COMPUTER-CONTROLLED MACHINING

WEEK 7

- Make something big

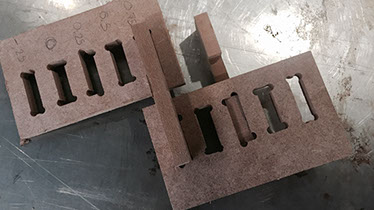

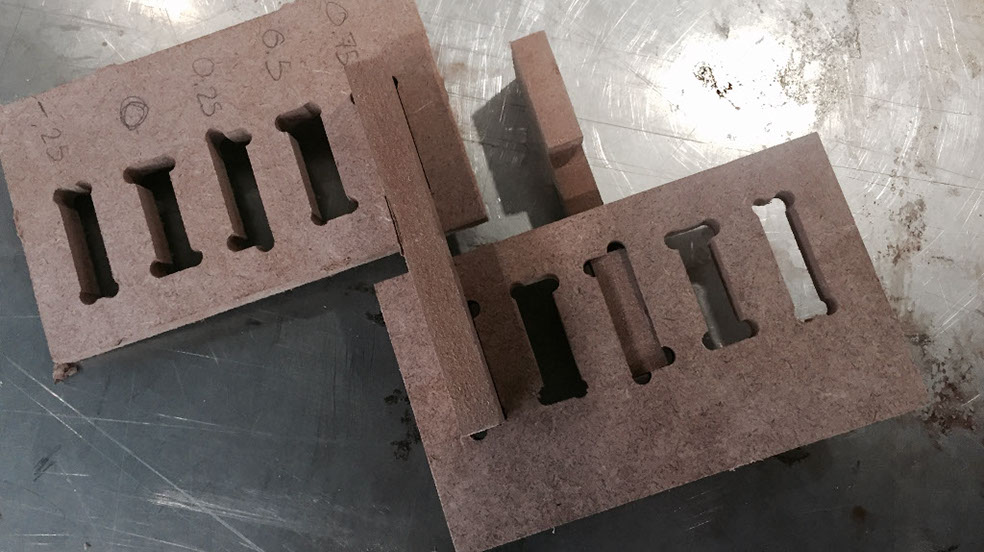

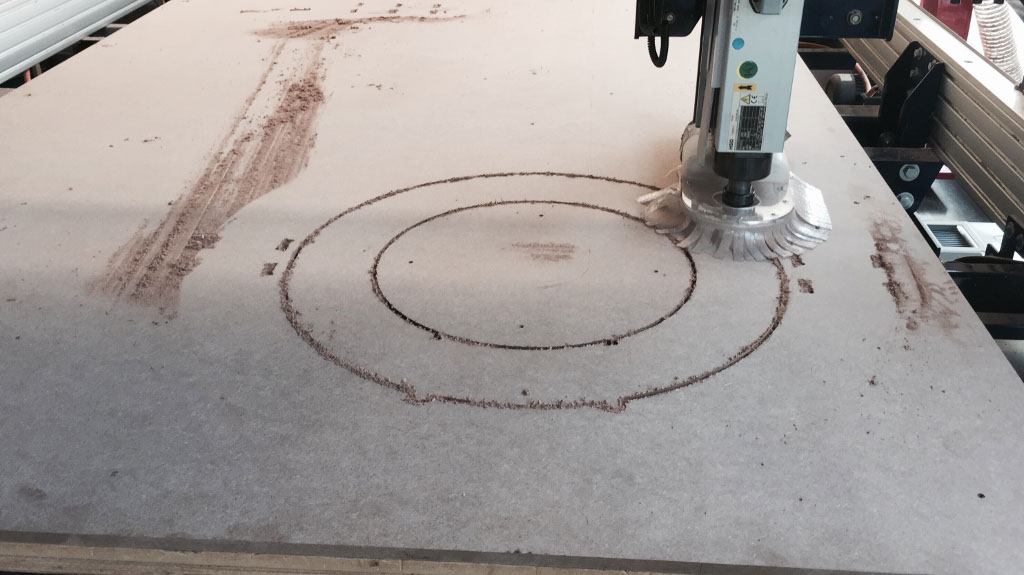

TESTING

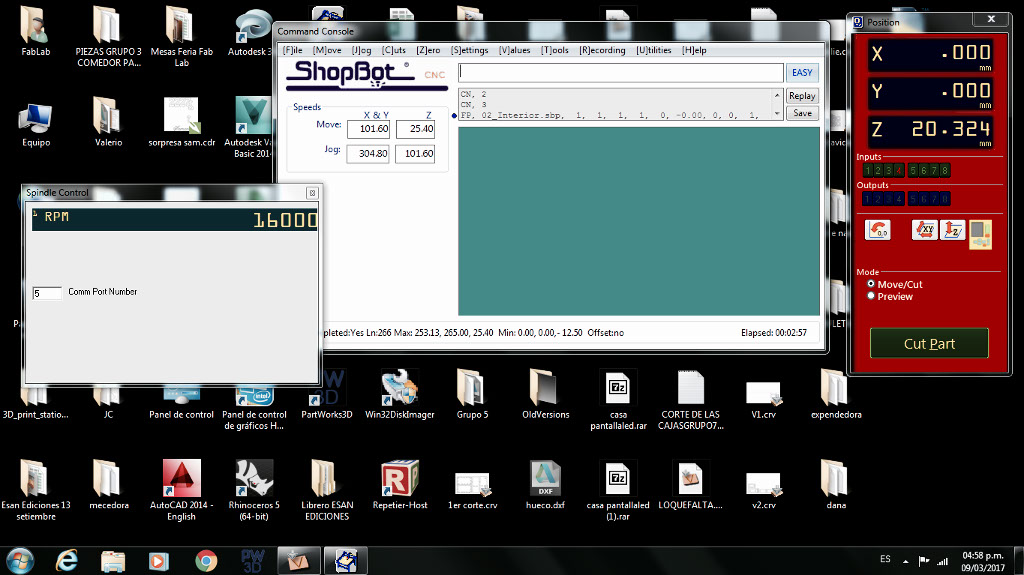

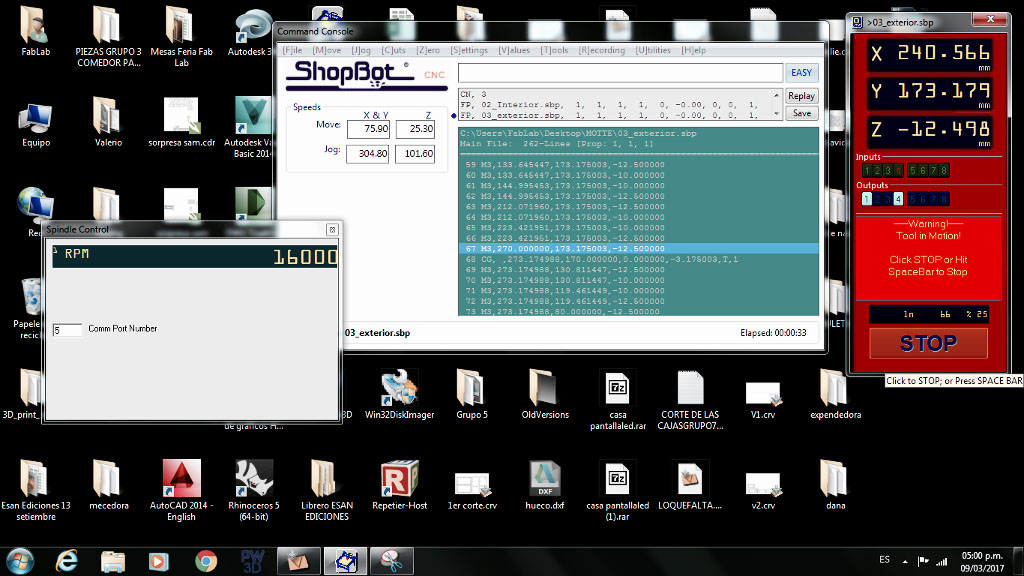

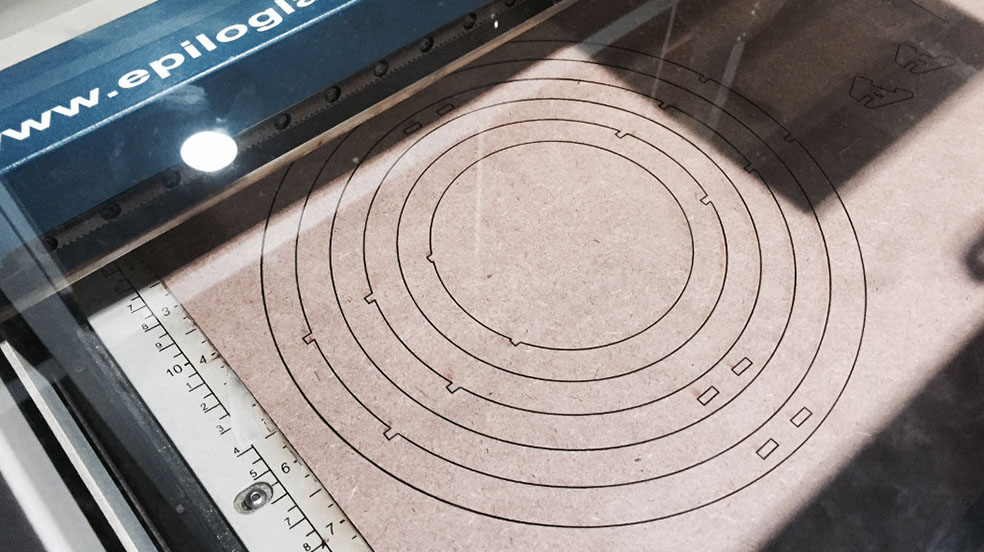

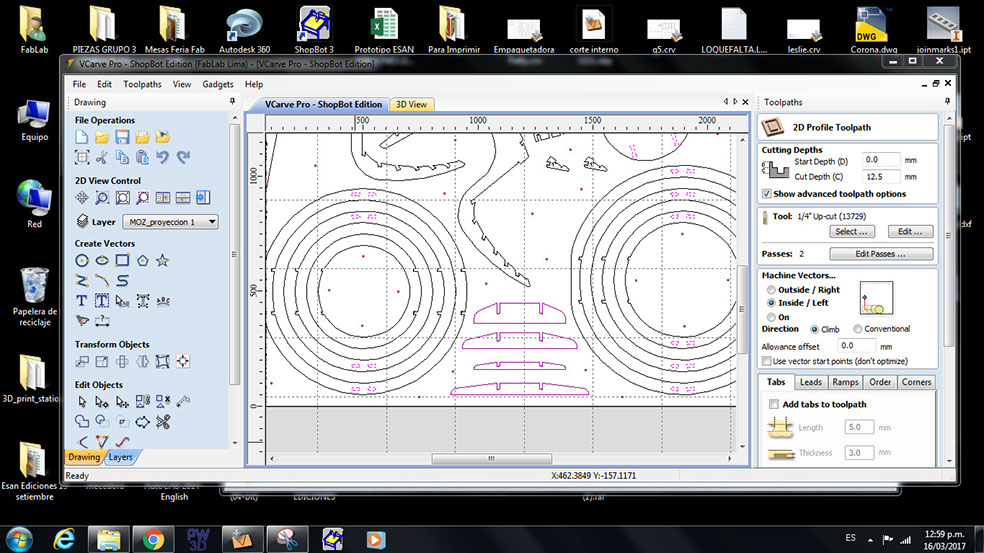

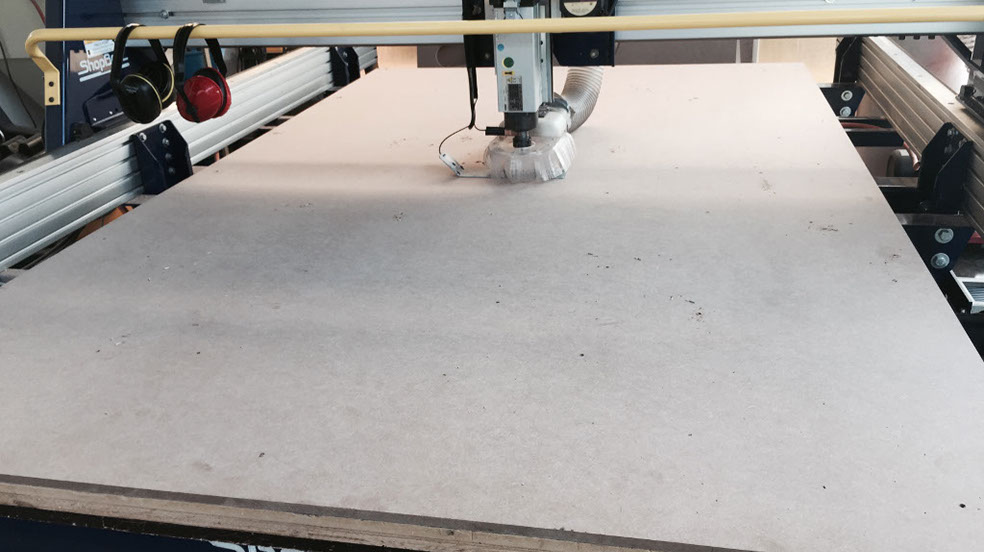

To be able to design for big format, we have to test the press fit joints for MDF and Triplay machine cutting, so we made several tests on a 12mm and 18mm board. To operate the Shopbot, the first we have to do is to fix the board to the machine, then we have turn on the machine to set up XY axis and Z axis using an aluminium plate. After setting the origin, we have to open a .dxf file with the design into the vcarve software to set it for the machine and saved it into a .sbp file. In the vcarve, we set the size and thickness of the board, we set the cutting path and order, and the type of drilling mill. To begin cutting, we open the .sbp file on the shopbot software, turn the air extractor, then turn the spindle on and send the cutting order.

- FILES

O-CHAIR

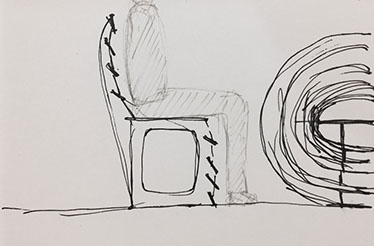

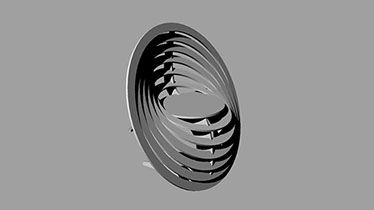

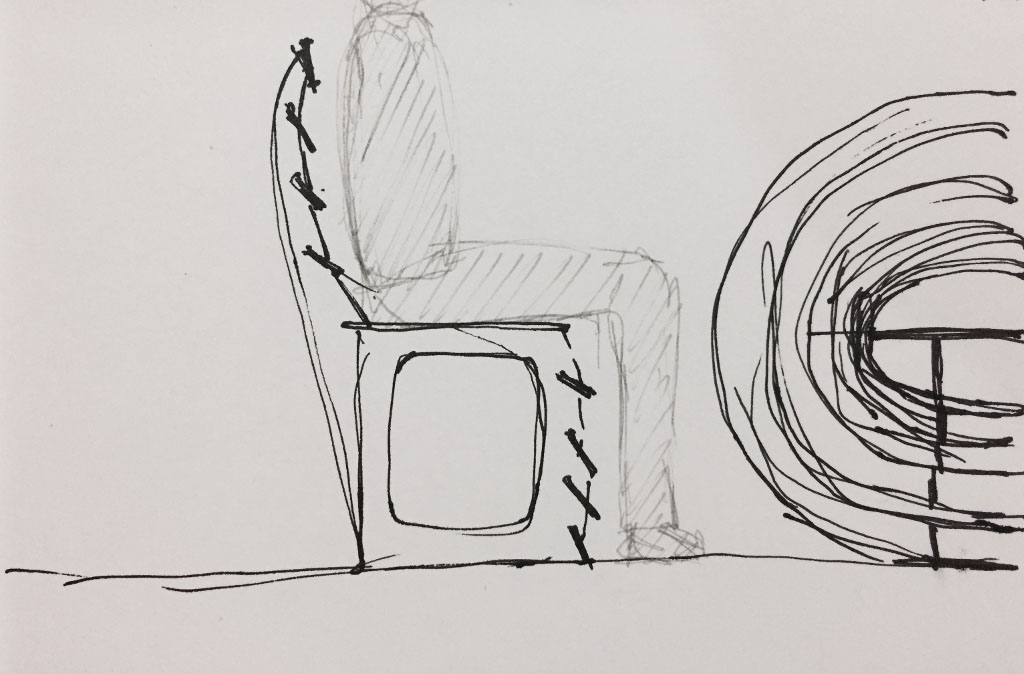

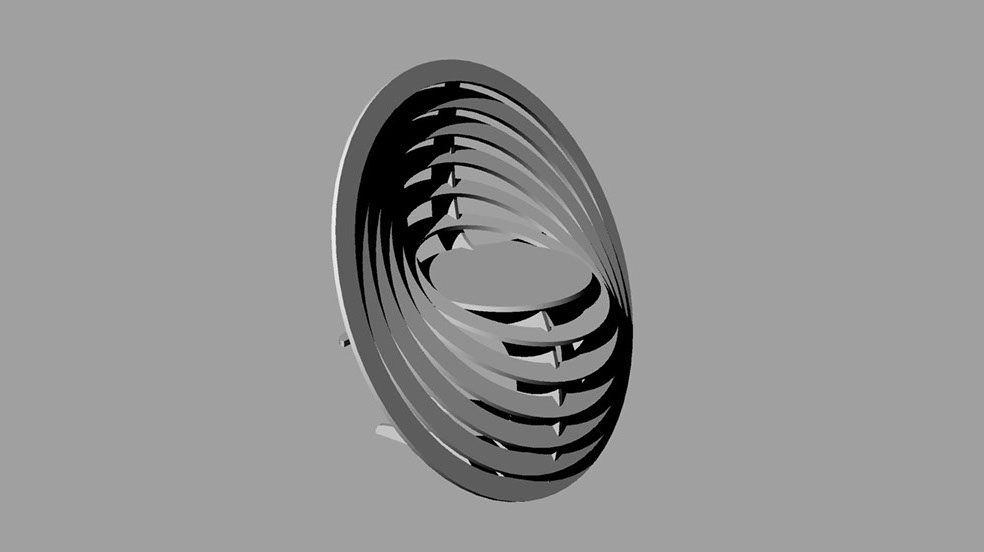

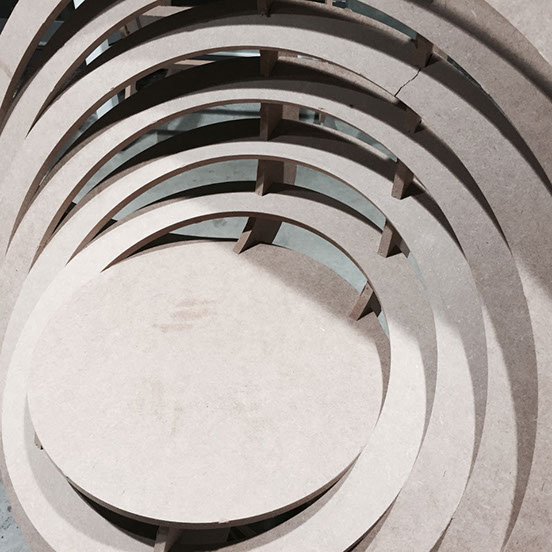

At first, i didn't know what to make, then i thought every known architect has also designed a famous chair, so I look for some references on pinterest that inspire mine. I find this 3D model stool image, but sadly didn´t know who the author is to mention him here. I wanted to make a chair with movement that enfatize the person that sits there, almost like a throne. The idea was to use the concentric rotating circles from the reference as part of the chair structure. Then I draw the schemes and the model on Rhino5.

RHINO FILES

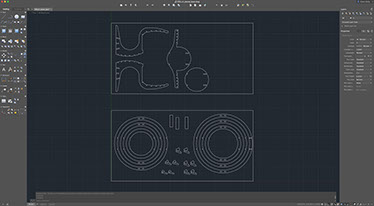

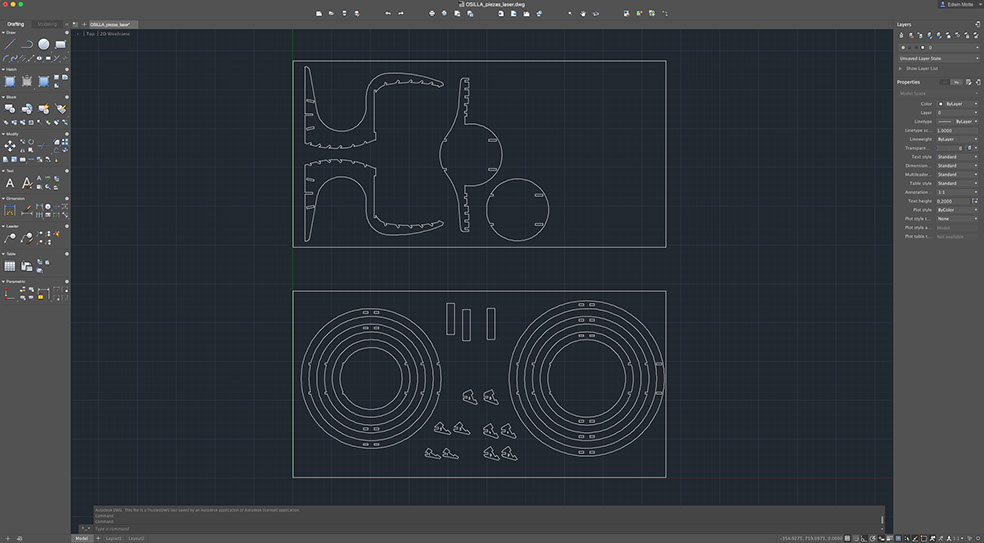

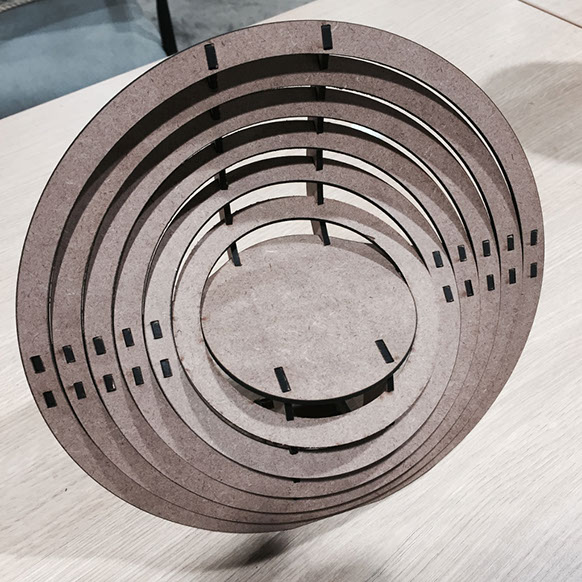

After defining the idea and modeling it in Rhino, I started to make all the pieces on the lasercutter in order to make a model with MDF (3mm), before configuring the pieces for cutting them on the shopbot.

AUTOCAD LASER FILES

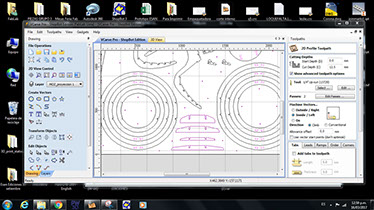

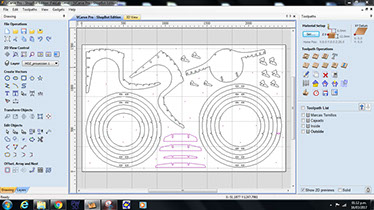

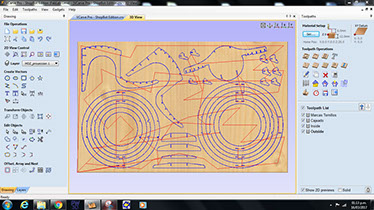

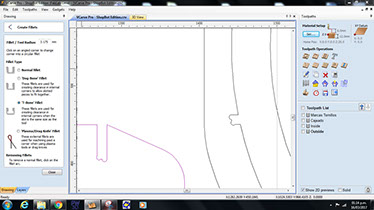

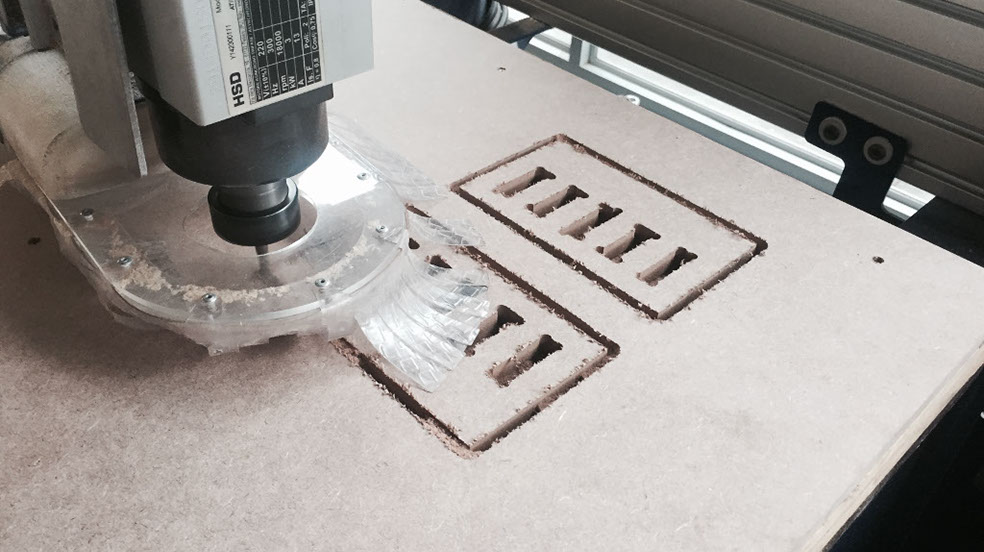

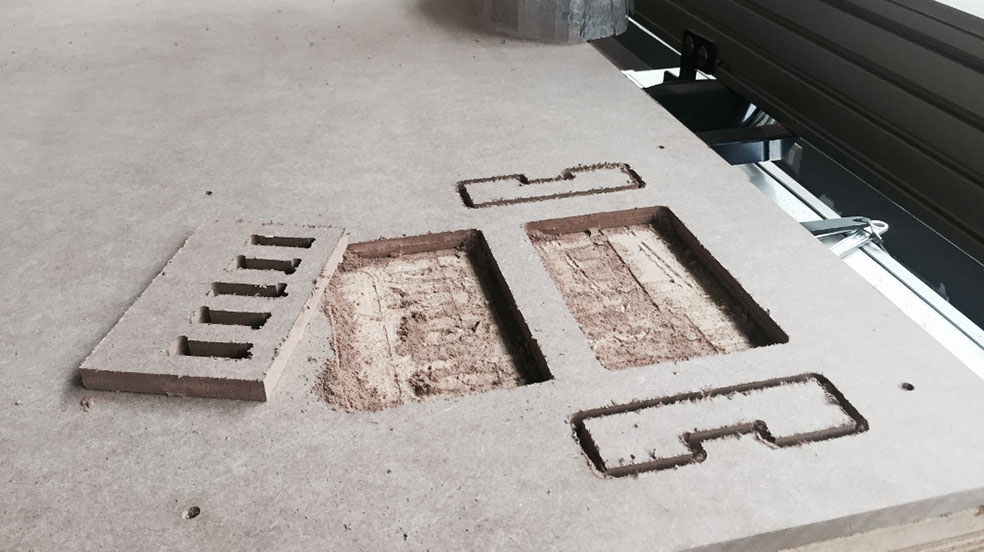

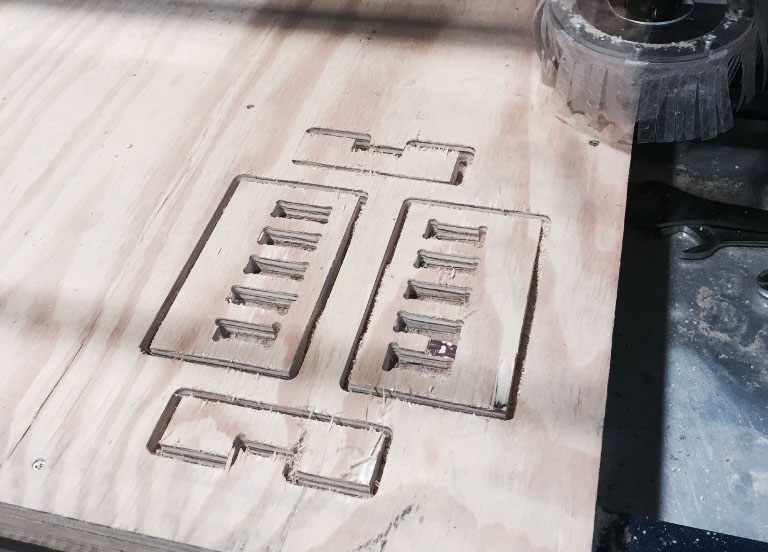

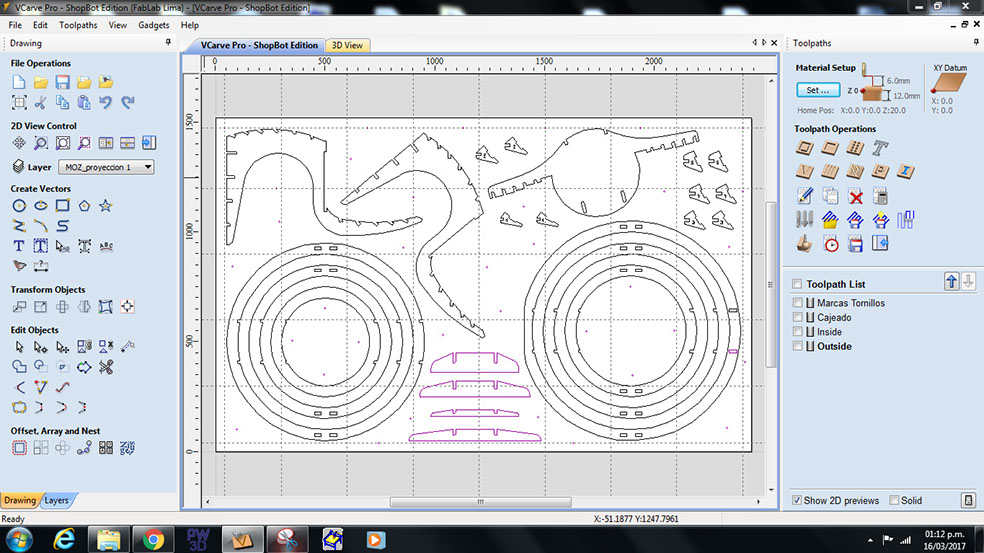

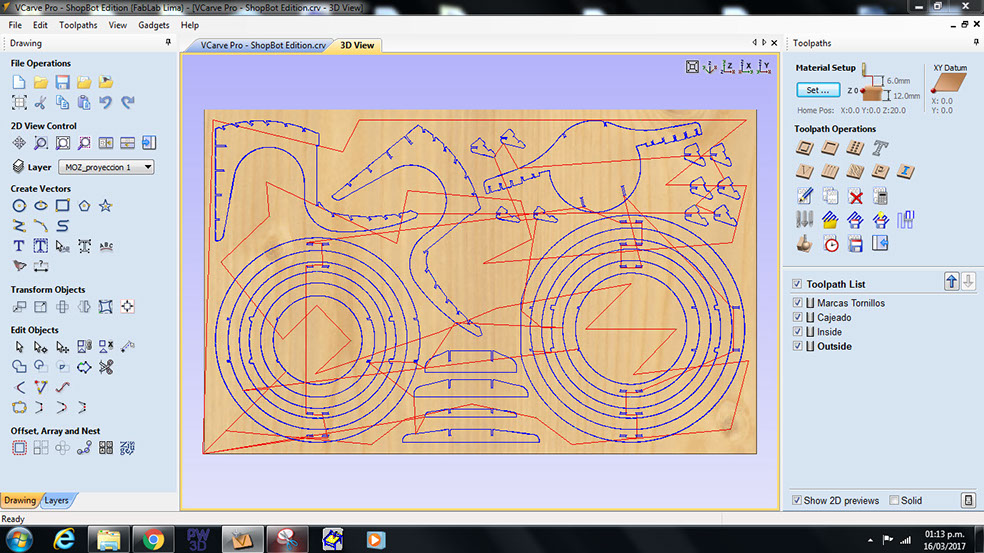

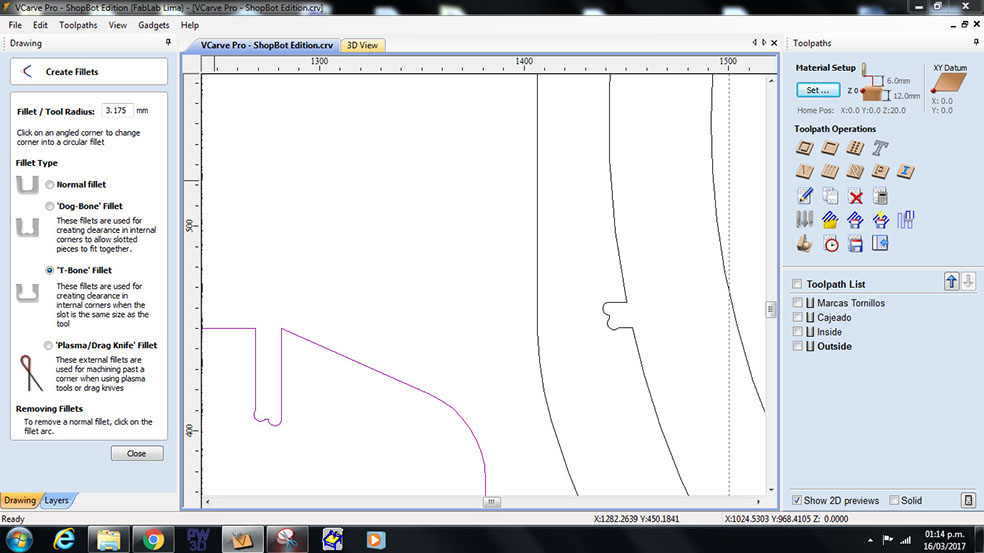

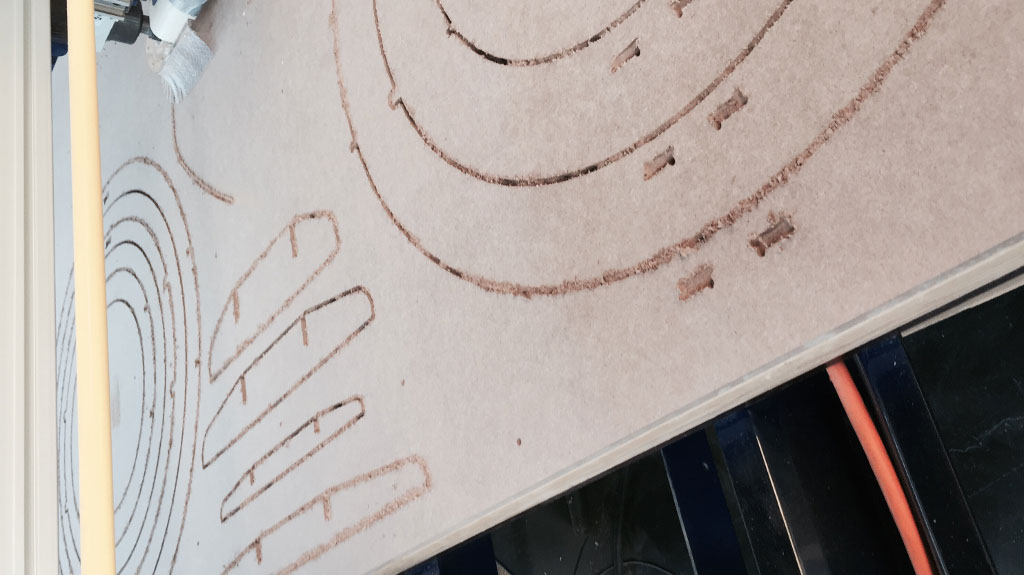

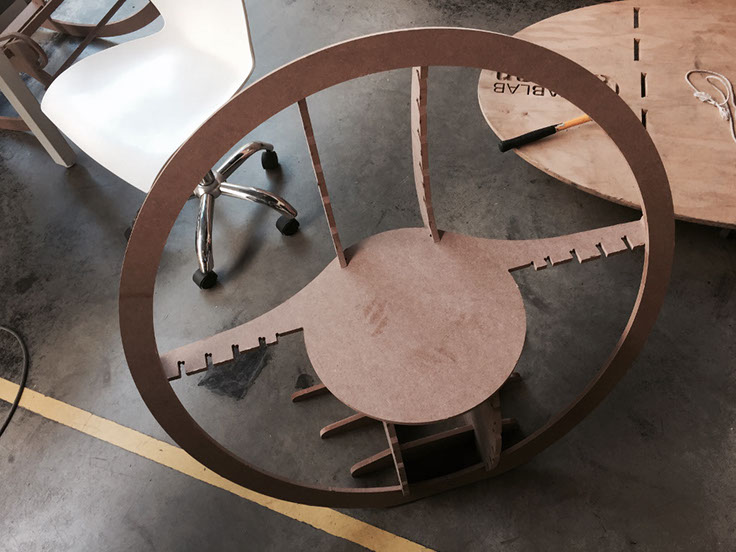

With the scale model I was able to fix some stability problems, so I begin to set the pieces for the shopbot. For this scale, I defined some more details, like hiding the press fit pins. On the vcarve software I set up to four toolpath's, places for the screws, boxing, inside and outside cuts. The mill I used was 1/4" Up-cut. On every toolpath, i had to define machine vectors and mill direction, for example for boxing and inside cut I set inside/left machine vectors, while for outside cuts I selected outside/left machine vectors. Looking for better cut quality, I chose climb as mill direction. I also set the tabs, which make that the pieces do not move after cutting before finishing the process, and fillets for the pressfit joints. The cutting and millin order for the process, was very important to avoid milling problems with the MDF board.

VCARVE FILES

When everything was ready, after fixing the board to the machime, I send the order for the milling process, first poket milling, then the inside cut and finally the outside cut.

After milling with the shopbot, the next thing to do was to sand the edges of the pieces to have good finish, and then the assembly of the chair. I had a problem with the turning of the rings and the thickness of the MDF, so I had to force the material a lot.

Finally I have my throne and a chair, that everyone enjoys at home.