MECHANICAL AND MACHINE DESIGN

WEEK 9 + WEEK 11

WEEK 9

- Design a machine (mechanism+automation), including the end effector build the passive parts and operate it manually

- Document the group project and your individual contribution

WEEK 11

- Automate your machine

- Document the group project and your individual contribution

THE FOOD SCANNER

GROUP WEBPAGE

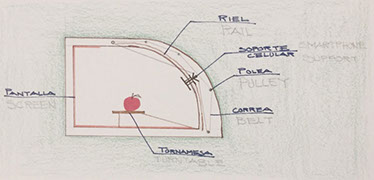

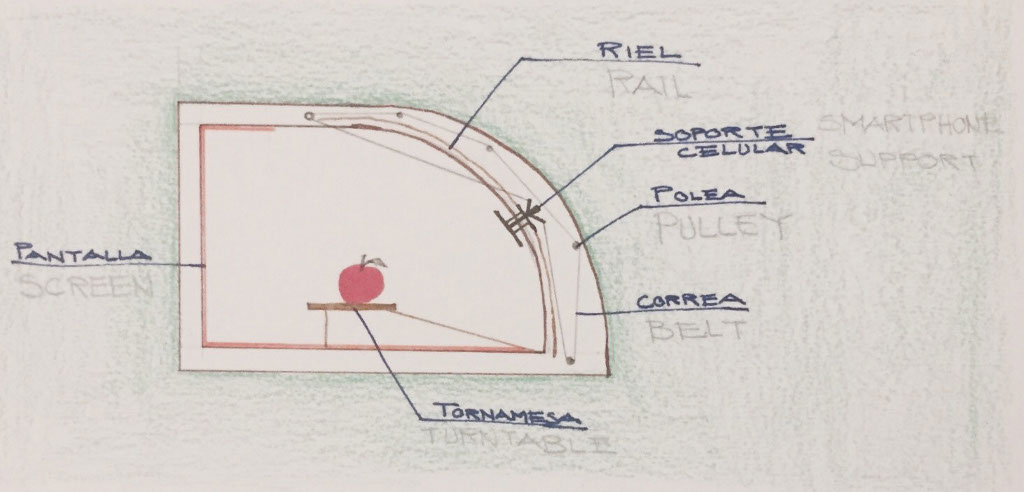

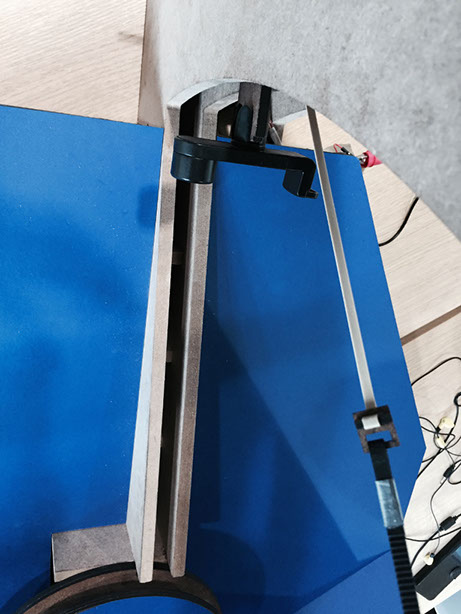

For this task I was in charge of the general design and structure design. So after we defined the main idea of what we were going to do I begin to think and discuss my ideas with the group. The Scanner was supposed to use photogrammetry, so it can use any Android OS cellphone. Because of that, I started researching about photogrammetry and found Nedim Dzananovic's final project, which was very useful for me to understand the subject. So, I came to the conclusion that we had to make a machine with two degrees of freedom.

Nedim Dzananovic's final project - download link

FIRST IDEA

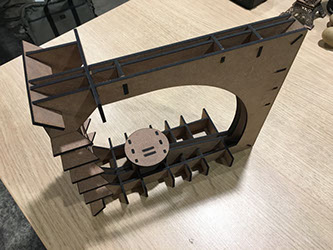

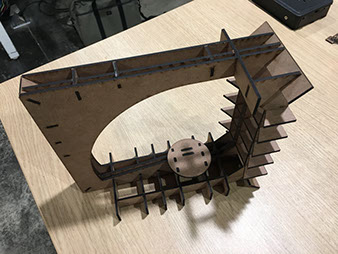

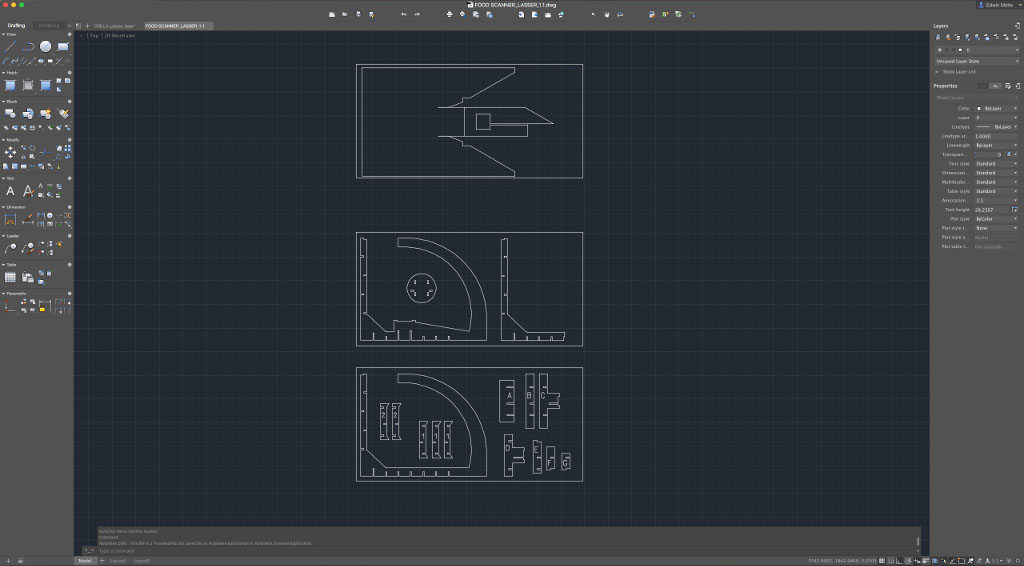

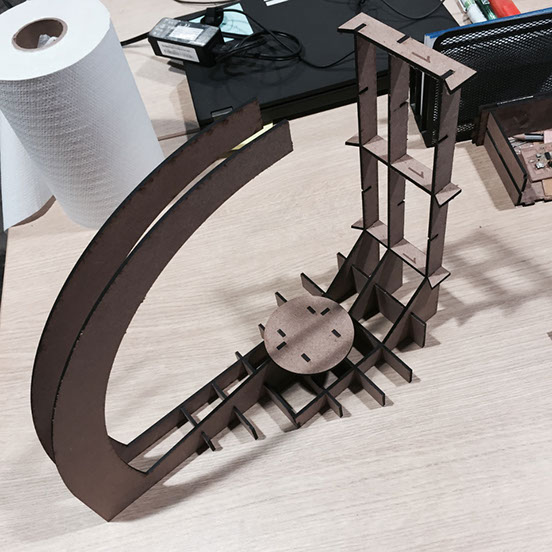

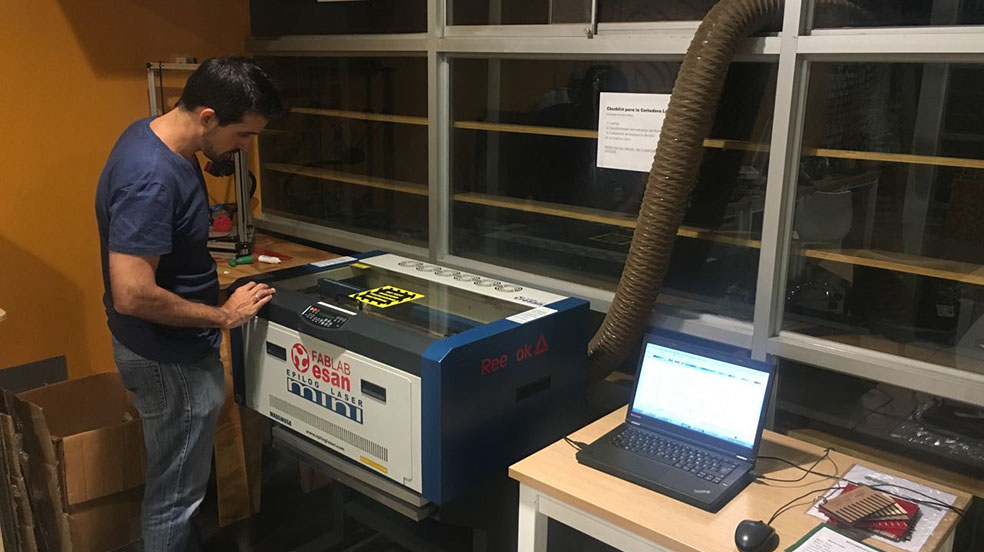

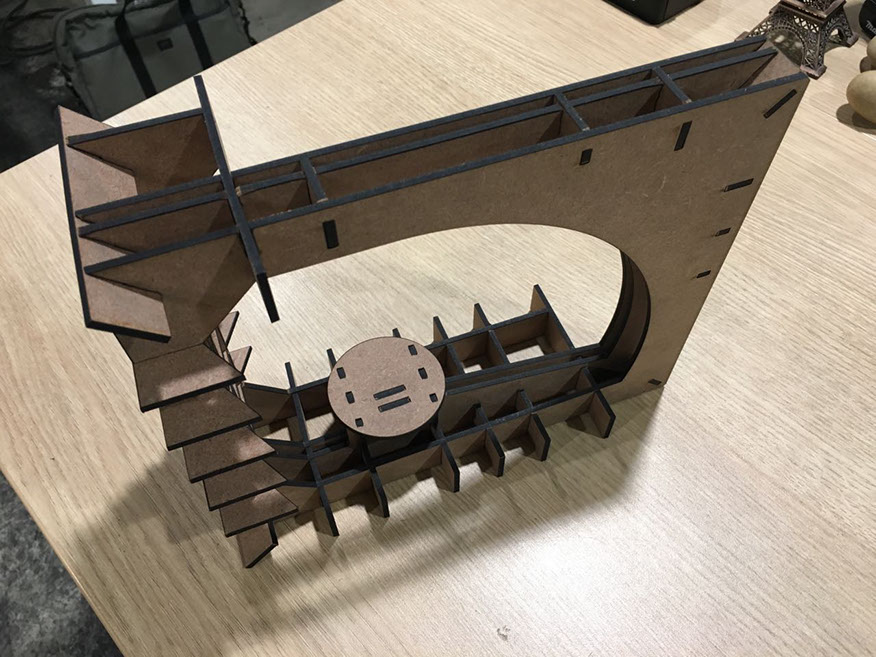

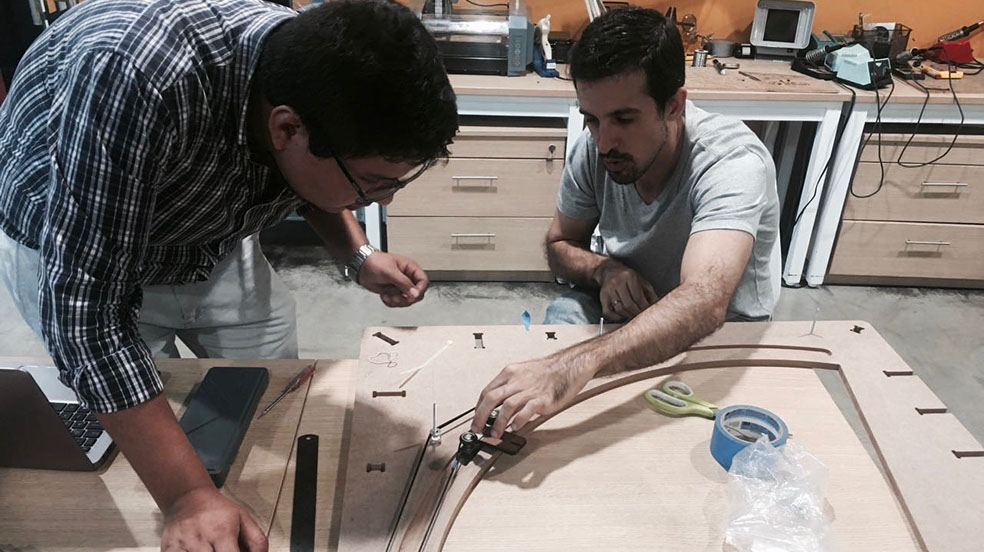

For the first idea, I made a scale model with MDF (3mm) using the lasercutter, but it turned out to be a very weak structure for the desired movement.

- DWG FIRST IDEA SCALE MODEL FILES

SECONDE IDEA

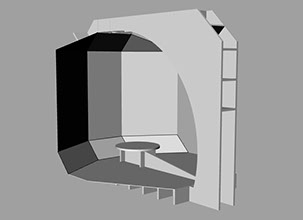

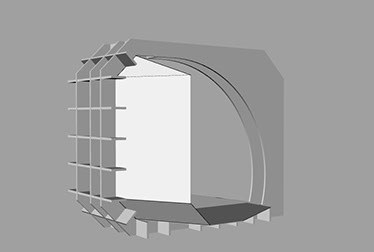

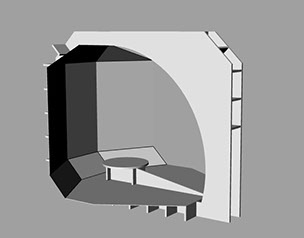

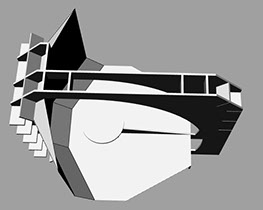

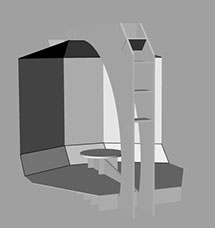

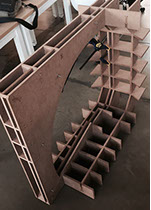

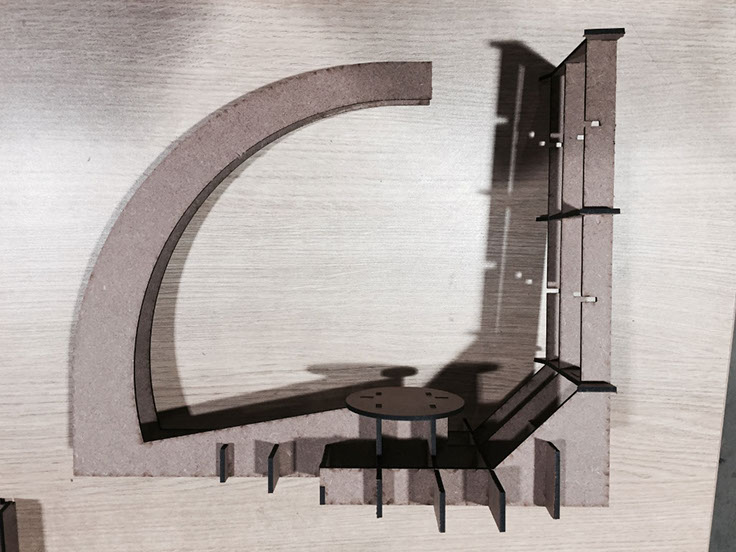

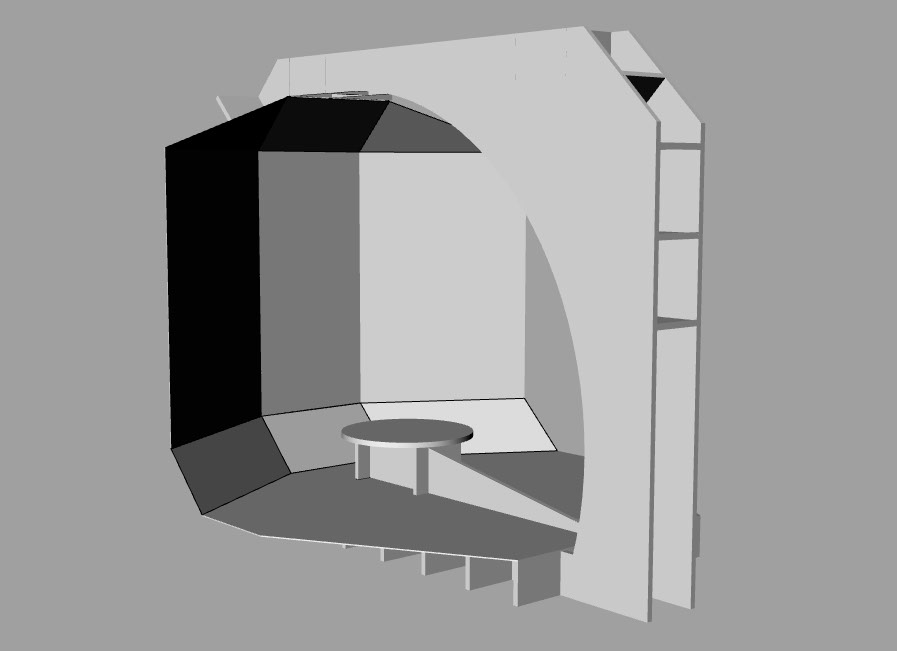

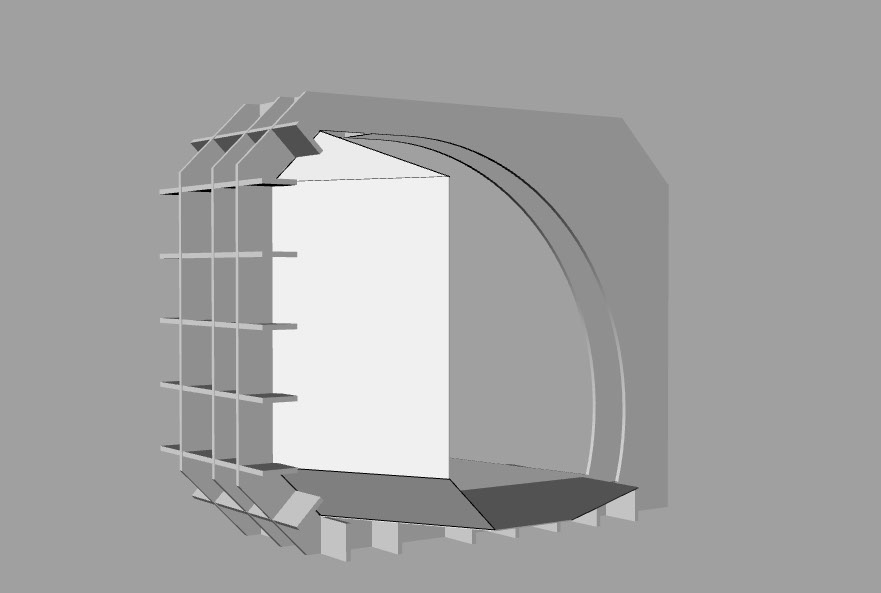

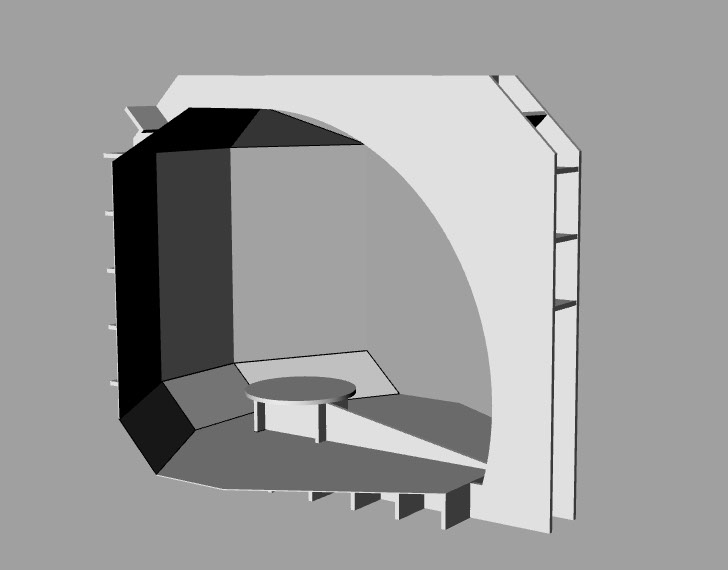

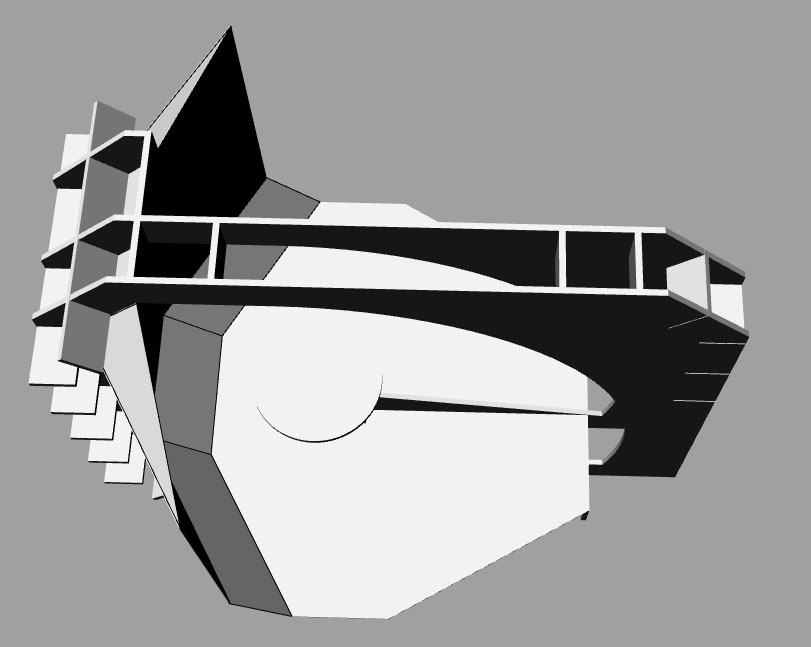

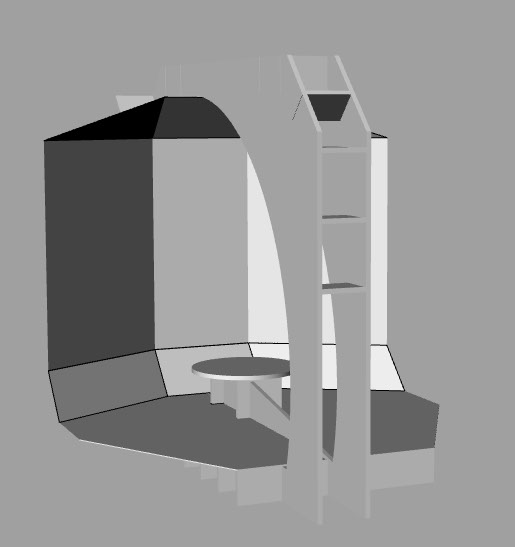

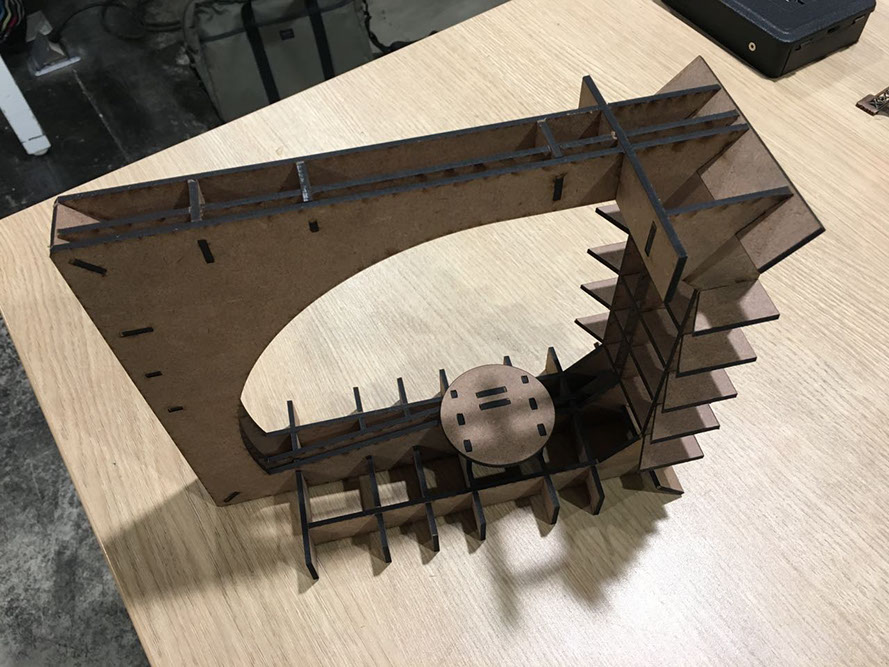

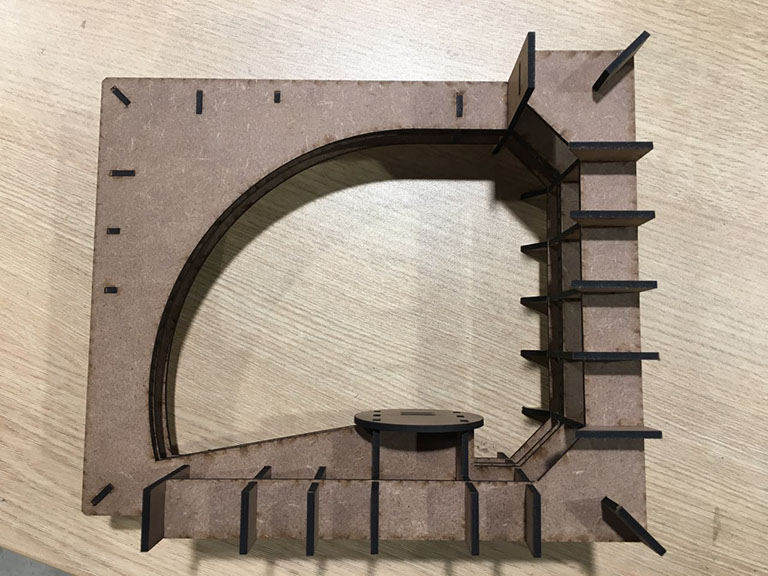

After the first experience, I decided to model the structure in Rhino and make another scale model. This time fixing the structure problems. For example the frame of the machine is completed to give greater stability and rigidity to the object. The turntable would consist of two parts (fixed and movable)

- DWG SECOND IDEA SCALE MODEL FILES

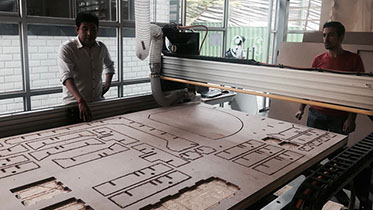

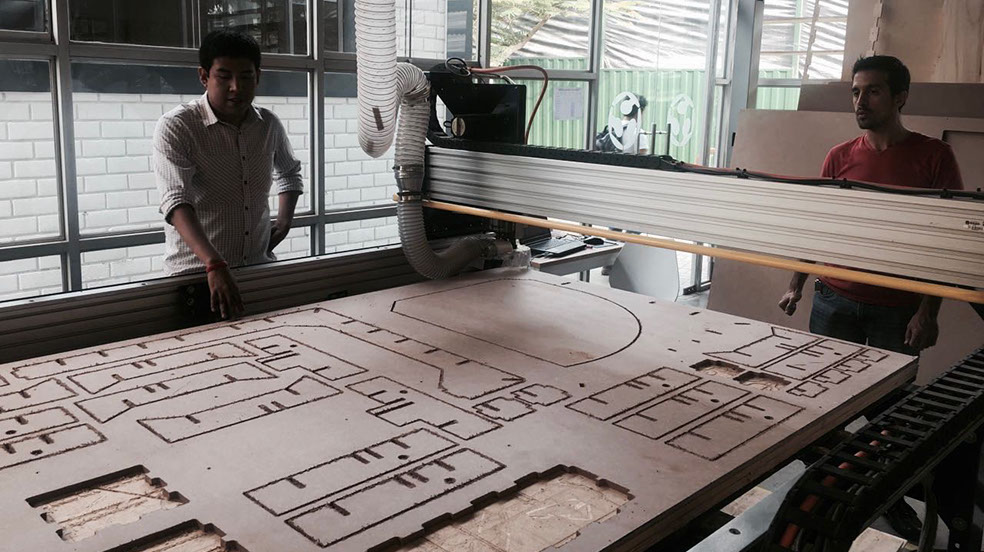

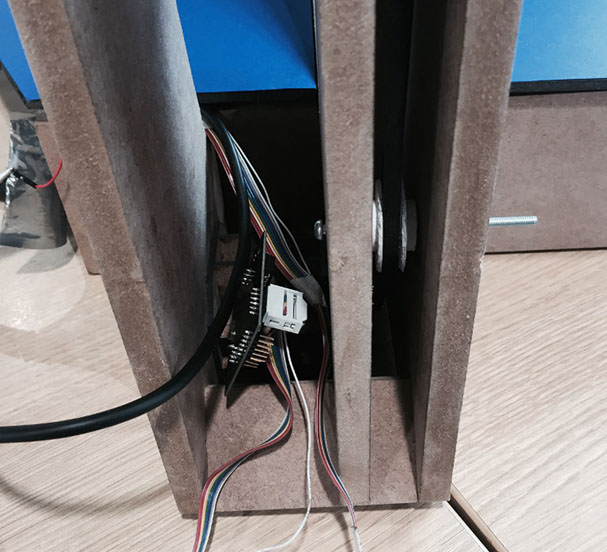

This second scale model was successful, from there I had to adjust the prototype to its mechanisms, considering passes for the cables, the place for the motors, the location of the rails, the pulleys, the stepper motors, the supports for the plate, etc. Then we have to cut the pieces on the shopbot and assemble them. The final material was MDF (12mm).

- DWG FOODSCANNER FILES

- VCARVE FOODSCANNER FILES

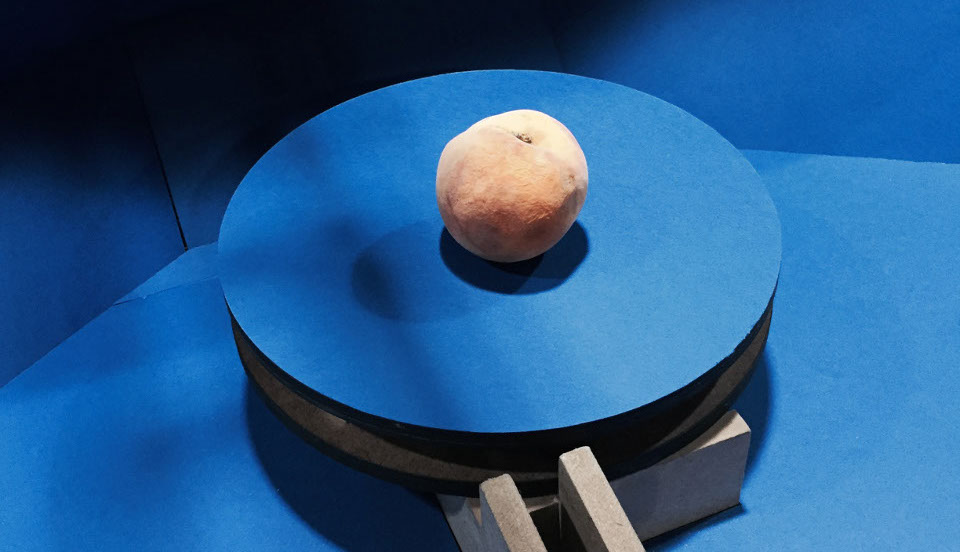

Once the structure was complete, we set some details, like the screen, the smartphone support and make sure that the motor cables were not visible. For the screen we used foam and blue paper so it could contrast on the image for better scanning.

The most complicated problem to solve in the design was the bow rope formed by the rails and the strap, because due to the position of the cart the distances varied and the rope should be, at times, longer and shorter. The solution was to place between the cart and the belt, elastic bands that assumed the difference in length. you can check that on the group video.

a

a

b

a+a = b

/

What we could have done better from the point of view of the design, was the background screen, since the angles obstruct a little the reading of the object. If the screen had been spherical the reconstruction of the 3d model would have been better. We could have done it using a mold, cloth and resin, then paint it.