WEEK 14 / Apr 26

Composites

The assignment

- read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using

- design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it

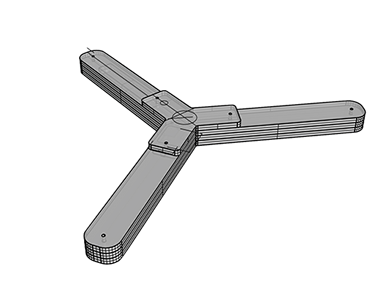

For this assignment I used the mold from Week 12 that I used of the Molding and Casting project since I wanted to continue adding value to the Fab Lab Coffee bar.

%201820391374x423.jpg?crc=4080772911)

%20072210.jpg?crc=3908371119)

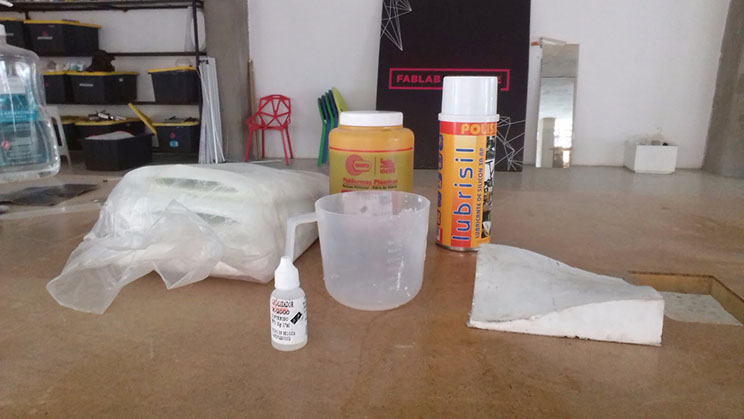

Materials to be used:

Fiberglass

Polyester Resin (PP38-MAQ)

Catalyst for resin (K-2000)

De-molding spray

1" Brush

Measuring glass

Scissors

Clean Silicon Mold

Mixer

1. Measure the Fiberglass to the size of the mold.

2. Divide the piece of fiberglass into layers

%20075237.jpg?crc=4055755181)

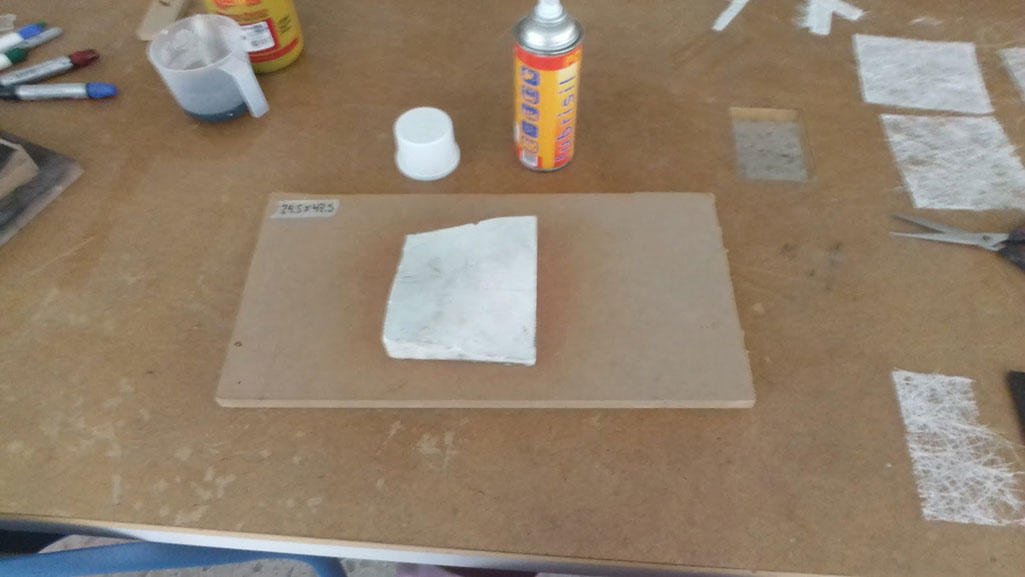

3. The area of the fiberglass helps calculate the amount of resin to be used; in this case 80 ml of resin. Clean the silicon mold and apply a layer of release spray on its surface and let it rest for 1 minute.

4. Clean the silicon mold and apply a layer of release spray on its surface and let it rest for 1 minute.

%20080830.jpg?crc=4280166507)

5. Following the manufacturer's specifications, to obtain 100 ml of 1.5% mixed resin, add 25 drops and at 2.0% add 33 (depending on temperature and climate), in our case we take the measuring glass with 80 ml of resin, add 20 drops of catalyst and mix.

%20082146.jpg?crc=366281933)

6. Using the brush apply a thin layer of resin and we add a layer of Fiberglass. Spread the the resin mixture on the layer, repeat this step until achieving the desired thickness.

%20082153.jpg?crc=4222971510)

7. Remove the fiber from the mold once it has hardened.

Oscar Velázquez