Molding and Casting

The homework for this week is design a 3D mold, machine it, and use it to cast parts

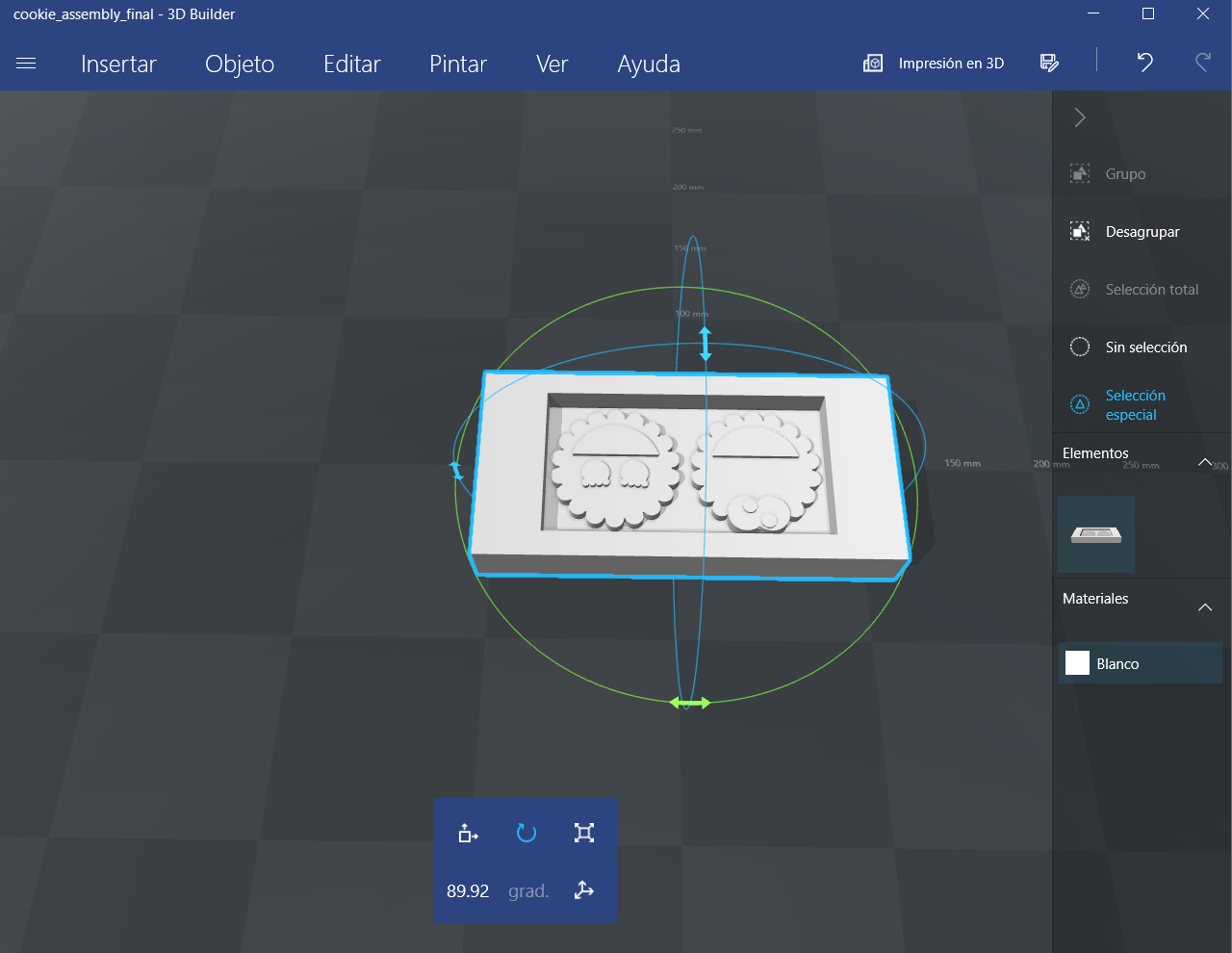

3D CAD model

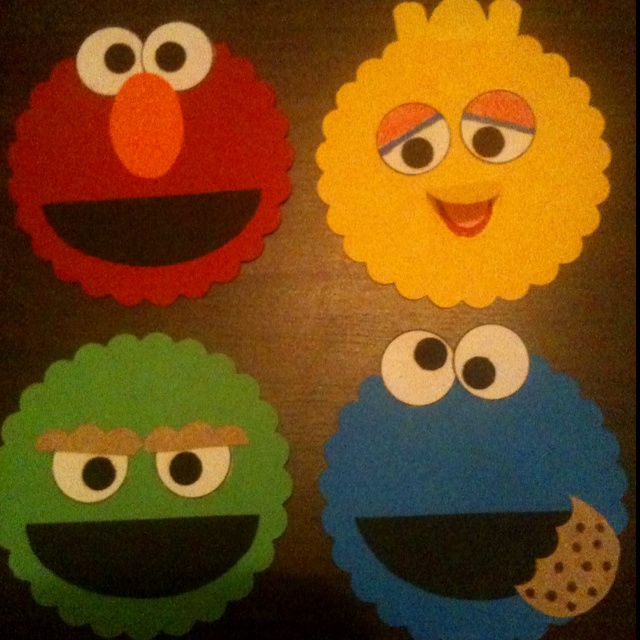

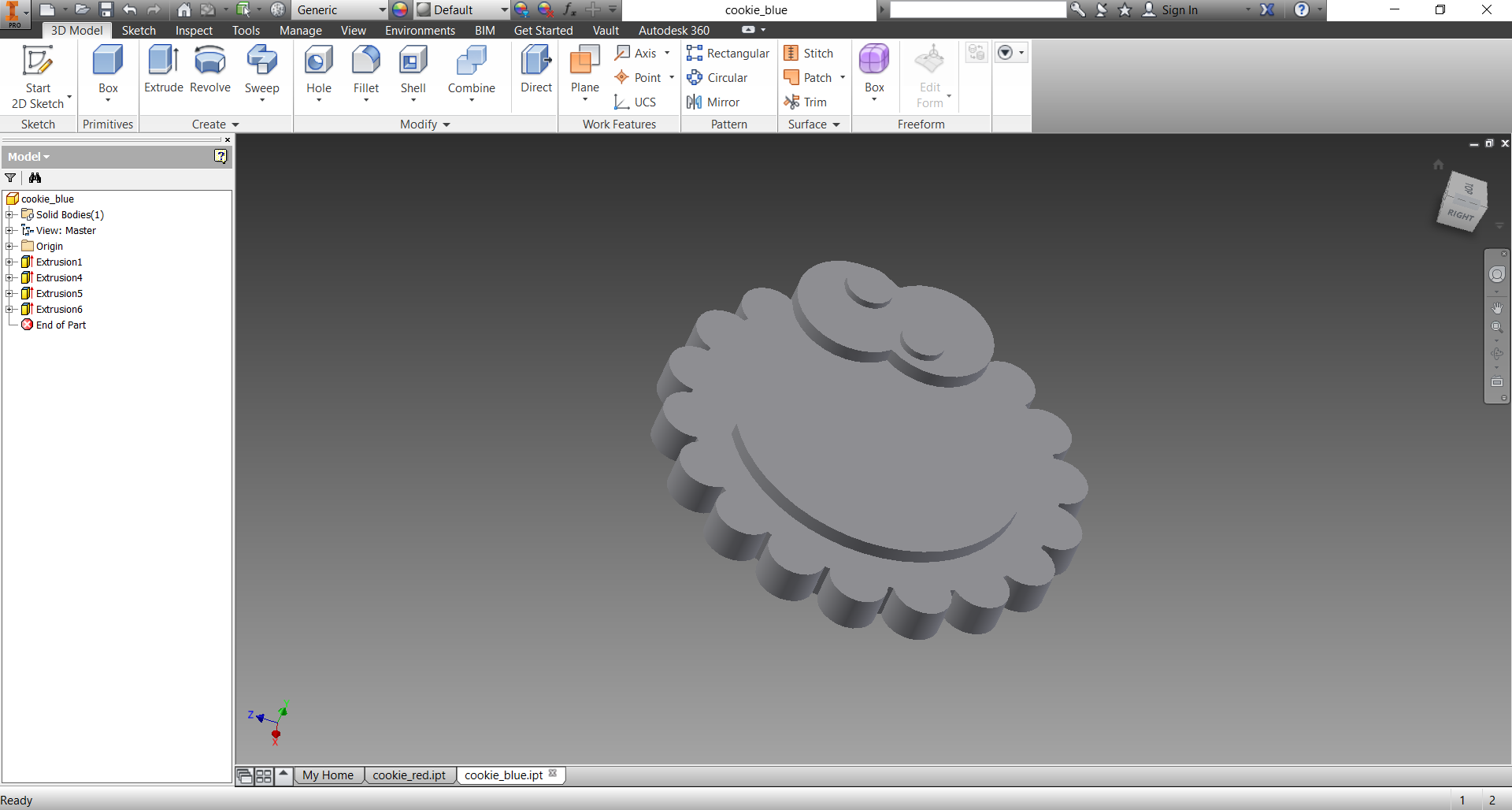

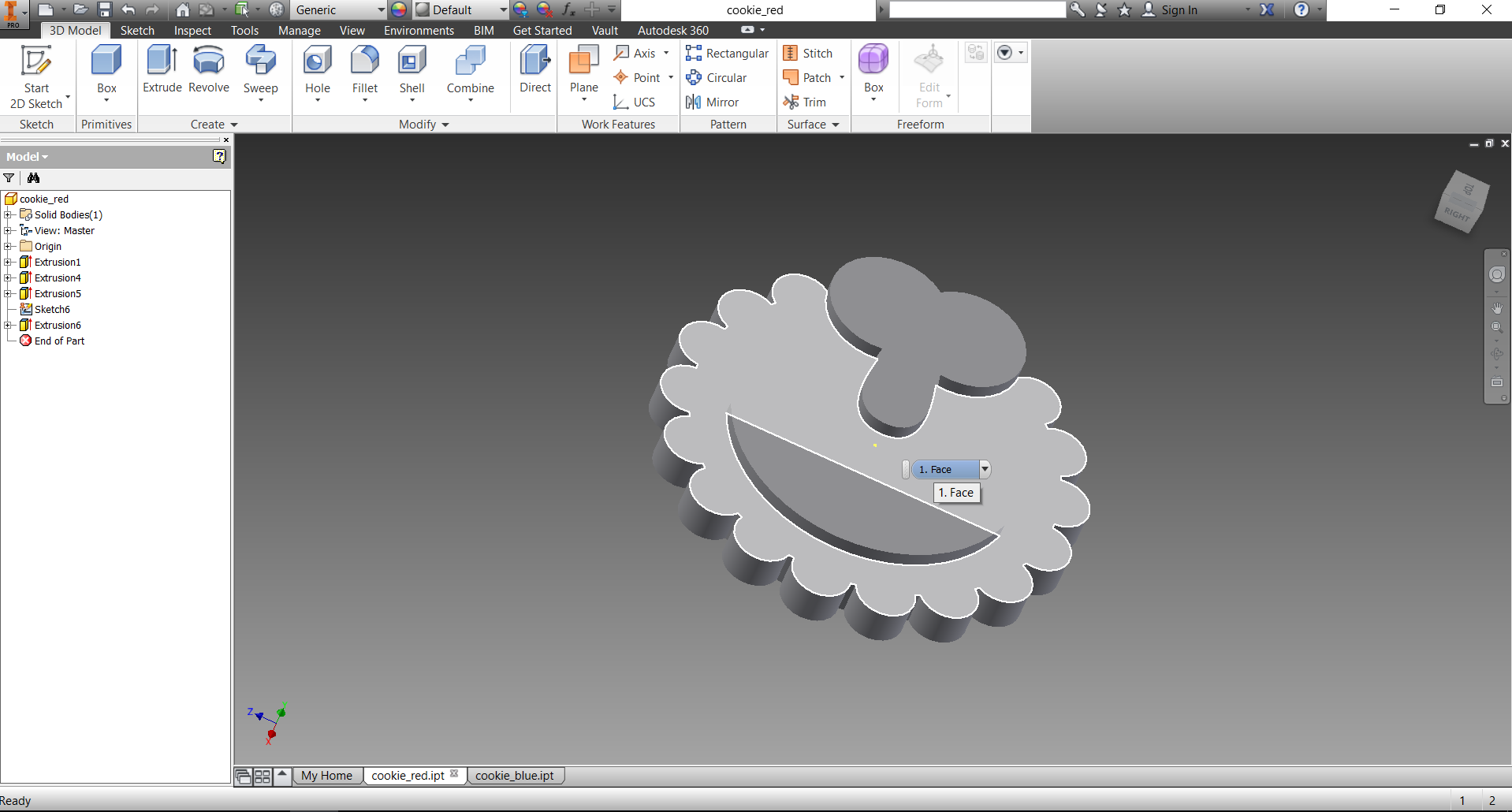

Surfing in web I found this image. So I decided to create a mould to cast two crazy cookies using Autocad Inventor 2015, the 3D models are formed with basic forms as circles and eclipse in one of them. The CAD files can download here

The blue cookie has 60 mm diameter and 20 mm of height.

The red one has the same features of blue cookie.

Shown how you made your mould and cast the parts

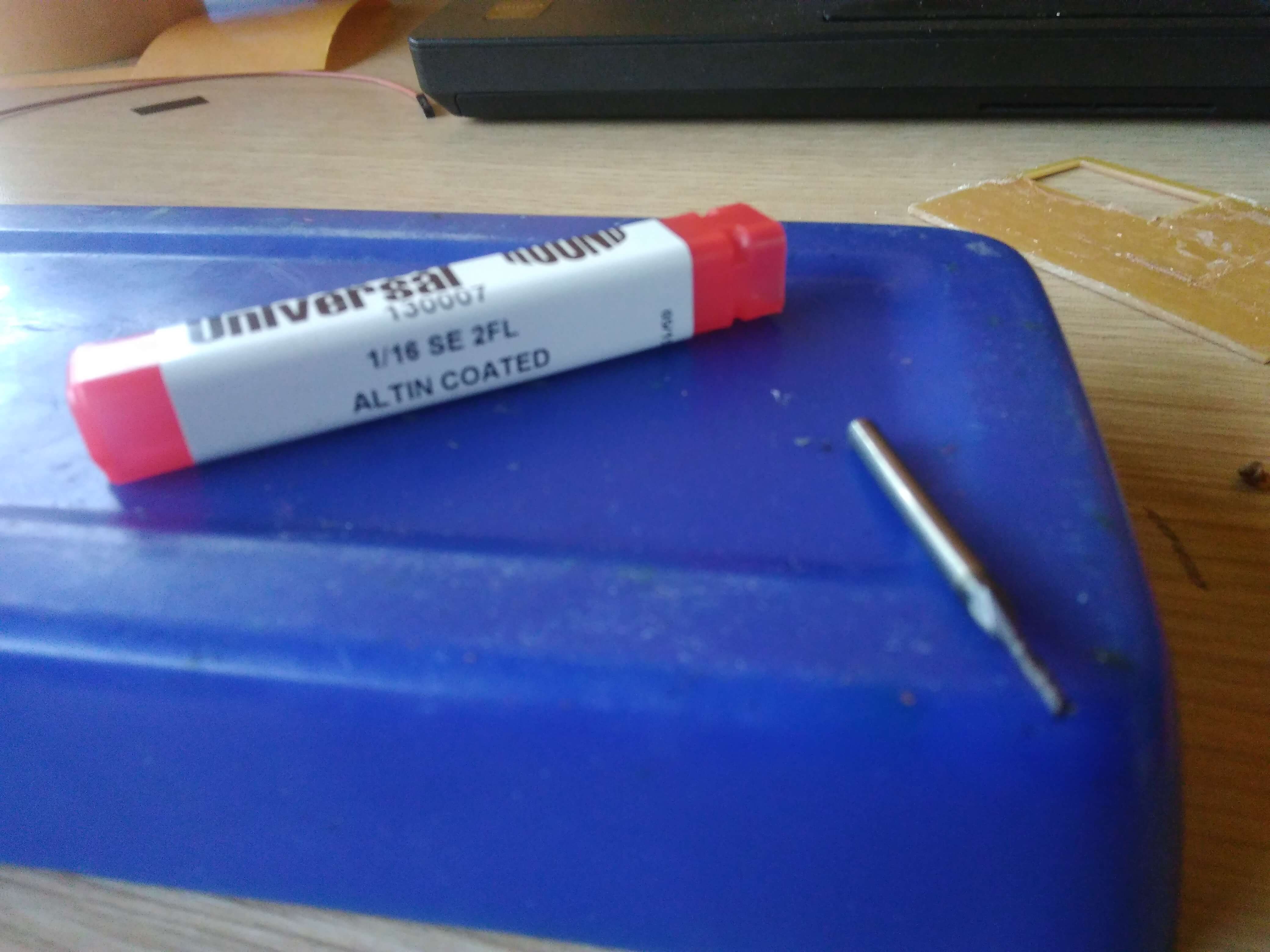

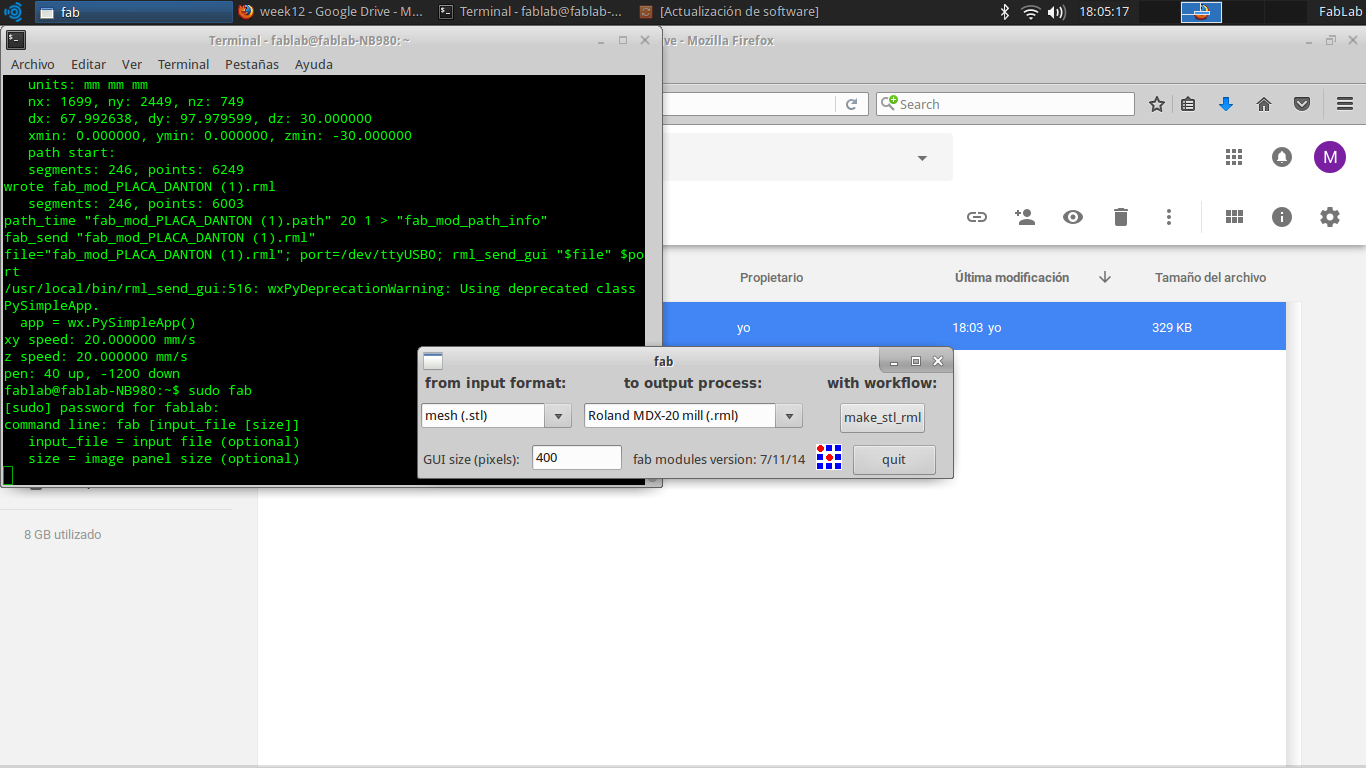

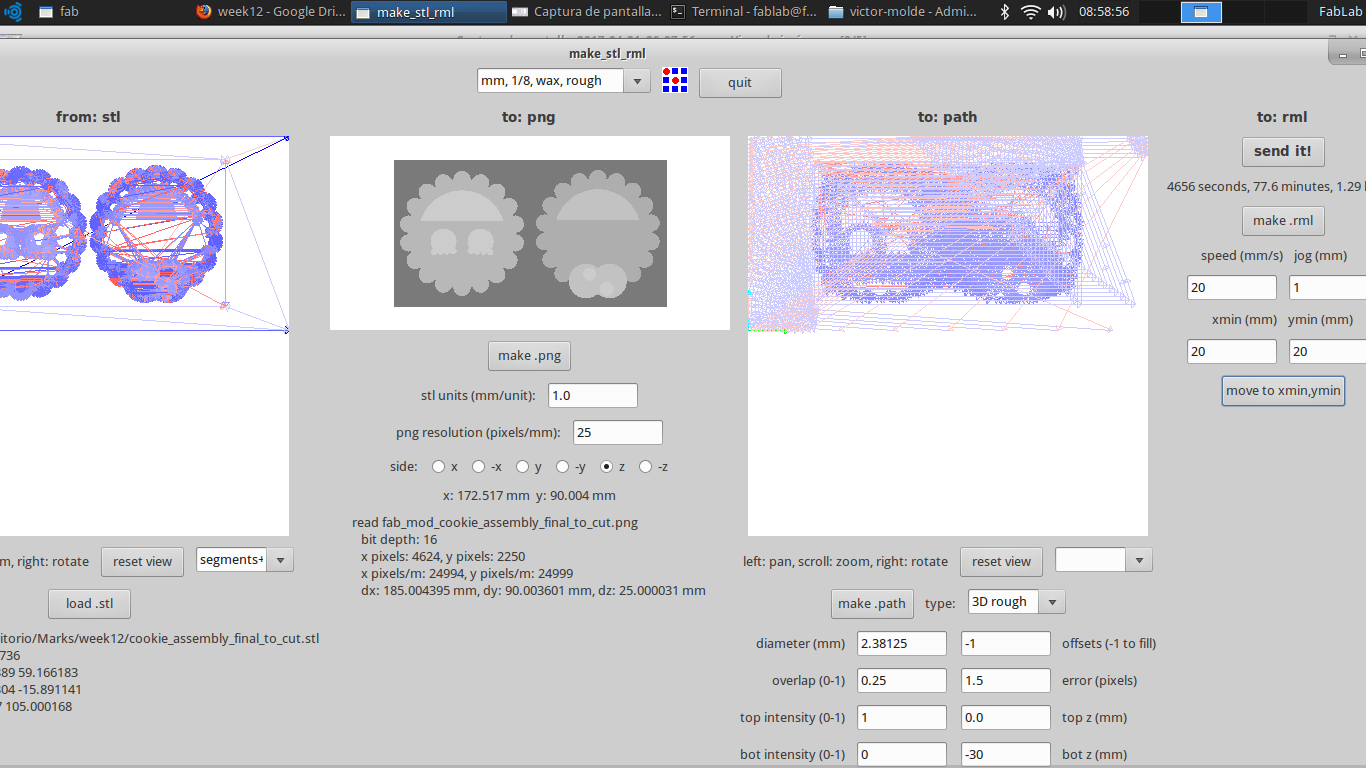

Use a wax that is not larger than the platform of the CNC. To attach the wax with platform we use double adhesive tape. Additionally, we use 1/16 inch flat end to extract the wax. This tool do not detail when it cuts the wax.

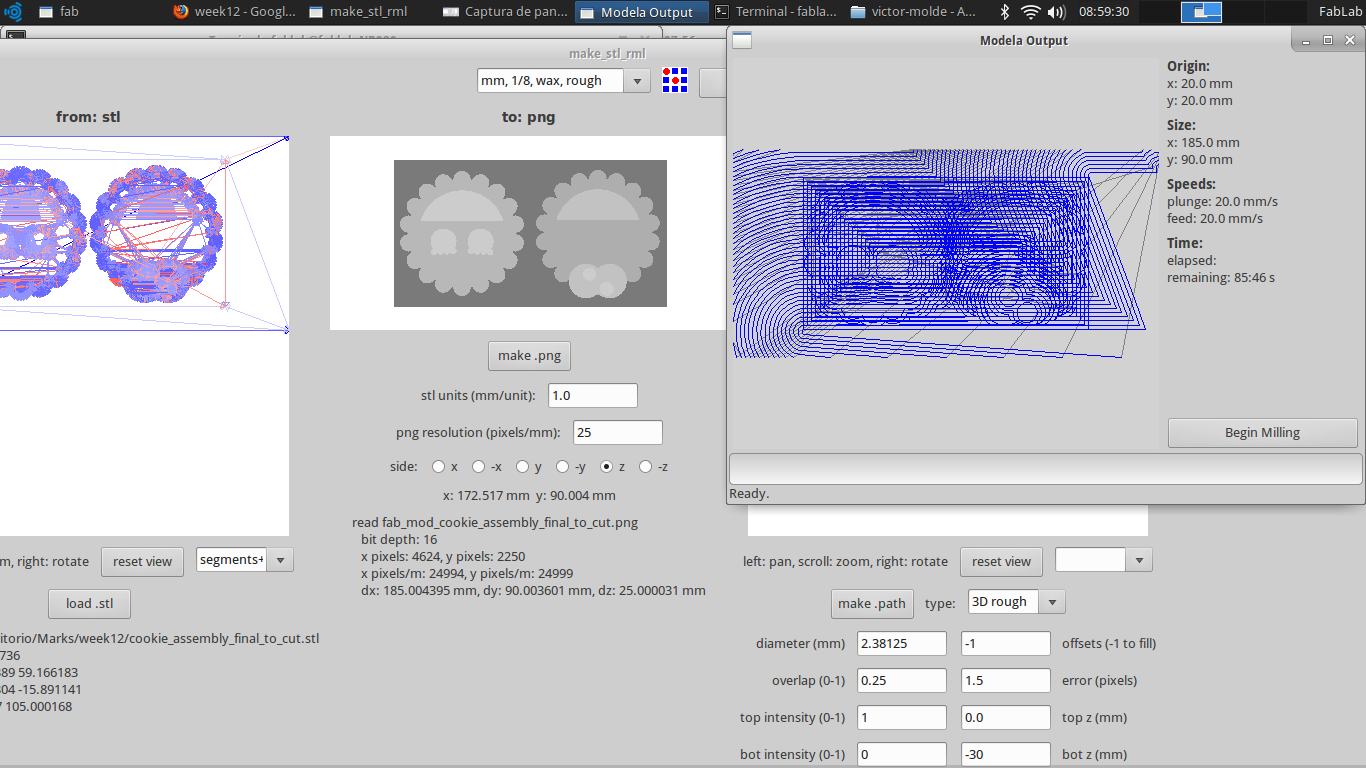

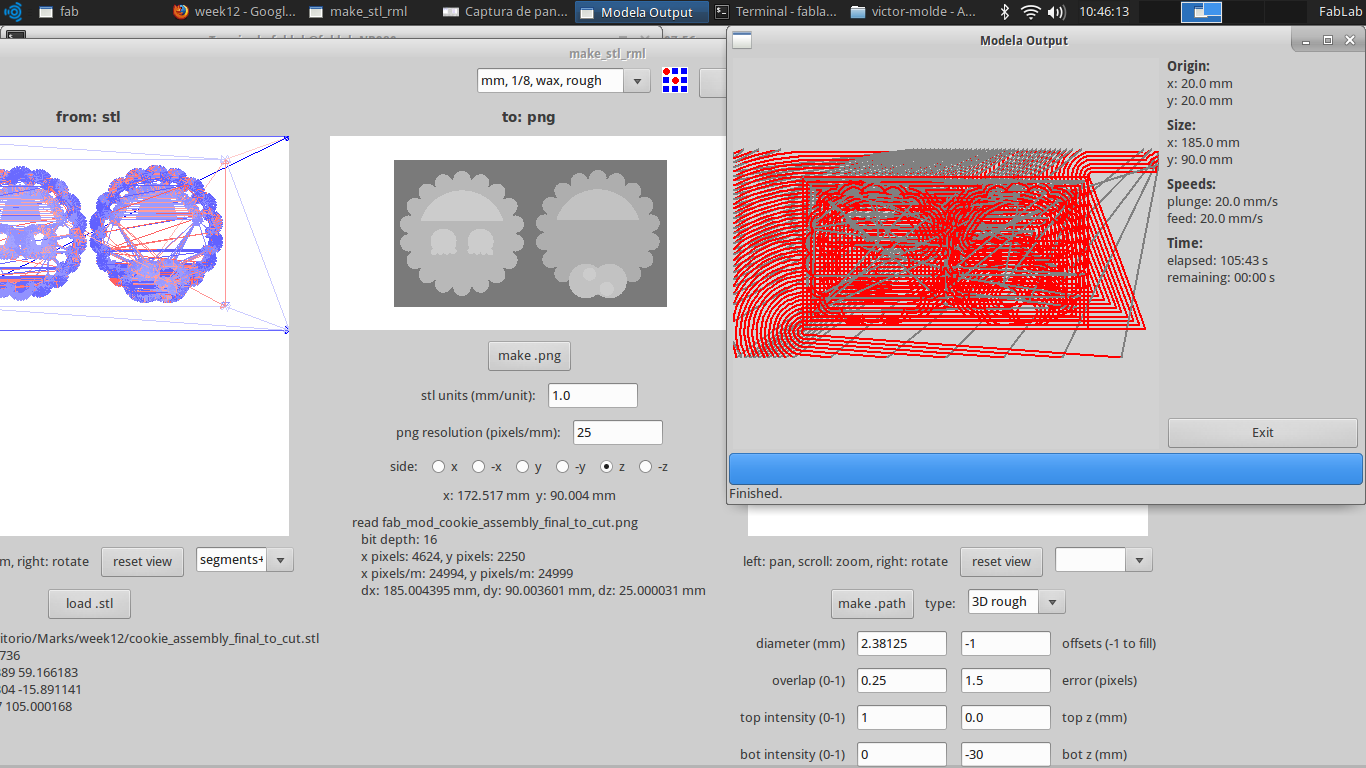

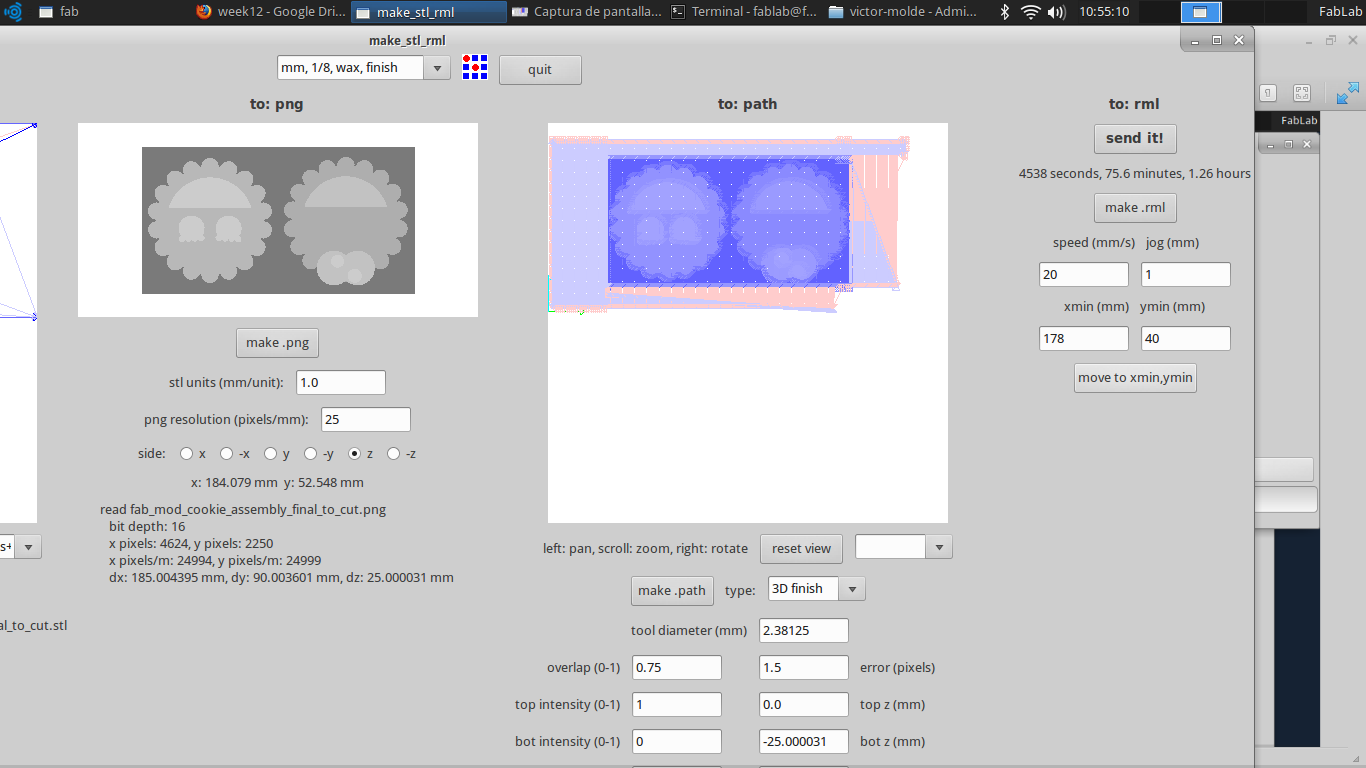

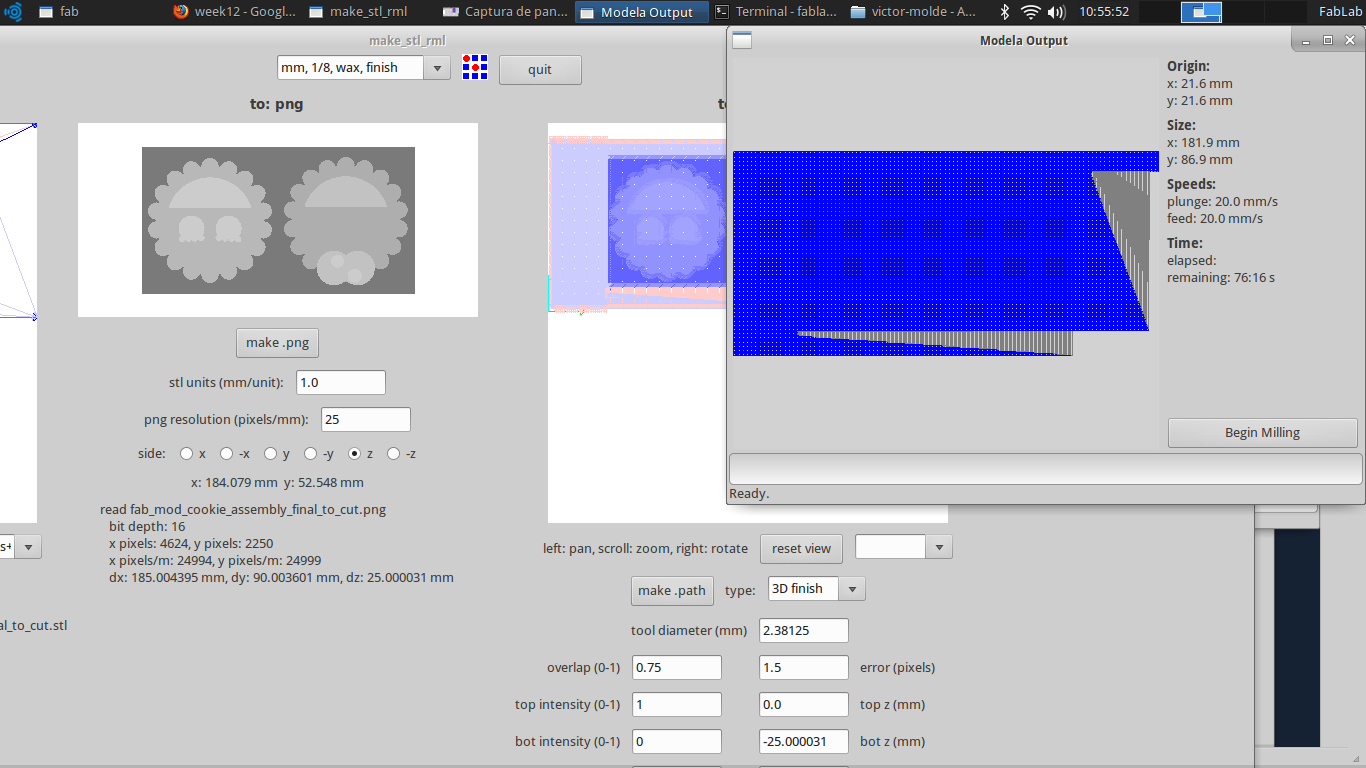

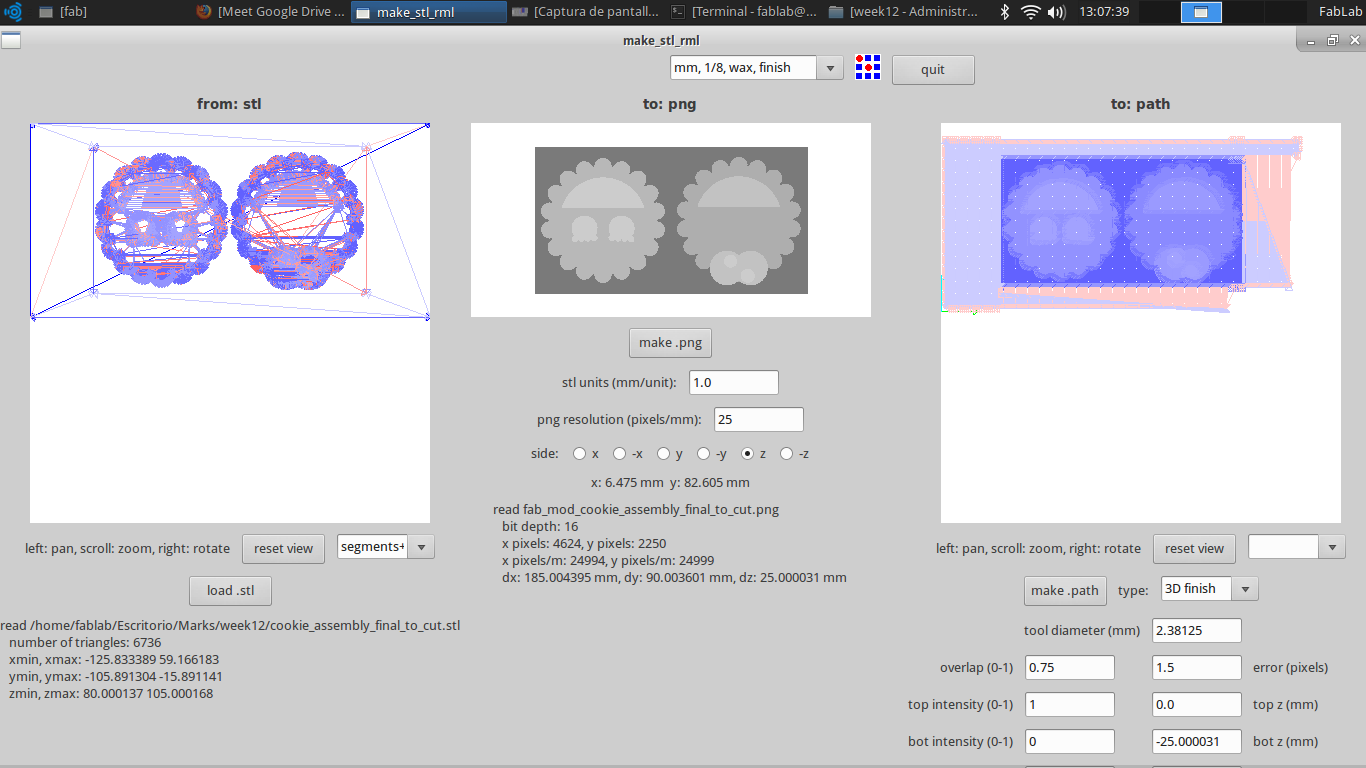

The final model has the wax shape, so this is neccesary to cut off the wax. The STL final loaded in fabmodule which loads .stl to cut in roland machine. Second, we choosed the correct cut: first rough and finally finish. The stl is transform in gray image png, now we selected face to project on the platfowm for example z. After getting the path we make .rml and sent it. Finally, we got the mould and the next images detail these process.

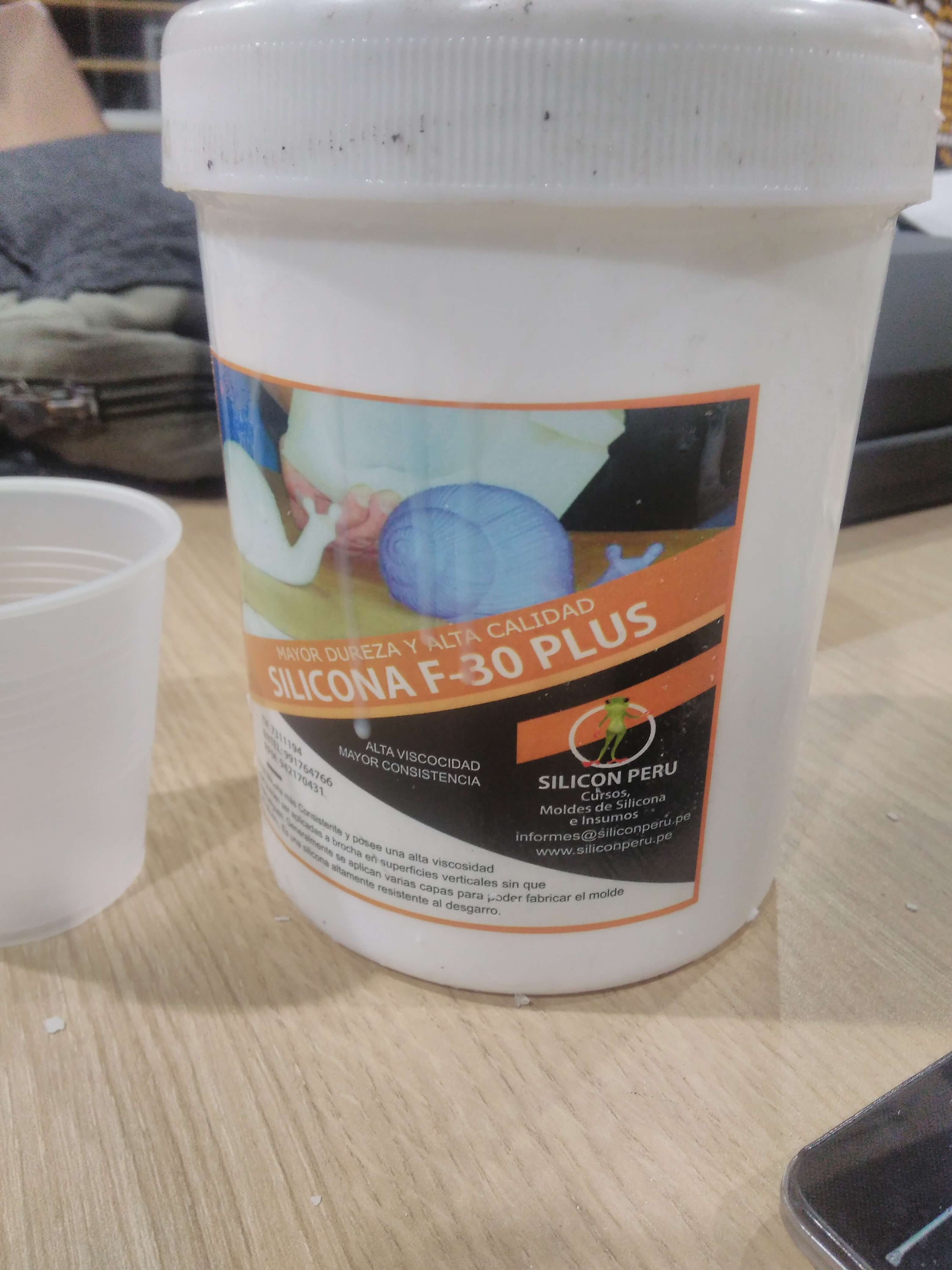

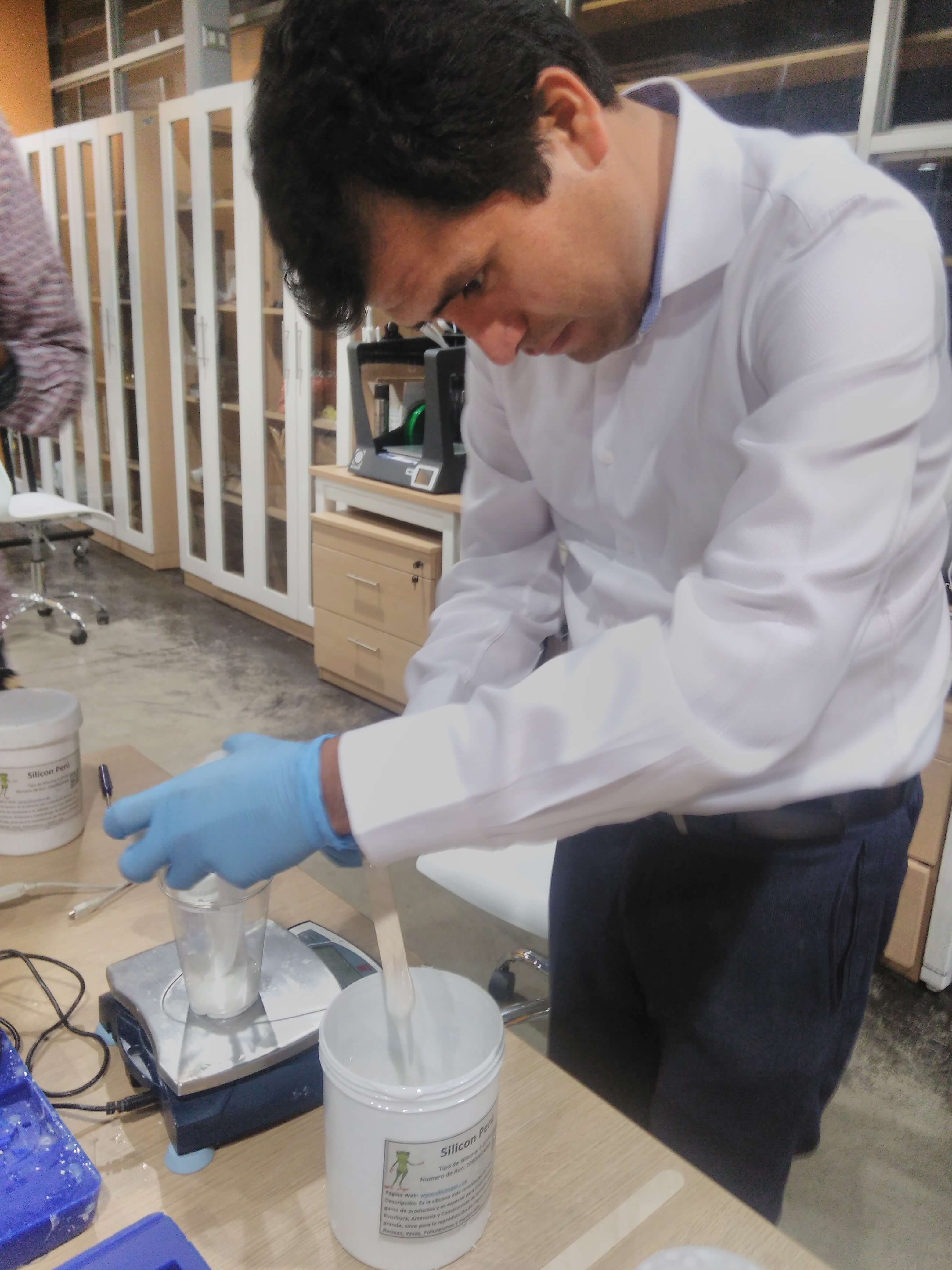

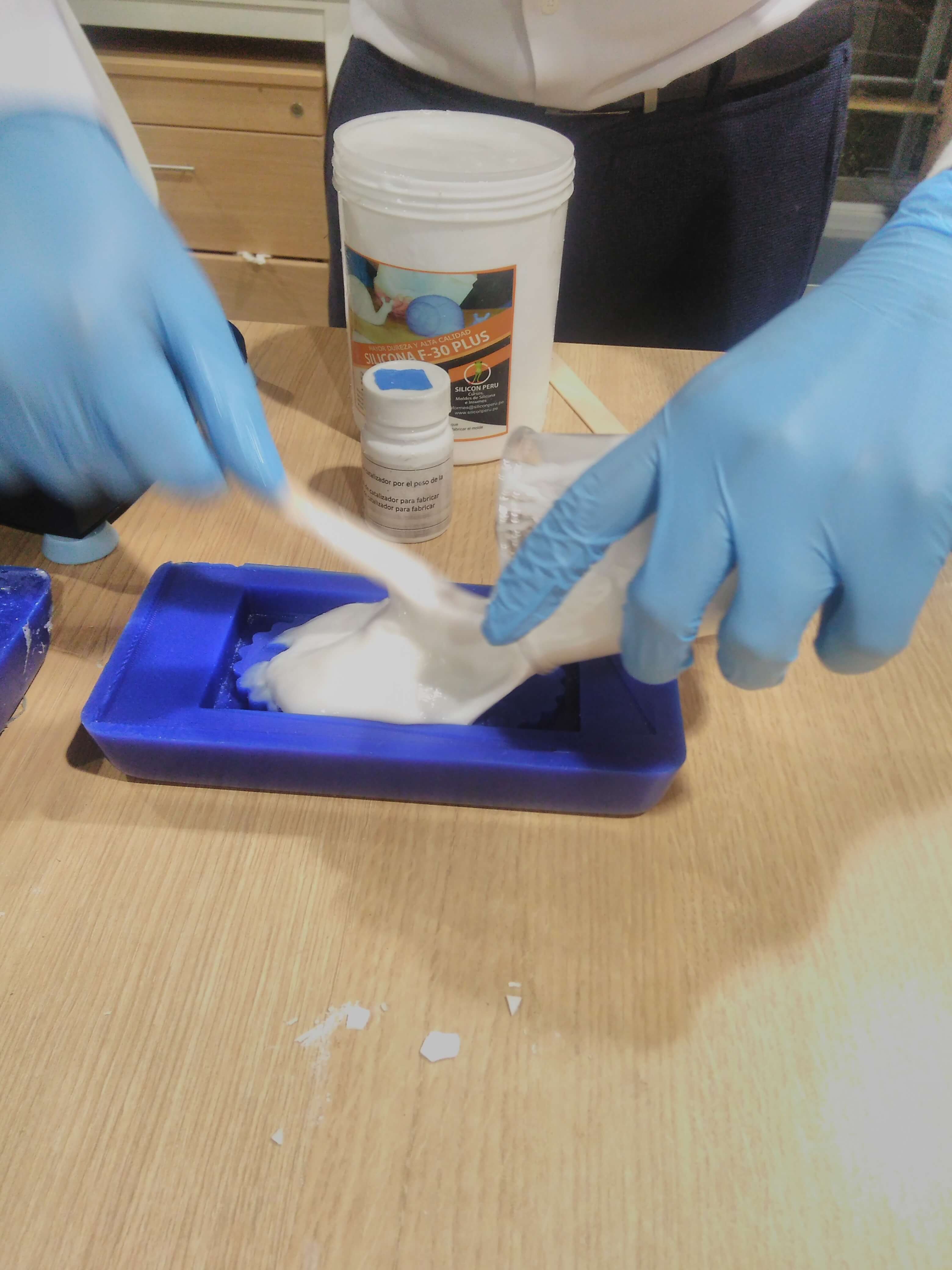

Casting the mold

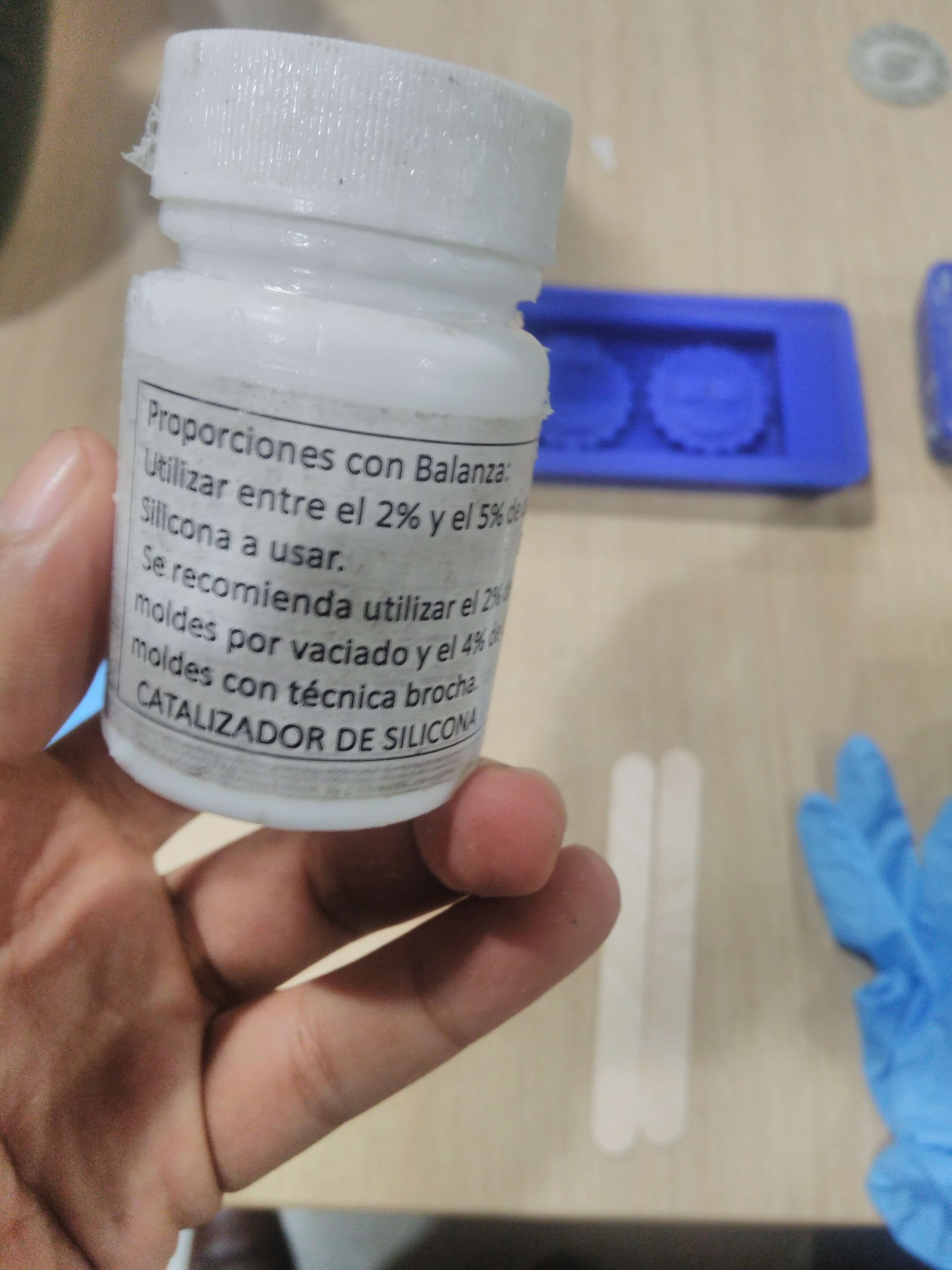

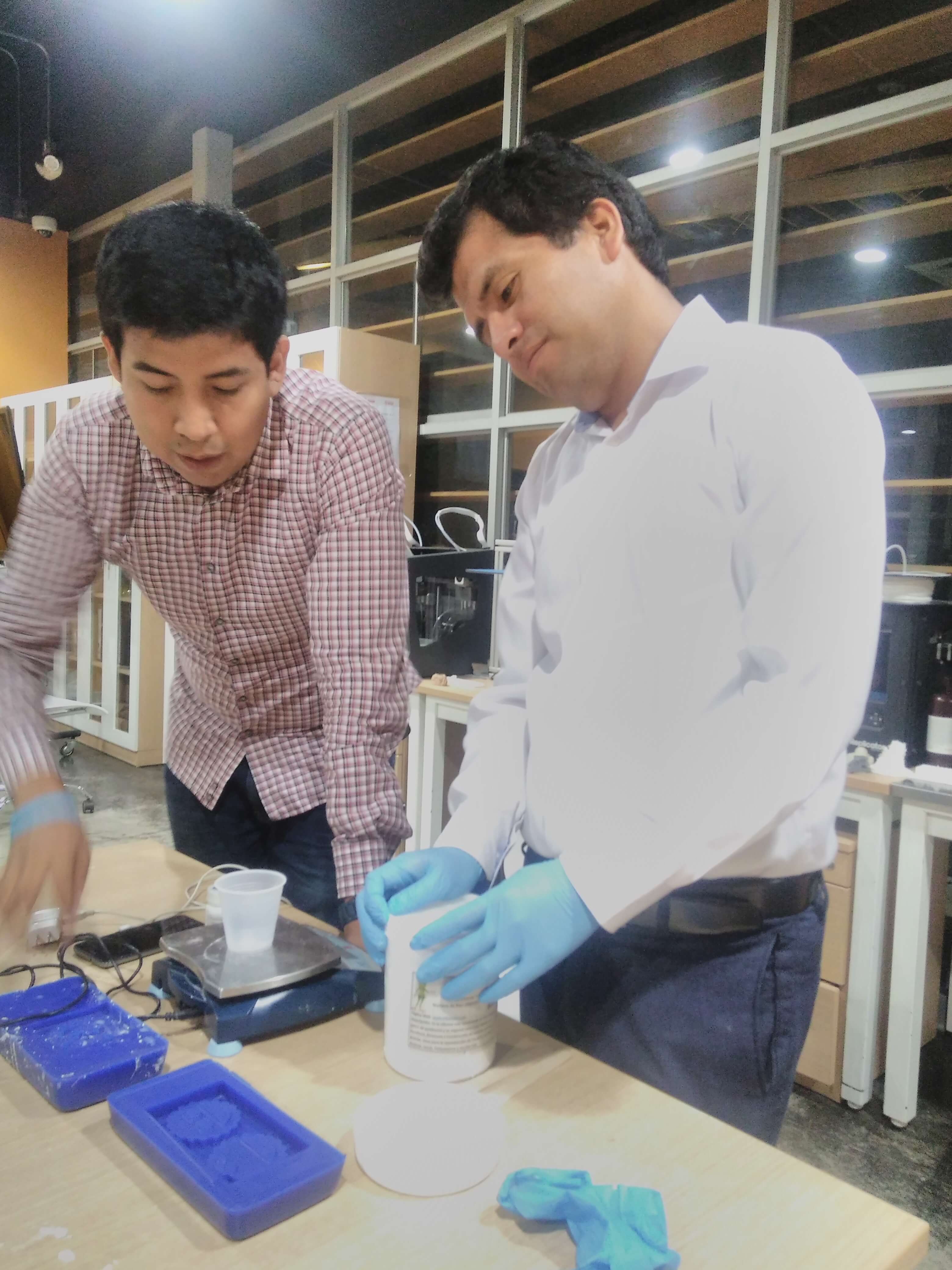

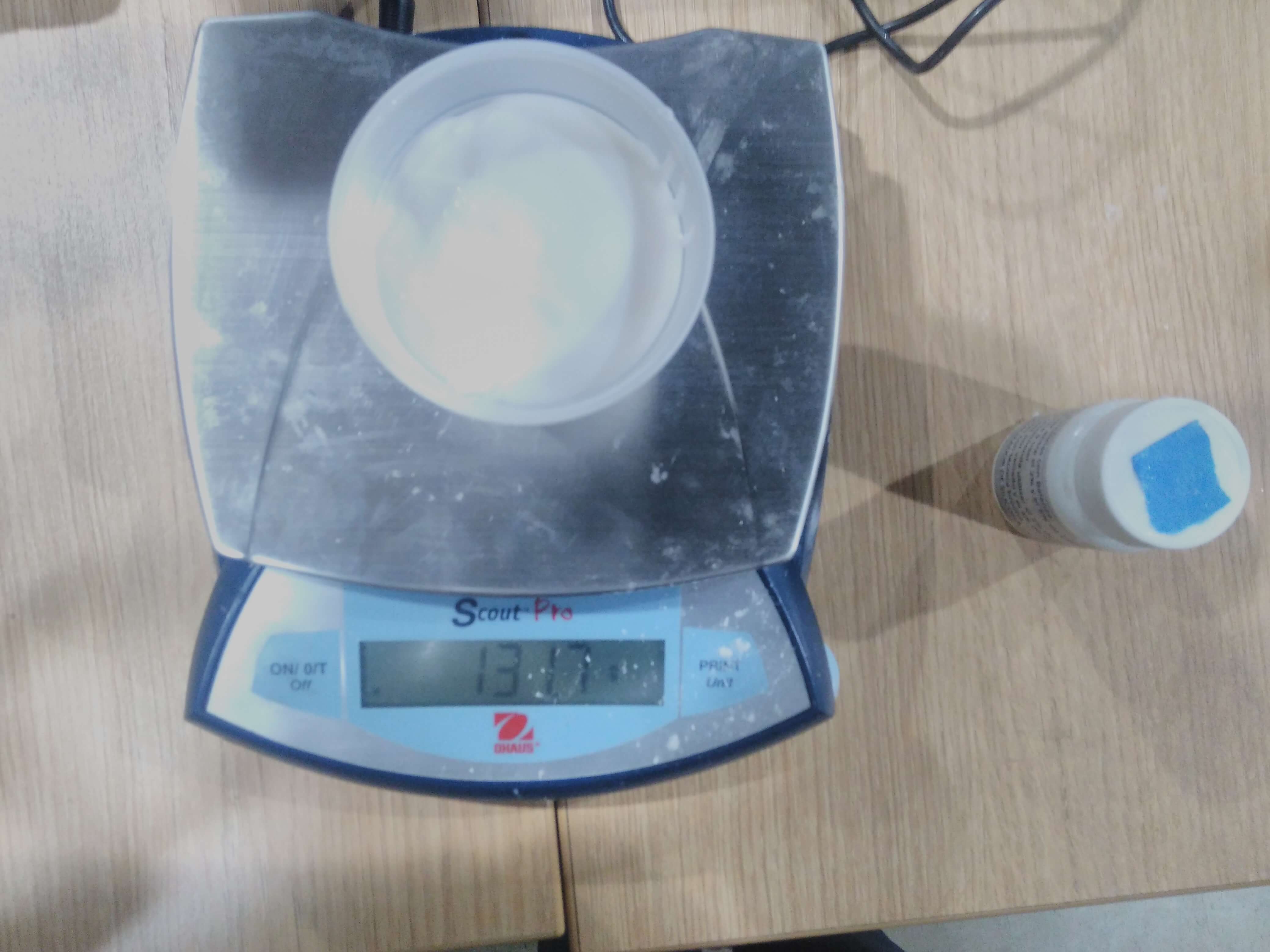

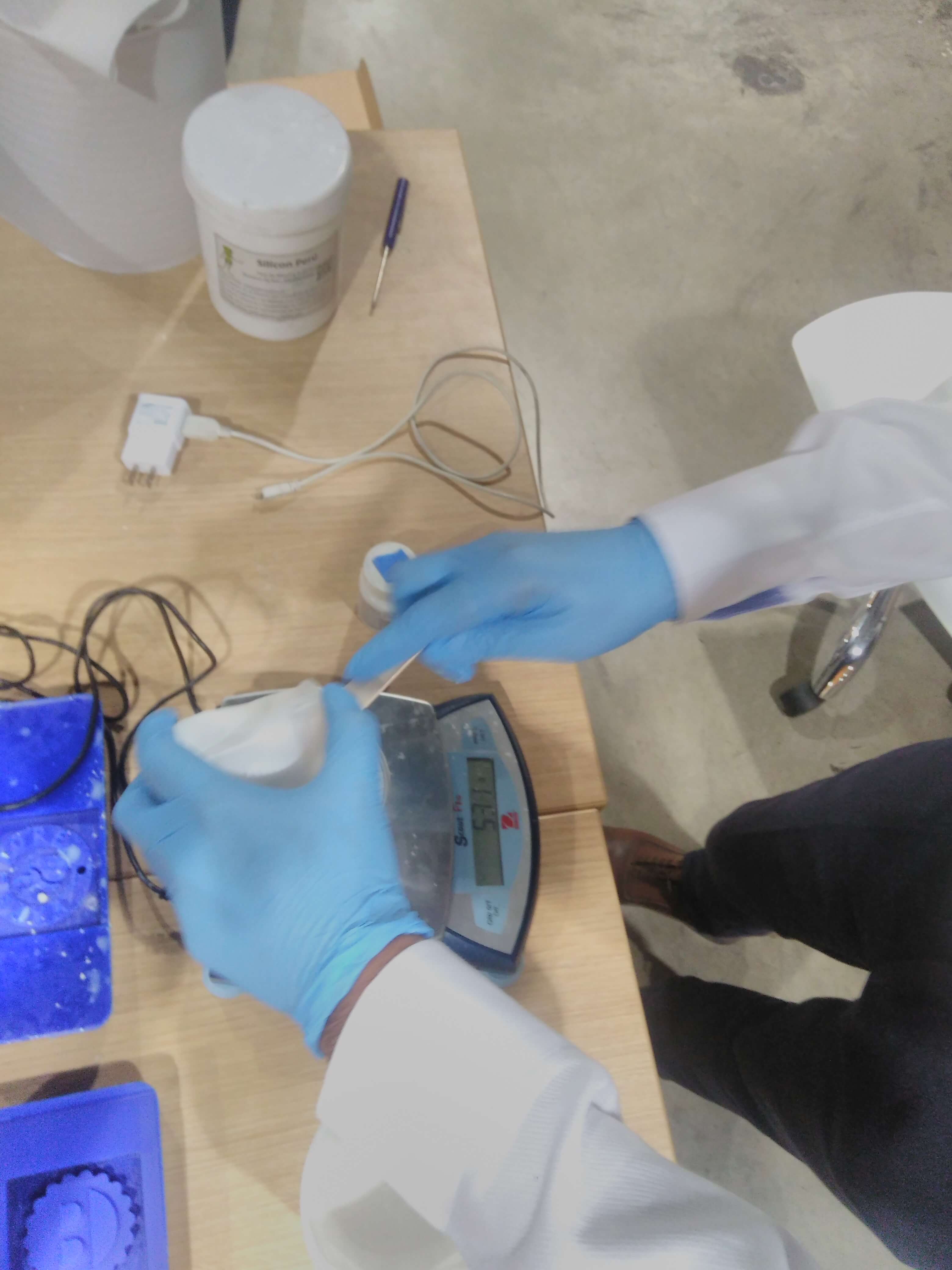

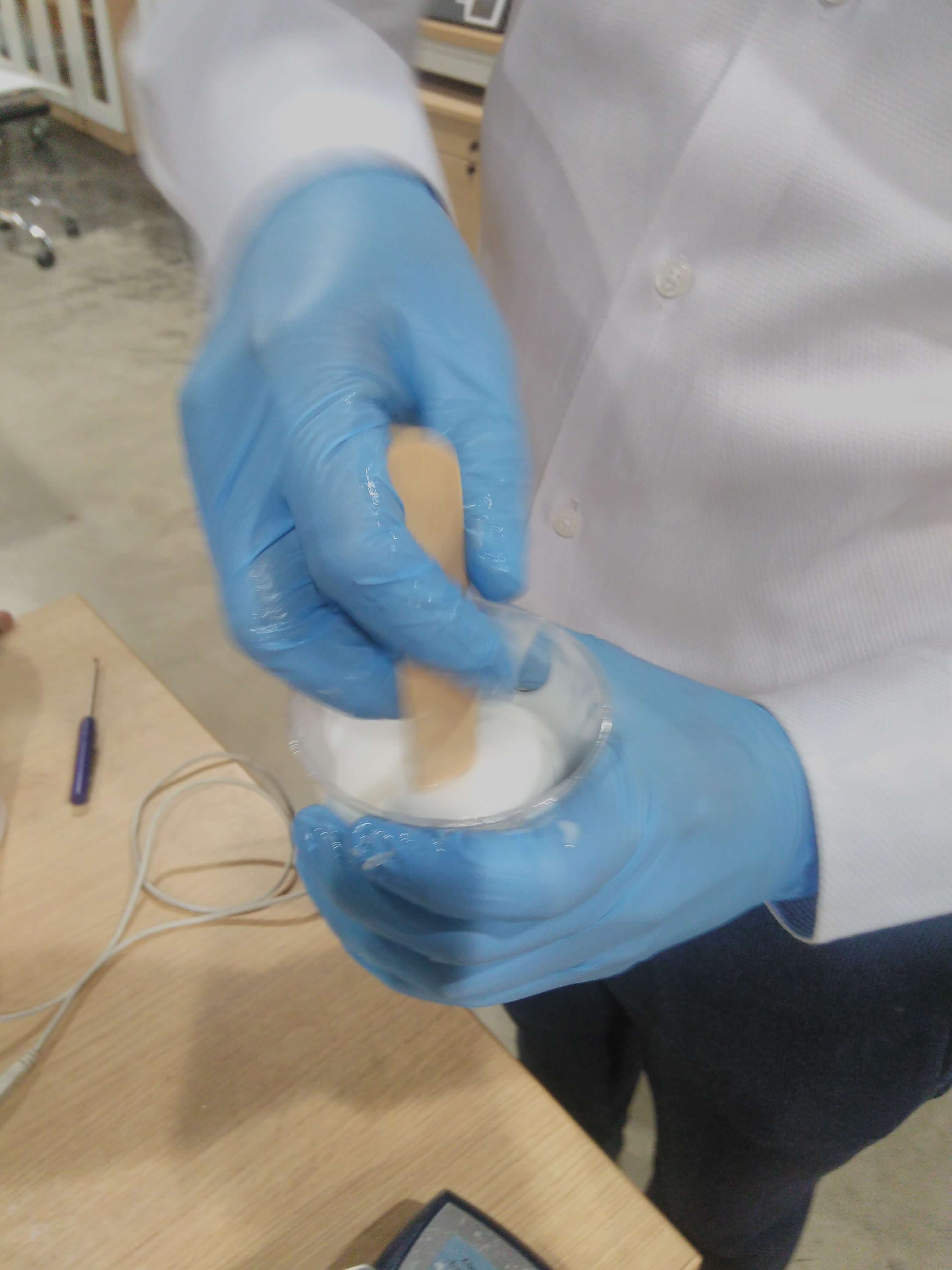

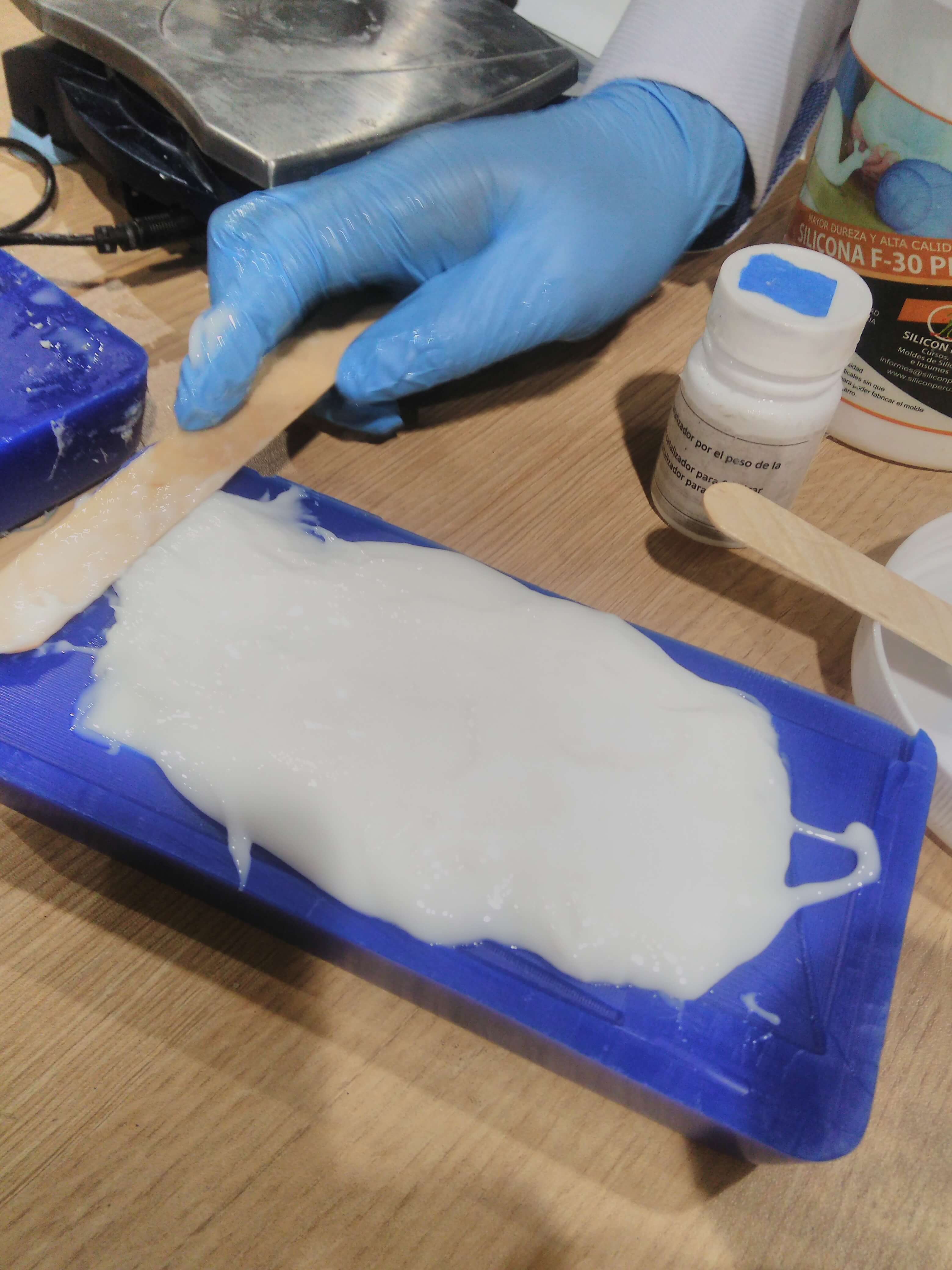

Now I had the wax positive mold, the next was to put silicon into negative mold. We must prepare the silicon with two components, the mix silicon was in balance a proportion 2% catalizer per mg of silicone. In my case I mixed 200 mg of silicon and 4 mg catalizer. Few minutes later mixing I put the silicon in mold.

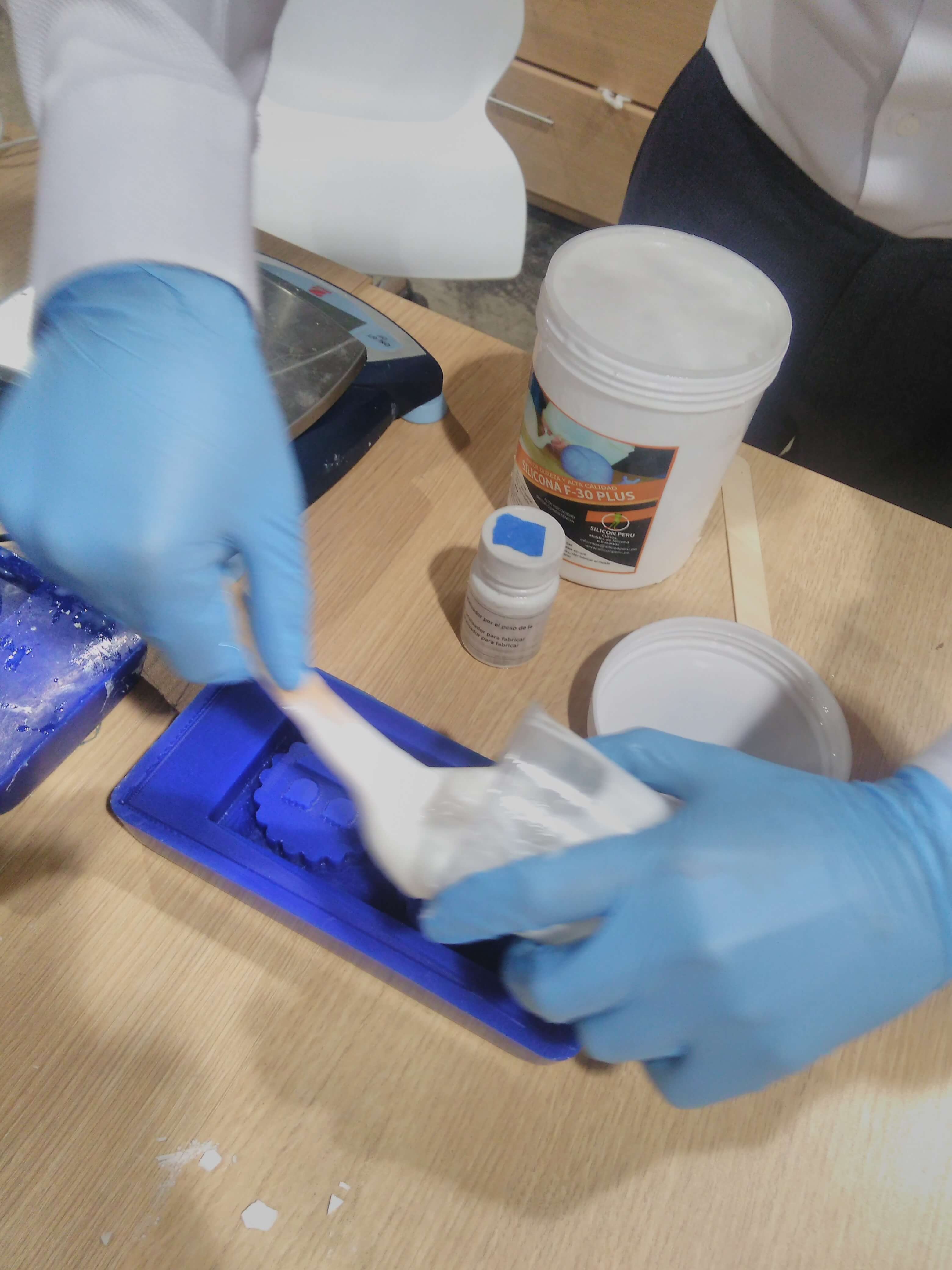

After a day from put the silicon on mold, I have retired the silicon mold which has some errors. The reason of these issues were I did not mix well, and it generated air balls inside. Now, I decicded to put 80mg of cement in mold and 17mg of water. The walls in the mold was incomplete, so I fill with paper.

Finally, we got these crazy cookies :D .