This week we have the task of creating something "big" using a CNC. As my final project is a table this is an excellent opportunity to study how to organize the joints and distribute weight.

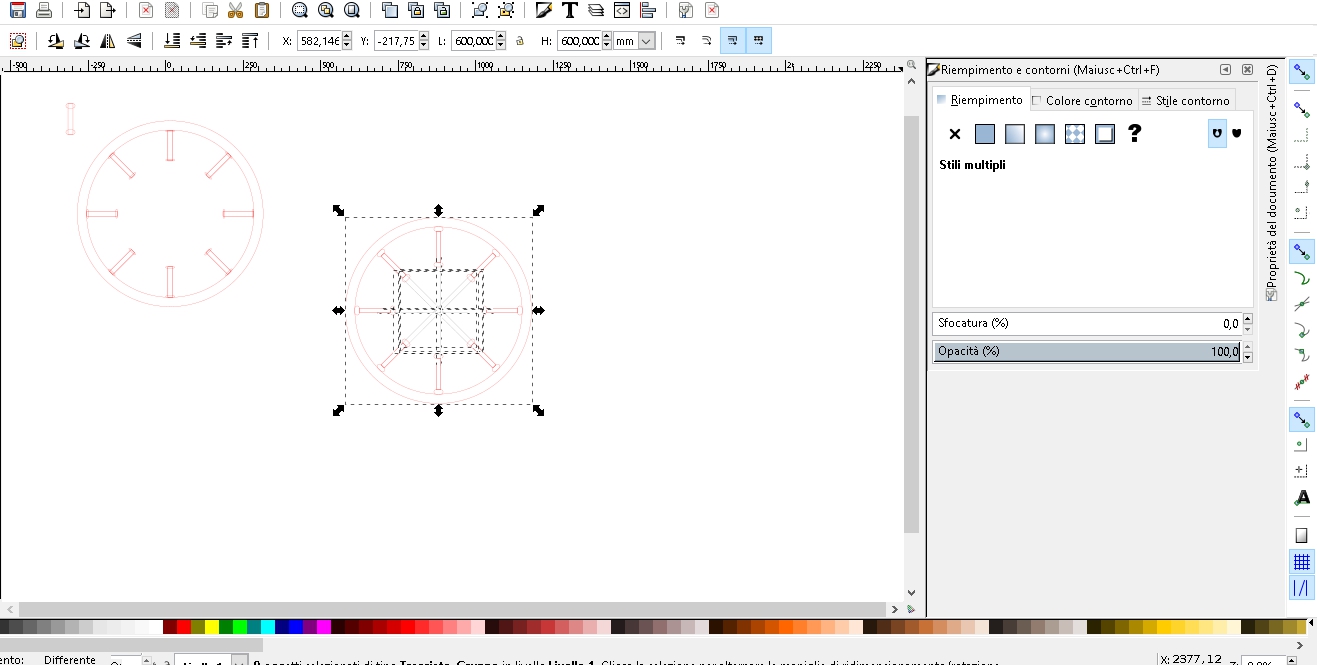

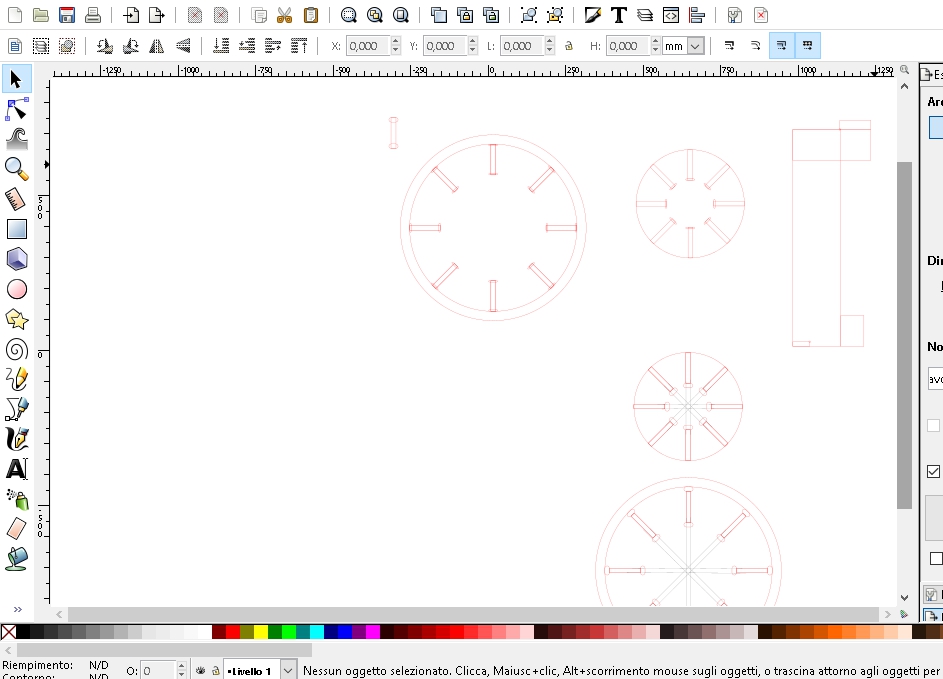

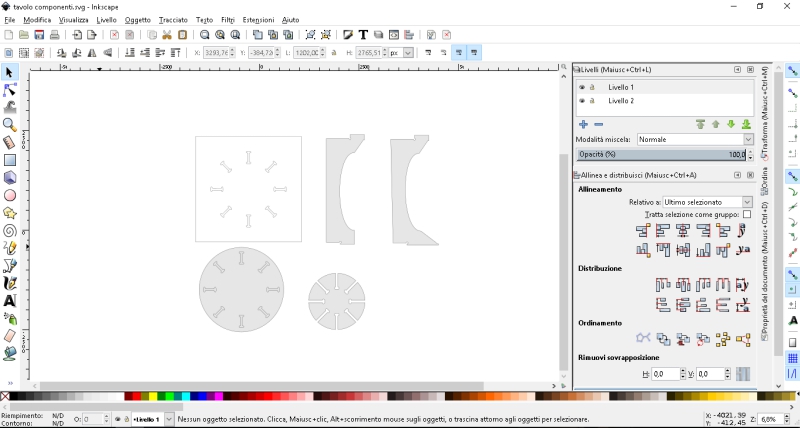

Design with inkscape

Before you start drawing the table i did a little research on what were the most common techniques to create furniture using CNC and only joints.

On the advice of my mentor I looked at the work of FablabPalermo taking inspiration from their table Gotico to realize mine.

The model chosen is ideal for my future project. The central foot will allow me to manage the weight of the monitor solving.

As joints I decided to use the dogbone

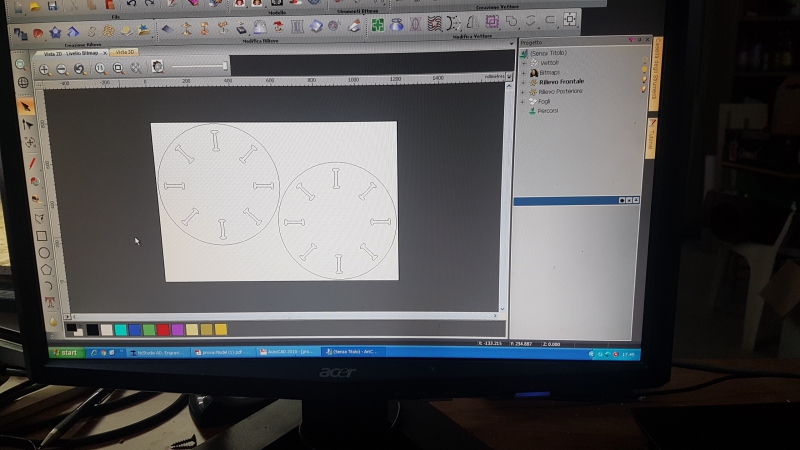

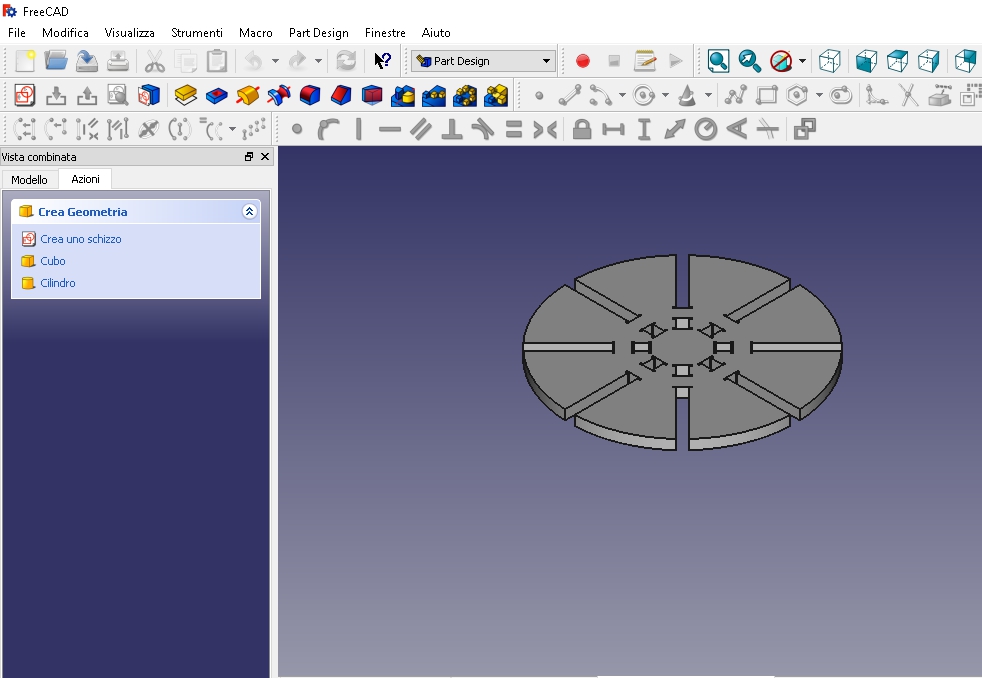

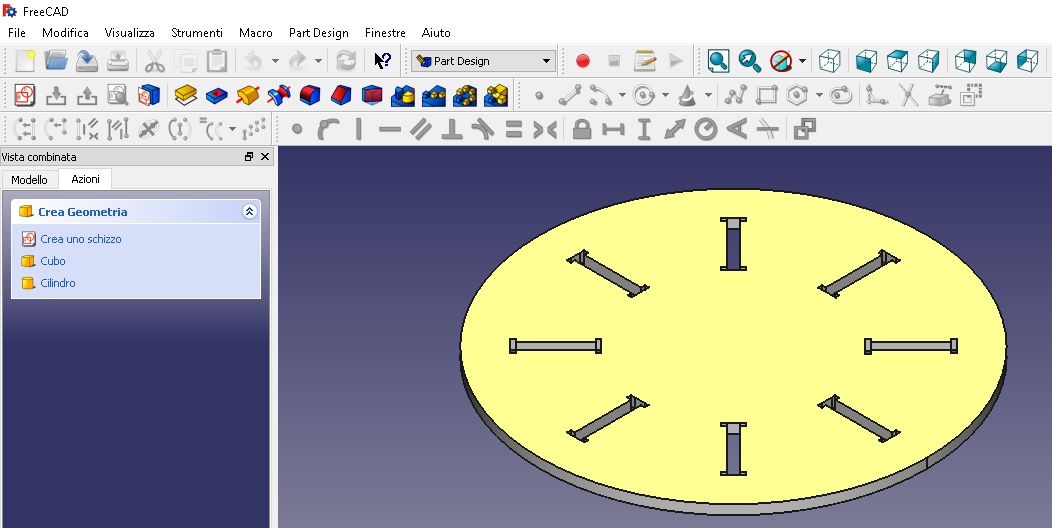

I started drawing circles to use as a base and, drawing another smaller, I identify the limits on which to place the first joints.

Right after I created a circle to use as a pedestal generating other joints.

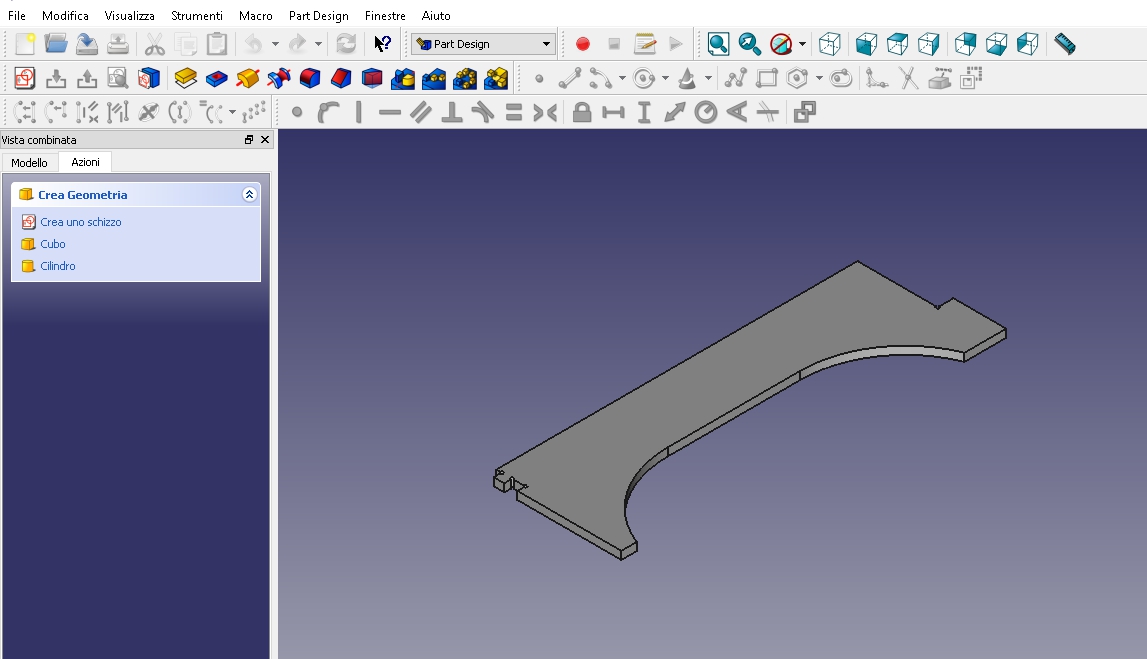

After you create the base and the pedestal I drew my feet, creating four elongated to provide stability and four shorter as a mere support.

Finished drawing I exported the file as DXF ready to be used in programs for the cutter

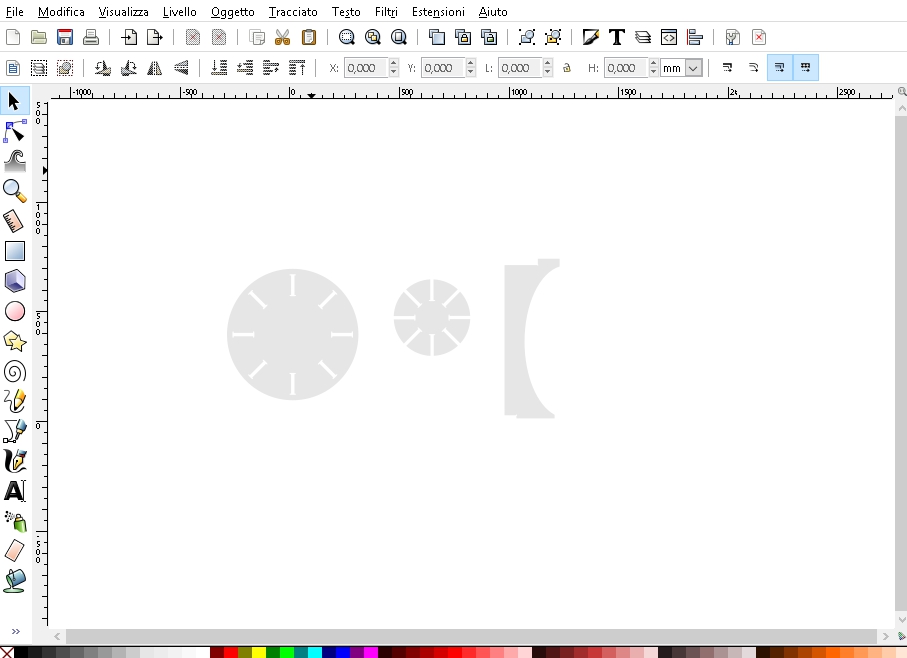

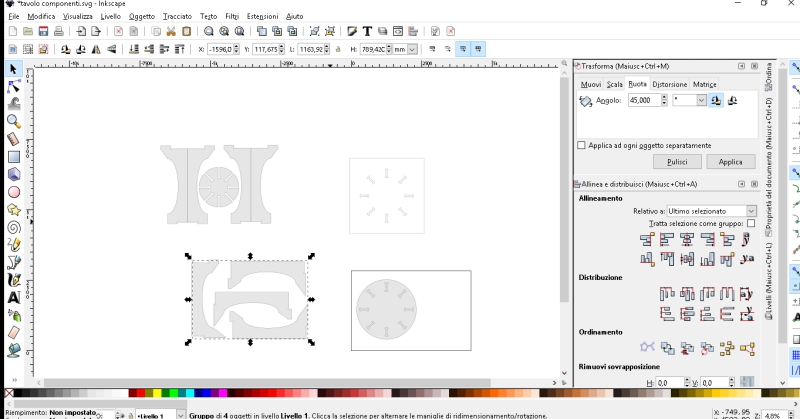

Working on the path with ARTCAM

--Insert text here--

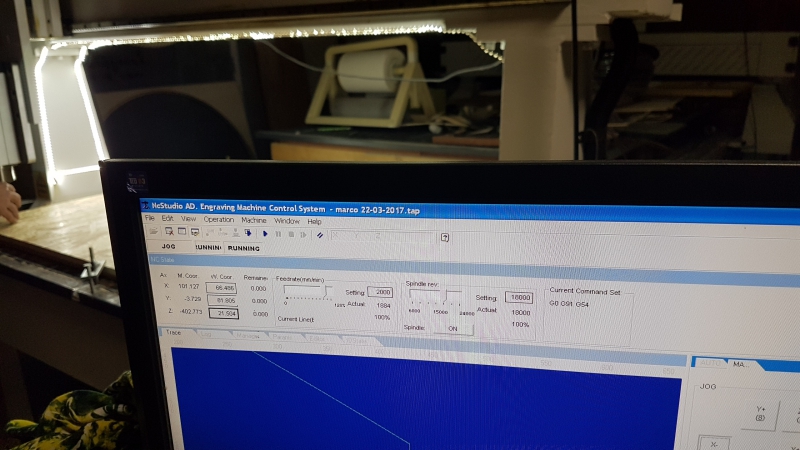

Milling the table

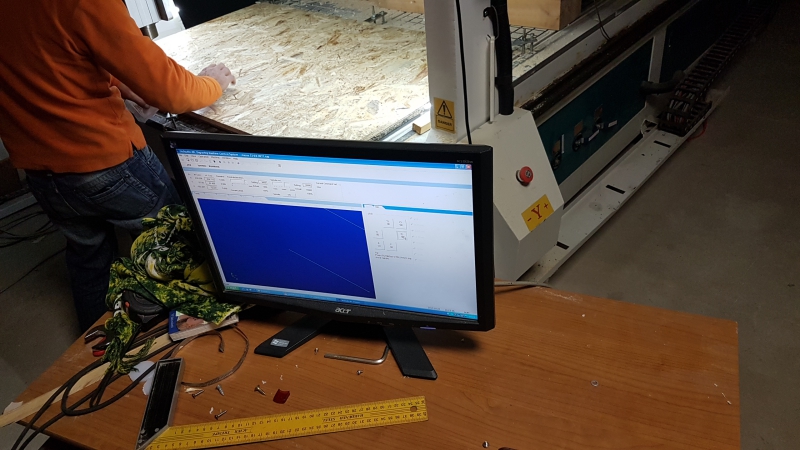

First we anchored the sheet of OSB to arranging machine latches at the points where the car would not have passed.

It's very important to pay attention to the stability of the sheet to be cut and the stop position.

Arranging hurt the work plan is likely to completely ruin the end result or break the tip of the machine if you go to touch the latches.

Switching between Inkscape and for the CNC software has been enough "painful".

How to generate the Gcode and test the movement of the machine we used ArtCam and we noticed immediately that all contour lines created at inkscape were interpreted as squares generating unnecessary steps to the machine.

.

Milling we used a machine with these features:

- Workspace: 1250 (X), 2500 (Y), 400 (Z) mm.

- Spindle power 3Kw

- Spindle rotation speed 18,000.00 rpm

Once you cut all the pieces that remained was sanded with sandpaper pieces and assemble them.

We immediately noticed that the joints for the base were too wide and tall ones too tight forcing me to add plugs to keep his feet straight on the base and broaden the joints in the other.

This work has highlighted the need to abandon inkscape for these jobs and began working exclusively on a cad like FreeCAD.

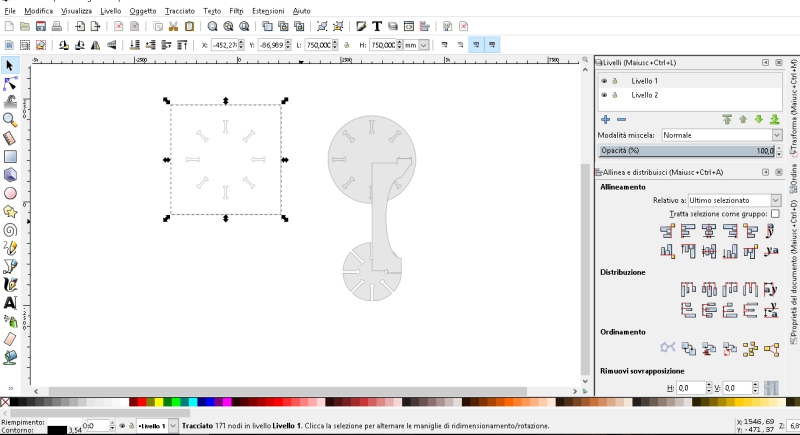

Update 03/30/2017

i've redo the work using Freecad instead of inkscape.

New files are avviable on dowload.

Update

06-10-2017

I've milled the table's top for the final project. All details are here