COMPUTER-CONTROLLED CUTTING

The assignment this week was:

- Cut something on the vinylcutter

- Design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

I started with the parametric press-fit construction kit.

Parametric press-fit construction kit

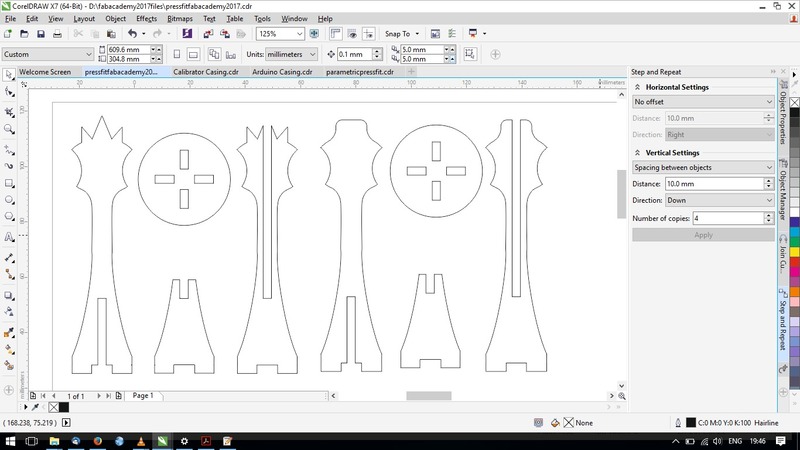

Software used; coreldraw.

I first made an attempt at press-fit construction without it necessarily being parametric. For this I designed and lasercut two chess pieces, the King and Queen.

The design:

The pieces are designed to be cut in 3mm acrylic.

I did a test cut using some grey 3mm acrylic I had lying around. The result...

I tested the fit, which was loose. After some small changes to the design to account for the kerf, I did the final cut on clear 3mm Acrylic...

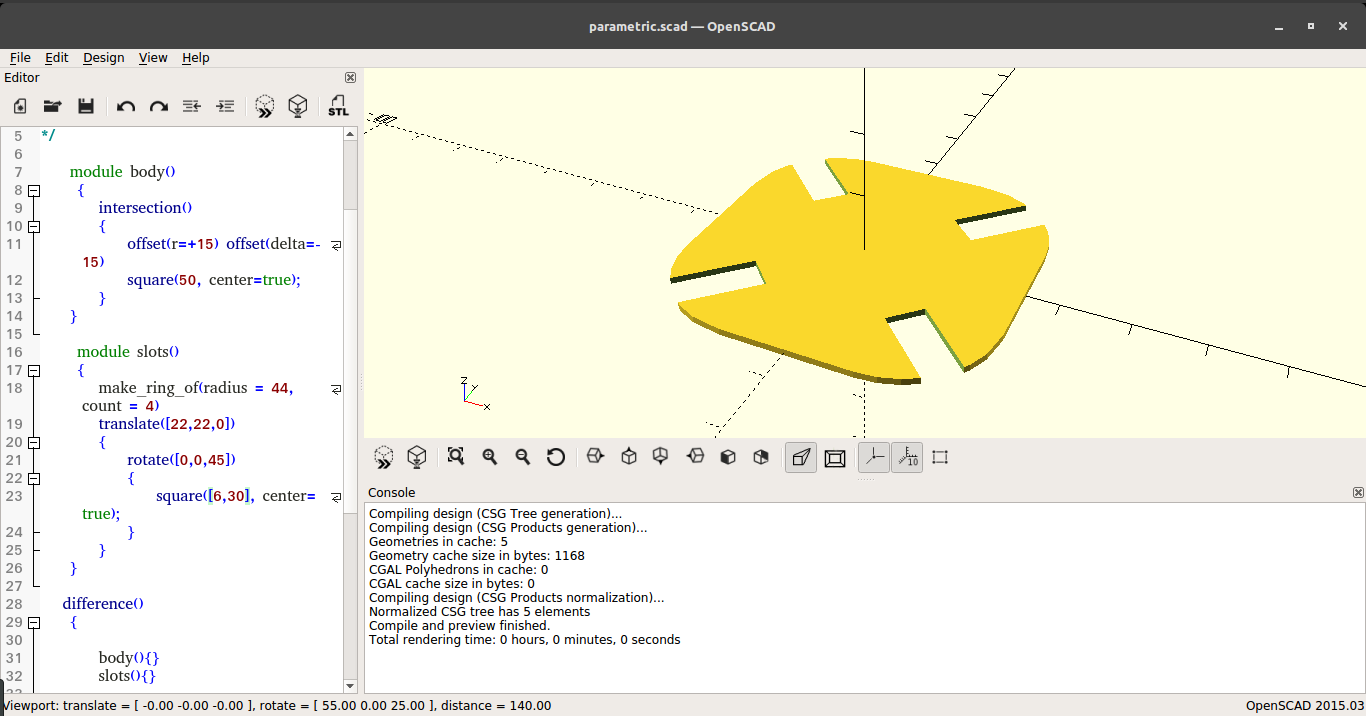

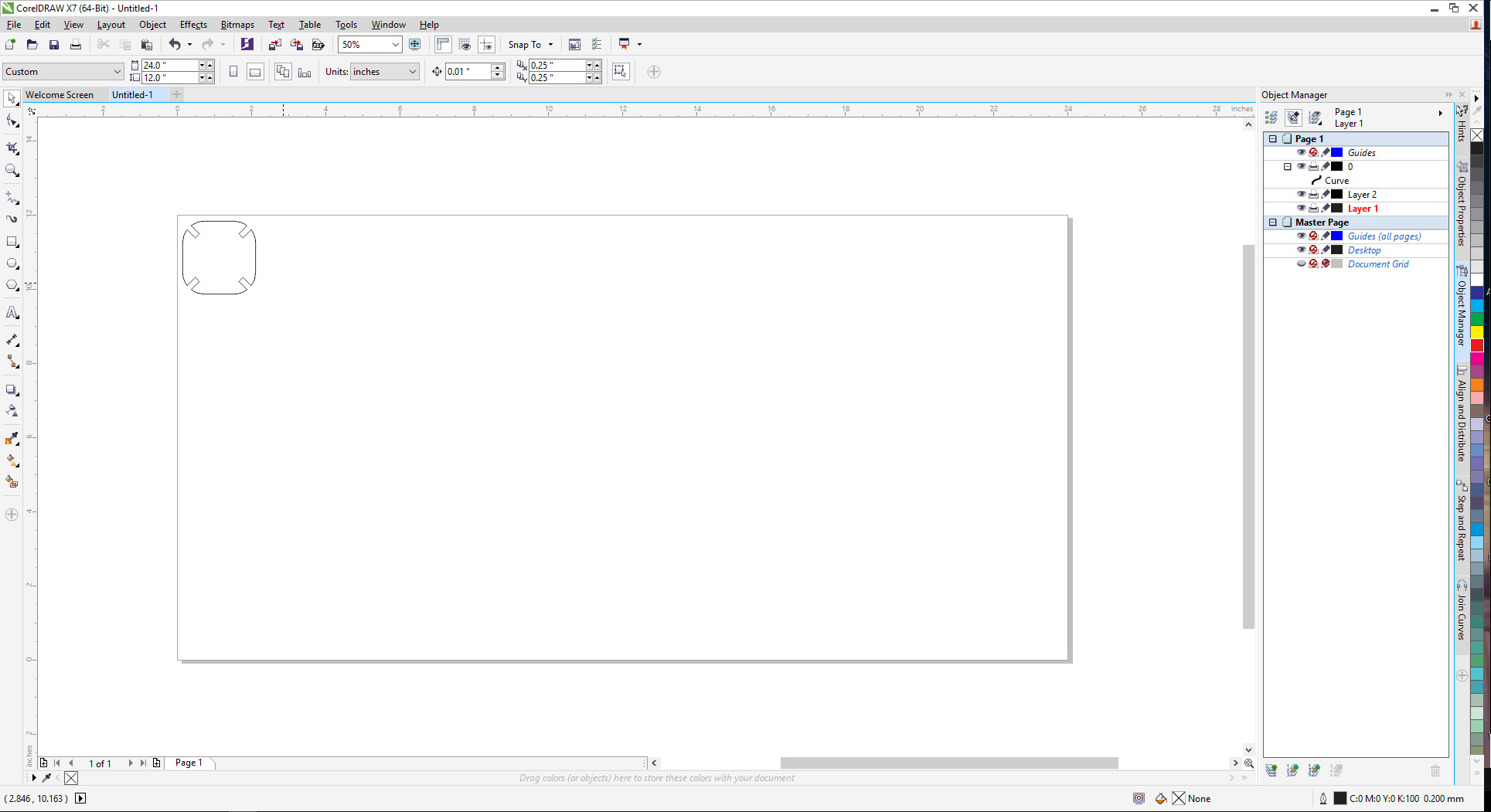

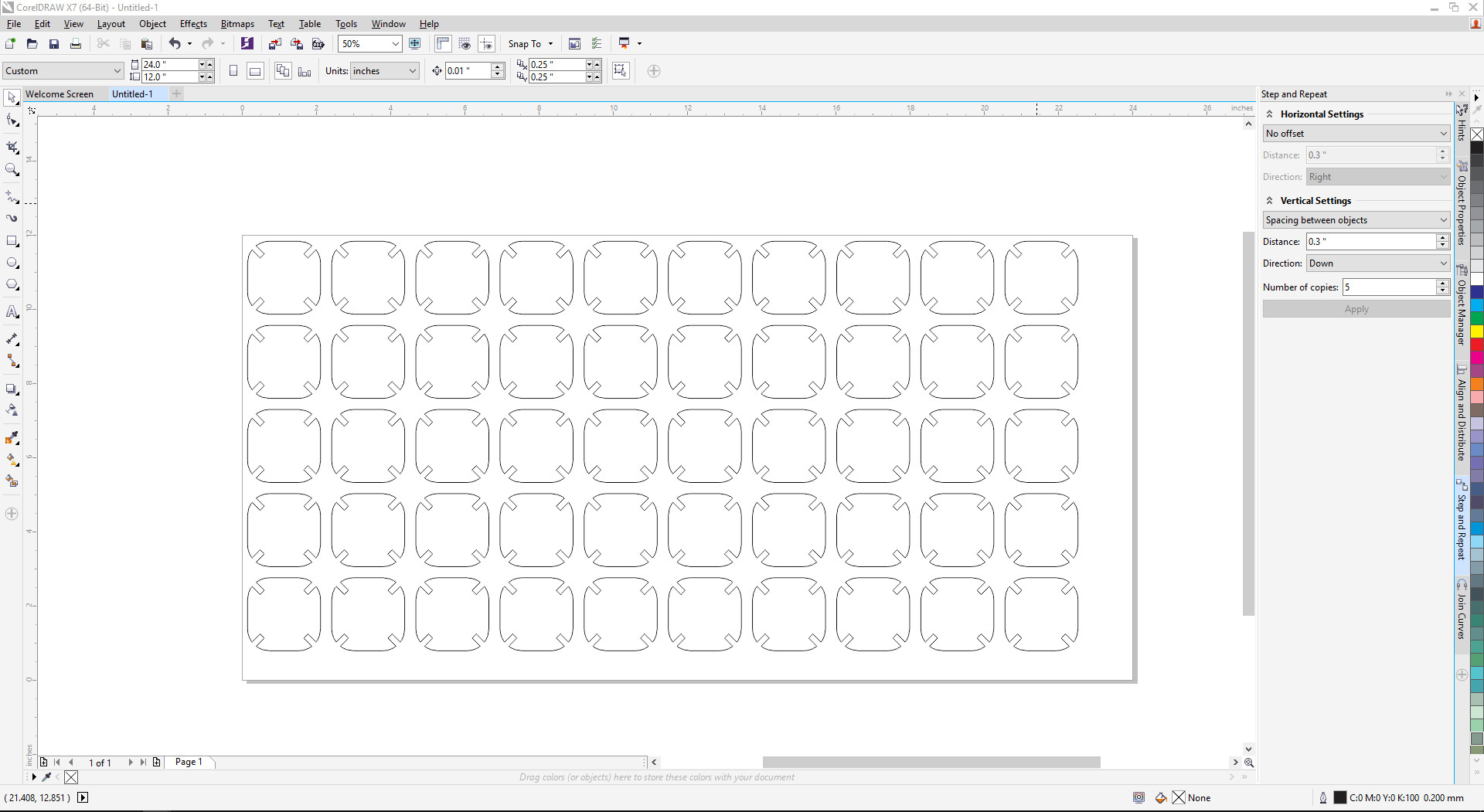

Finally, I got around to doing the parametric press-fit design.

The basic pieces in this kit are cubes with slots in the corners. The slots are where the cubes will be attached to each other.

Since this was a parametric design, I deided to use openscad to make the design. The result was...

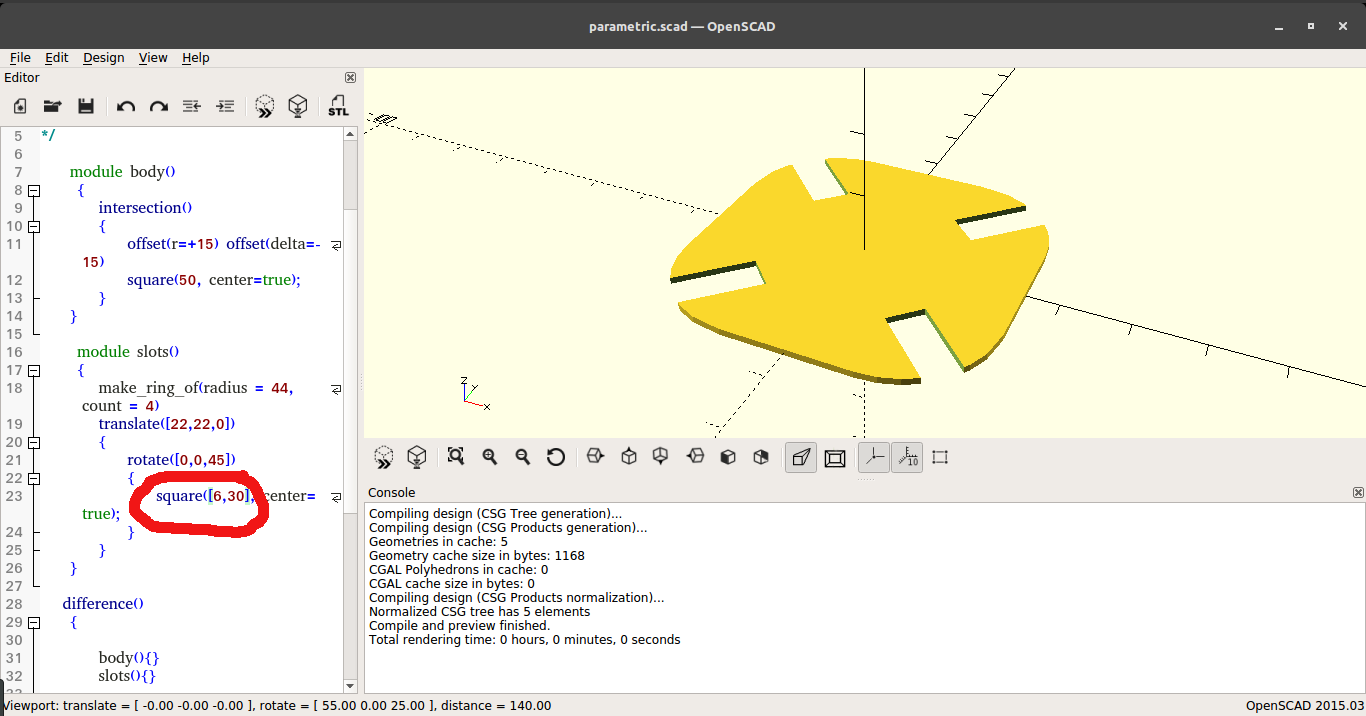

The circled area shows the code responsible for the size of the slots.

A copy of this code can be found here.

In order for the design to be parametric, I had to ensure that a variable was used that corresponded to the material thickness and by extension the width of the slots. I therefore changed the slot generating part of the code from...

square([6,30]

to...

square([mat_width,5*mat_width]

thus introducing the variable mat_width which is the material thickness.

The final code ishere.

I then rendered the design and exported a .dxf file which I then imported to corel draw and then sent to the laser cutter.

I then cut the cubes on 5mm thick cardboard.

The result...

Vinyl Cutter

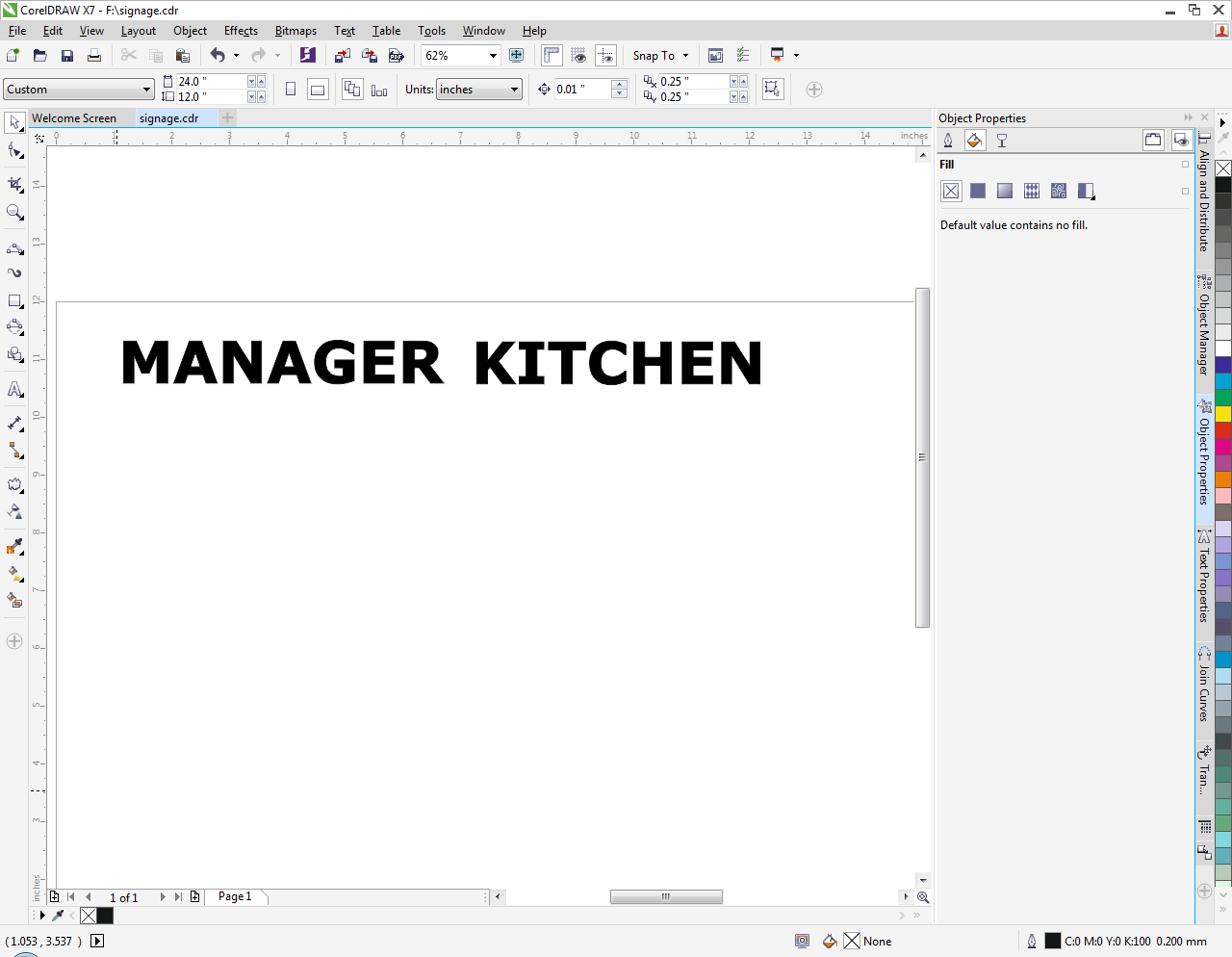

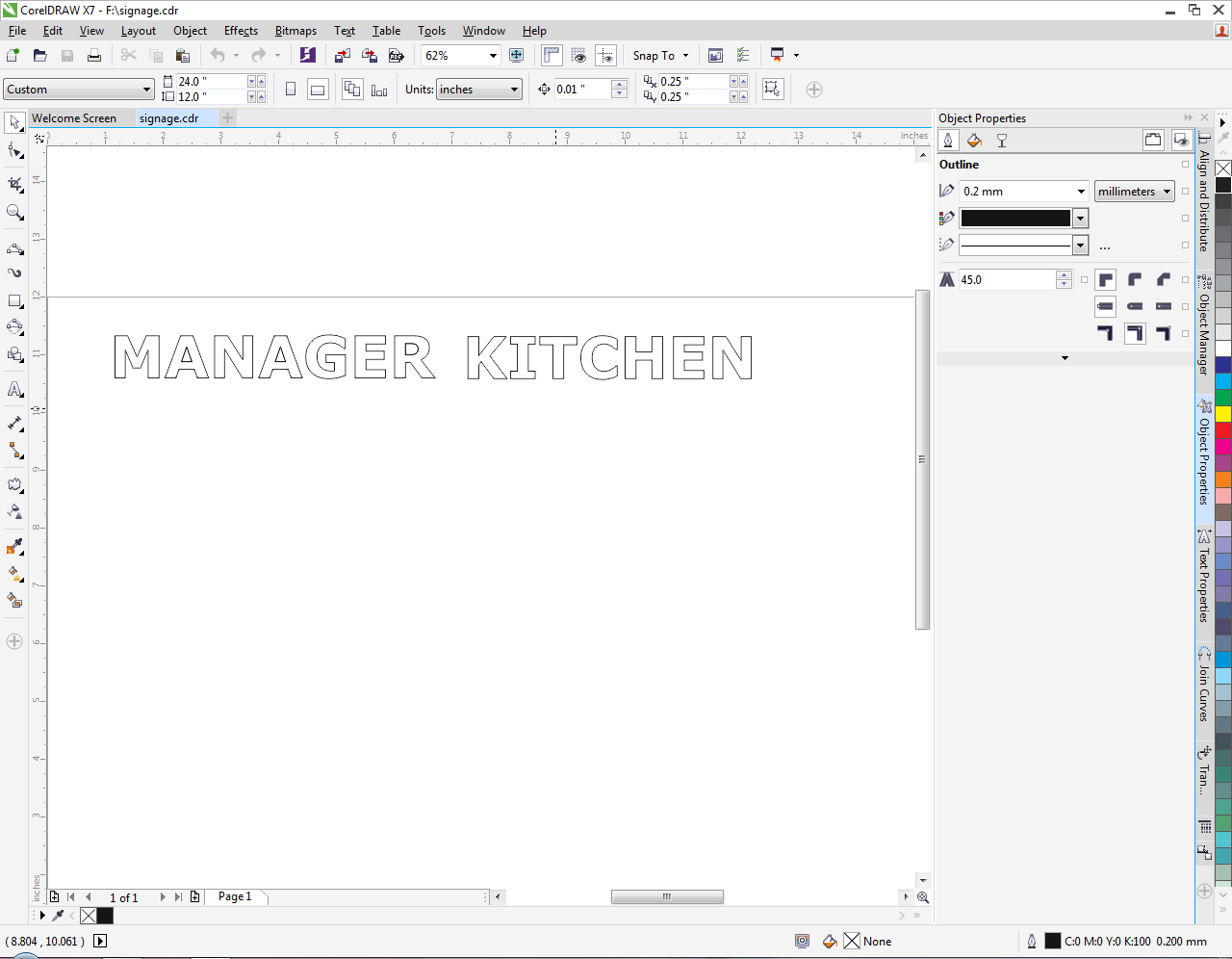

For this assignment, I decided to do something that had been pending for some time at the new lab;... door signs for some of the rooms, specifically the Manager's office and the Kitchen.

Before...

I designed the label in Coreldraw. I first created the text then extracted a an outline approximately 0.075mm or 0.003In (hairline in coreldraw) thick which I then proceeded to vinyl cut.

I had used the vinyl cutter before and already had the drivers installed so it did not present much of a problem to me. The drivers allow the vinyl cutter to be treated as a printer so vinyl cutting is as straightforward as printing.

Switching on the vinyl cutter...

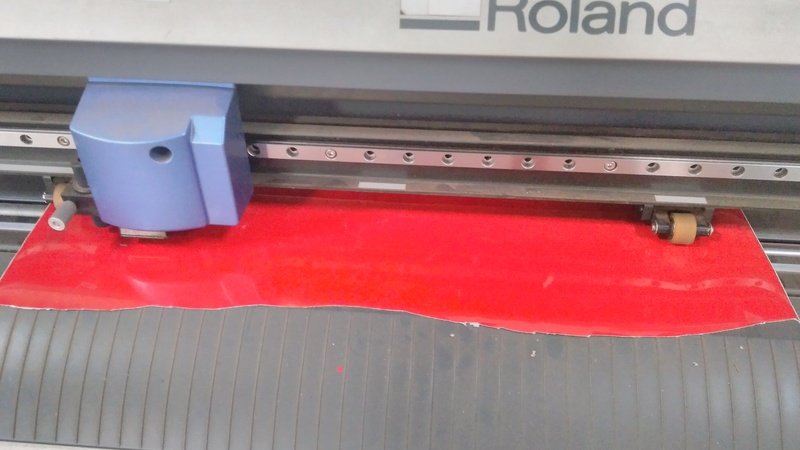

Selecting material type, which in my case was a roll of red vinyl...

Vinyl cutter ready to go...

Vinyl cutting done...

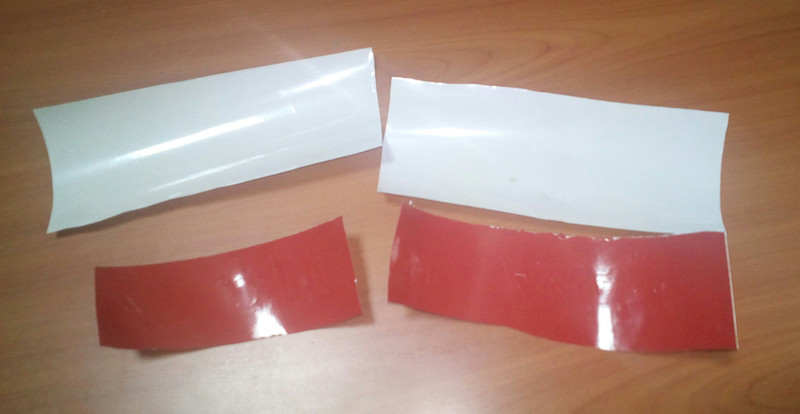

With transfer paper before weeding...

After weeding...

Ready to transfer...

Transfering to the Kitchen door...

Transfering to the Manager's door...

Assignment wise:

- Cut something on the vinyl cutter

- Design, make, and document a parametric press-fit construction kit

Files

OpenSCAD files

DXF files

Coreldraw files