WEEK 3 / Feb 08

Computer-controlled cutting

Assignment

- Make laser cutter test part(s), varying cutting settings and slot dimensions

Individual Assignment:

- cut something on the vinyl cutter

- design, make, and document a parametric press-fit construction kit,

- accounting for the laser cutter kerf, which can be assembled in multiple ways

Cutting with laser

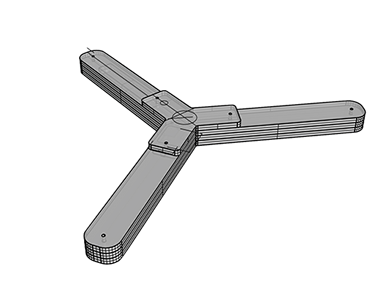

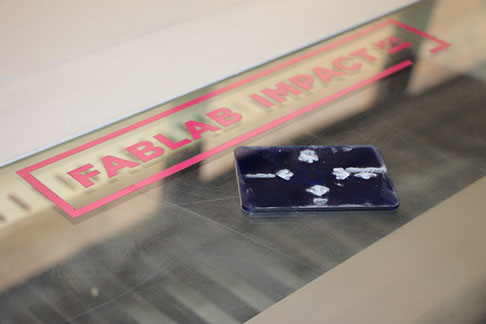

For this assignment I decided to create a press fit Box. During the time of the assignment a friend of mine asked me if I could help him making a box for some VR lenses for a project he had. So I decided to apply directly into a project. The main Idea it was to create a BOX using press fit and 6mm MDF.

1. First the piece was 2D Modeled in Rhinoceros which is a program that makes any design parametric.

%20160044.jpg?crc=124482374)

%20161524.jpg?crc=375381617)

%20161503.jpg?crc=4023226120)

2. With the same software the piece was 3d modeled and made into different options.

%20155914.jpg?crc=4277733110)

3. the pieces were vectorized and exported into adobe Illustrator in .ai format.

Cutting something with vinyl cutter

For this assignment I decided to make myself some cool stickers for my laptop.

So I got 1m2 of black vinyl with a mate finishing and 1m2 of transparent transfer paper.

1. I used the STM Plot Robot 721 / 1351 machine 150m long.

2. the sticker were designed in adobe Illustrator in .ai format.

2. the sticker were designed in adobe Illustrator in .ai format.

%20161655.jpg?crc=306225714)

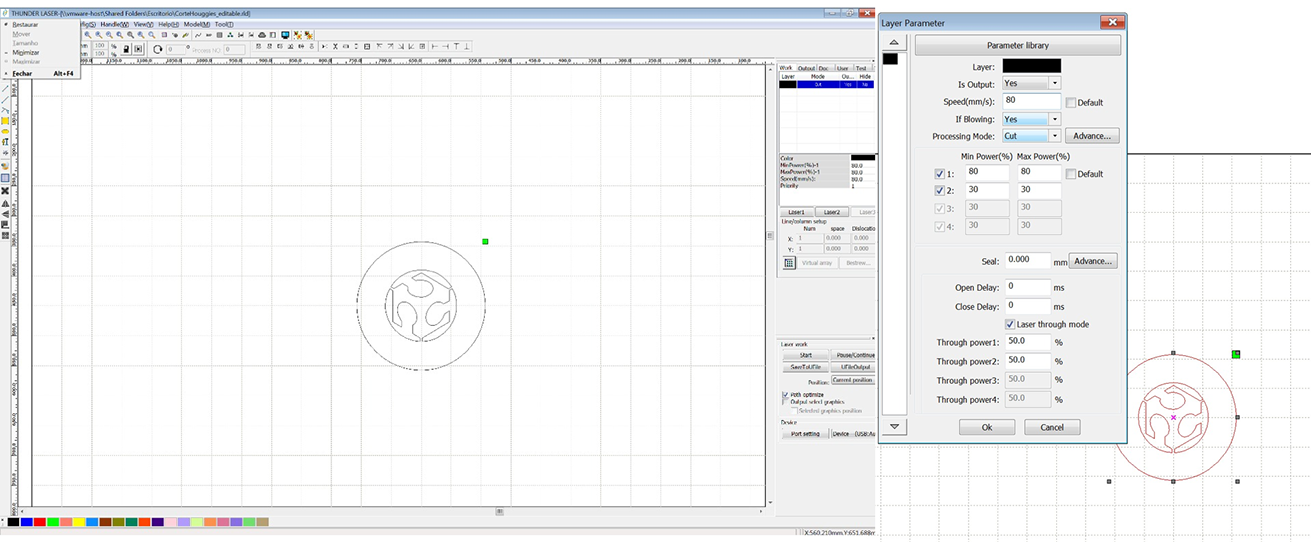

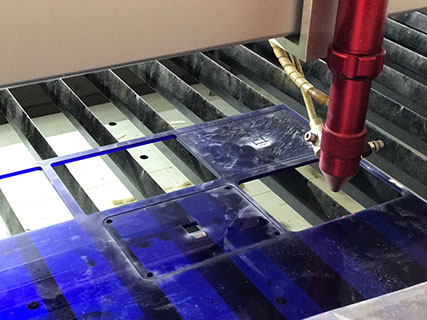

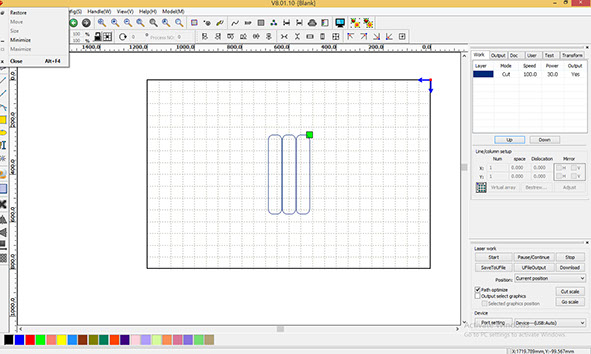

4. After having the illustrator file the files were imported into RDWorks where they were prepared for laser cutting.

- Speed 20mm/s

- Laser ray power in about 85%

%20163416.jpg?crc=208455749)

%20161310.jpg?crc=181038420)

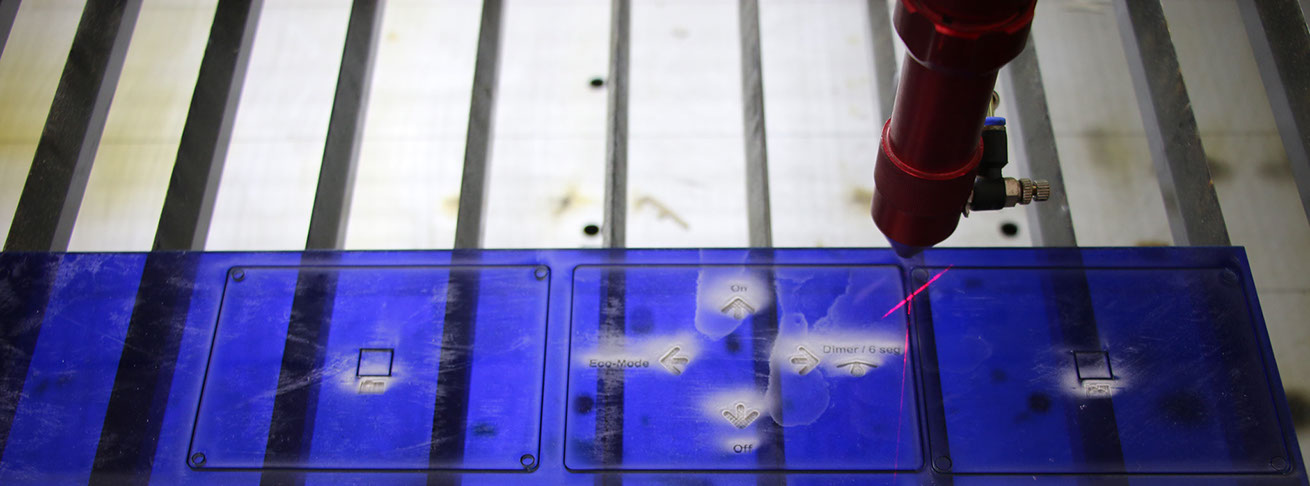

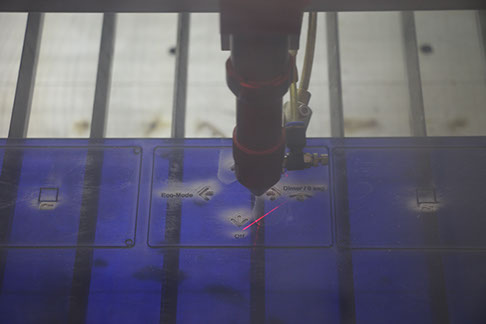

5. The box was laser cut with a 130x90 BODOR 100Watt tube.

i had to make 2 prototypes because the first one missed .5mm therefore the box lit was not fitting.

%20155710.jpg?crc=273755920)

I love my stickers, I placed them in the apple light of the lit of my Mac Book pro. It look very cool!

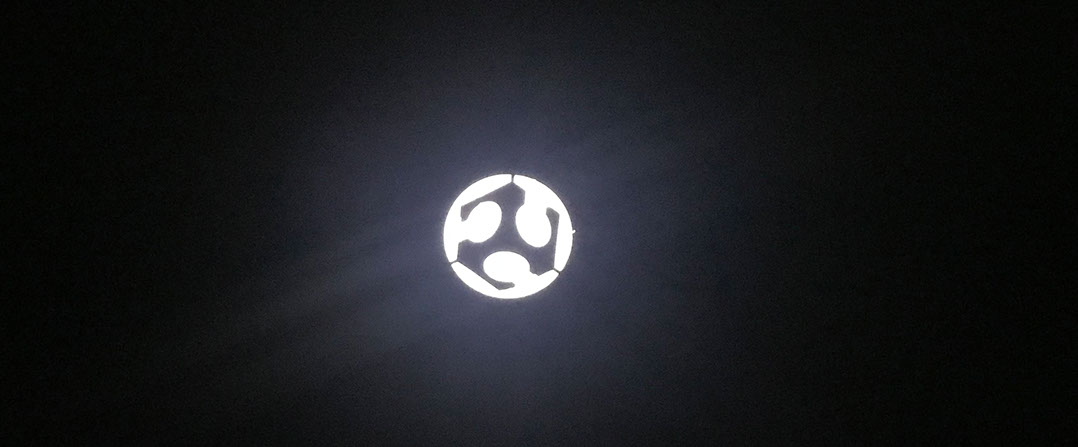

Computer control cutting for the final project

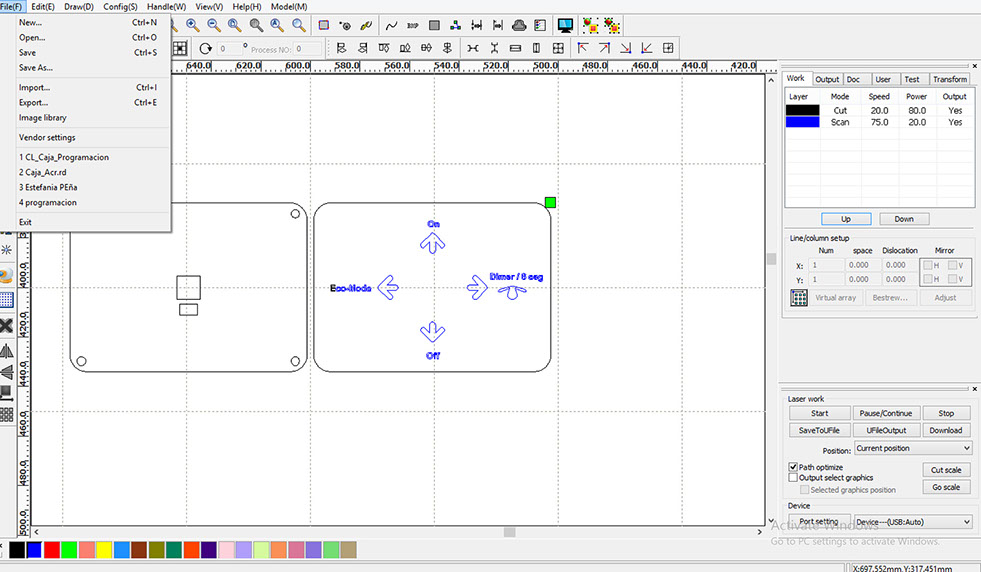

Open Smart Lamp Remote control laser cutting & Engraving

To make the pieces made by the laser cutting machine, the first step was to create Adobe illustrator .ai files.

Then, those files were imported into RDWorks software. Once imported, lines were classified between cutting and scan. Finally those files were exported for the machine.

%20163030.jpg?crc=3786487380)

I needed up adding my friend logo, painting nicely the box and adding some foam inside to protect the VR glasses.

Interface lit Laser cutting & engraving

The first layer includes the instructions and is a file that will be laser engraved. A CO2 Laser Bodor Machine was used to engrave the files.

The second layer has the design for laser cutting the screws and a middle opening for the gesture sensor. A CO2 Laser Bodor Machine was used to cut the file.

4. Then files are opened in Corel Draw. Here you select the image and select the plotter icon to generate the files.

- Select size and orientation of the file.

- Saved in a USB drive and place it in to the plotter.

- Placed the vinyl paper into the plotter and the machine was cutting.

- Use tiny tweezers to remove some pieces of the vinyl.

- After your sticker is ready you place the transfer paper in top of it so you can later remove it.

Acrylic light diffuser laser cutting

To can cut the diffuser light, files must be done in Adobe Illustrator software. Those files must be imported into RDWorks to be cutted. A CO2 Laser Bodor Machine was used to cut the files.

Oscar Velázquez