This week’s assignment is to design a 3D mold, machine it, and cast parts from it.

Manufacturing process by which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

Casting materials are usually metals or various cold setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay.

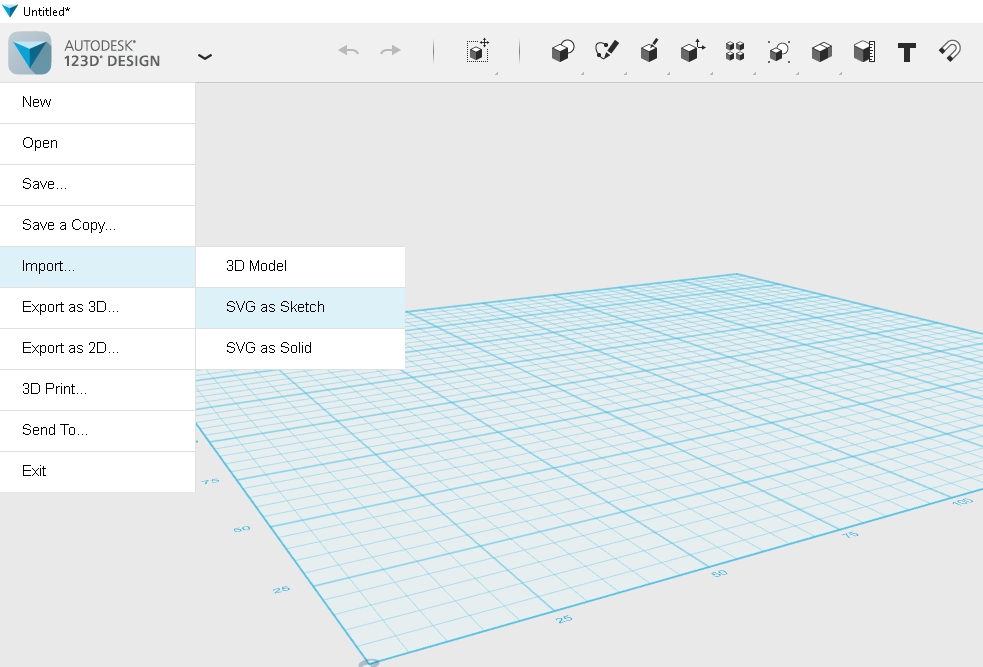

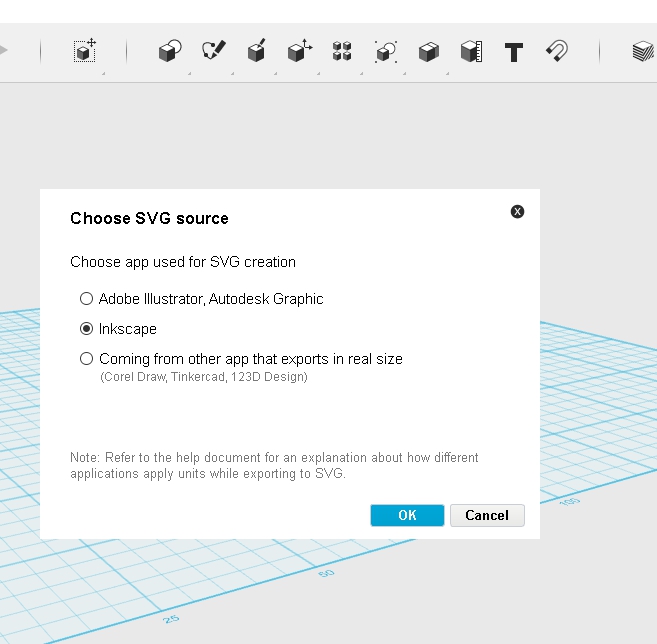

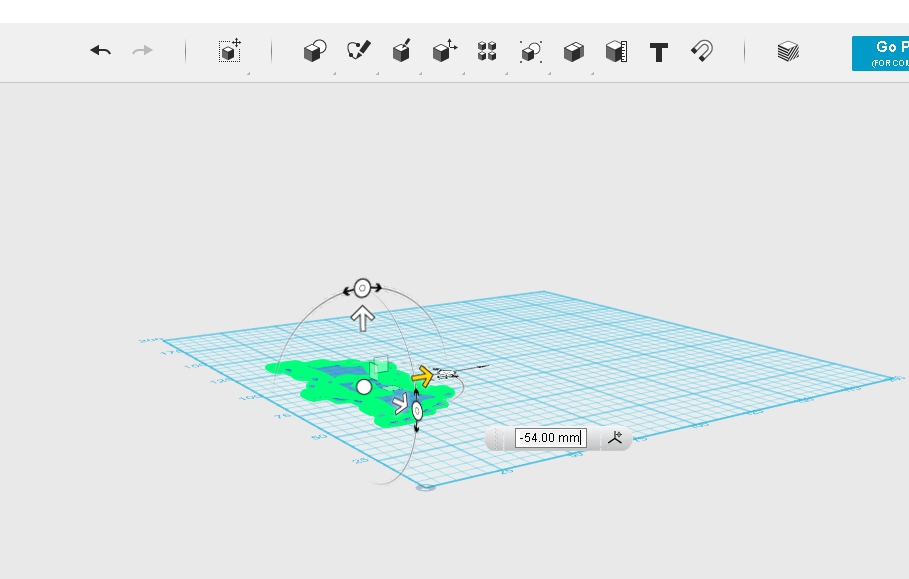

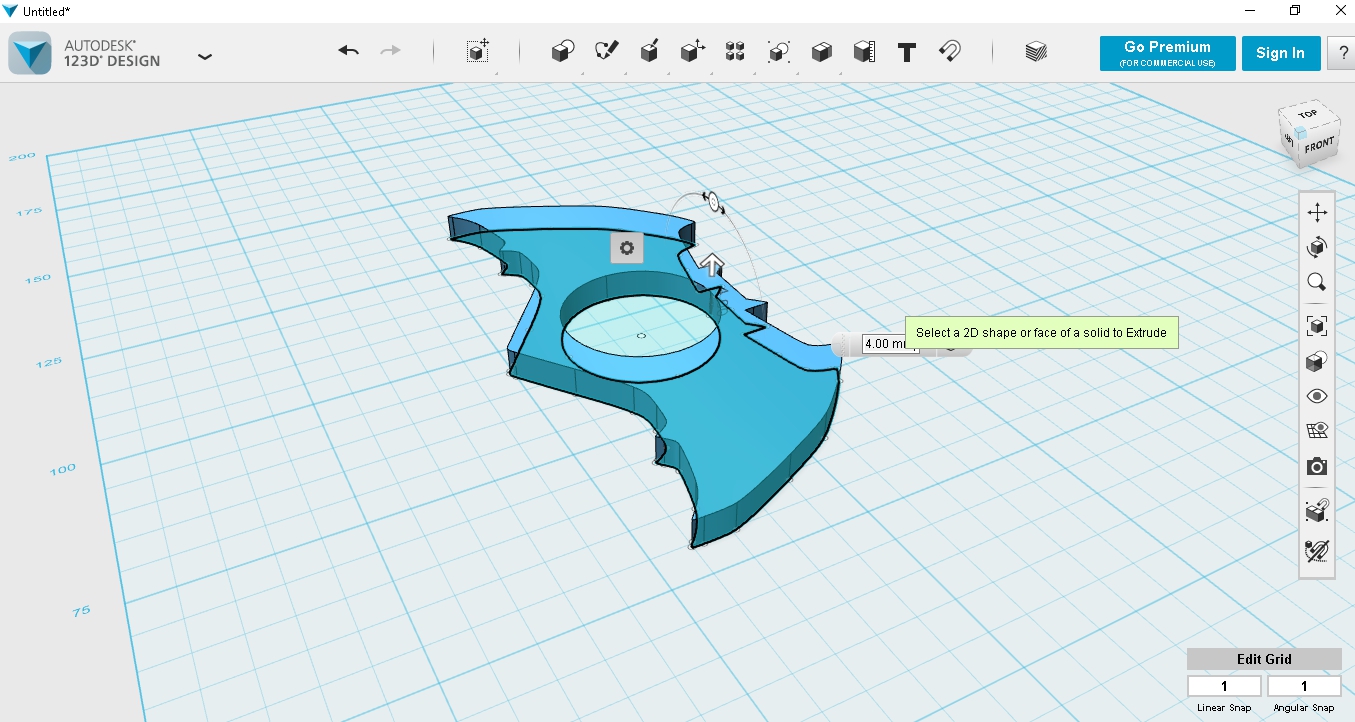

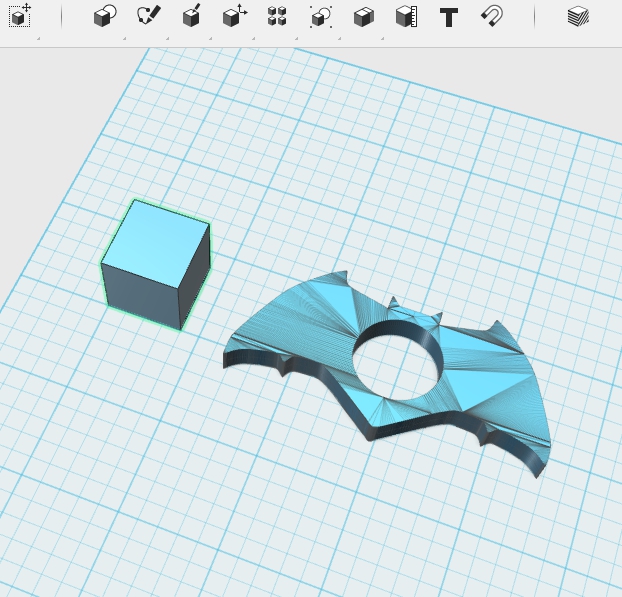

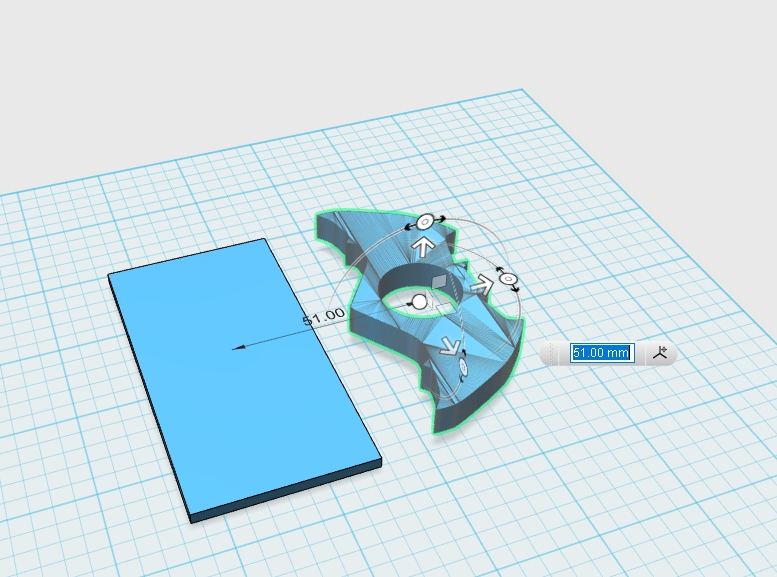

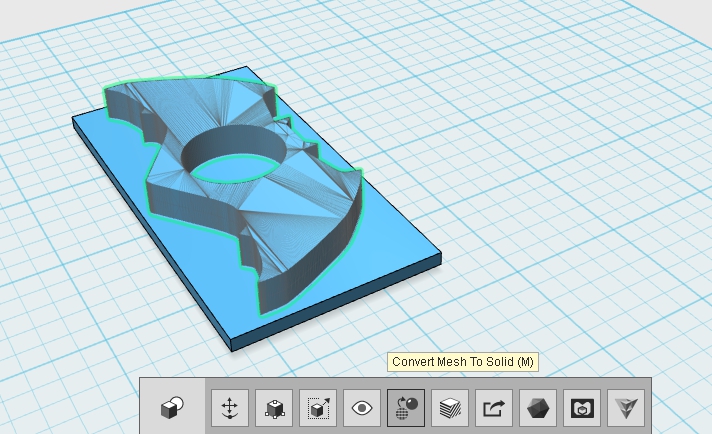

Design with 123Design

To draw the positive of the piece I used 123Design.

After importing a vector image, I turned it into a solid and added walls around it to get a box.

After finishing the file I generated the gcode carefully and sent it to print.

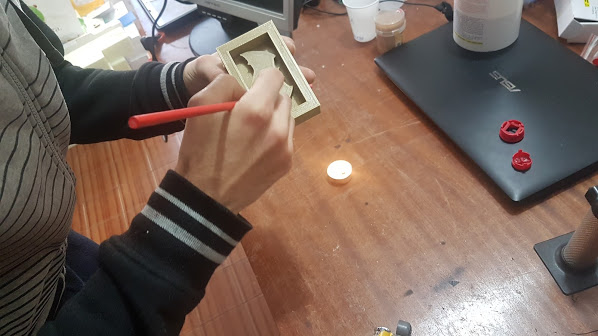

Casting and Molding

Once the piece is printed, we just have to create the mold.

First of all, we assure that there are no holes in the piece wrapping it with wax.

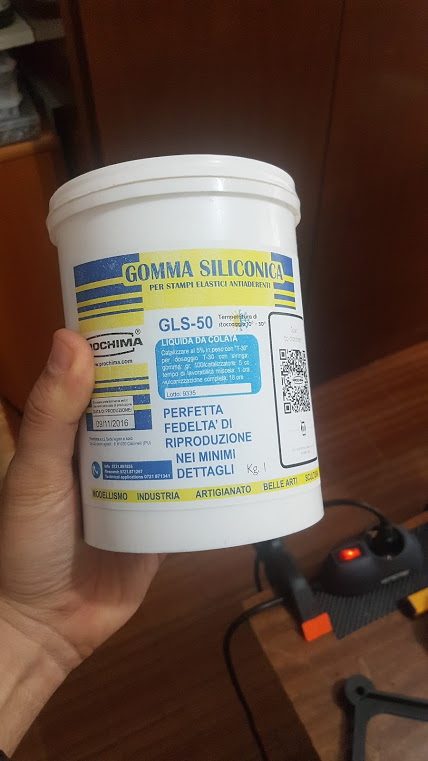

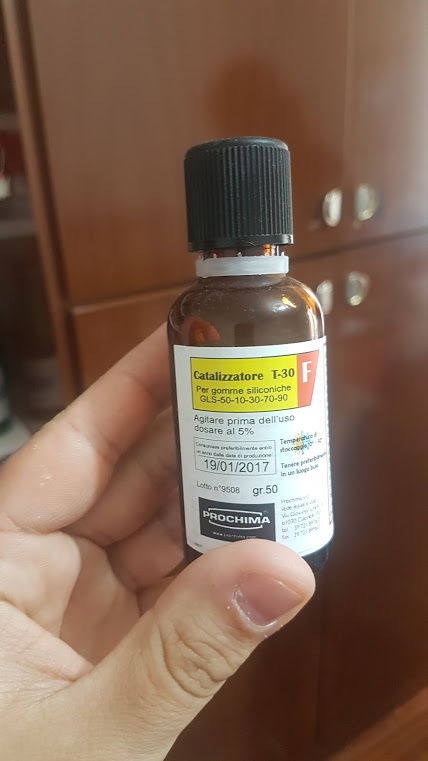

To create our mold we used silicone rubber.

We mix the Silicone Rubber, usually tends to deposit on the bottom before adding the catalyst.

With the aid of an electronic scale we mixed 70 grams of silicone rubber and 3.5 of catalyst (5% of the rubber weight).

When mixed, let's beat the bottom to raise the air up.

After having well bent, the compound has only to pour into the positive part and wait for it to catalyze.

Once we got the mold to play the piece we used the syntaphon following the same mold process.

Update

06-10-2017

I've casted the arcade joystick buttons. All details are here