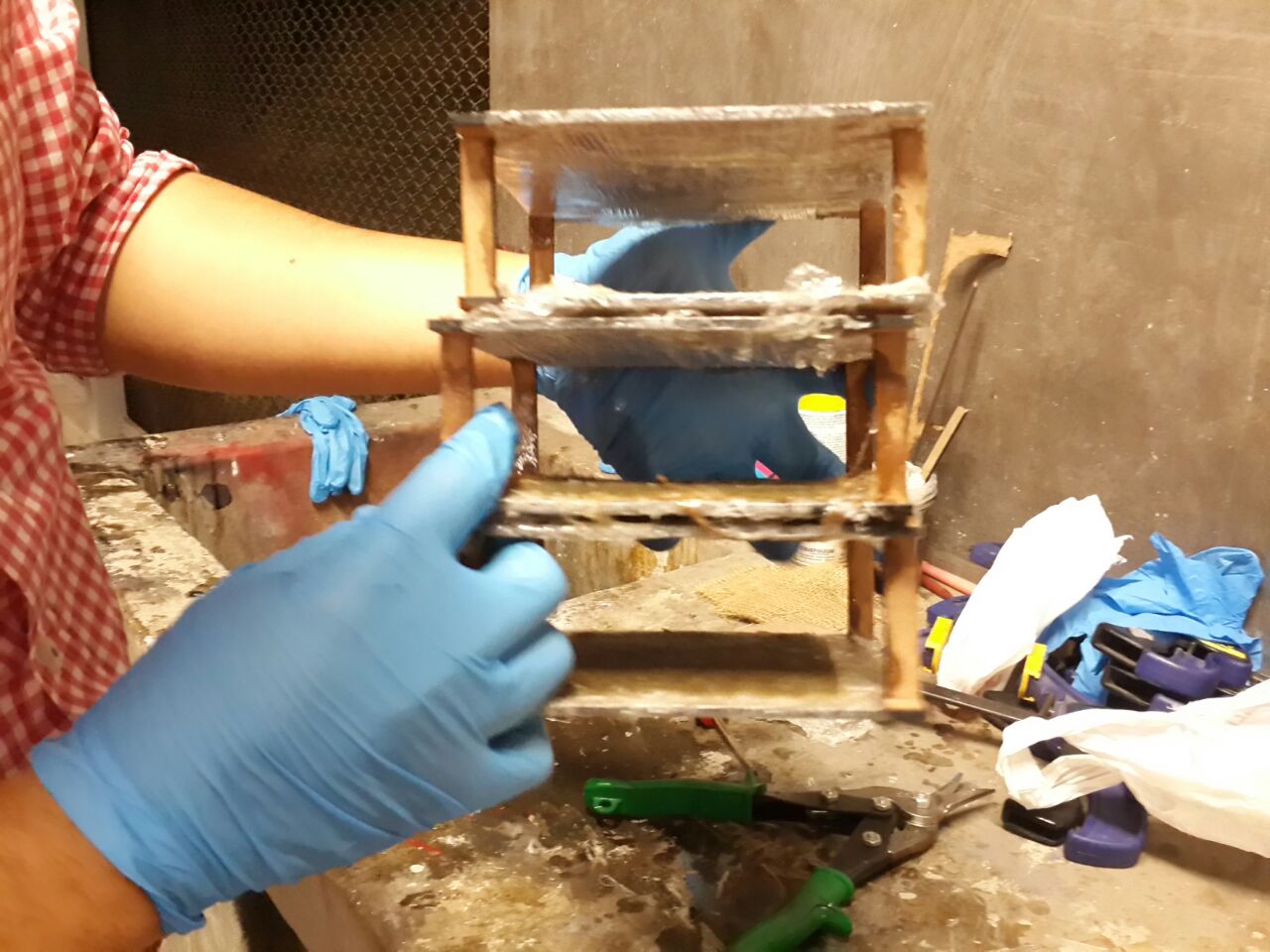

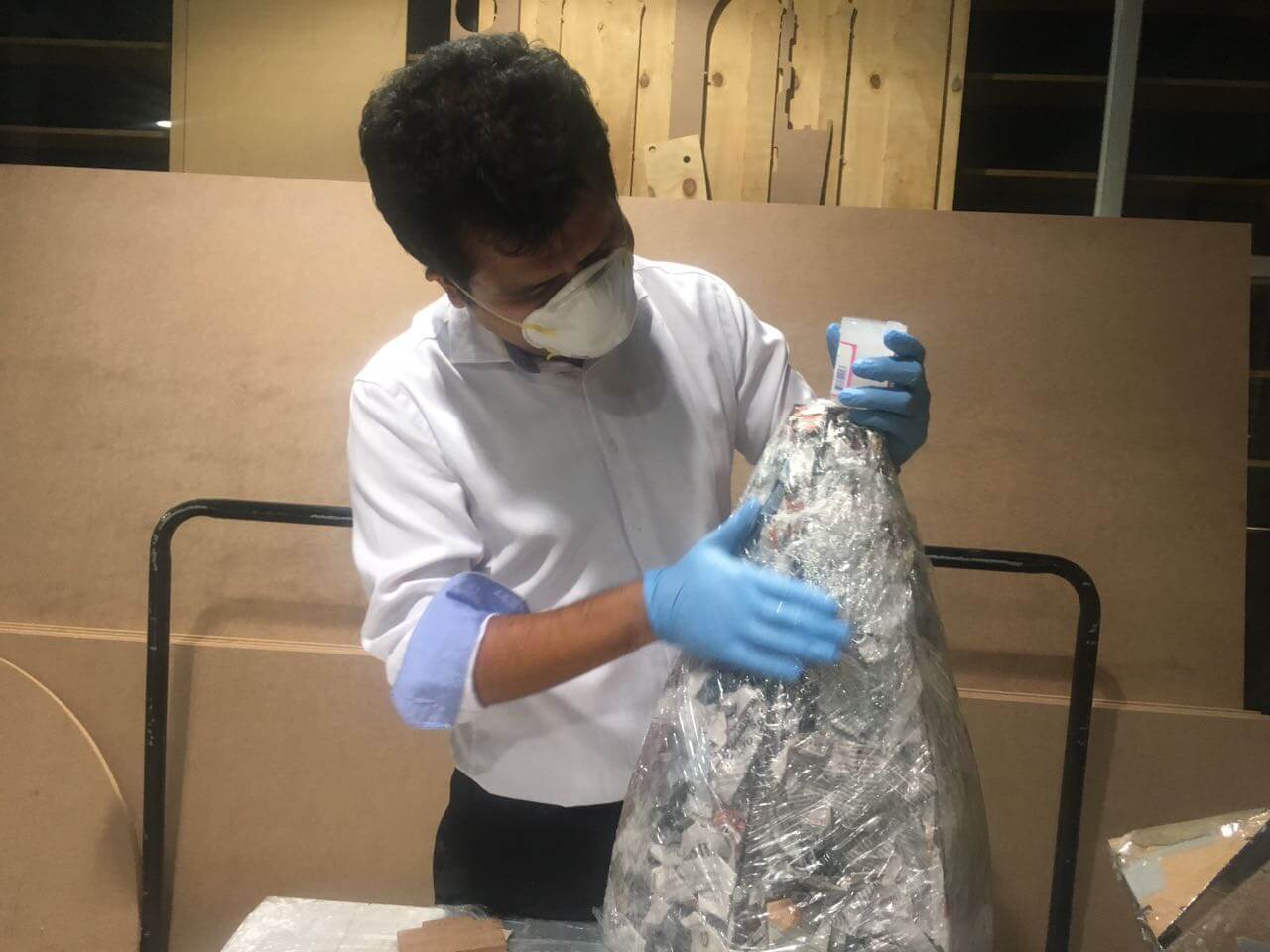

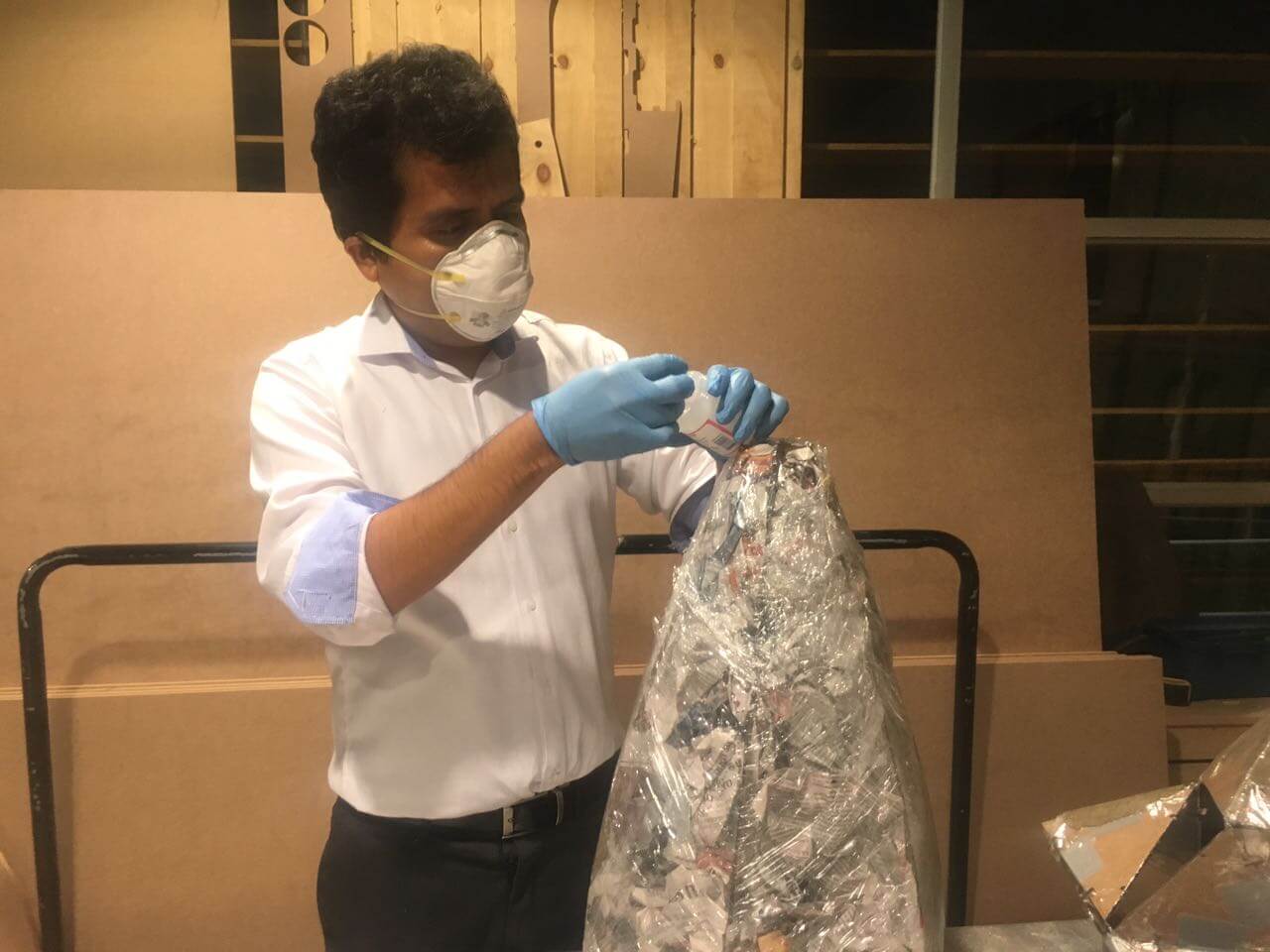

After assemble our design, I had not any idea about how to fill the structure. But after minutes I decided to fill with old newspapers to fill structure like an egg. After that, we are wrapping with stretch film.

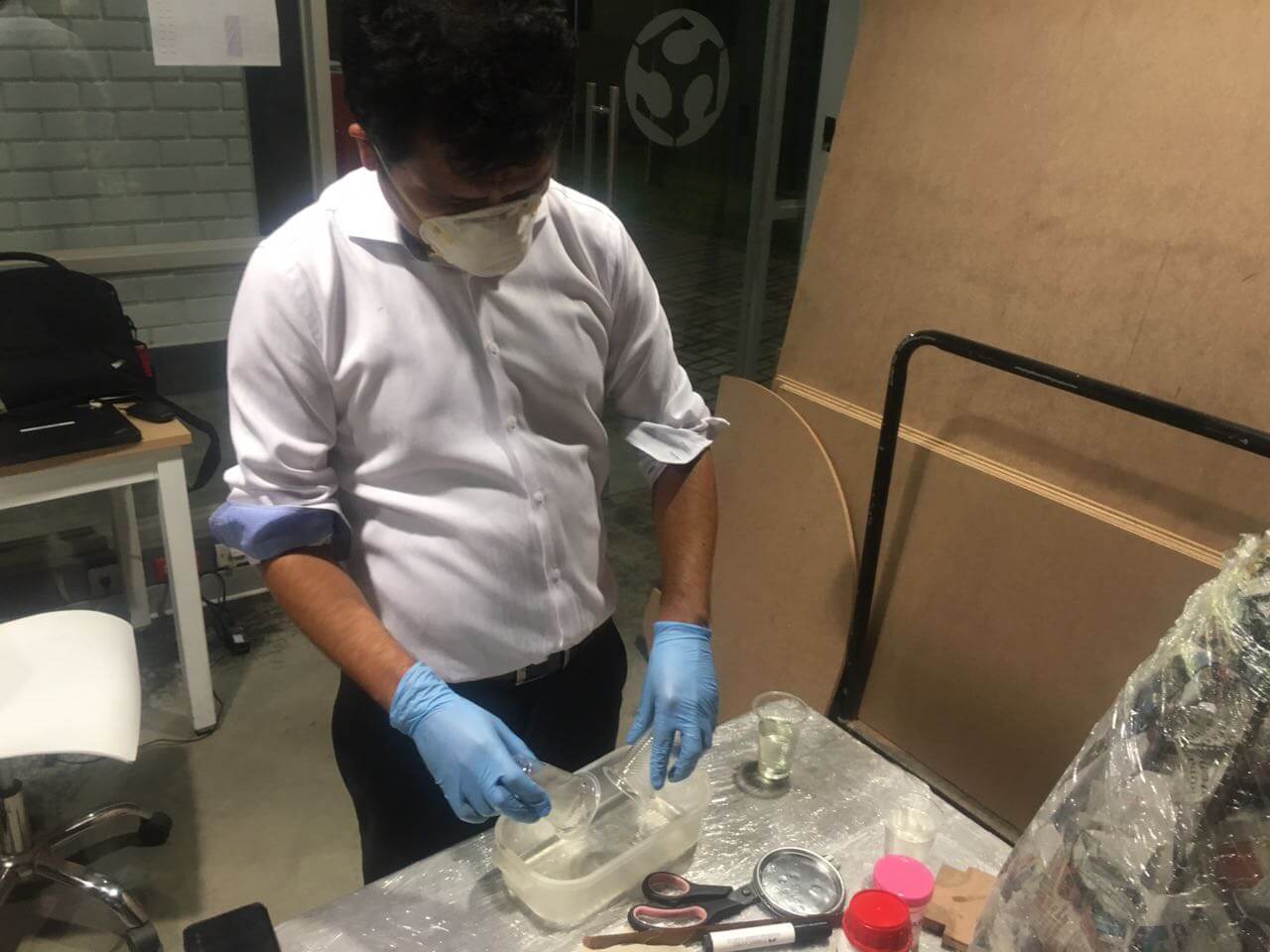

Also, we cut linen patterns which is rectangle with 50 mm of height and 150 mm of width; and we separated the resin before mixing.

Apply petroleum jelly everywhere to prevent sticking. So mixing the resin and the linen patterns were

soaking in resint to put it the structure. Also, we add other layer with red linen and repeat the process. Finally, we got

structure but the surface was not uniform because the curve was not fill constant with newpapers.

Other composite was designed to test the presion.

So we design three experiments, one of then with presses, the second test was consisted on letting with resin and it exposed to air.

and finall test did with inflation bag which we extracted air

and the element were inside it.

Other composite

First test

Second test

Third test

Third test

After two days