Assignment: Moulding and casting

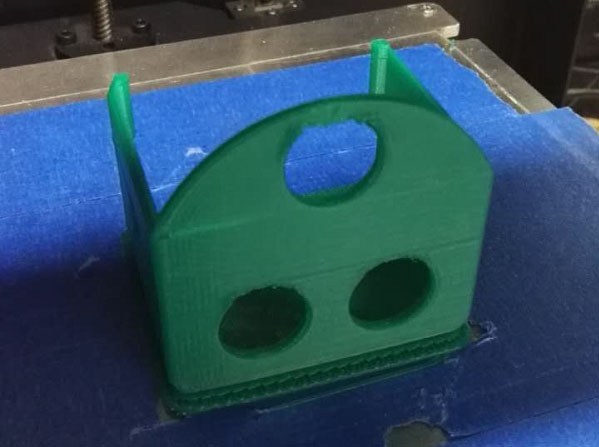

Work 1 : Heard Cover of Rocking Robot Work 2 : Seal of FabLab BeijingHome

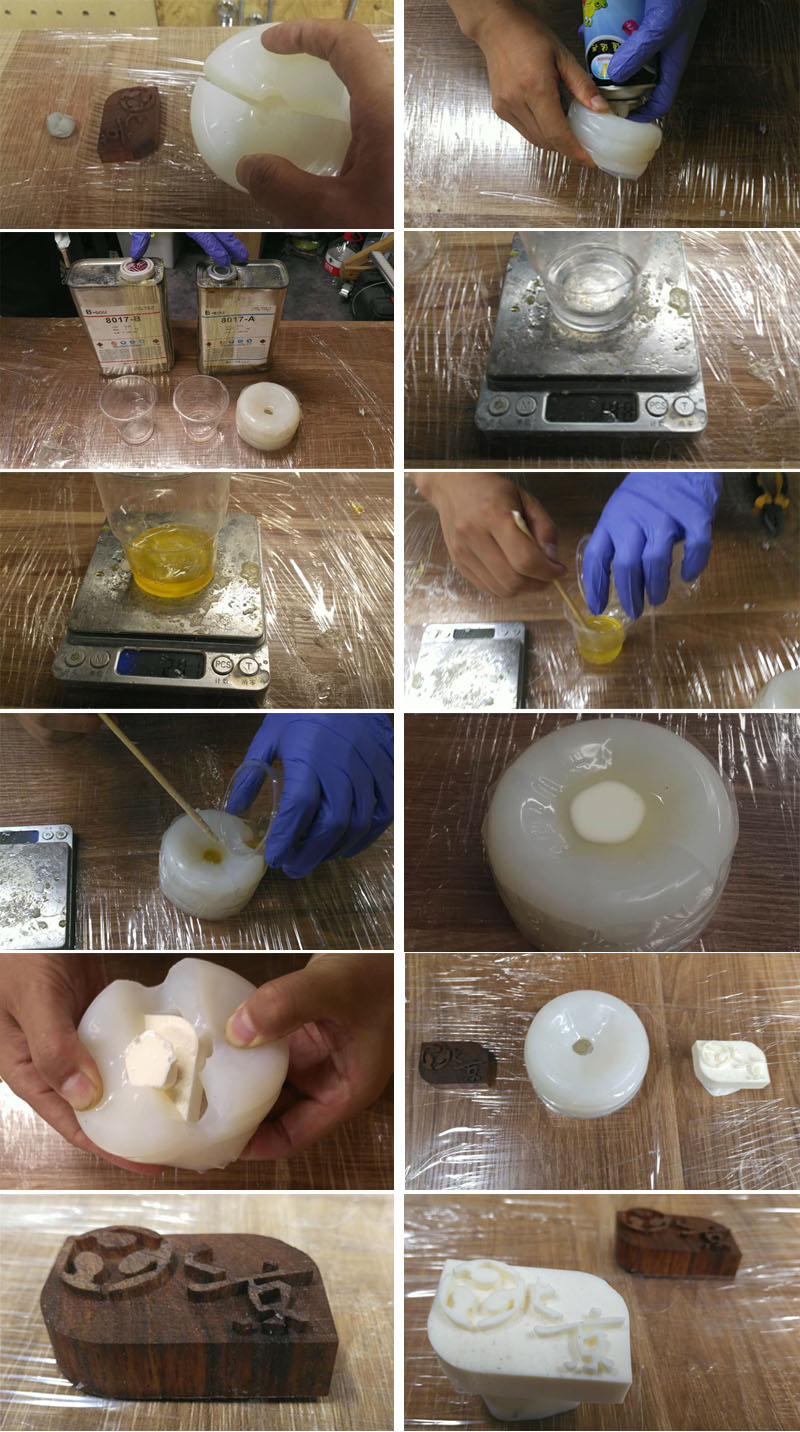

Material preparation

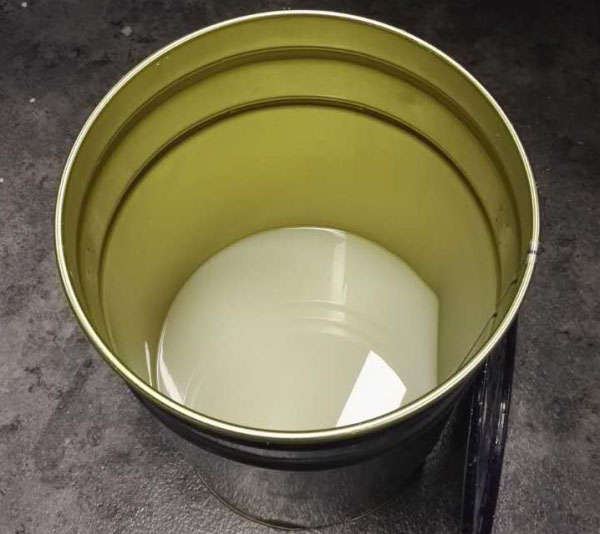

The materials for moulding: Silicon gel, curing agent and release agent. The equipment is :electronic scale.

Moulding

Casting

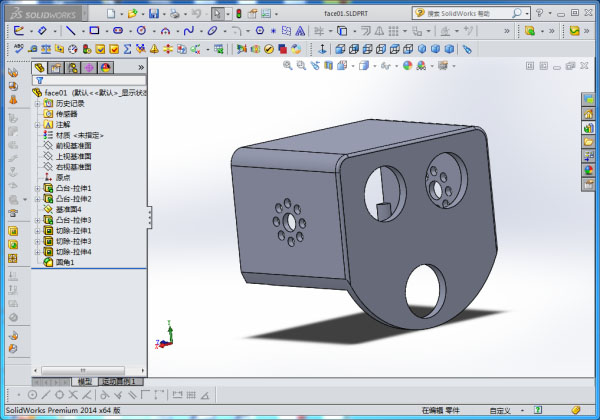

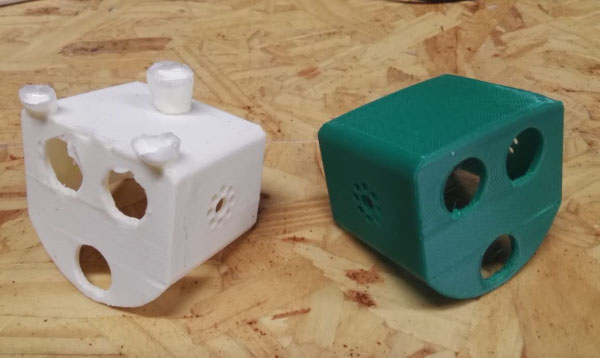

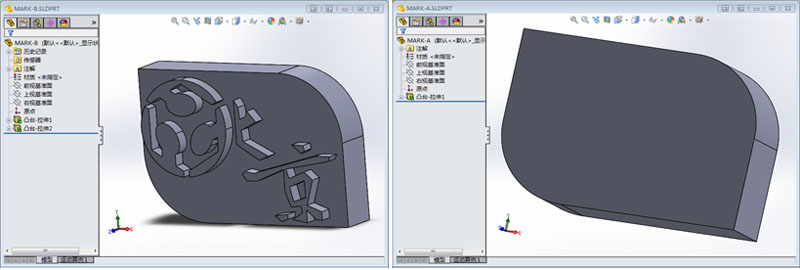

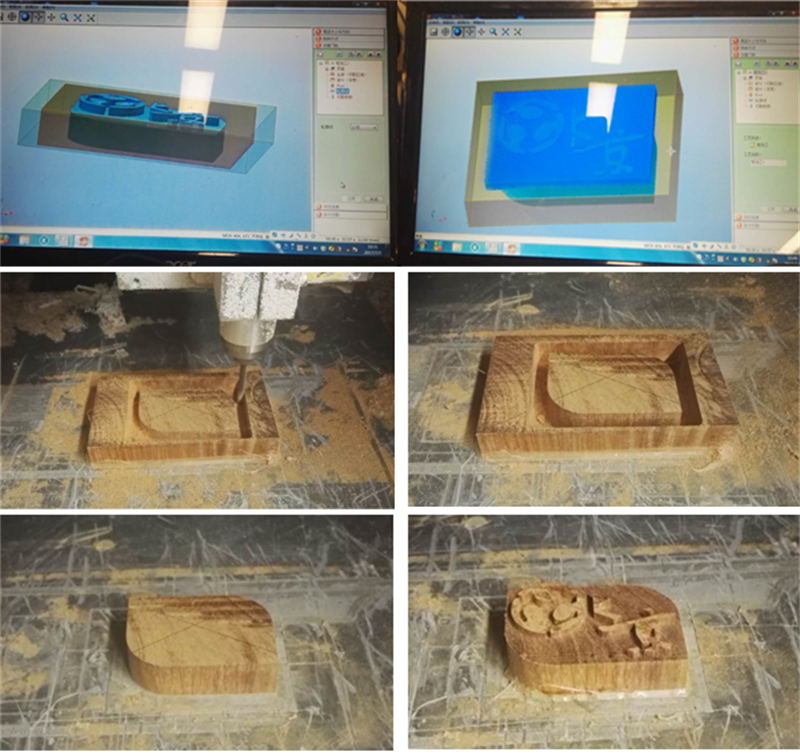

I design a seal of FabLab Beijing .

You can download the boat mould file here.

I use CNC to process the seal. It is divided into two steps. The first step is to use the milling cutter with 4mm Diameter to process the shape of the seal. The second step is to use 1mm diameter milling cutter to process the seal.

Preparation

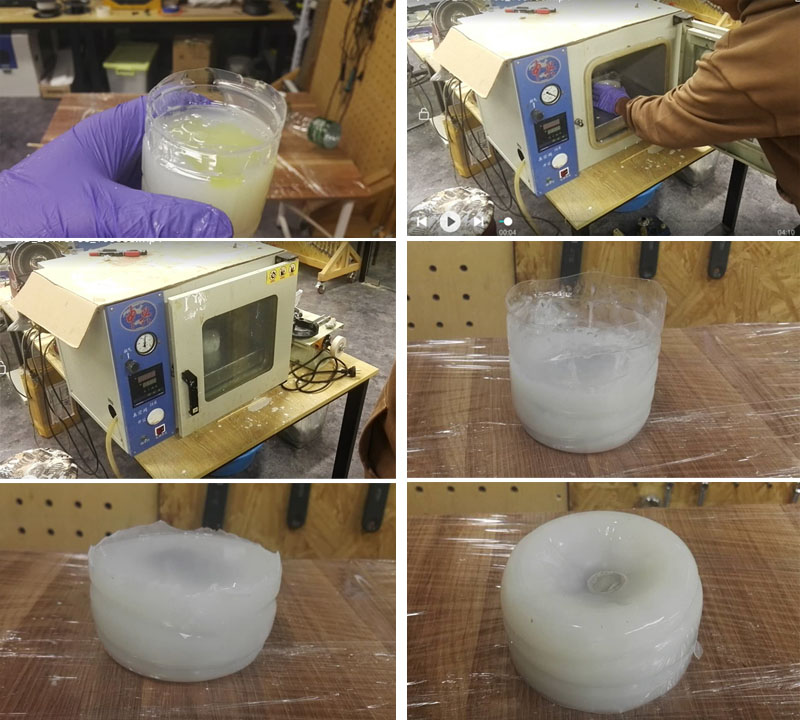

I use a water bottle as a container, and the round container helps to keep it stable during the casting. Since the material of the seal is wood, I use Vaseline as a release agent to prevent the release agent from being absorbed by wood. Finish the release agent and put the seal in the bottle. To save the material, I cut the top of the silicone into small pieces and put it in.

Moulding

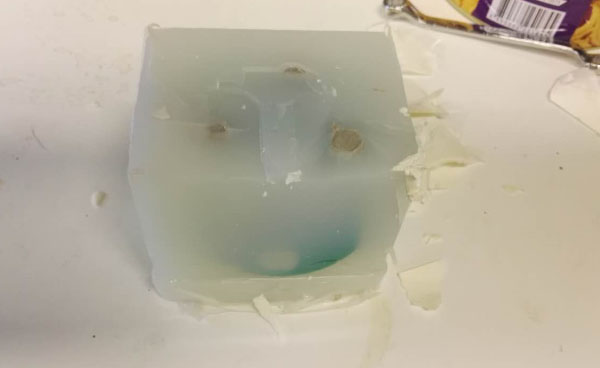

The ratio of silica gel to mold release is the same as before. The silica gel is injected into the container and placed in the vacuum machine. The air is taken out and the air pressure is restored to atmospheric pressure before the silica gel is cured. It can be cured for 30 minutes

Casting

Cut the silicone, remove the seal, spray the release agent into the silicone film, and then wrap the silicone mold with tape. Take 8017-A and 8017-B 20 grams each, stir evenly, then put the resin into the silica gel mold, 5 minutes later, the copy born.