composites

Assignments;

- Read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using

- Design and fabricate a 3D mold and produce a fiber composite part in it

The resin and hardener we had available was Henkel's and so I went online to search for the safety and technical datasheets.

Of note were:

Composition/Information on Ingredients

First Aid measures

Fire Fighting measures

Accidental release measure

Handling and storage

Exposure controls.Personal Protection

Stability and Reactivity

Disposal conditions

For this assignment I wanted to work with the Bishop I had designed for Week12:Molding and Casting for my mold.

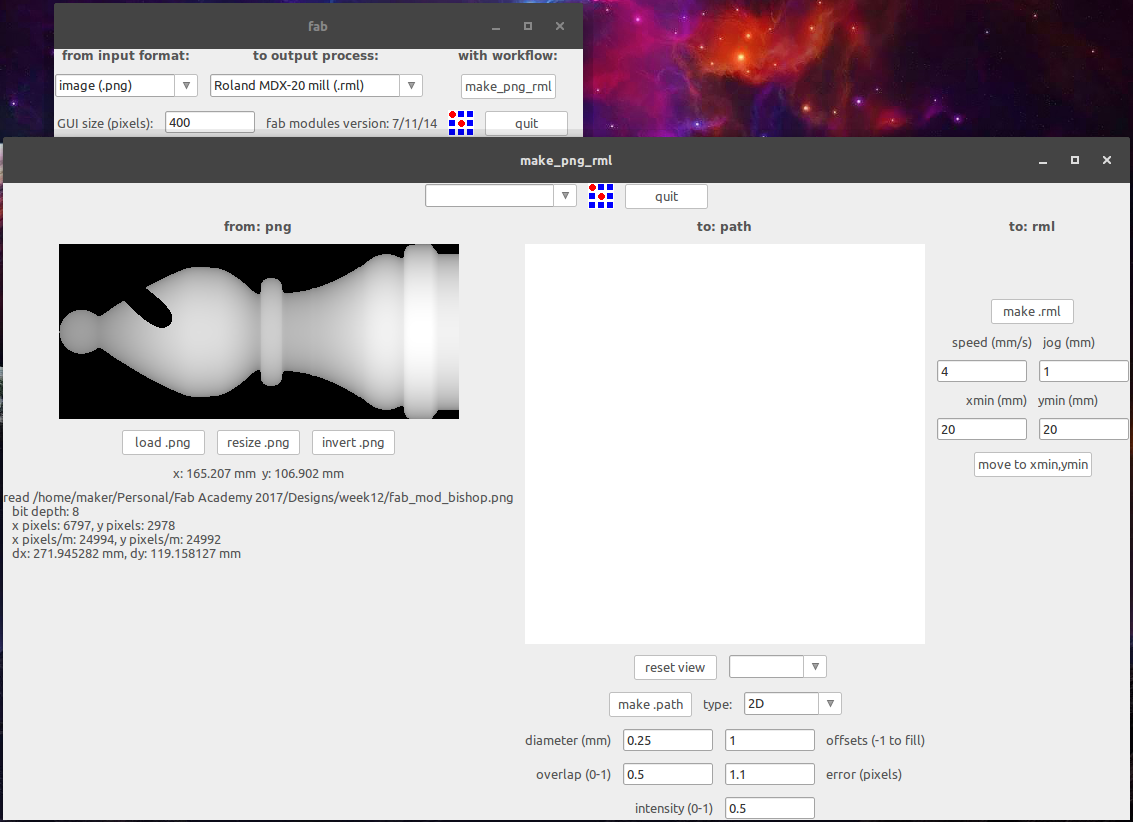

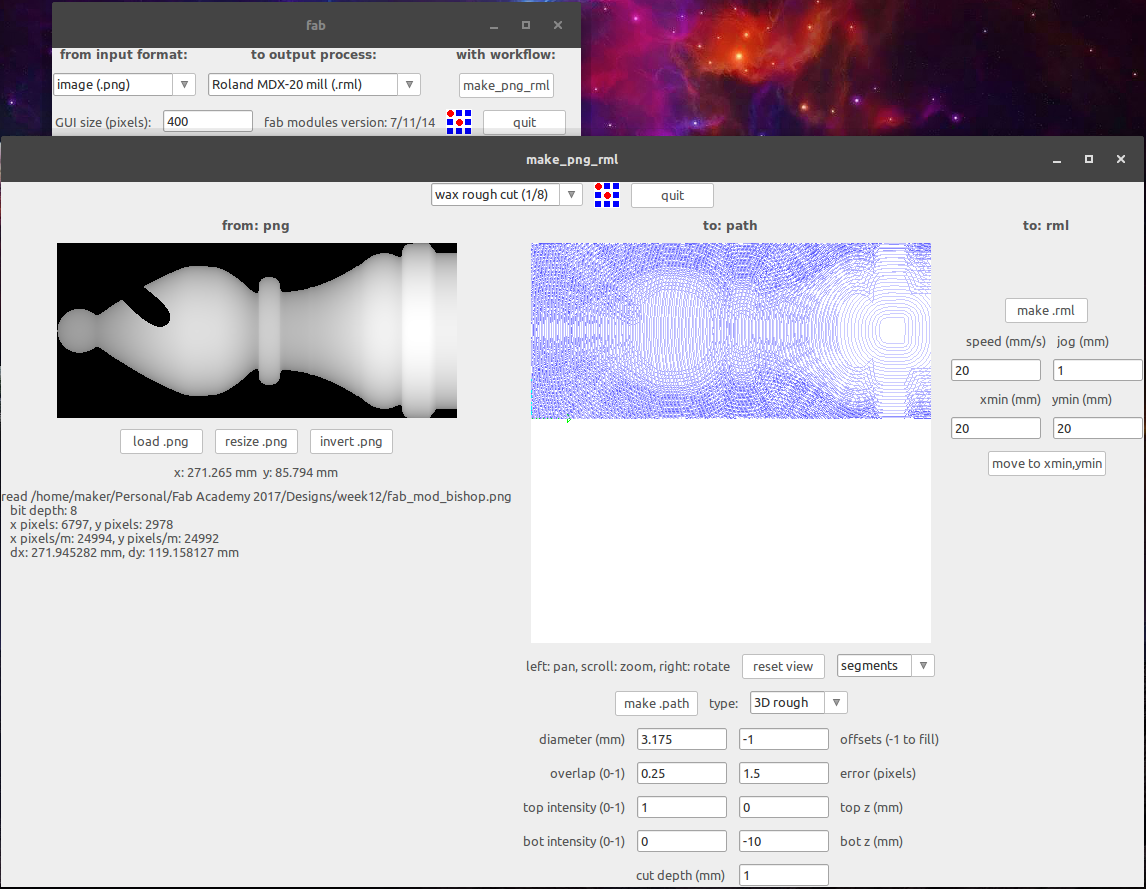

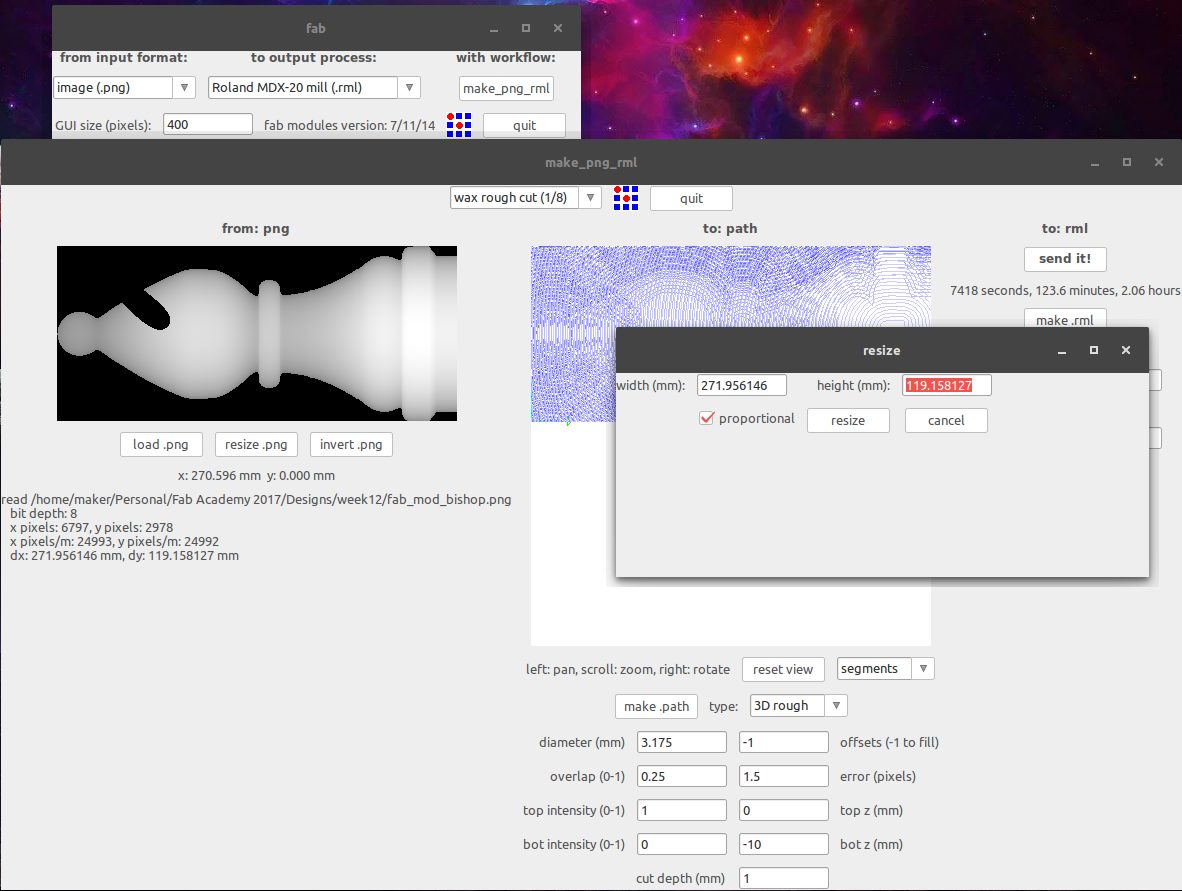

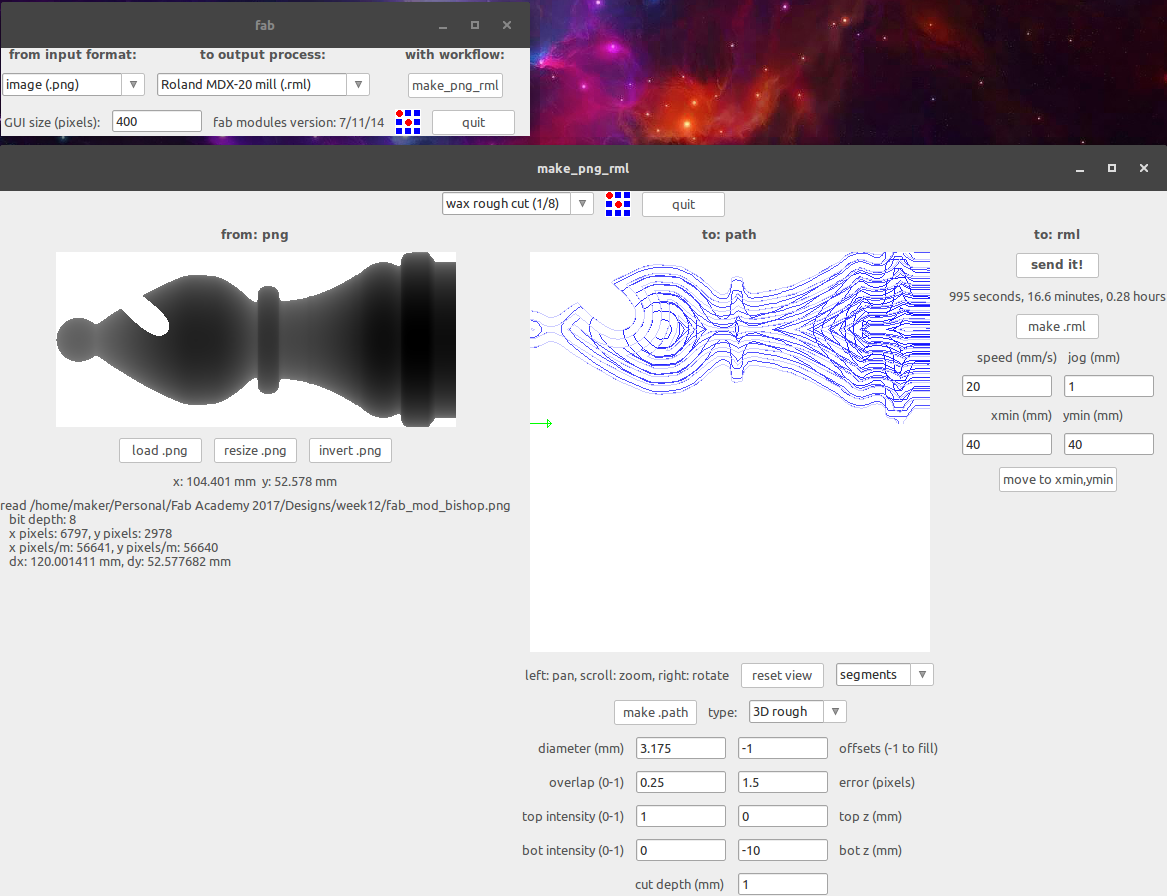

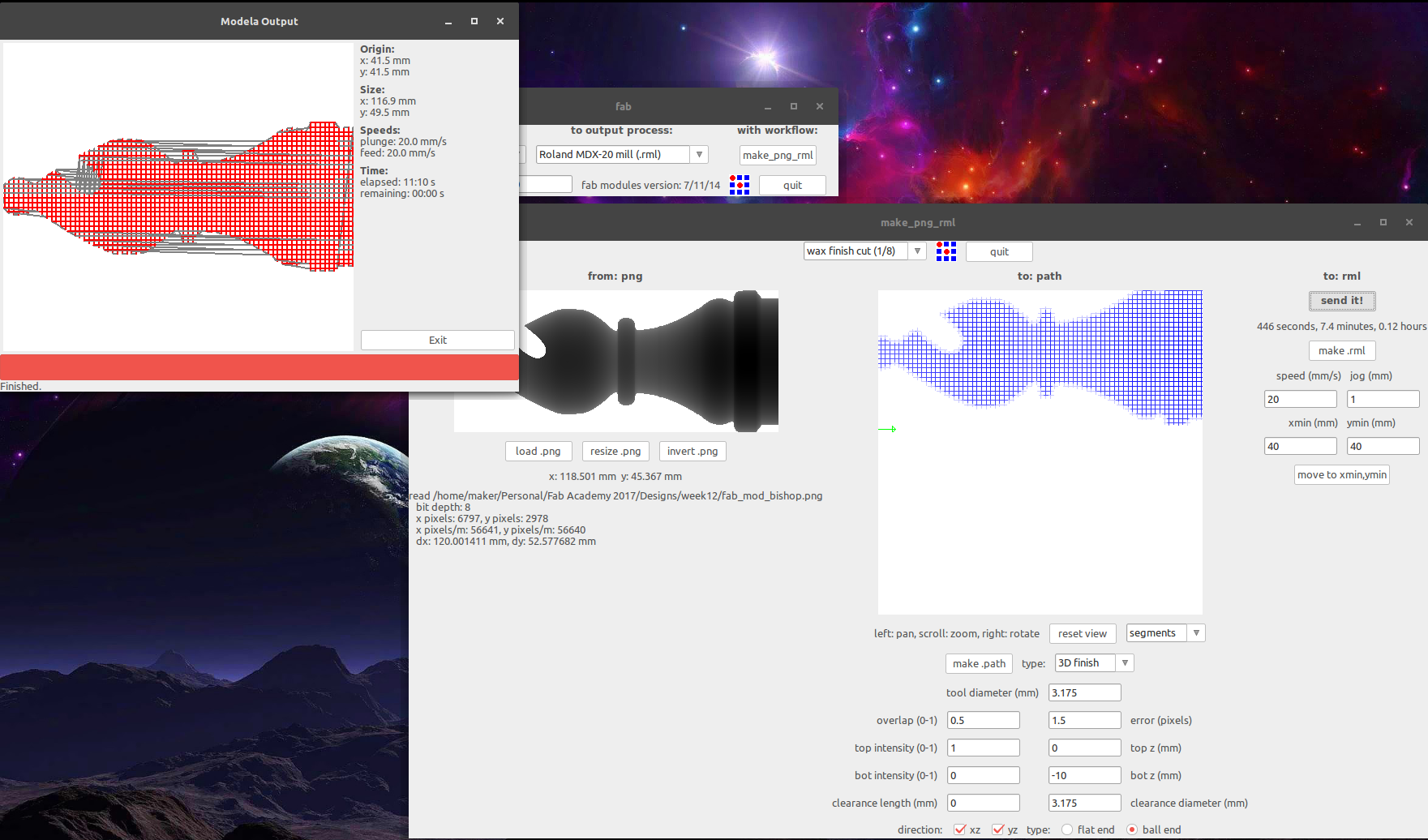

I opened fabmodules and opened the .png file that I had available from week12.

I resized the model from the fabmodules interface.

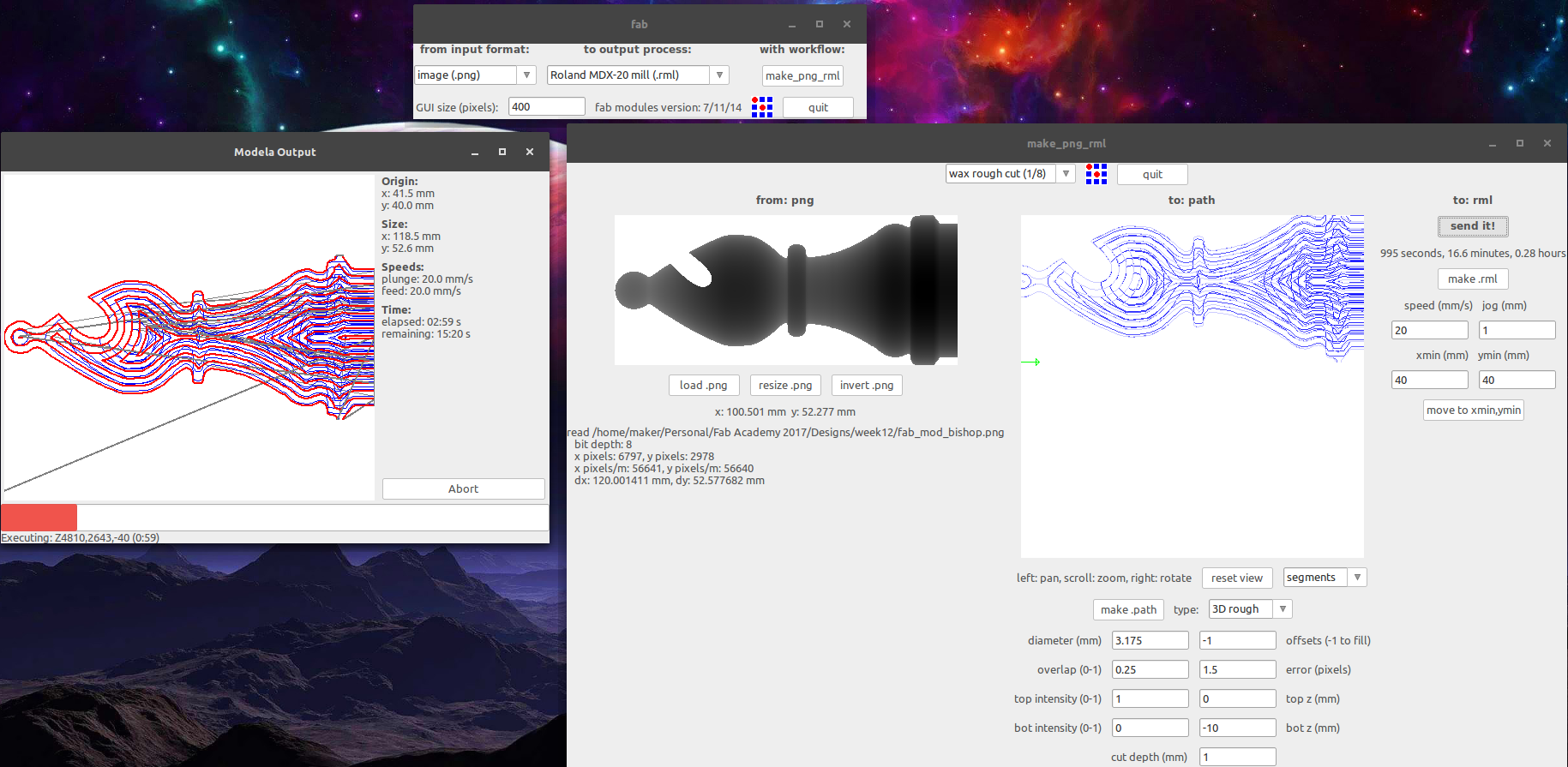

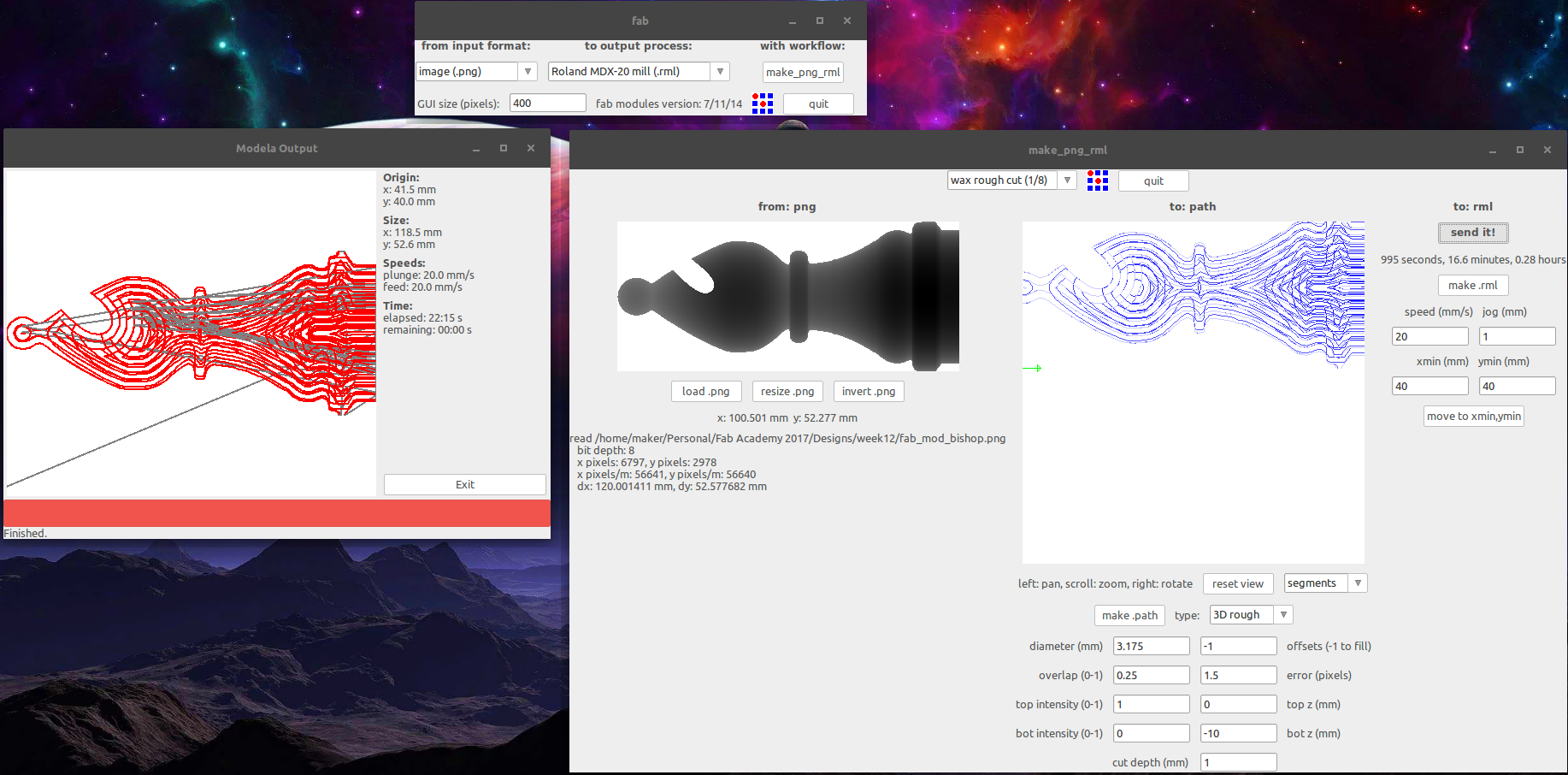

I inverted the .png file so as to create a negative mould and set it up for the rough mill and sent it to the machine.

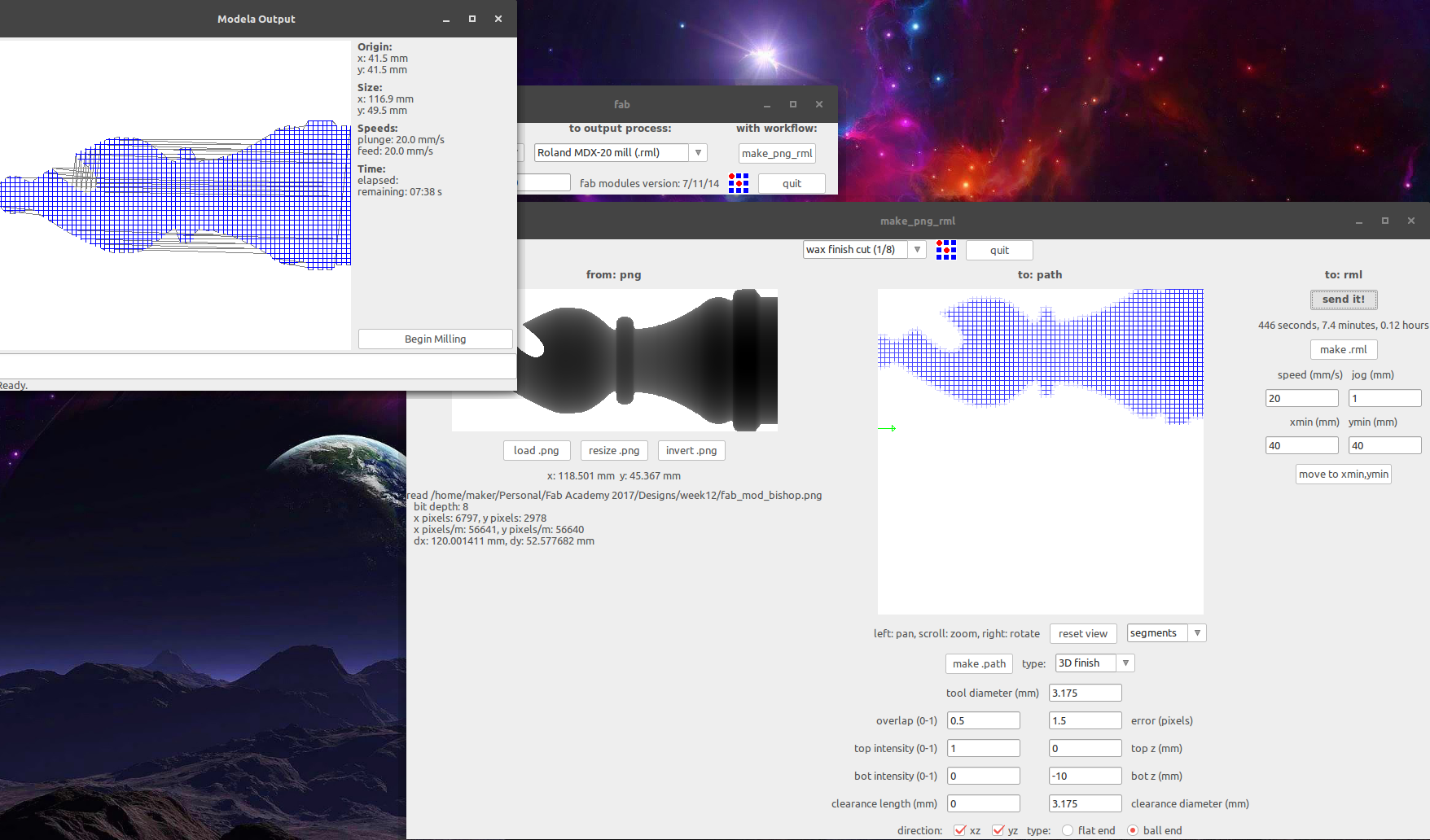

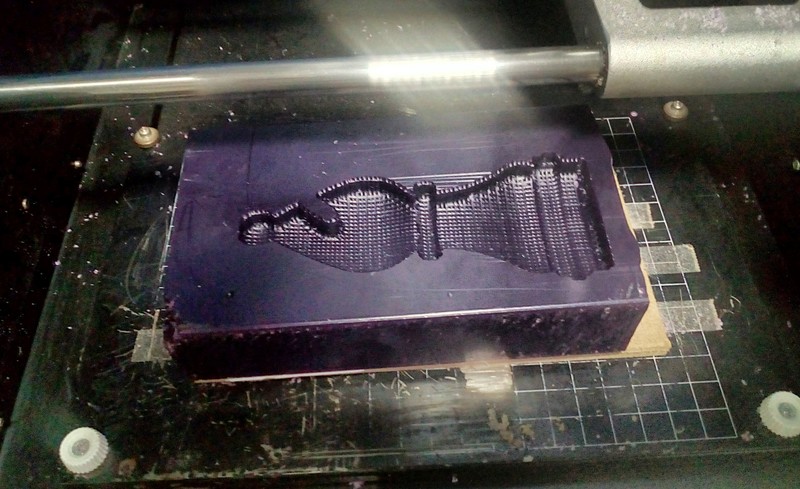

Once the rough mill was done I prepared and sent the finish mill.

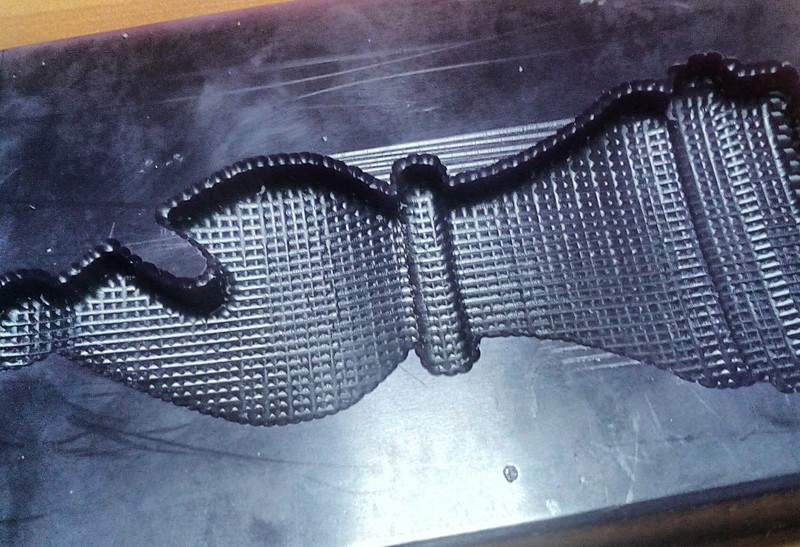

The result was...

Putting everything together in preparation to create composite...

I mixed the resin and hardener in a resin:hardener ratio of 2:1

I applied a small amount of petroleum jelly to allow the composite come off the mold. I applied the first layer of fibreglass and applied the resin mixture using a paint brush. I did this for 3 layers and finally...

I put the mold into an airtight static bag. I then used our handheld vacuum to create a vacuum.

3 hours later...

Assignment wise:

- Read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using

- Design and fabricate a 3D mold and produce a fiber composite part in it

Files

Rhinoceros files (.3dm)

Stereolithography files (.stl)

Images