FAB LAB

Puebla

WEEK ASSIGNMENT:

-3D scan an object

Extra credit: make your own scanner

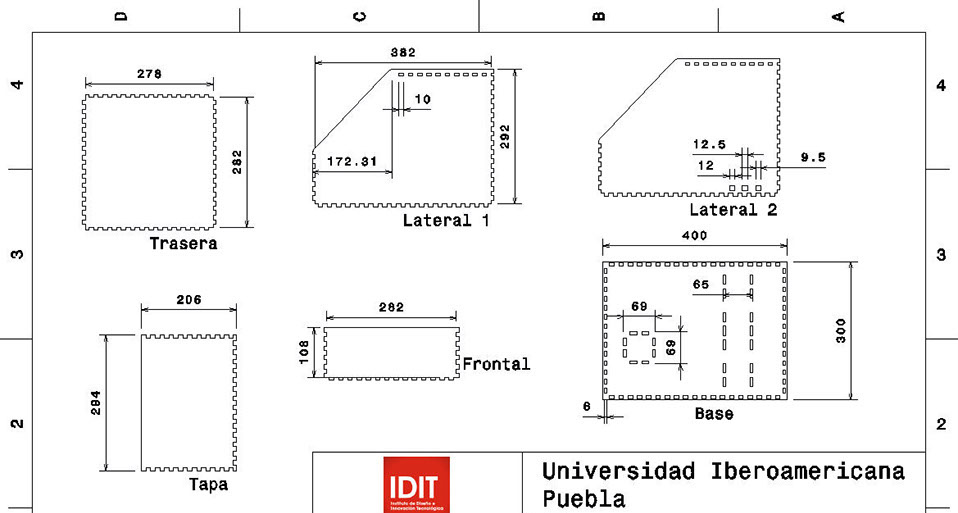

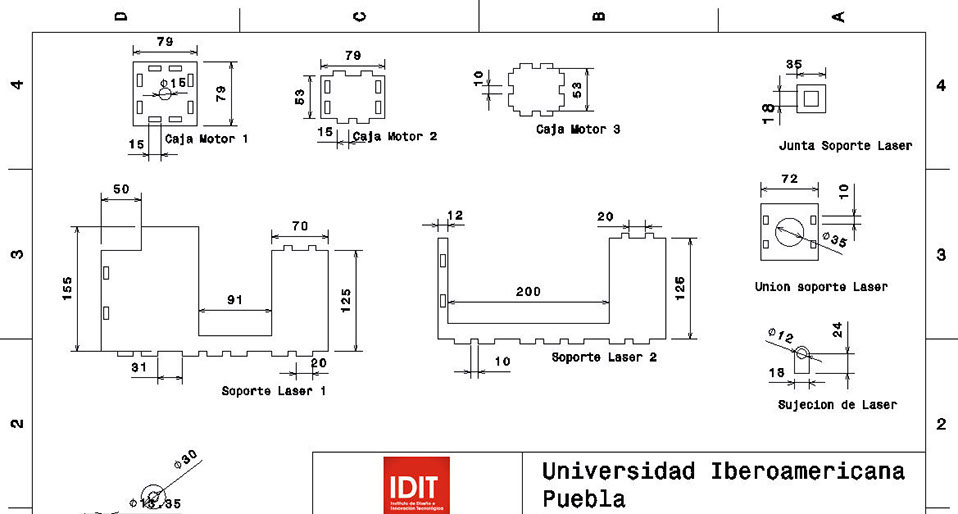

For this part of the assignment i decided to take on the challenge of building my own 3d scanner. Even though here in fablab Puebla we have a Romer Scanner arm to make 3d scans. I opted to follow an open source 3d scanner made by Francis Engelmann from the media computing group which are part of FabLab Aachen. I started by designing the structure following roughly the same sizes used by the original. I used Catia which is the program im most proficient in as my CAD software

DRAFT 1

DRAFT 2

RENDER

Physical product

For the electronics i used a pololu, an arduino and a ste we had leftover from past projects and a logitech c270 and lineal laser i bought.

For software i used arduino as the controller for the stepper motor and the laser, which together with GUI made by the fabscan guy i was able to control how the scanning was done.

Image of the scanning in progress using the GUI

Image of the scanning in progress after applying filter

Video of the process

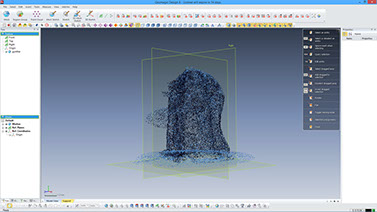

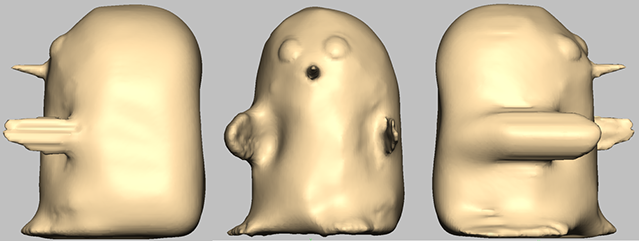

After the scanning process I got a point cloud which I meshed to create a solid

My first solid wasn't quite what I expected but after investigating a bit i came on the realization that as my original piece had been polished, it reflected the laser making it les precise with the scanning.

After trying quite a bit, i used talcum powder spray to stop the reflecting, I also passed my piece twice trough the scanner but changing direction of rotation on each try so i could have more` points to create my solid