FAB LAB

Puebla

MACHINE BUILDING

WEEK ASSIGNMENT:

-Make a machine, including the end effector

-Build the passive part and operate it manually

-Document the group project and your individual contribution.

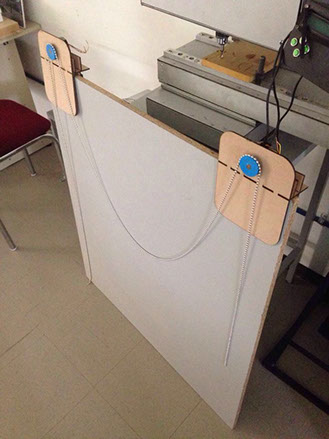

For the assignment we made a drawing machine. It is a portable device that makes drawings in vertical surfaces. Our machine consist only of two motors, toothed belts and a marker. By the means of geometric triangulation and gravity, our machine draws, with a custom software, pre-assigned images.

Our machine is controlled by an open-source bespoke software written in Processing, running inside Arduino. A geometric path-finding algorithm calculates the motion paths required by the fragile mechanical installation to move smoothly and negotiate image with gravity.

Background and inspiration: Hektor is a portable spray paint output device for computers. It was created in collaboration with engineer Uli Franke for Jürg Lehniʼs diploma project at ECAL (École cantonale dʼart de Lausanne) in 2002.

During the process of the machine the mechanical design, was made by Luis Camacho, the wiring and programming was donde by Oliver Ochoa with the help of Santiago Perez.

1. First we started with the design of the structure and all the pieces that will allow our machine to adapt to any vertical surface. For that, we used the laser cutter machine and the 3D printer.

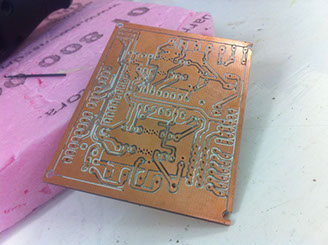

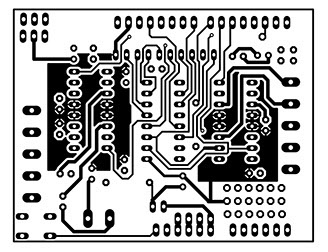

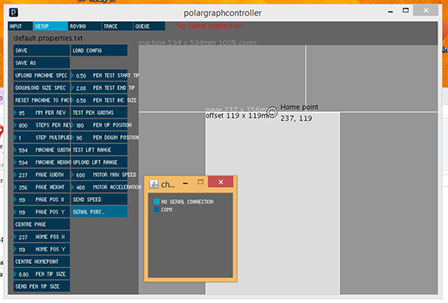

* Because of time issues, we decided to use an Arduino to build the interface between our machine and the software.

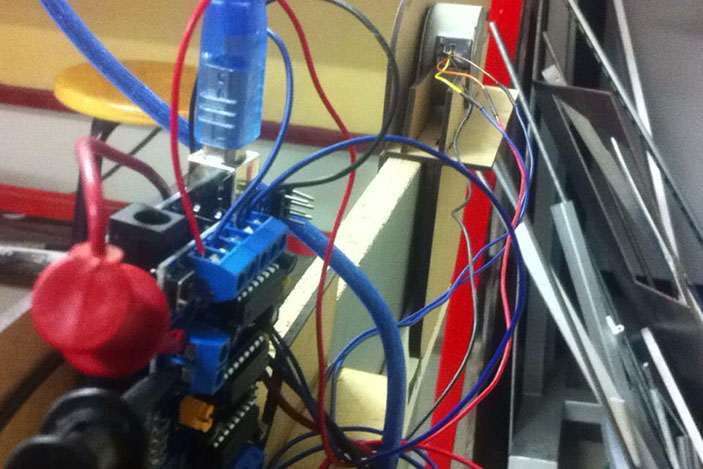

2. Once we assemble the machine we started the electronics. We needed to produce a circuit that could allow us to move two Stepper Motors.

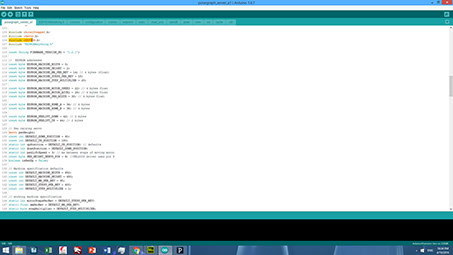

3. Programming:

For the programmong we used the arduino IDE as the controller for the stepper motors, along with the free polargraph processing software which took care of the GUI and command part of the programming.

4. Once we had the code running, we test our mechanism manually.

5. After trying it manually and verifying the weight, the angles and the speed, we proceed to make some trials with the code.

In conclusion due to time we couldn't arrive to the quality we expected but we'll continue working on it due to the fact thats it's an artists new tool.

We decided to test it's modular ways by moving it to a new surface in this case a blackboard

In conclusion due to time we couldn't arrive to the quality we expected because of the vibrations in the machine one possibility is to add more motors so the chain is always tensed, however we'll continue working on it due to the fact thats it's an artists new tool.