14.Composite

Making Mold

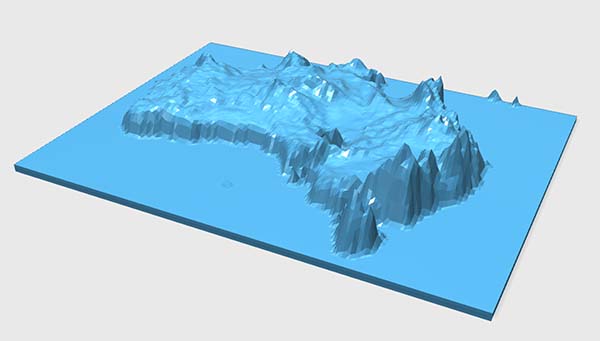

At first, I tried to make a 3D map of Australia by looking at a contour map and mocking it by 3D CAD.

However, it was so difficult to body out different layers and gradient. so I asked a question how I can make 3D modeling file of map in regional meeting and some of the members talked about stl generator sites. (http://jthatch.com/Terrain2STL/ or http://maperitive.net/)

I knew Australia has mostly flatland, but I thought it would have at least some kind of up and down slopes on the surface.

However, it rarely has gradient so I had to exaggerate it to make the result look better.

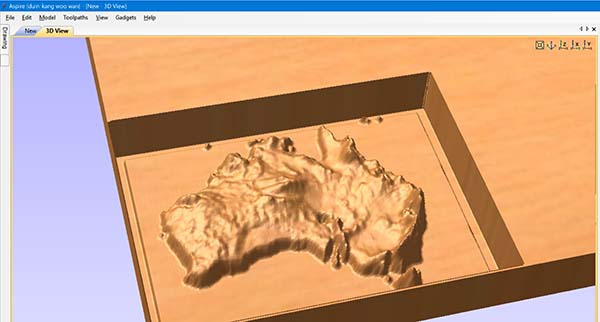

I used "Aspire" to make 3D cut file.

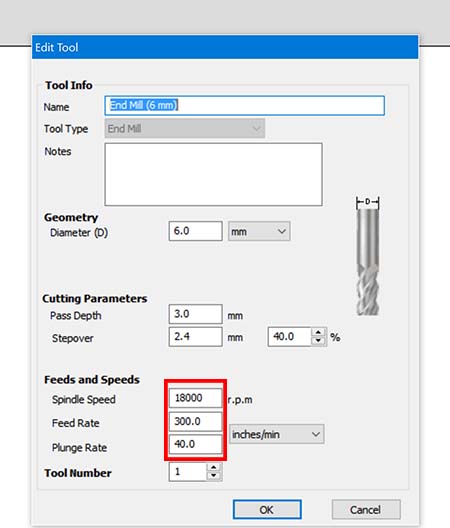

I set material circumstances and made to files, roughing(with 6mm square mill), and finishing(with 6mm round mill).

Since I planned to use pink foam, I could set rpm up to 18000 and made feed rate 300.

For the finish cut I chose "offset-conventional".

3D View of rough cut and finishing cut.

The height of my modelling file is 85mm so I sticked 3 of 3T pinkfoam together.

And this.... brought me on to disaster......

The sticky tape stucked on the endmill and made loud and wierd sound.

I had to pause the machine every 5 minutes and take the stucked tapes off from the endmill. It was very harsh....

Result of rough cut

One problem was the dustcollector. It hits on the surface so small pieces on the top were broken down.

Result of final cut

Make Composite

I covered it with a thin plastic bag and sprayed "ease release 200" on my open mold.

I cut fabric

Next step was to make mixture with polyester and harder with 100:1 ratio.

After I made the mixture, I had to finish the rest of the steps in 10 minutes, before it gets solid.

I put a fabric, poured the mixture and spread it.

I used 3 pieces of fabrics so I put the mixture between the fabric layers.

On top of the fabric, I put plastic vinyl and two more fabrics without the mixture which would function as a cover for the composite.

Then I put them all into a huge plastic bag to used vacuum cleaner to make the composite in a state of vacuum.

Result

After 24 hours, I finally got the result.

I hope Australia could have fab academy next year. Join us!

and my mold.. you poor thing... dissolved by the heat generated when it was hardening.

I liked you more than the composite. Bye bye...

.

.

.

.

.

.

.