WEEK 12 / Apr 19

Molding and casting

The assignment

Design a 3D mold, machine it, and cast parts from it

The design process

At our Fab Lab we have a small terrace where we want to put a Coffee bar for all the fabbers to drink nice coffee and snack while they work in the Lab. The molding and casting project will produce a tile designed to cover the main Coffee bar.

%20182039.jpg?crc=3886579866)

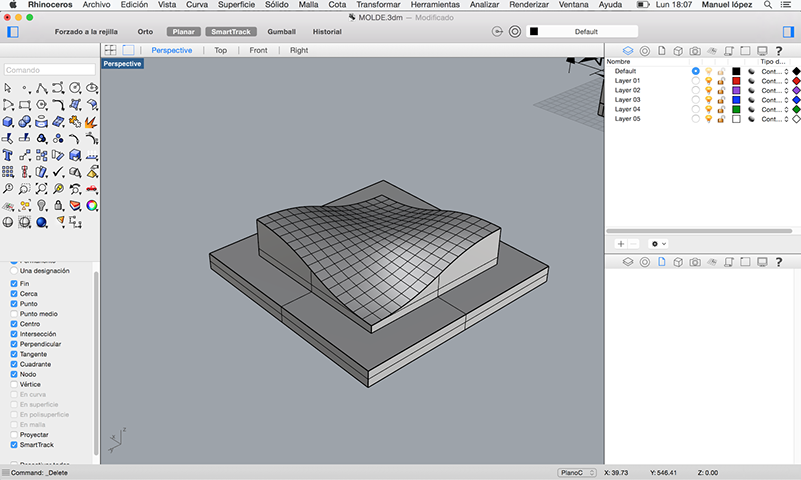

Rhinoceros is used for modeling (CAD) the part to make the first positive face. The objective is to carve an MDF solid base and then in case it into a press fit box that will hold the silicon material.

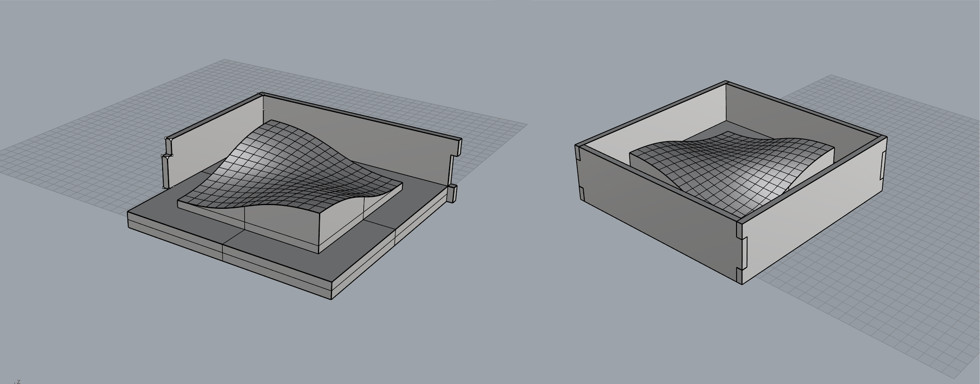

The walls represent a press fit box and was modeled and drawn in Rhinoceros.

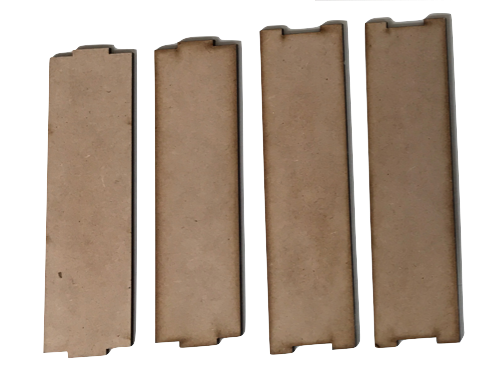

These are the 4 walls that will contain the silicon when casting.

The curves were exported in .DWG, and imported into the RD Works software to prepare it for laser cutting.

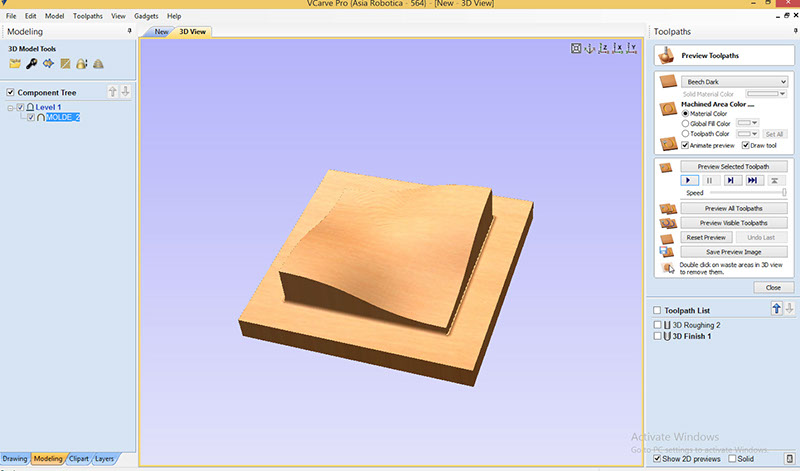

Post processing 3D files for CNC carving

After having the 3D design, the part is exported as .stl and then the part is then imported into the VCarve software.

In VCarve, the mold is imported as a 3D model.

Machining with CNC

- The first machining will be the "Roughing", which will remove the most material with the ½ "" end mill "drill bit, at 10 000 rpm.

- The second machining will be the "Finishing", with which the surface will be polished with a ¼ "nouse ball "drill bit, at 10 000 rpm.

%20201153.jpg?crc=197382540)

Laser Cutting the container Box

The container box was Laser Cut with 50 speed, and 70 lightning power into a 6mm MDF.

Casting the project

%20204334.jpg?crc=189239303)

The piece was sealed with Wood putty so that there was a pore-free surface, then it was sanded with a fine wood sand to suppress any imperfections.

%20205024.jpg?crc=4094567725)

The piece is painted with lacquer to further seal the MDF.

Subsequently transparent lacquer was placed to give the finish to be able to receive the release agent afterwards.

Vaseline was used as a release agent, which was uniformly placed over the entire surface.

%20205135.jpg?crc=57448442)

The silicone rubber P-53, of the mark "Poliformas", was prepared with a catalyst "TP". 100 drops of catalyst were added per 100 grams of silicon.

The mixture was emptied and allowed to dry for 3 hours.

Finally the silicon mold was ready to cast some mosaic tiles.

I used one fine cement mixture and colored in white, red and black.

hopefully this Mosaic tiles will be used for the Coffee bar at the Fab Lab.

First project not completed

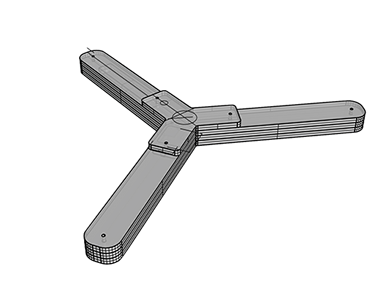

In the beginning of the assignment I tried to create key-chains with the logo of the Fab Lab I work at. The process was done in Grasshopper from Rhinoceros and I used some voronoy pattern to make it look cool. I wanted to mini mill it but the mini mill never worked.

%20210011.jpg?crc=3931750638)

Oscar Velázquez