9.Mechanical design, Machine design

Background

For the machine making project, I wanted to make a machine that has a bit of randomness.

When I looked up the past academy students' machines, I found out that the results which the machines make were already expected to be like it.

For example, a machine that writes or draw, people already have a result in their mind and expect the machine to make the result.

However, I wanted a machine that has a random feature in it.

If the previous project machines made an outcome that is directly produced by the direction that were given, like pictures, letters, or XYZ moves, I gave an idea that has an intention of giving an unexpected and undetermined result from the direction given from us.

Concept

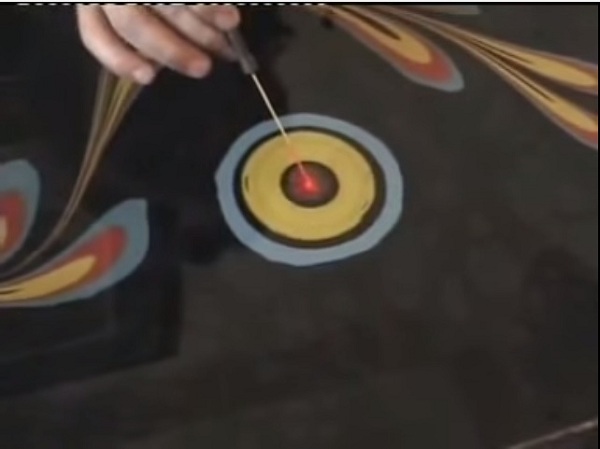

I thought of paint drops.

If dropping a paint on a surface, it makes a different spots or shapes as you drop them eventhough it is dropped from the same height.

Furthermore, when surface comes to water and oil paint, it would make more dramatic result because of wind, temperature or natural features that human cannot control.

This is one of oil paint technics. (link)

Our team planned to make a machine that drops oil paint on water surface.

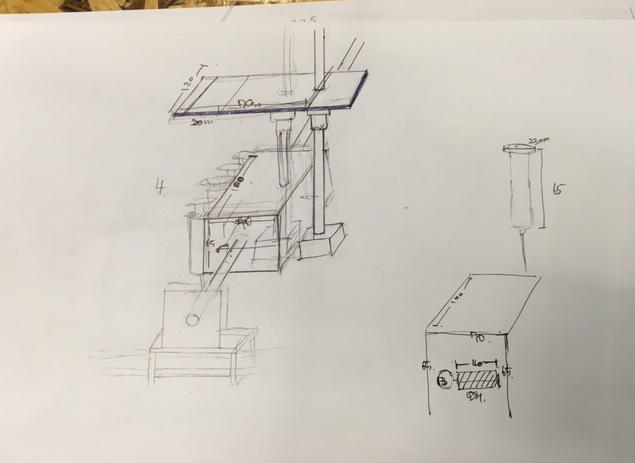

This is one of my first sketches of the machine.

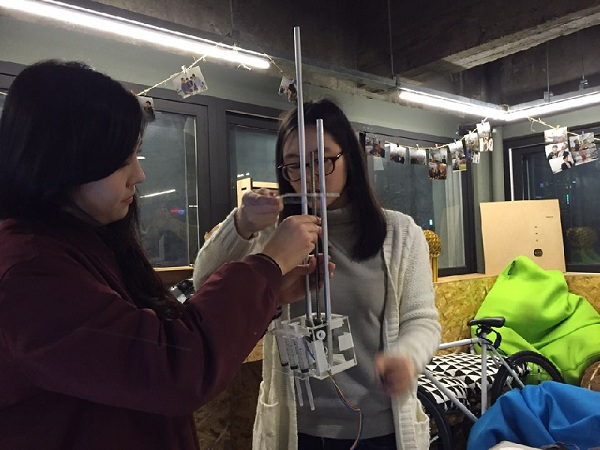

Some people in our group made a machine that moves in X and Y axis first, and then the rest of the group members including myself, made a header part of the machine which drops the oil paint.

At first, our team had trouble in dropping the paint.

While then, we found some projects that works similar to ours, such as ketchap machine and pneumatic extruder machine.

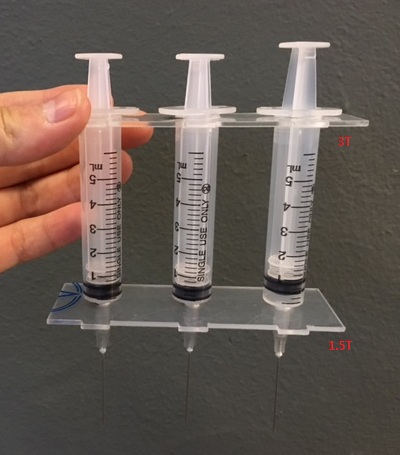

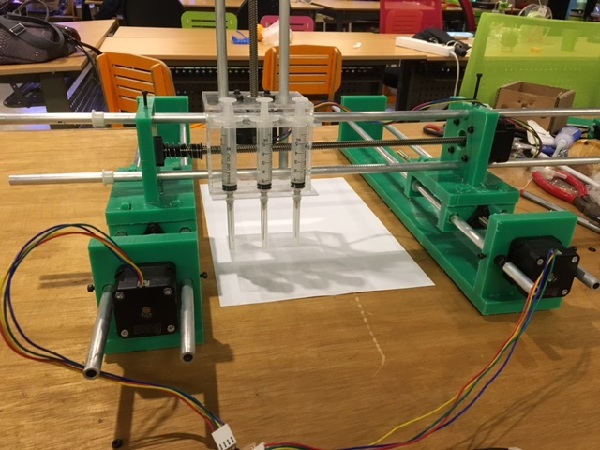

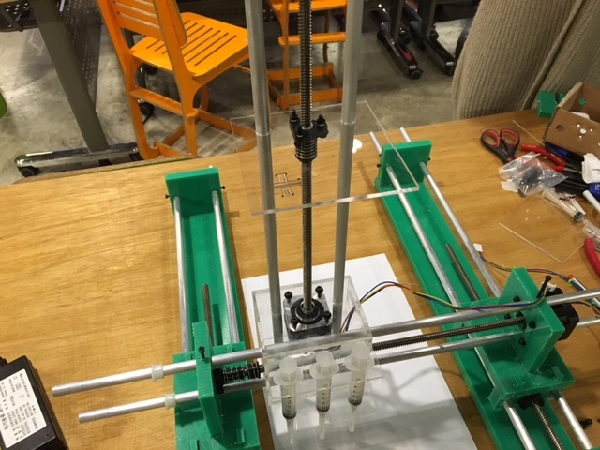

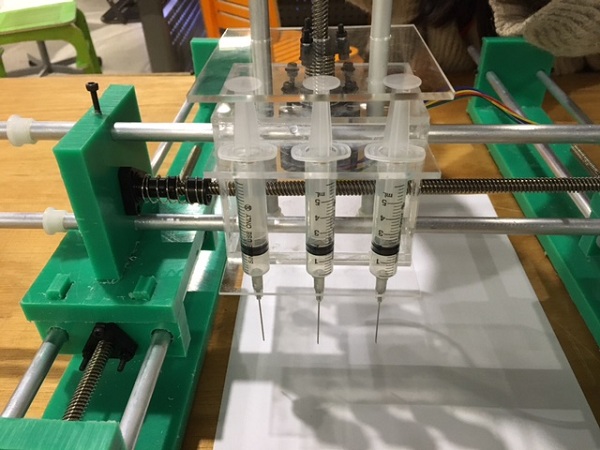

We chose to use syringes to drop the paints and make piston move with stepper motor.

Therefore, our machine moves in 3 axis.

The Z axis movement is made by stepper motor to press down plungers of the syringes, and X and Y axis movement makes positions to drop down the paint.

I wish we had more stepper motors and make different piston moves with different color syringes. Unfortunately, we were lack of materials and programming skills.

Make

I tried to make the header smaller because as bigger it is, the range it can make gets smaller.

Firstable, I made a injector holder.

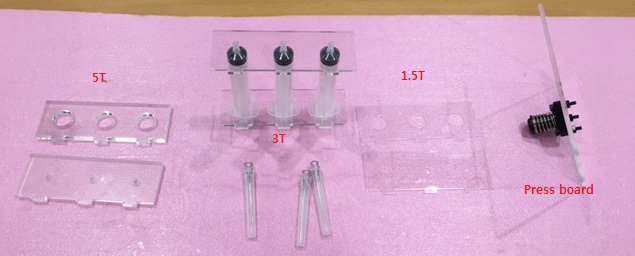

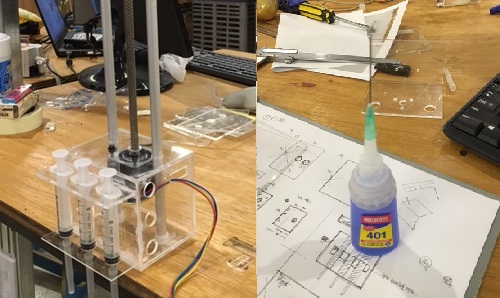

We chose clear acrylic for our material, so that it could look better with colors of paint.

We had 3 different acrylics, 1.5t, 3t, and 5t.

Since our syringe has a different circumference like an upside down cone, I had to think of a way to make a holder that fits perfectly.

I tried several times and made three different holders.

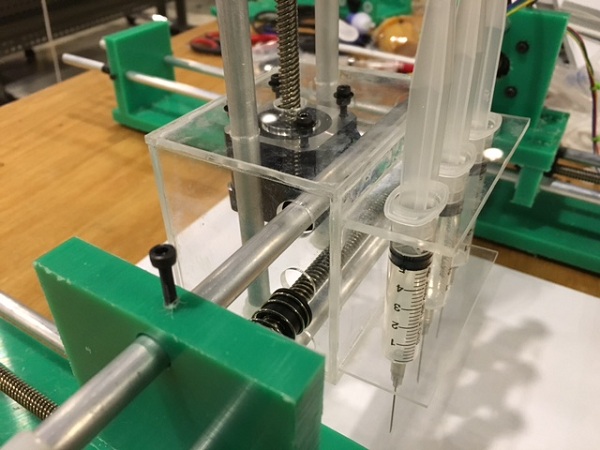

The best way was to make two holders, one in Luer-Lock tip and one under the finger flange, with using different thickness of acrilic.

The Luer- Lock tip is very thin and short that it can only fit is to 1.5t acrylic since it has narrow down shape.

The part under the finger flange, I used 3t. Not only fit perfectly but also hold the finger flange.

It is important because the syringes have to stay still in their position when pressing down oil paints with plunger and stepper motor.

The air pressure between liquid and a rubber bulb inside the hollow barrel is strong.

I cut the pole and made the length even.

Since Mirae and I made the CAD together but with different computers and different part, we had to make the joinary parts several times again.

However, it was fun and each time we made the change, we had better ideas and better result.

Su glued on some acrylic pieces to make harder. She used needle to put glue between the pieces. I thought it was good idea.

We put water in first and tested it. The pressure was fine and stable.Mission clear!

Mission clear!

Future possibility

When the machine makes the unpredictable patterns, then people can print it on a t-shirt.

It can be printed on a t-shirt by pressing it on the water gently. The machine can be improved as a fancy t-shirt design machine.