12.Molding and Casting

Molding

There are some choices when making a mold.

First of all, I chose chocolate for casting material which is soft. Soft casting materials need soft mold so that it can taken off from the mold easily.

Obviously, hard casting materials need hard mold.

It is more simple when using hard materials because you can make make the mold directly with CNC. However, the process goes complex when you cast with soft materials, since it is very difficult to mill directly soft materials like silicone or latex.

To make a soft mold, you first need to make positive mold by CNC and wax block, and then cast it to make a soft and negative mold.

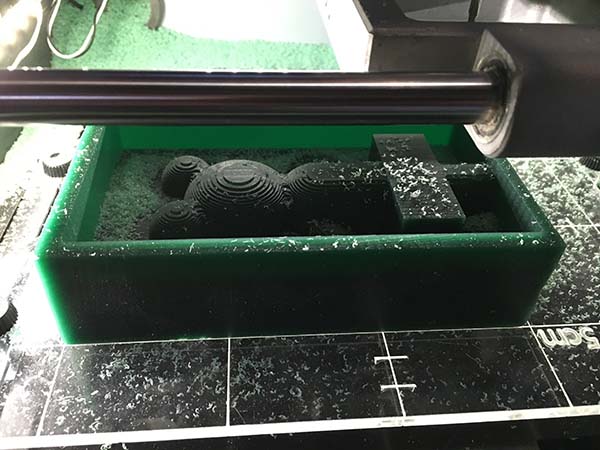

I used SRM-20 to mill wax. I needed a soft mold so I designed "positive cut" file.

Actually, negative cut is easiler because you can just 3D design the final casting shape that you want to get.

When designing the mold, I had to think about the size of the mill that goes between the shape.

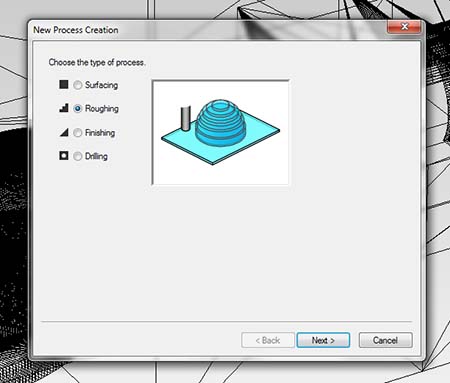

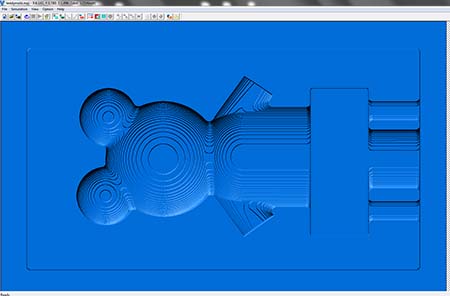

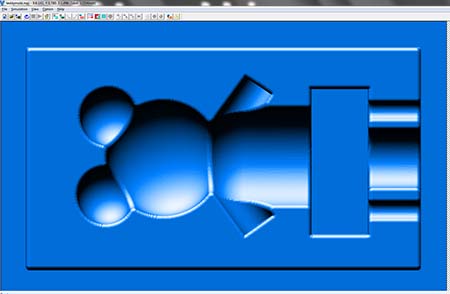

After I desined the file, I used "Modela player 4"

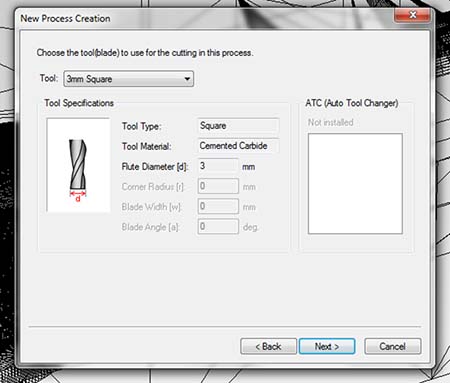

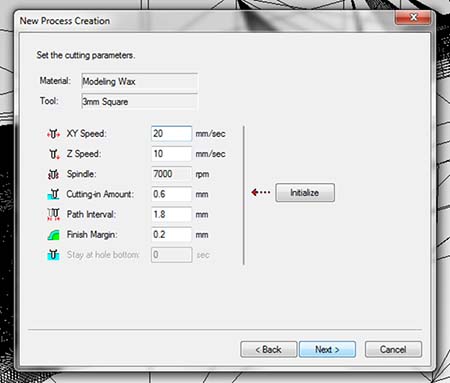

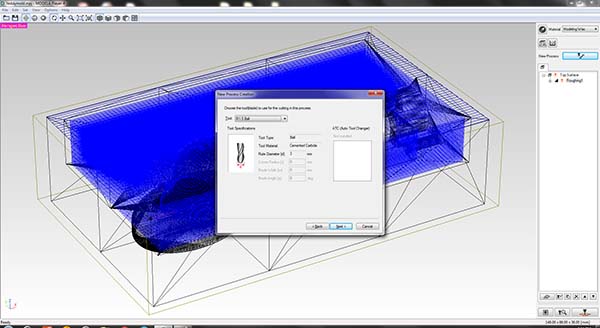

I decide to use two different mills, 3mm(square) for rough cut and 1.5R(3mm) mills for finishing cut. First, I set up materials to "Modelling Wax" and set circumstances correctly with the buttons on the left corner.

Next, I clicked on "New Process" and made two different files which are "Roughing1" and "Finishing1". Just in case, I changed XY speed from 25mm/sec to 20mm/sec.

This is the result of the rought cut

and this is the result of finishing cut.

It is much smoother than I thought!

Before I made my mixture, I sprayed "Ease Realease 200" on my mold. It is better to it in the first step because you have to wait for 30 minutes to dry it.

I used "Smooth Sil 940" for mixture.

On the webpage of "SMOOTH-ON" there are date sheets of each of materials.

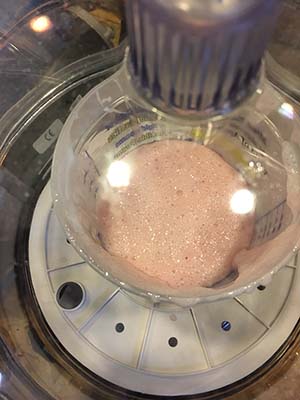

I made a mixture according to the data sheet. I put part A 20ml, and part B 200ml and then slowly mixed them.

Then I put them into a vaccumm chamber for 4 minutes to kill bubbles.

Die! Die!!

I poured it gently. There were two different comments on this.

One of my classmate told me to pour it at the highest point little by little, so that it could kill the bubbles while it hits on the ground. One the other hand, the data sheet tells to pour it at the lowest point.

I listened to my classmate because she already finished her mold nicely.

I am so proud that I made just appropriate amount of mixture:)

Result

Casting

I wanted to make a big gummy bear, so I made a jell-o and grape juice mixture.

However, the mixture was not thick enought and the jelly got too soft that I couldn't take the bear off properly.

I poured water in it and made an ice bear.