Assignment: Composites

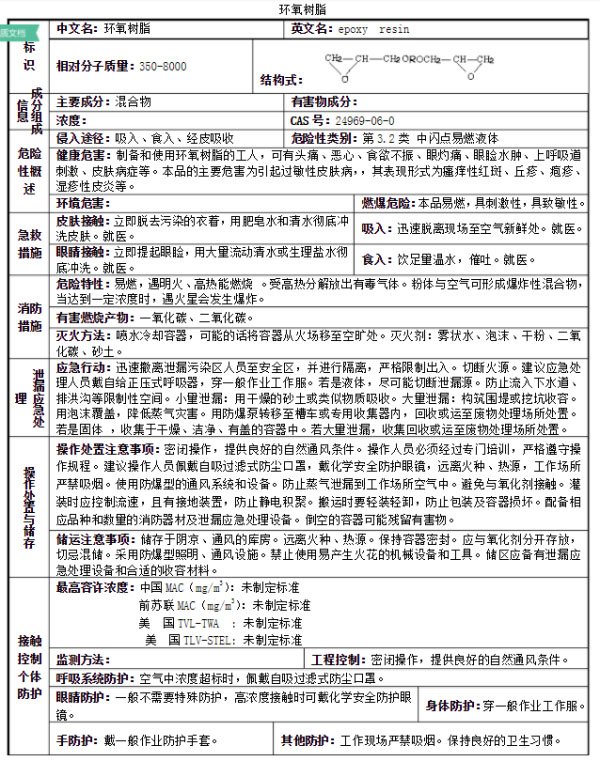

The assignment,I use two types of resin, for boat is epoxy resin,for bowl is 8017 resin. I read the MSDS for expoxy resin from the internet, here is the site.

I can not get the TDS of the resin i used . So I read the TDS for expoxy resin MY721 from the internet, here is the site.

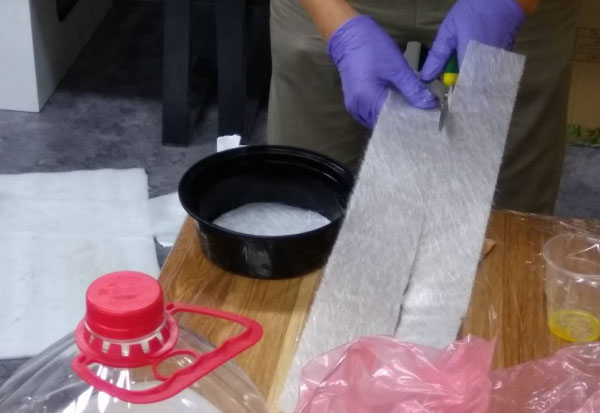

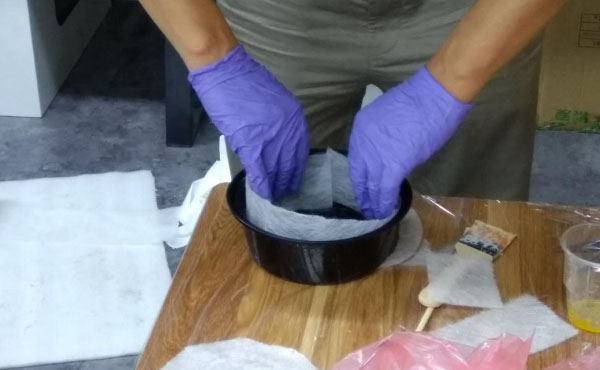

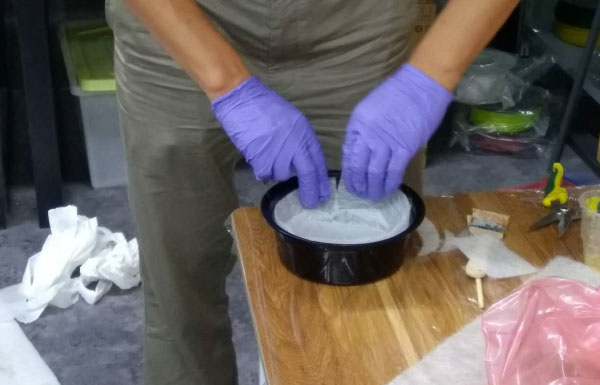

We use the 8017 resin and the fiber mat to produce the bowl. During operation, pay more attention as the following:

I read the MSDS for Fiber mat and cloth from the internet, here is the site.

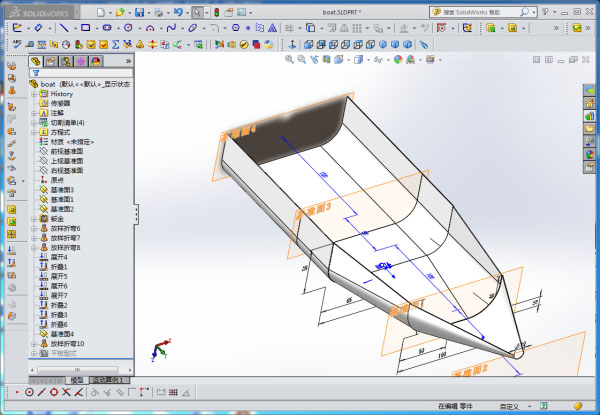

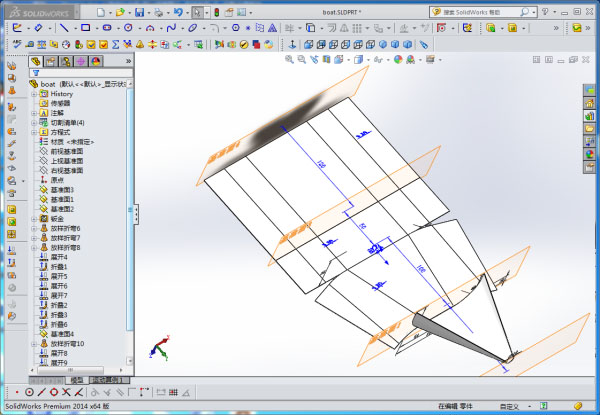

I design the model of the boat by Solidworks, then loft the model int dxf file, cut the cardboard by laser cutting machine, then molded it and finally molded it through epoxy and glass cloth.

Model design

You can download the boat mould file here.

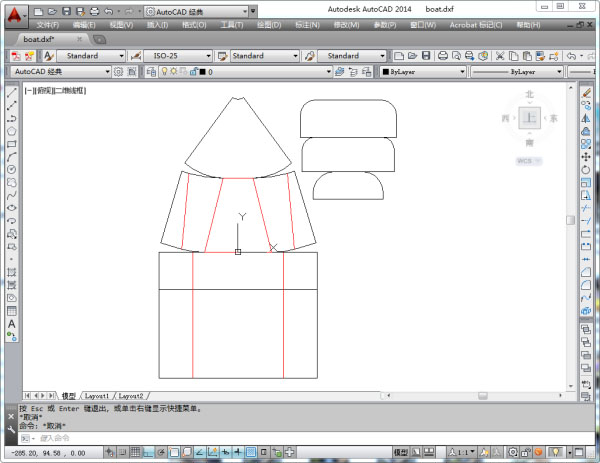

Modeling completed, lofting the model to DXF file.

You can download the boat dxf file here.

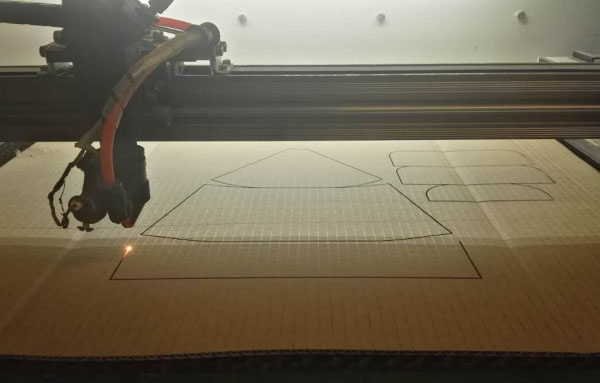

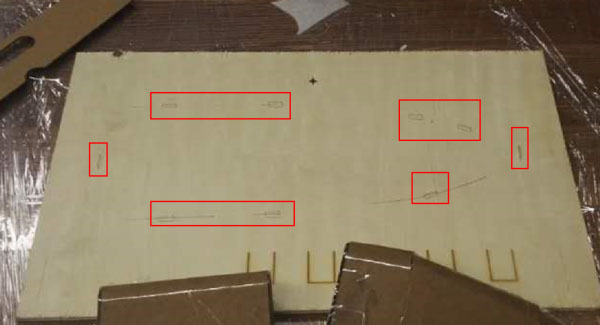

Laser cutting and assembling

Moulding

Step 1: the positioning point is fixed on the base plate, and the positioning point is used with a drawing pin

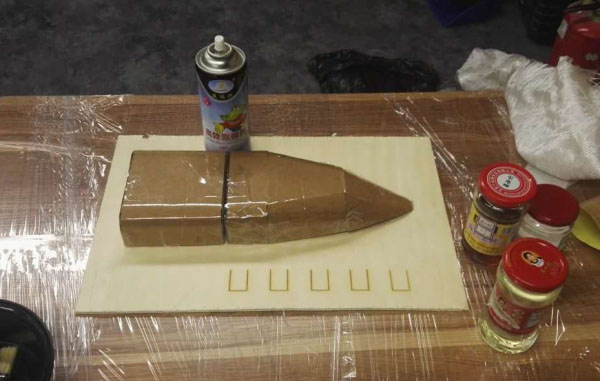

Step 2: Spray release agent on the surface of the base plate and ship model

Step 3: Mixing the resin

The materials used in the model are the following, the scale of epoxy resin and diluent is 1:1.

Step 4: Moulding the partition

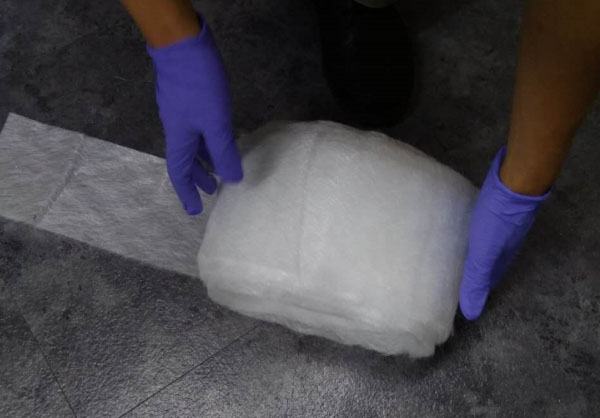

Step 5: Moulding the surface and then Pressurization by vacuum

Prepare several large plastic bags, spray the release agent inside, and put the model into the bag. Because my plastic bag is very thin, I use more than one. Use vacuum pumps to remove air from the bag and close the resin and fiberglass cloth to the model.

The full cure time of epoxy resin at room temperature is about 8 hours.

Step 6: mold unloading

The transparent boat was born !