Oscar Velázquez

WEEK 7 / Mar 08

Computer-controlled machining

Assignment

make something big

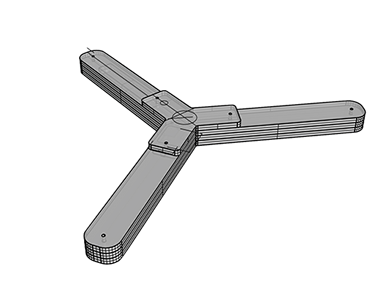

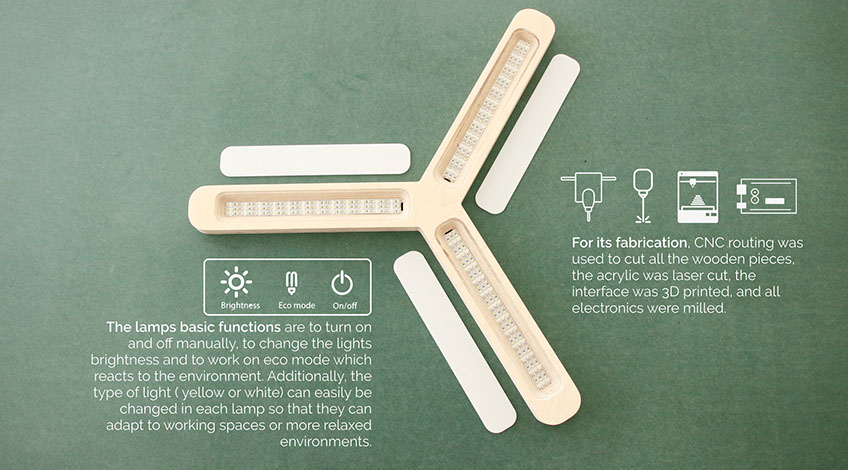

Final project CNC Routing & Assembly

I decided to use 15mm russian birch plywood, which is a very stable and precise material for CNC routing. There were two changes of tools, so I made two different files for the CNC Router Machine.

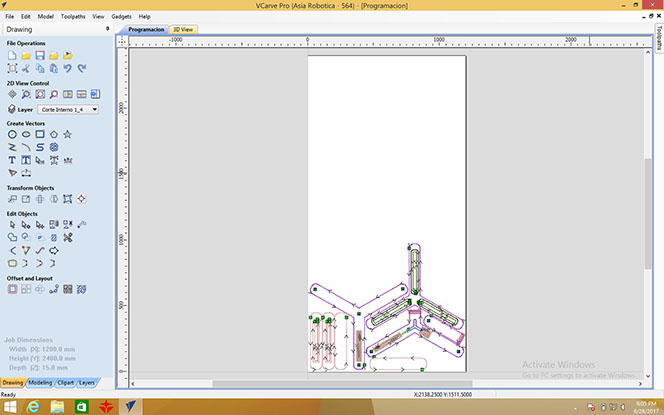

Machining the lamp´s body

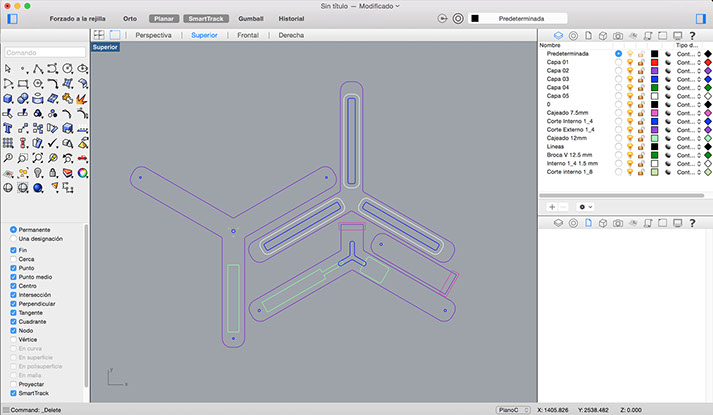

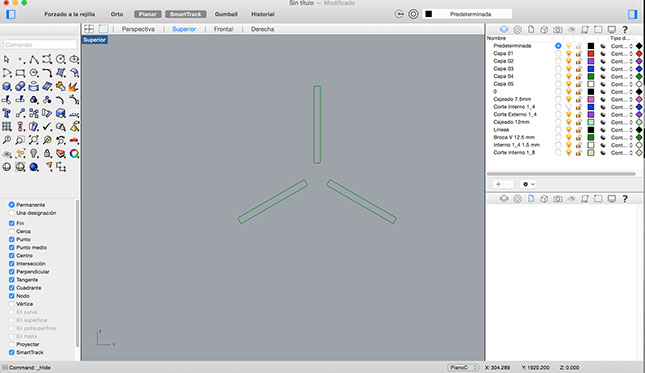

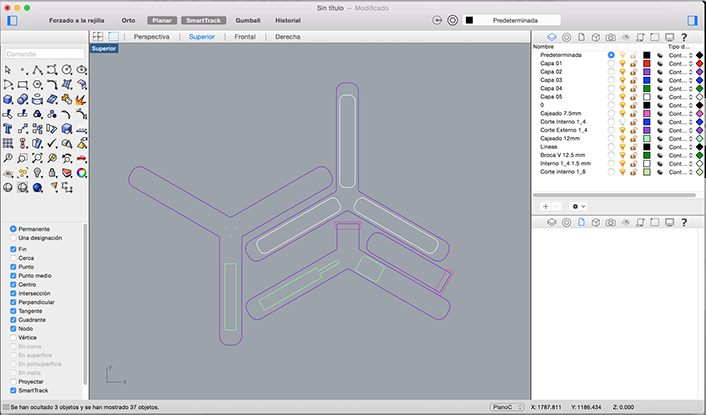

The first step was to generate 2D files in rhino, and after that, those files were exported to .dxf files. Then those .dxf files were imported into VCarve Software to make the files for de CNC Router Machine.

Pocket machining the lamp´s body

There were two changes of drills, so there were made two different files for the CNC Router Machine.

Drill change for led pockets

The first drill was the 90 degree chamfer end mill, with which some pockets were made. This pockets will give the angle that led’s halo needs.

Lamp sanding and wood sealing

Having all the pieces of the lamp cutted, it was sanded in order to apply after that, an organic wood sealer to protect it.

Lamp Assembly

Once the pieces were ready, the first two layers of the lamp were sticked with glue. And the last layer were assembled with ¼” insert nut.

Russian birch plywood

The second drill was rounded edge end mill. There was a pocket tool, for the spaces where the circuits boards and electronic components were placed. And finally, with the same tool, to profile the pieces.

%20193007.jpg?crc=222568826)

%20193012.jpg?crc=523529975)

%20192942.jpg?crc=3974654156)

%20193201.jpg?crc=370330336)

%20193346.jpg?crc=3782156785)

%20193325.jpg?crc=4093900578)

Extra project

Before making my lamps body, I designed and fabricated a standing base for the Ipad to be used as access point in the FabLab Impact.

%20020131.png?crc=468972640)

%20193207.jpg?crc=4035546207)