5. 3D Scanning and 3D Printing

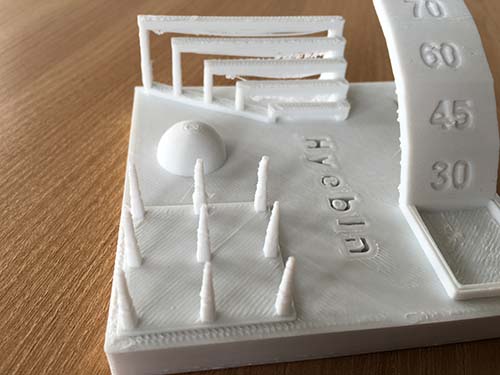

Printer Test

This week's assignment is to test the limit of 3D printing.

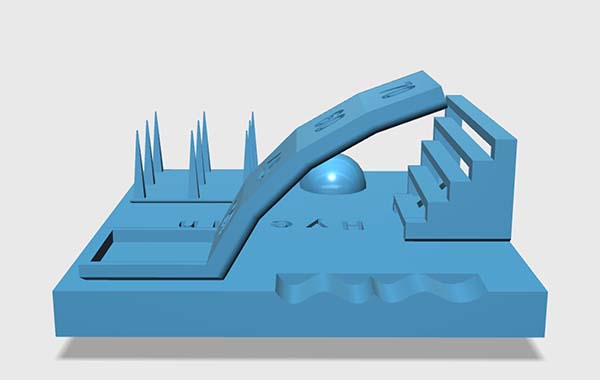

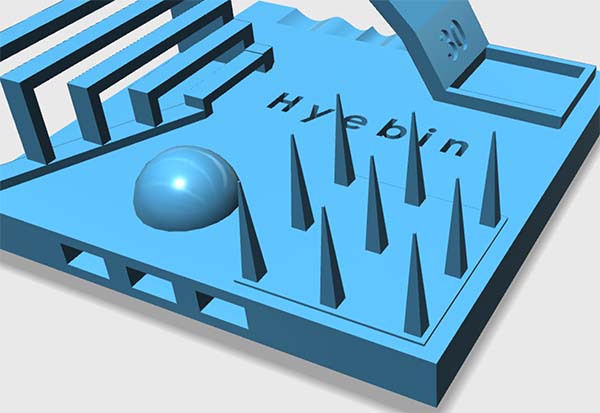

I thought of some missions for 3D printers and made 3D printer test file.

I had many chances to use different machines, such as Davinci 1.0A(XYZ Printing), Ultimaker2, Edison, Makerbot2, Cube Pro single(3D Systems), and Almond(Opencreators)

Among those machines, I prefer Cube Pro and Ultimaker2 for there nice quality of output. (However, these two machines use there own filament which is more expensive than others. This is one of their weak point.)

I made a testfile. I wanted to compare their

- Horizontal distance they can make without support,

- Quality of small points they can make

- Three-dimensional curves

- Different angles that they can make without support,

- 1-2mm holes

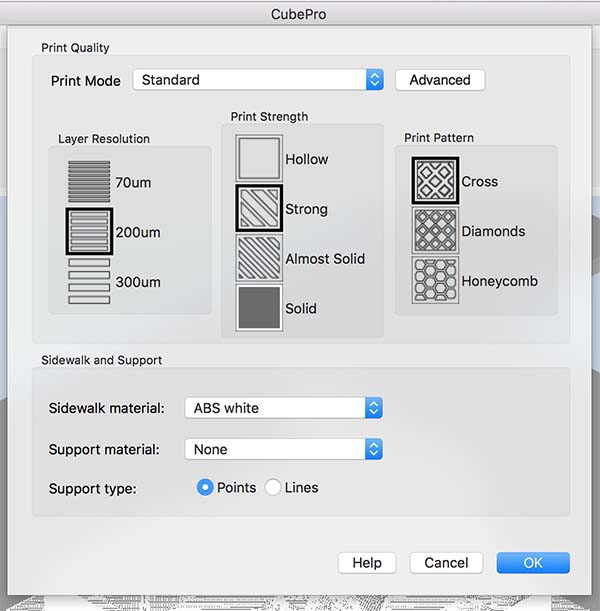

I made settings of both printers as similar as possible.

Layer=0.3mm

Material=ABS(Filament from each company)

Print pattern=Cross

Cube pro uses its' own software and Ultimaker uses Cura, so I couldn't make exactly the same setting.

Here are the result.

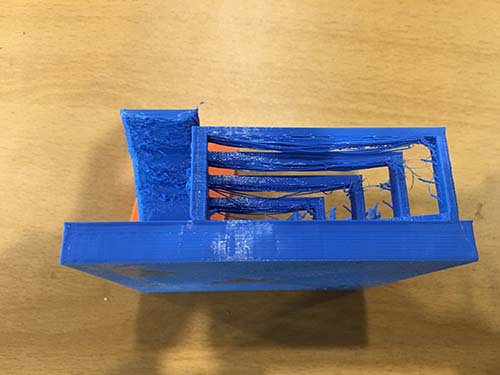

Ultimaker2

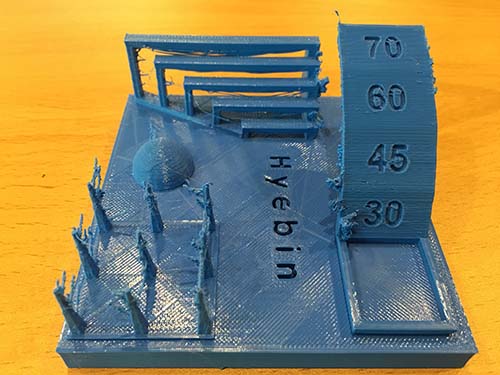

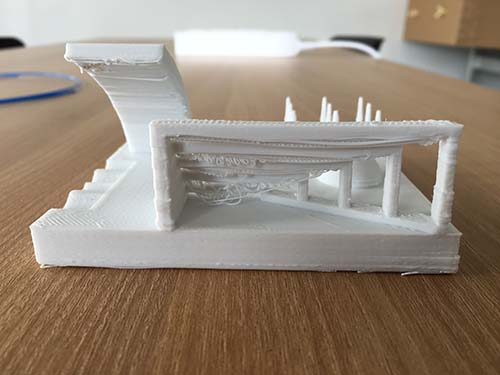

Cube Pro Single

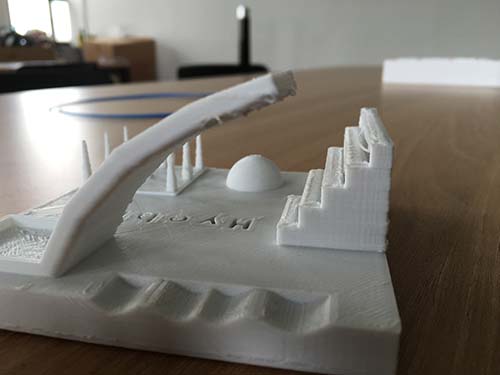

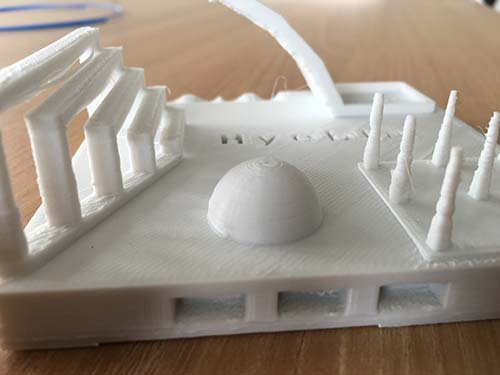

Comparing Ultimaker to Cube Pro Single

1. Fineness

Cube Pro made more elborate result compare to Ultimaker.

For example, Ultimaker is worse at making sharp point. I don't know how it made like this.(I should have watched it while printing this!) It barely shows what the original shape was.

Ultimaker seems difficult to make not only the sharp shape, but also the most of part except the curve of flat shape.

Cube pro was also not as good as I expected, but it was better than Ultimaker2.

2. Surface

However, what I like about ultimaker is its' fine surface. It's smooth and glowy.

Both of the machine was set to print with 0.3mm layer height but Ultimaker makes more smooth surface.

3. Time

Cube Pro was slower.

I forgot to measure how much time each machine took.

Eventhough both machines show required time on their LCD screens but it always vary and Ultimaker finished it first.

Everytime I use Cube pro, I like the result but it takes way longer than other machines. It tests my patience.

4. Others

One of my mistake was caliboration. I had to check caliboration of both machines but I skiped it.

However, both machines were managed by skilled persons.

One more difference of the machine setting is their filament.

Even though I used ABS for both of the machine, they were different filament since each machine used the filament made in their own company.

My personal preference for the filament is Ultimaker.

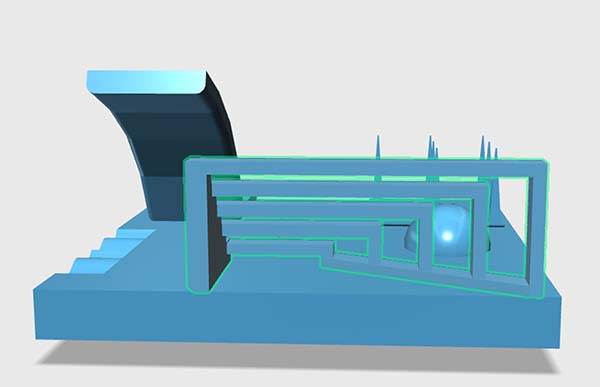

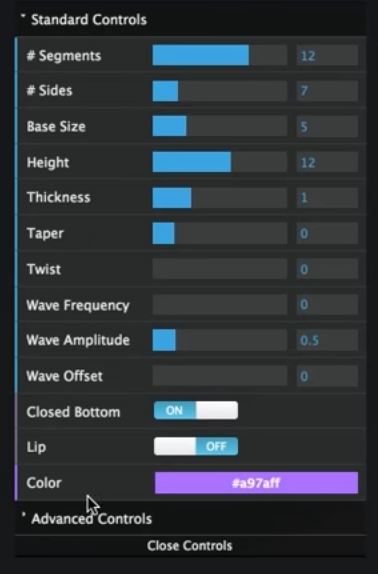

Something that could not be made subtractively

There can be many object which cannot made subtractively such as an object that covers another object inside, or sphere.

I thought that an object with patterns in different slopes and degree in z-axis is hard to make subtractively.

It's nearly impossible to design it with 3D Modelling tool, so I chose "Shape Shifter" which has a great interface for making 3D patterns, twisting wave frequency, amplitude, offset and etc.

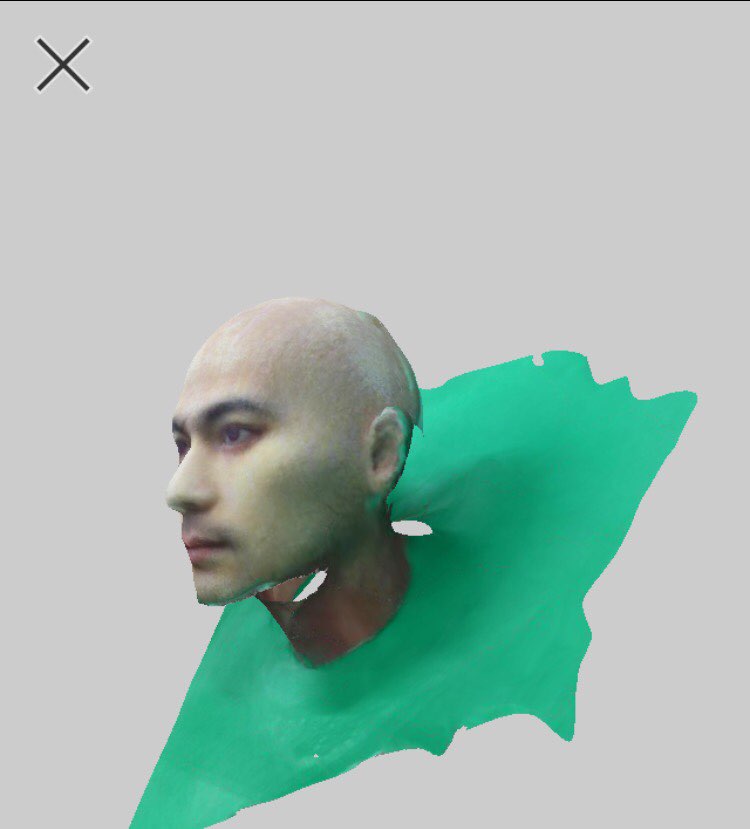

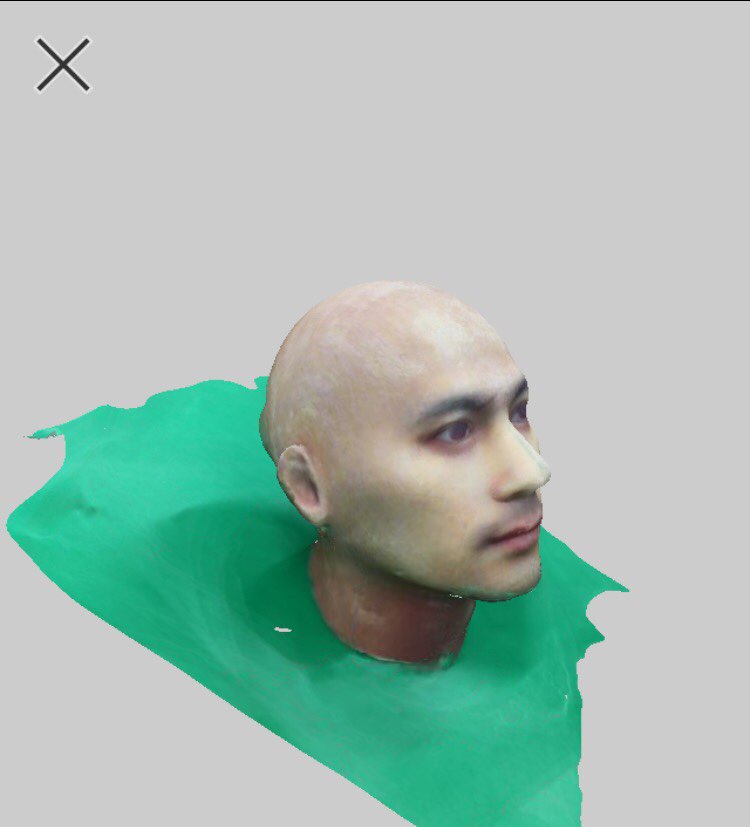

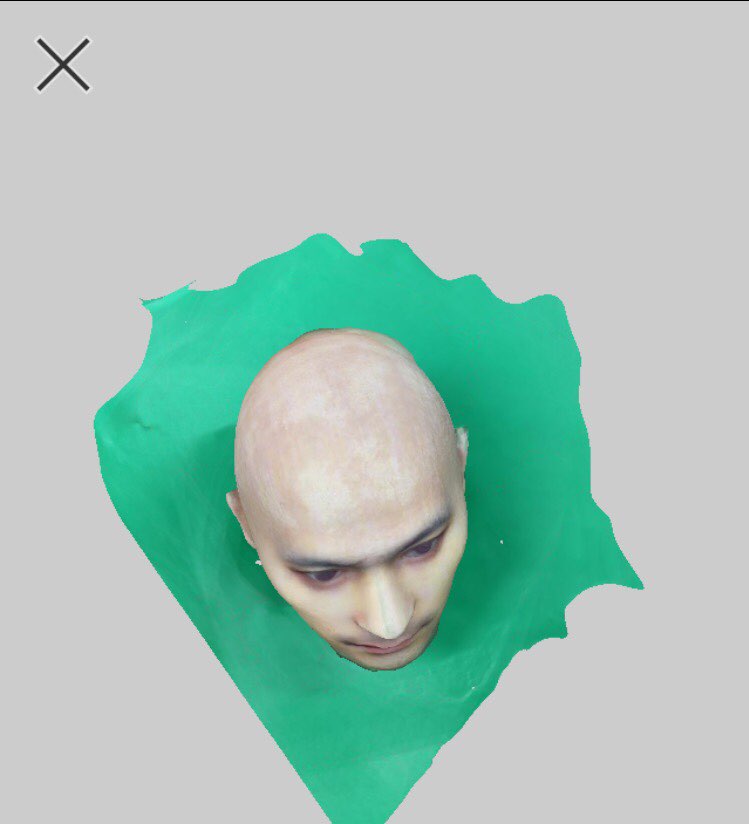

3D Scanning

I found a 3D modelling iphone application called 123D Catch.

I used iPhone camera and took 40 pictures of an object in various angles.

I was difficult to move my hands in 360 degrees but the quality came out pretty nice.

I scanned a 3D printed figure of a Korean celebrity.