Computer-controlled Cutting (CNC)

1. Week assignment

group assignment:

- make lasercutter test part(s), varying cutting settings and slot dimensions

individual assignment:

- cut something on the vinylcutter

- design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

2. Development Environment

I used Corel Draw X7, SolidWorks 2016, Roland Cut studio on a Windows 10 environment.

3. VinylCutter

I decided to use an existing image:

Then, using Corel Draw, i got the image outline by hand, with this result:

With the aid of Cut Studio i cut the image on white vinyl.

I applied this using adhesive tape:

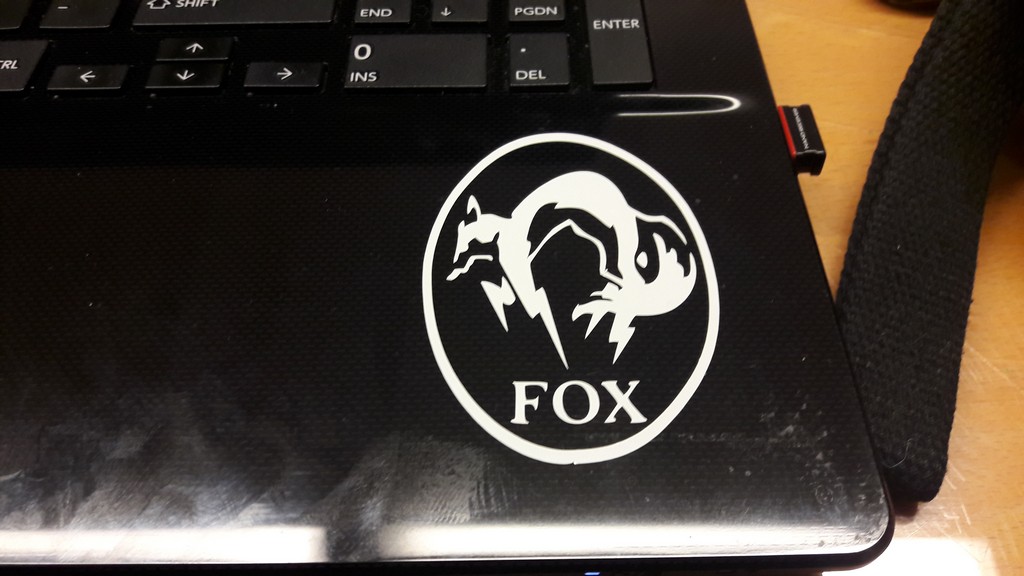

Here’s the result:

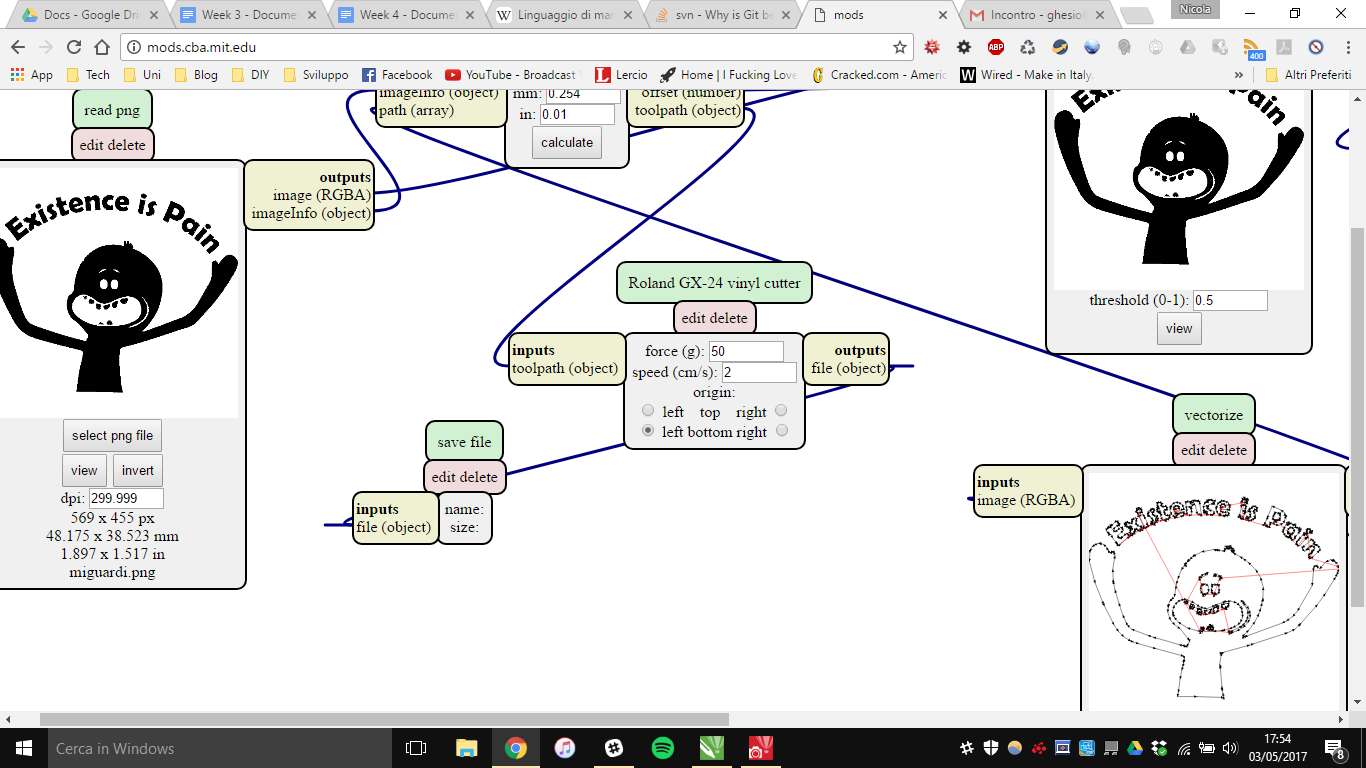

Then I tried using the fabmodules (the new one) with this image (a Mr. Meeseeks from “Rick and Morty TV show).

I loaded the png, inverted it, set force and speed (50g, 2 cm/s) and added save file module.

You also have to set the origin of where the file will start (in this case left bottom).

This is the result (the dimensions were too small so I lost the write and some details) and I decided to do something bigger for my locker in the lab.

I tried to redo the Pink Floyd “Wish you were here” album cover. I found this image:

Using Corel Draw i made up two new png:

I made the .camm files using fabmodules and this is the result:

To send the file to the Roland cutter I used linux:

- Plug in the cutter

- Find where it is, by typing ls /dev/usb in a terminal

- You will see a lpx in the output (where x is a number)

- become sudo by typing sudo su (note: doing sudo on the next command did not work on my machine)

- send the file using cat file.camm > /dev/usb/lpx

Pressfit

I modelled a modular box kit, using Solidworks and parametric design.

To learn how to use parametric design and Solidworks equations, i followed this video tutorial.

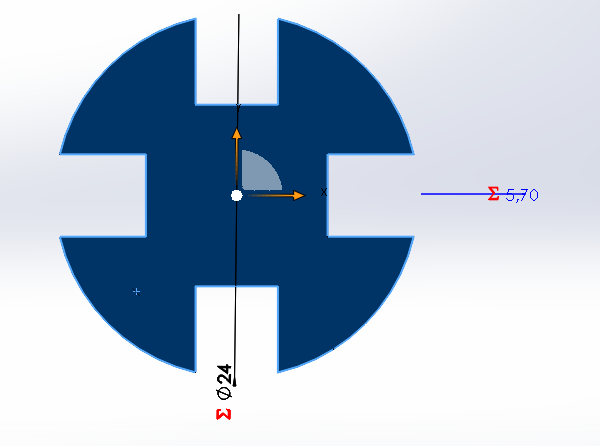

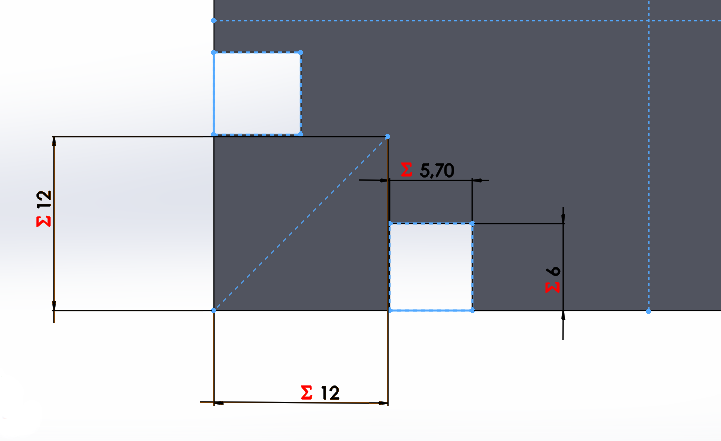

This is the base joint:

The parameters are:

- Radius of the joint (r)

- Kerf - (kerf), 0.13mm

- The wood thickness (h), 5.7mm

- The slot depth, of which I made 2 tries, one equals to r/3 and other equals to r/2

- The slot width, equals to h-2*kerf

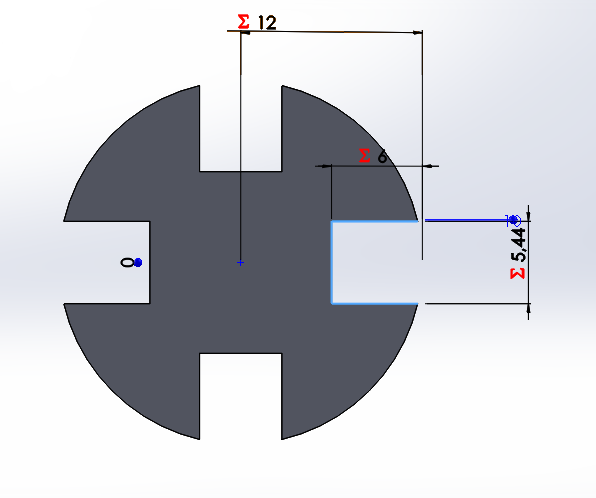

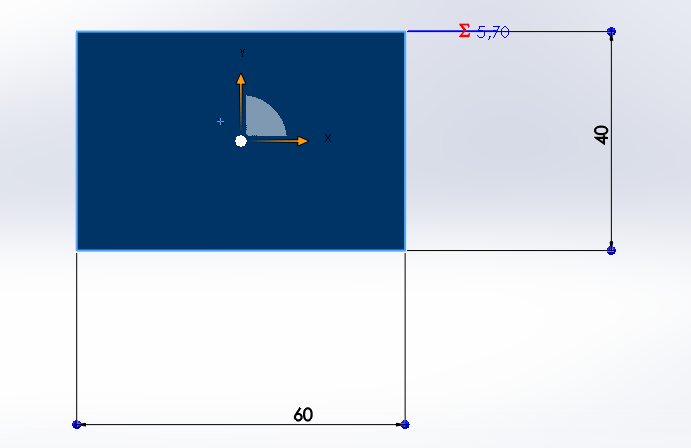

The sizes, one with slots for the joint and two without.

The parameters are:

- Radius of the joint (r)

- The wood thickness (h)

- The base lenght (l), 60mm

- The height lenght (lh), 40mm

- The slot depth, same as the joint but without kerf

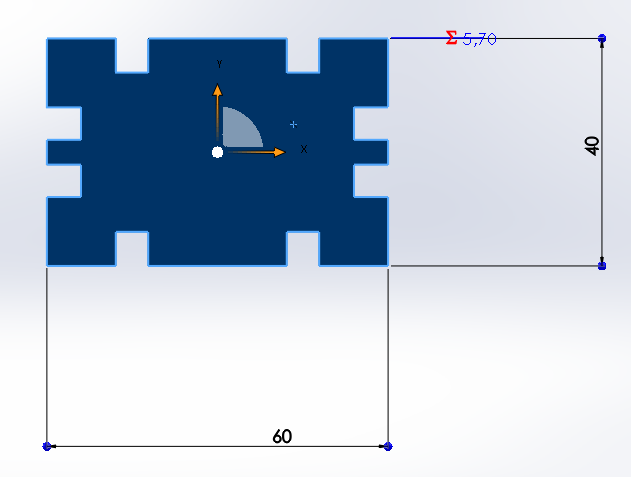

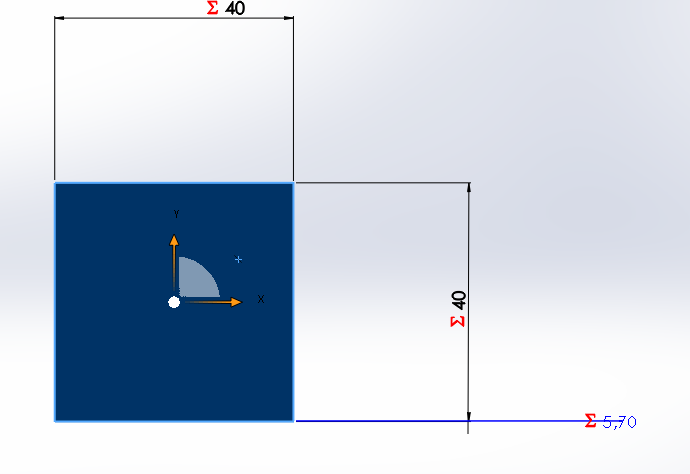

The parameters are:

- The wood thickness (h)

- The base lenght (l), 60mm

- The height lenght (lh), 40mm

The parameters are:

- The wood thickness (h)

- The base lenght (lh), 40mm

I exported all the pieces outline using SolidWorks drawings, and finally i proceeded to cut them using Adobe Illustrator on the Trotac lasercut.

I used the optimal kerf value found in the group assignment and the relative settings of power (80%) and speed (0.4 of max speed). - Link

I also tried using FabModules (the first version) to export the outline from the .stl file, but it did not work with my PC (I tried 2 different OS and 2 different browers). I’ll try more testing in the next weeks.

Here’s the final assemblement:

4. Files

Vinyl files - .cdr

SolidWorks box files - .zip

Update

It's possible to find more work about this week on the final project page in the related development section