MOLDING AND CASTING

WEEK 12

- Design a 3D mold, machine it, and use it to cast parts

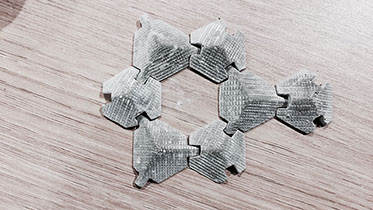

MODULAR PIECE

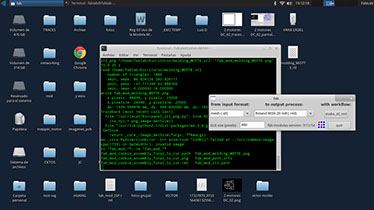

I wanted to make a modular construction piece that let you play with geometry. So I had the idea of dividing a regular pyramid into four equal parts, that would be the modular piece. First I had to model the piece on Rhino and export it as STL file. The model must be like a container with the pieces inside.

- WAX MOLD STL

- WAX MOLD RHINO

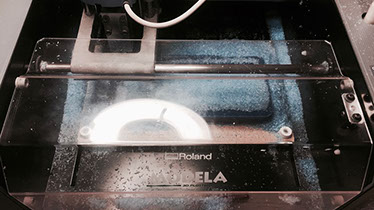

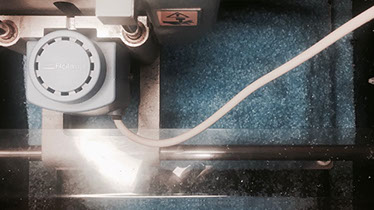

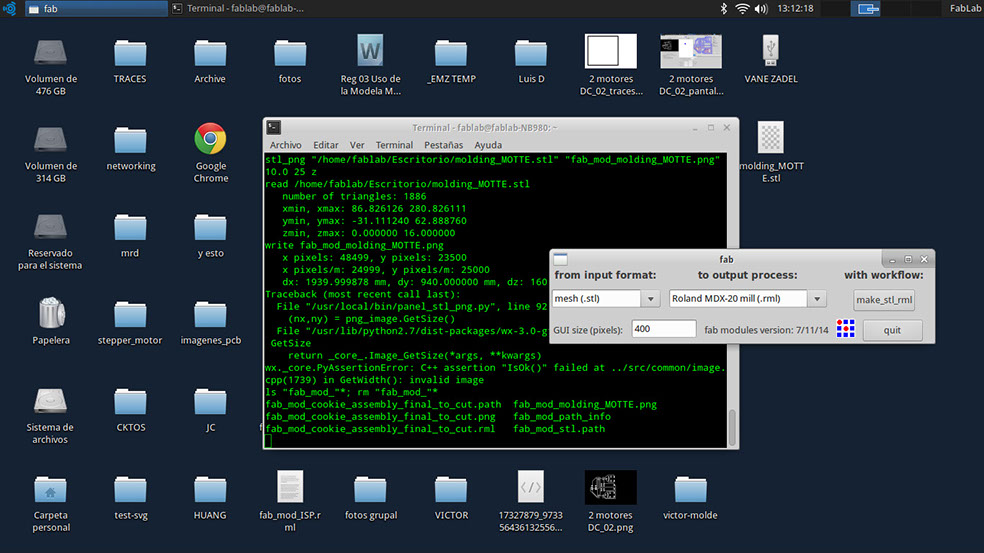

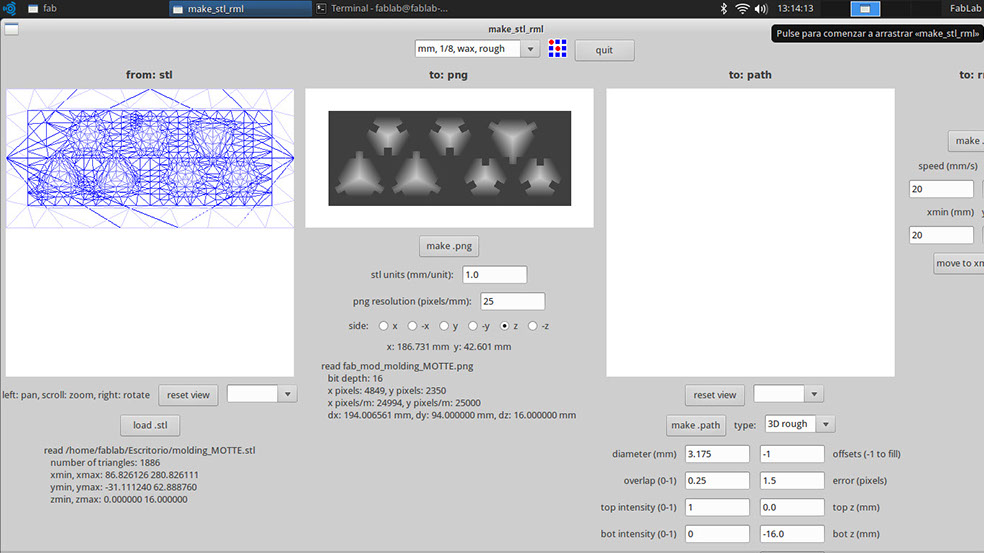

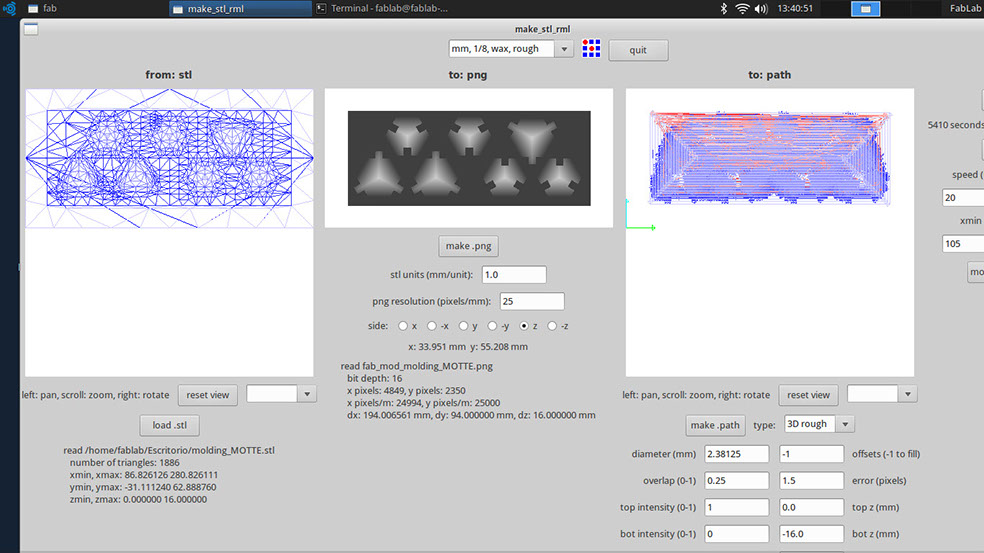

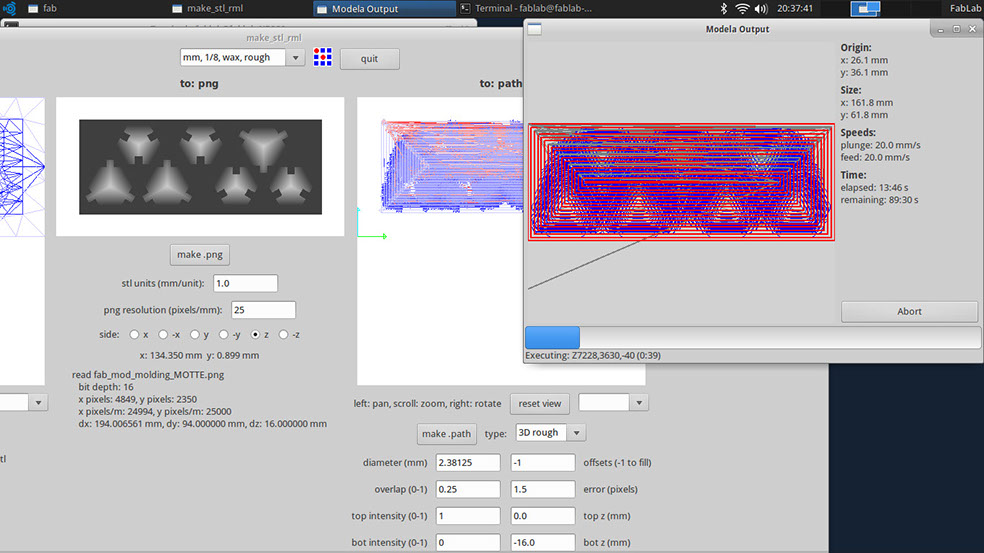

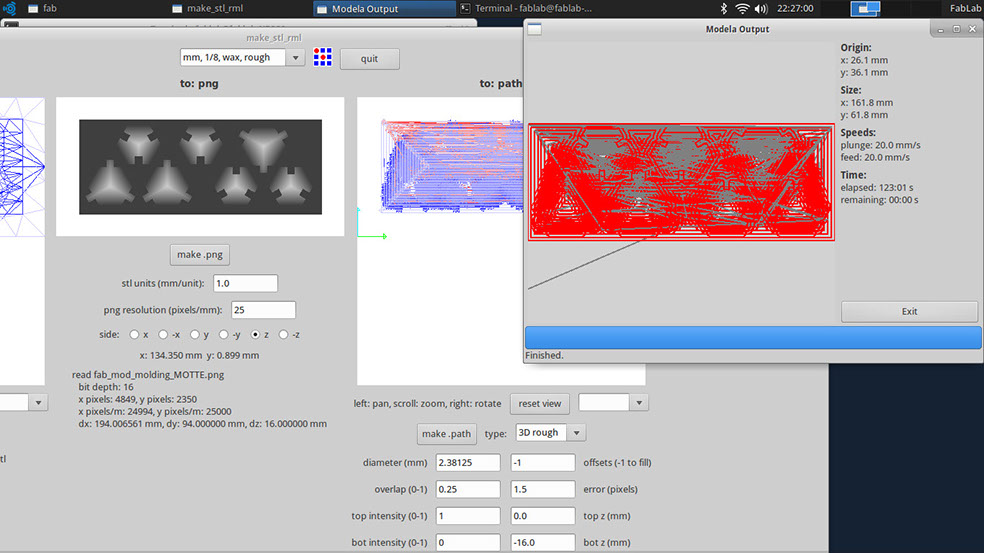

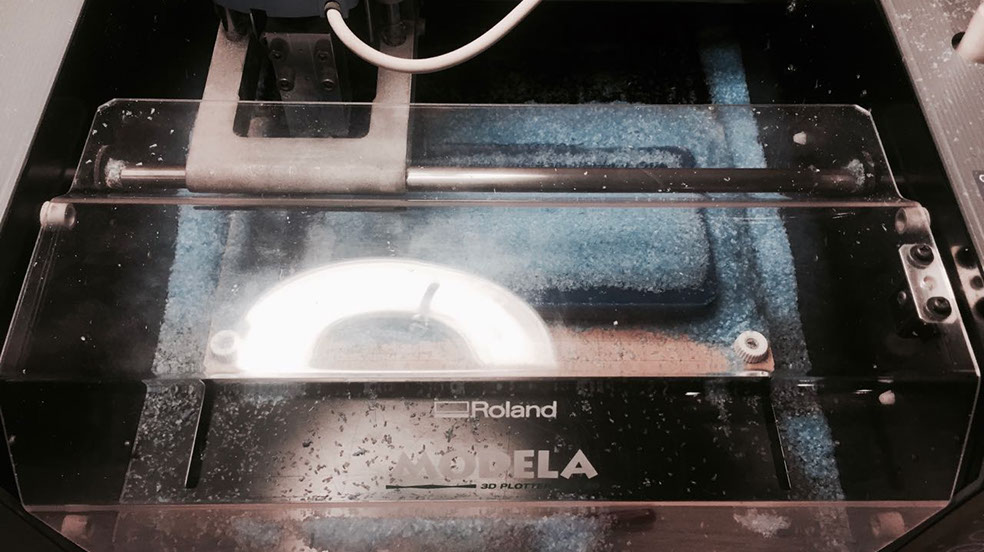

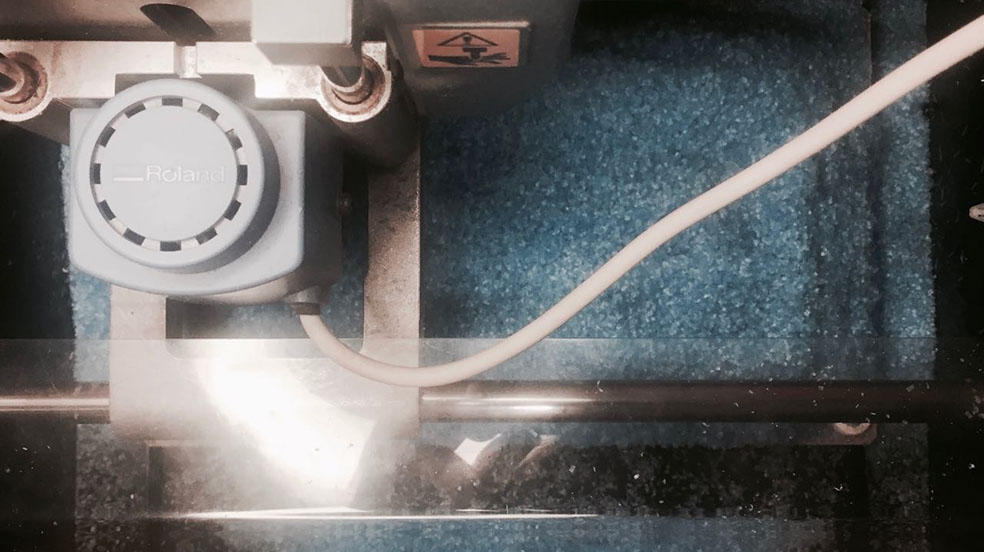

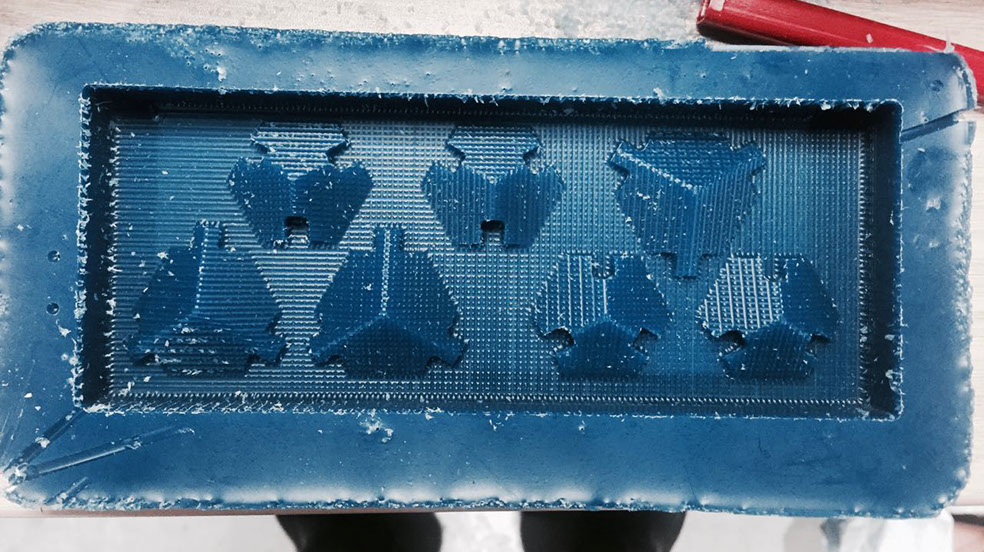

When the model is finished, I used the modela MDX to mill it on a block of blue wax, prepared by FABLAB ESAN. The wax model would be the mold for the silicone negative. The recomended mill for this task was 1/8. The milling machine, mill the wax first in one direction and then in the other perpendicular direction. First make a rough mill and then a finishing mill.

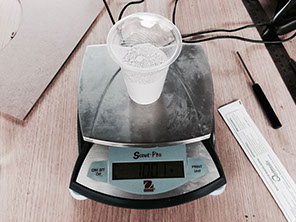

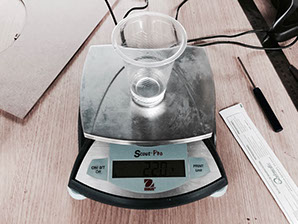

With the first mold finished, I had to prepare the silicone for the negative mold. The silicone used was F-30 Plus and had to be mixed with a catalyst in a proportion of 2% of the total mixture. First I had to weigh the glass in which I would mix the silicone, then I weighed the amount of silicone to be able to add the 2% of catalyst, when adding the catalyst it was necessary to move the mixture until it obtained a harder consistency and thus to pour it in the mold of wax . Then I had to wait almost a day to have the negative mold ready.

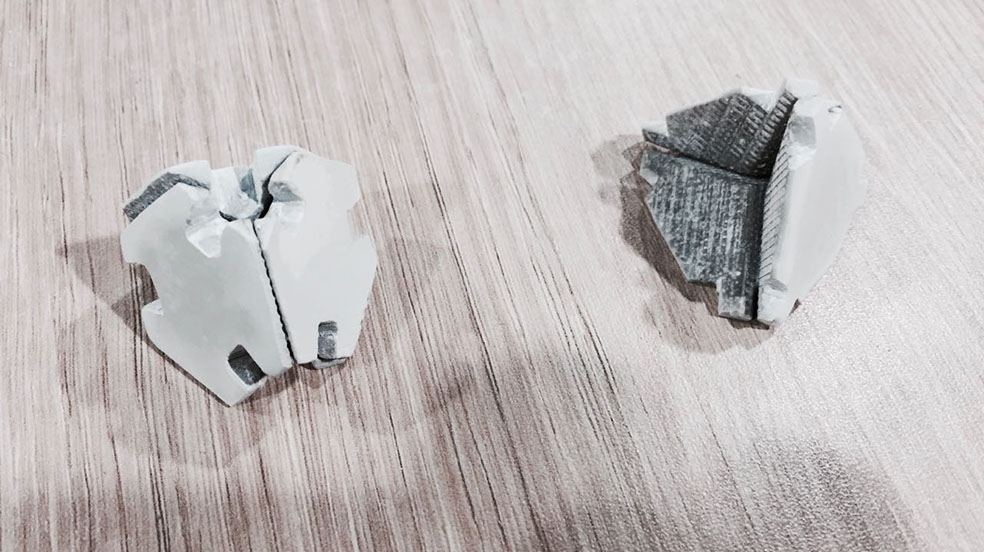

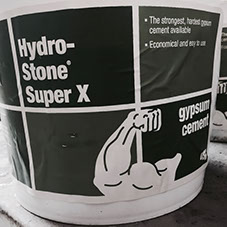

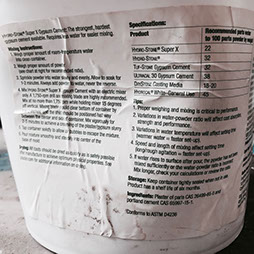

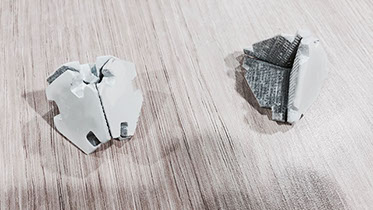

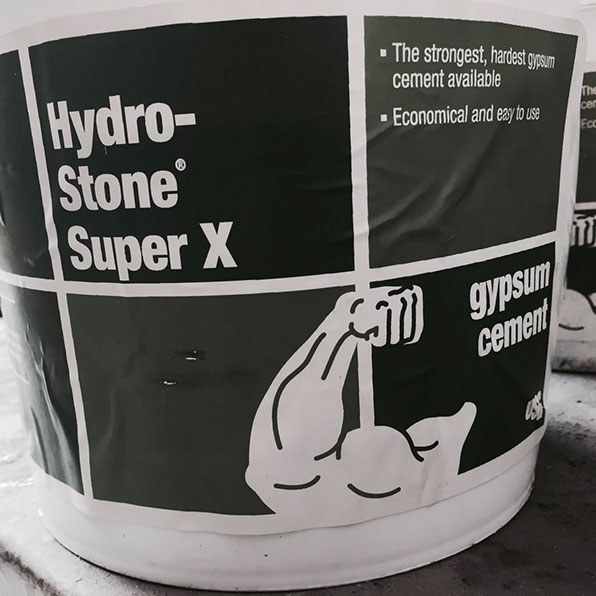

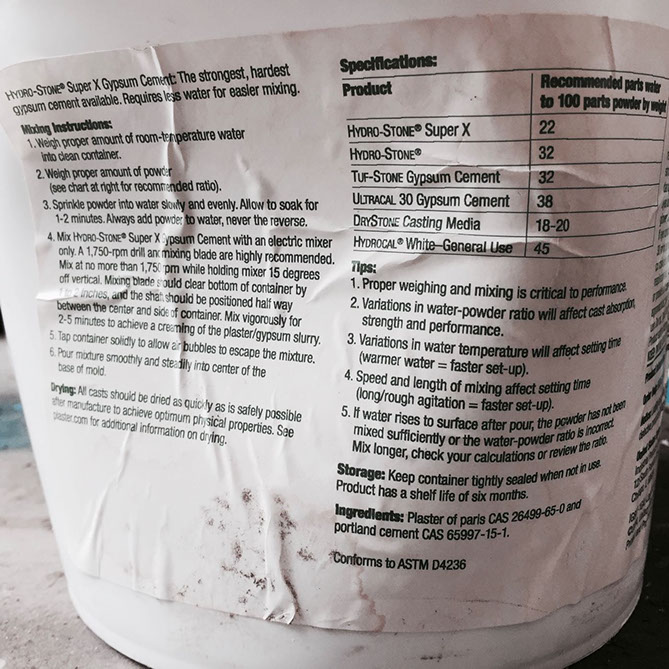

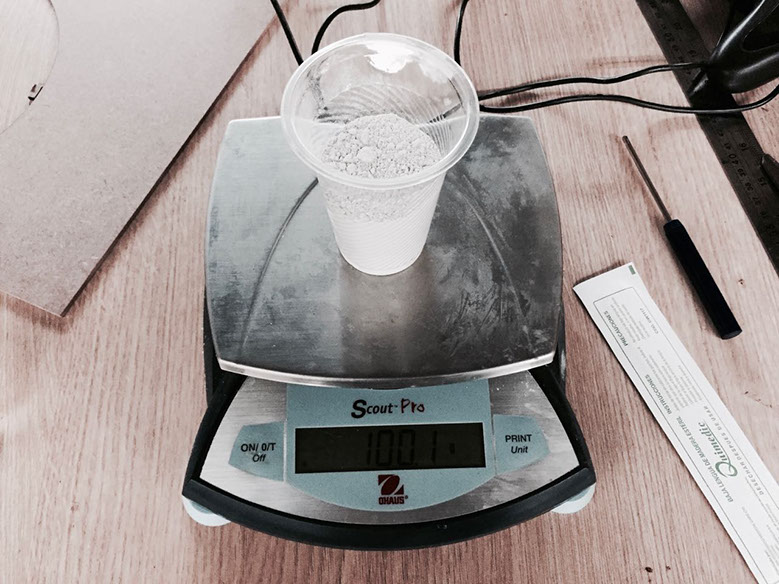

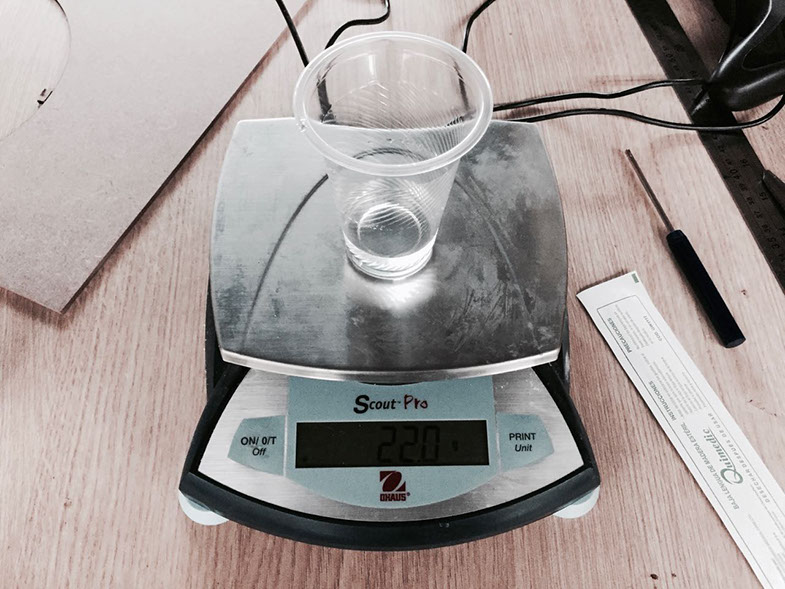

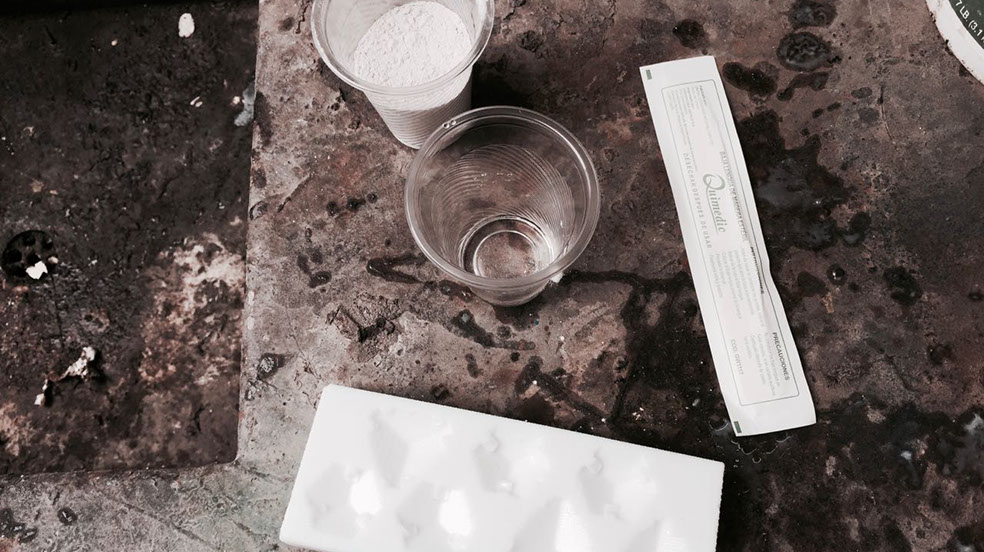

The silicone mold had several gaps, since I could not get all the air out of the mix. With the negative ready, what followed was to prepare the gypsum cement for the final pieces. The gypsum had to be mixed with water in a proportion depending on the type of cement, for this one (Hydro-Stone Super X) the proportion was 100 parts of cement an 22parts of water. Unlike what I thought, the cement was the one that had to be poured slowly into the 22 parts of water, while stirring in a mixture as homogeneous as possible and without air. Once the mixture was ready I added it to the silicone mold and let it harden. The result was the desired pieces.

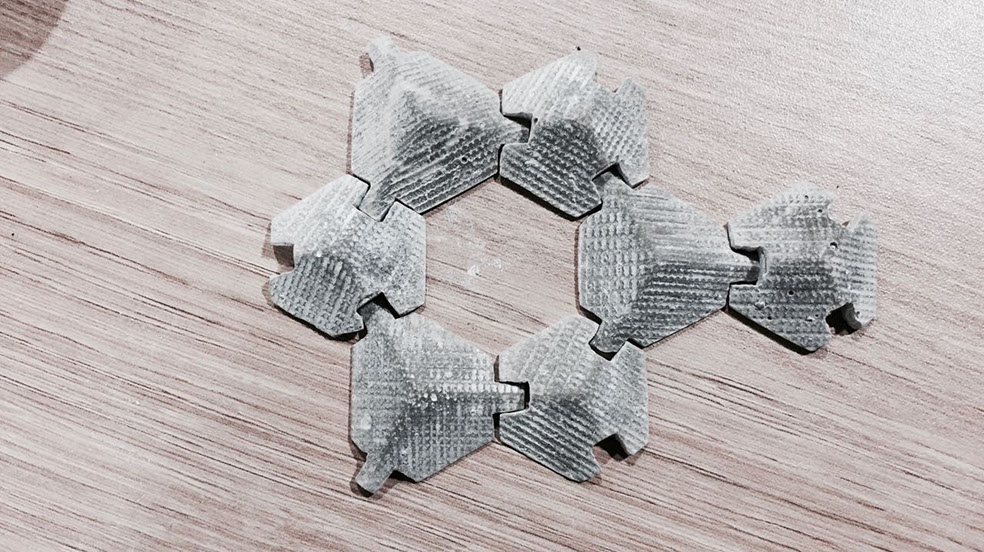

After demolding, I had to sand the pieces a bit and started to explore the possibilities of the system.