This week we have to make a machine, including the end effector, build the passive parts and operate it manually. We have to document the group project and our individual contribution.

Working as a team

First you had to organize the working group and, being pretty much alone, I've been helped by other members of FabLab to complete the exercise this week.

To organize the work I created first thing in a dashboard on Trello, and I added all participants in the project.

each one defined the priorities we have started working on their tasks

All FabLab waited impatiently for this week as the machine created last year was the first group work done by our group that is.

Inspired dallla structure and movements of the Eggbot we decided to create a machine that wrote on glass bottles with a coupling adaptable to use any type of bottle.

To do this we needed a motor that rotates the glass bottle, one that moved the pen to the x axis, and another that get up and lowered.

Dividing tasks

First we split the team into two groups, one of which dealt with the structure and one that took care of the electronic part.

Personally I am in charge of managing the group and the work of designing the PCB.

To make available all documents necessary to work and assign tasks to all I created a dashboard of Trello.

To organize ourselves the best we split up into tasks: To Do, production and completed. Finally we have collected all the resources in a single list for all.

Electronic design with Fritzing

To draw the PCB this votla I tried to use Fritzing..

Fritzing is an open source program that allows you to design an electronic board in all its phases from the simulation of the breadboard.

The program does not ask so installation is compatible with any system.

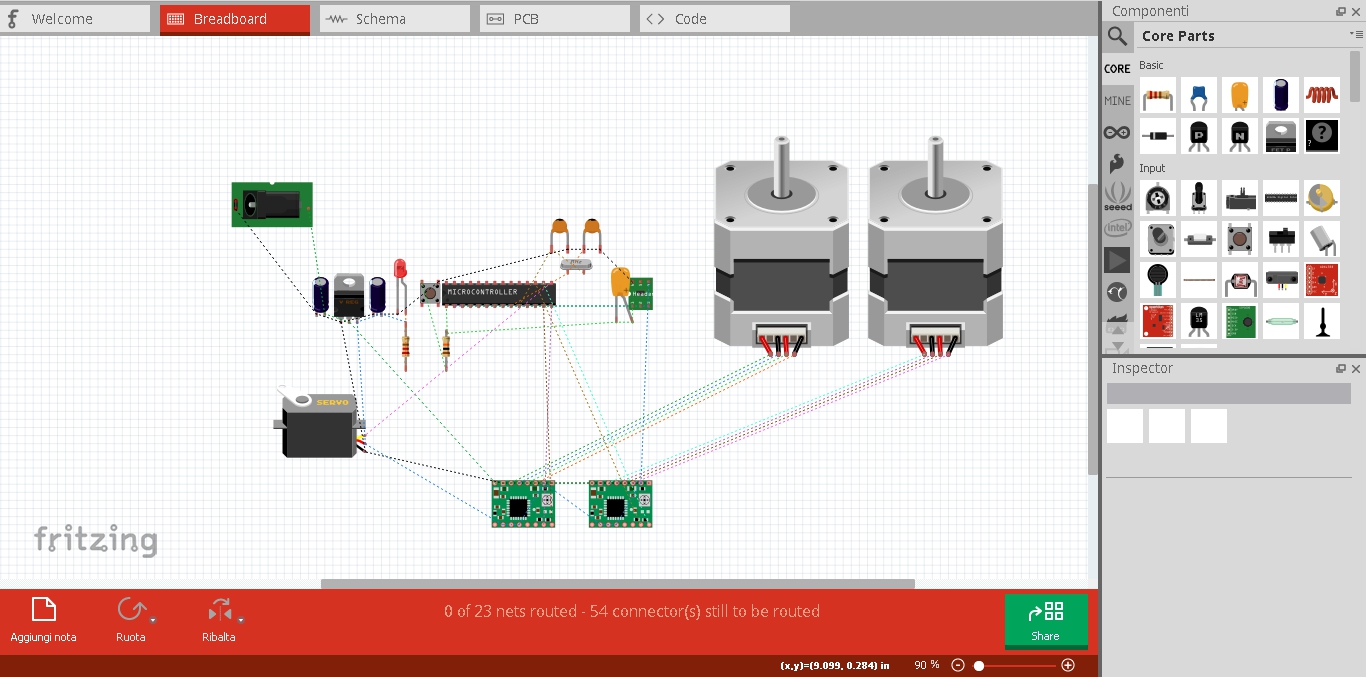

First I wanted to simulate the circuit on the breadboard so I placed all the components and have them connected to each other using simple jack.

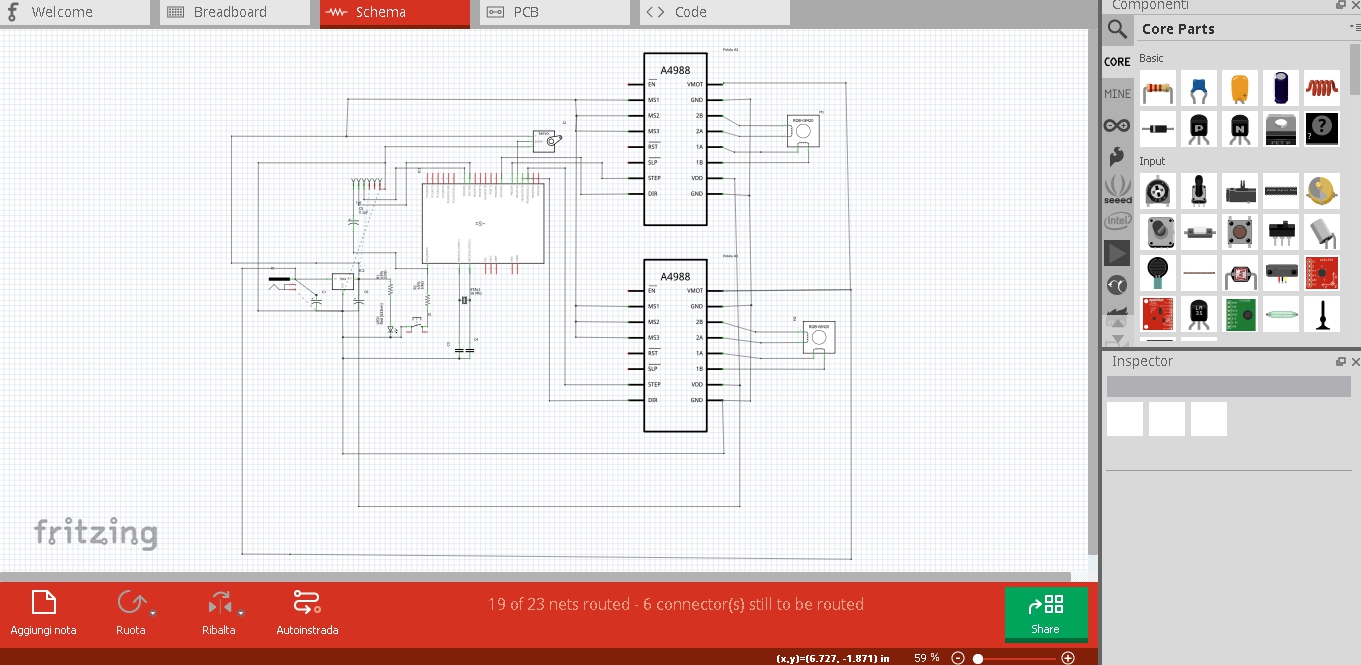

Finished scheme on breadboard are passed to the wiring diagram screen.

Unfortunately, the links created with the simulation of the breadboard have only created problems, so I came back to simulation and I deleted all the jacks.

Back to the electronic scheme page I found only the components so was enough to recreate the links.

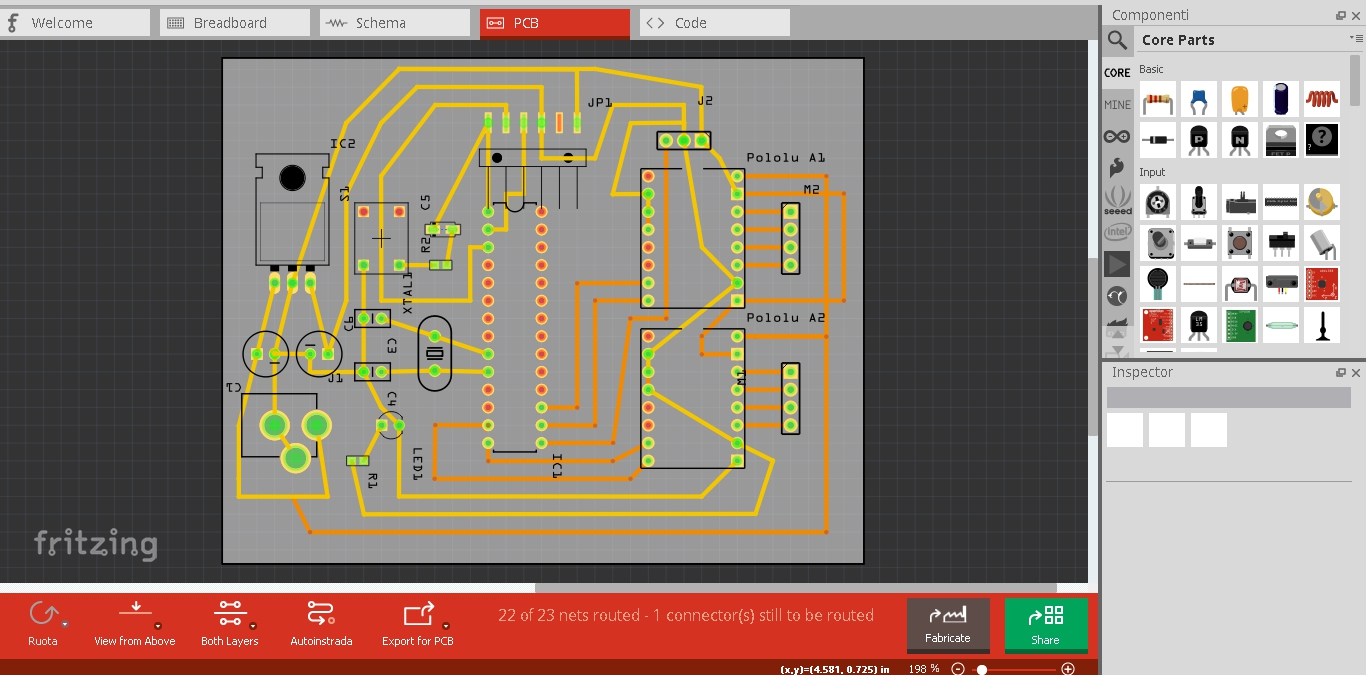

Finished the circuit diagram is enough to trace the runs on the board to complete the job.

It fritzing proved to be an easy to use but too little performance than eagle.

I'm afraid I'll have to redesign before milling around on eagle to make sure everything goes smoothly.

Machine Manual Movement

Creating a prototype cardboard and scratching a few ideas on paper helped us understand the movements needed for the machine.

Once you've made the ideas and made the pieces, we mounted everything and tested the movements.