COMPUTER-CONTROLLED MACHINING

Assignment; make something big.

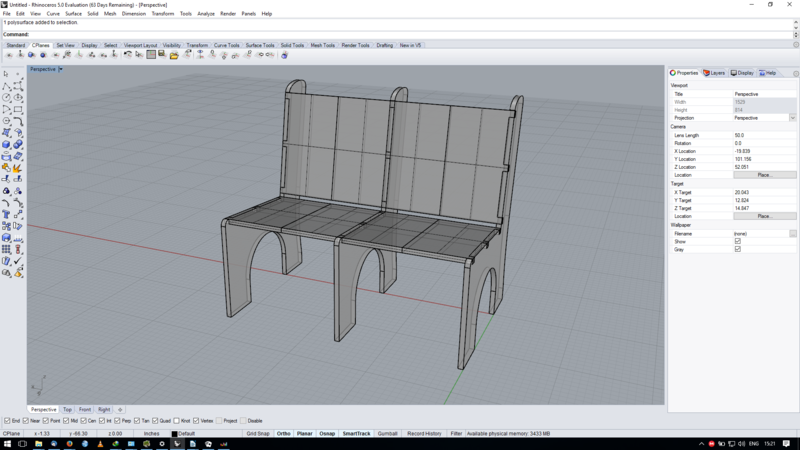

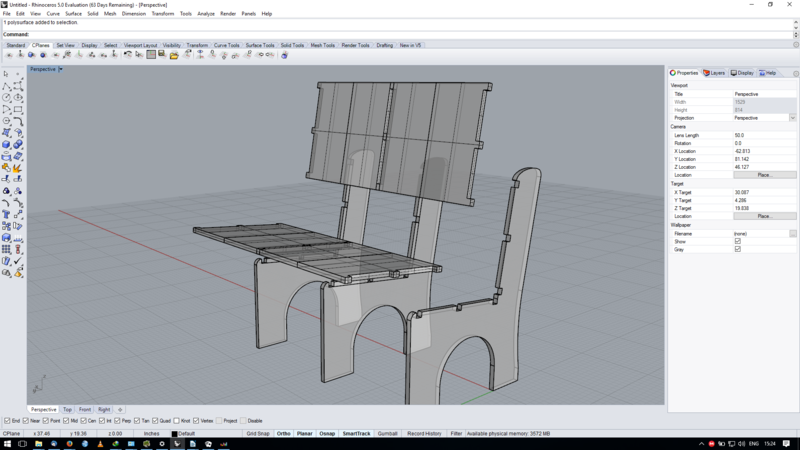

As part of the assignment, I decided to make a park bench.

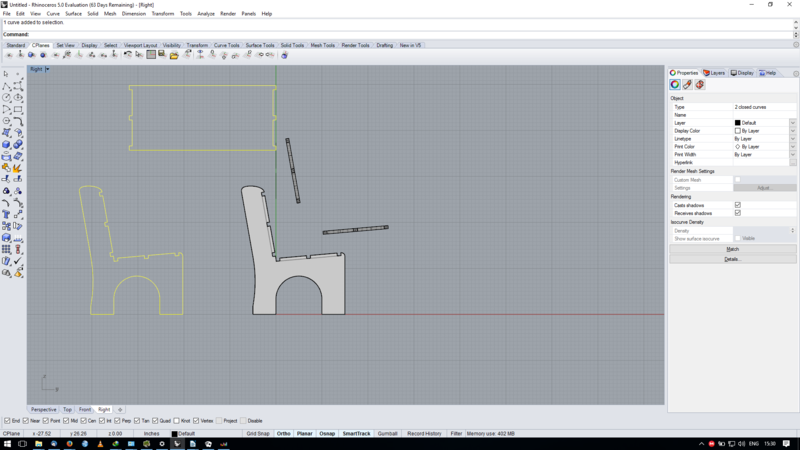

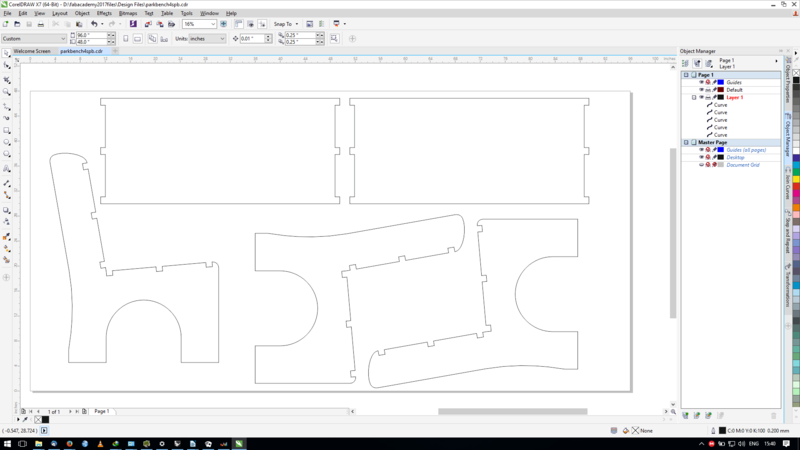

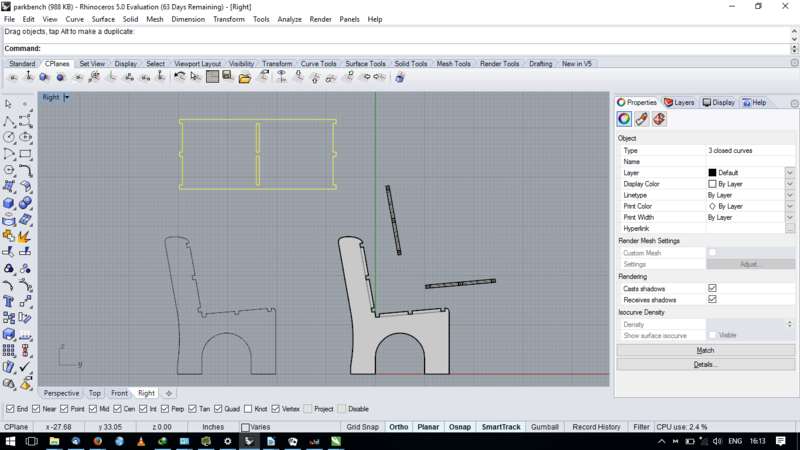

I did the concept design on rhinoceros and extracted the curves in .dxf format.

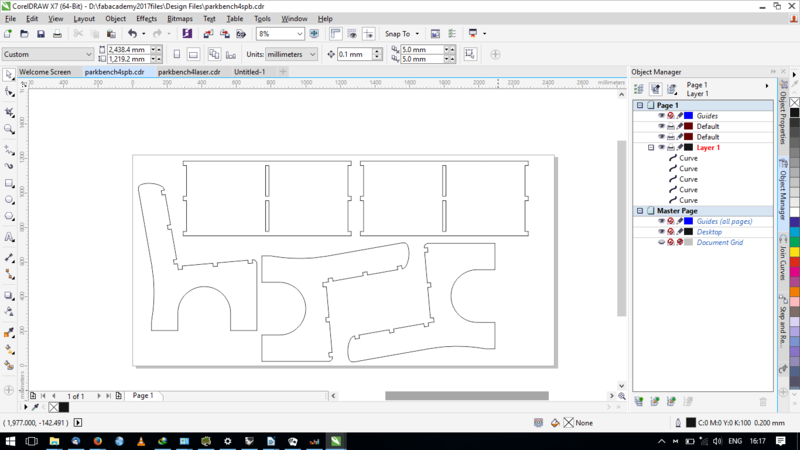

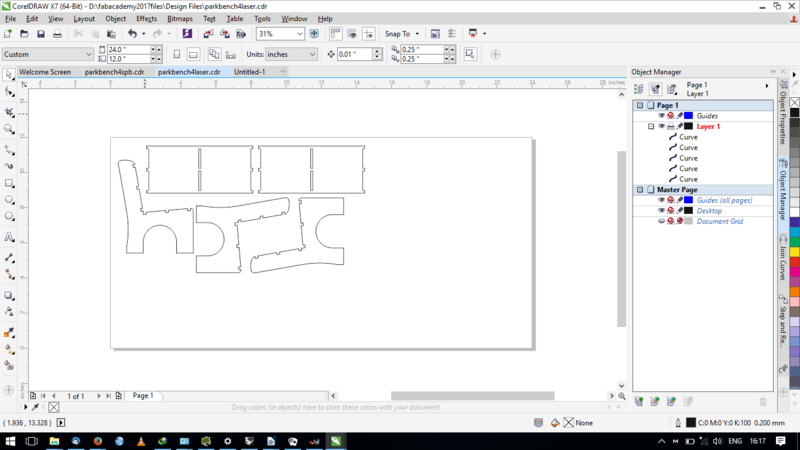

I then imported the dxf file into corel draw and edited it to enable me to run a test-cut with the laser-cutter. I scaled the design down for use with 3mm acrylic.

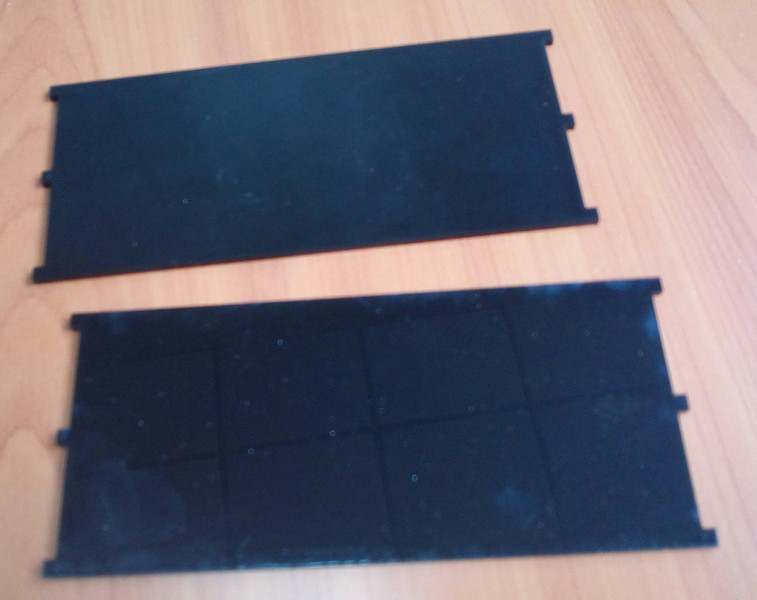

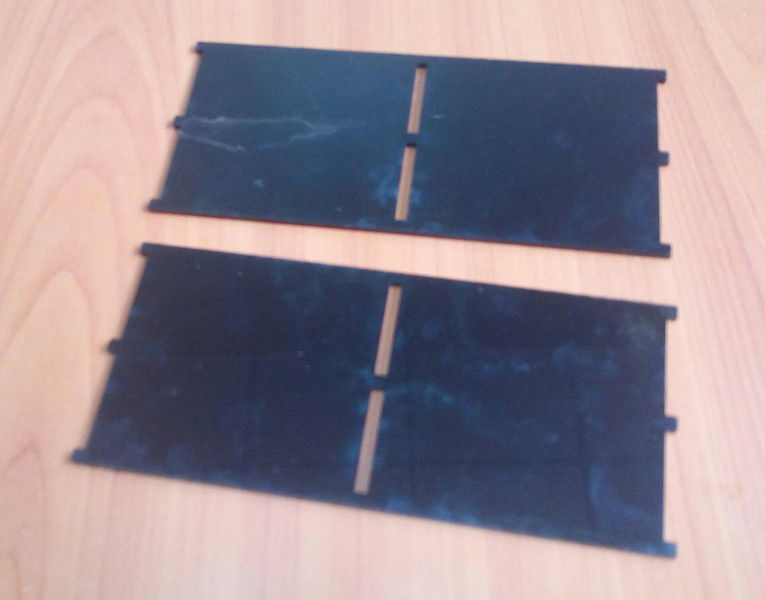

The first cut revealed some fatal errors in the seat and back pieces.

I went back into rhinoceros and extracted a new .dxf file and following the same procedure I finally got proper seat and back pieces.

I assembled it...

In order to increase stability, I made some changes and laser-cut the files.

Next up, the final object.

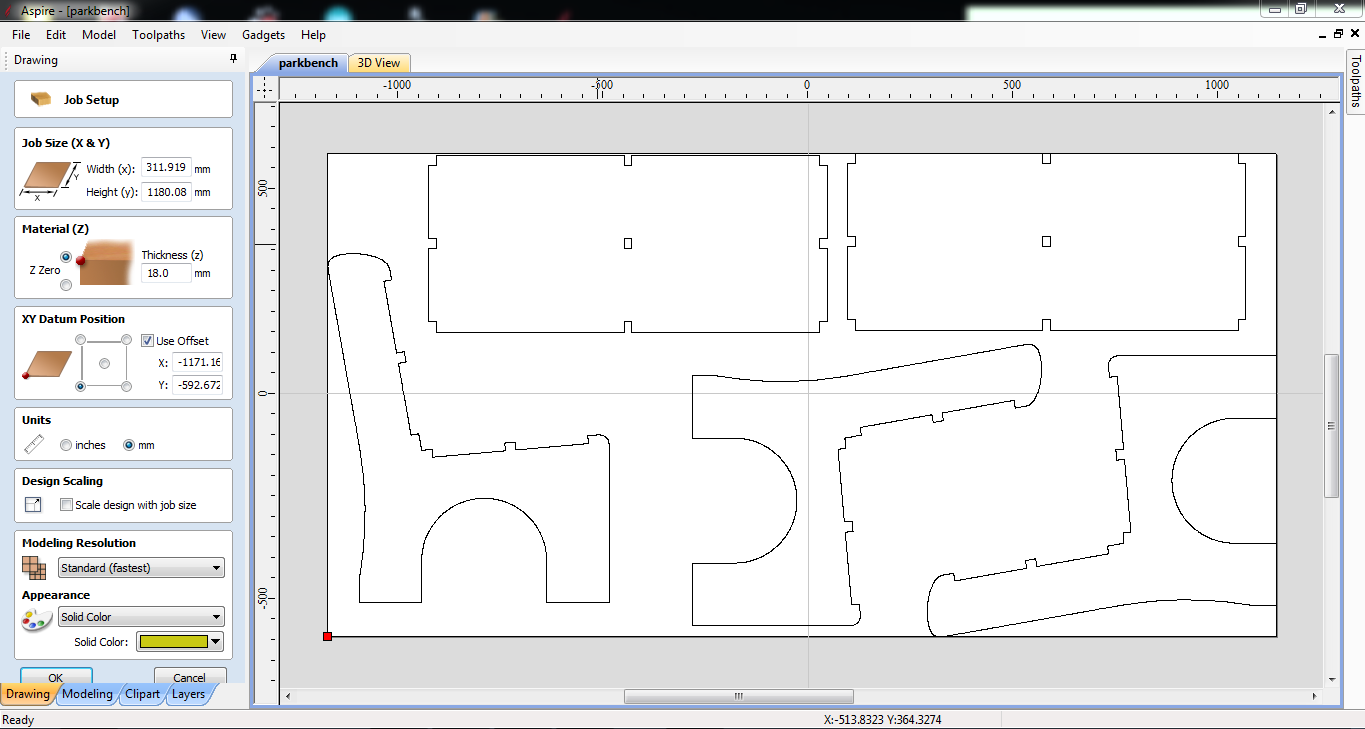

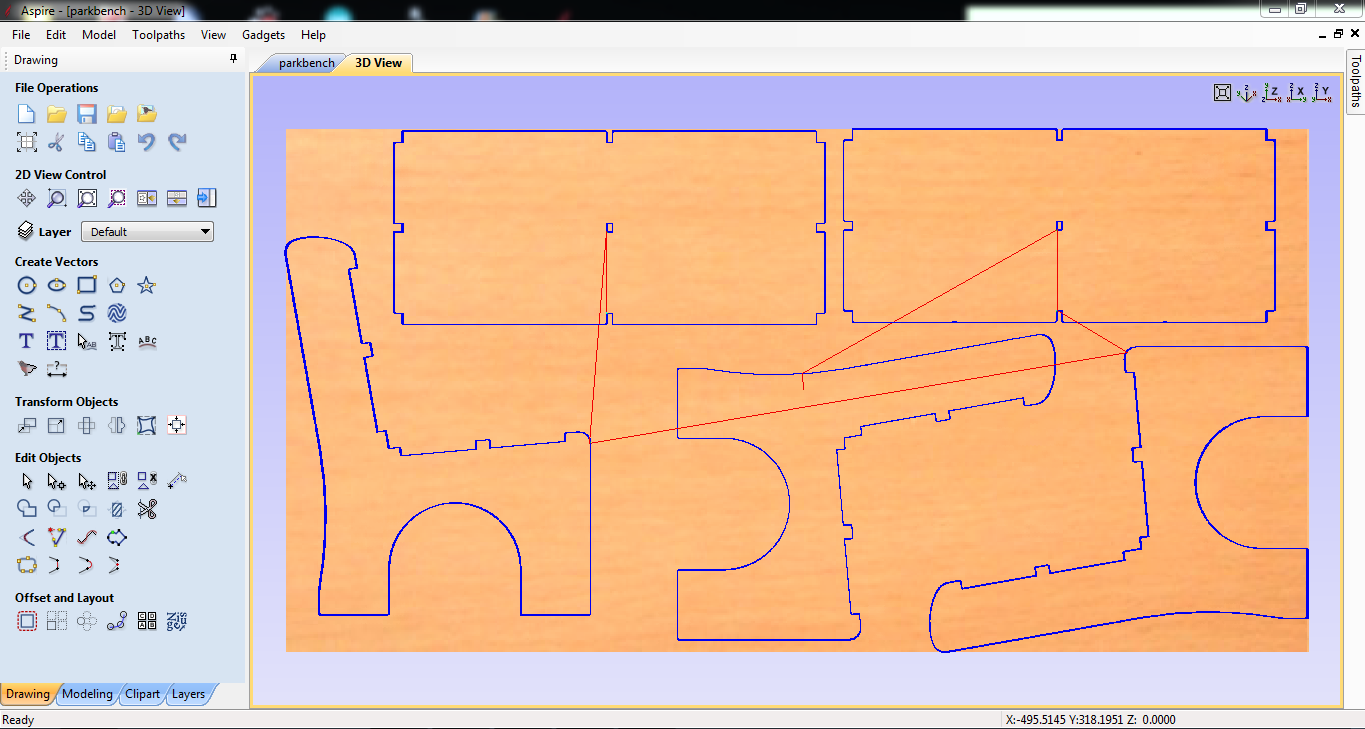

Importing the dxf file and setting up...

Generating the toolpaths...

I used 18mm MDF. The MDF was held down using nails as shown in the closeup...

The result ...

After assembly...

Taking a breather after some had work...

Assignment wise:

- Make somethomg big

Files

Rhinoceros files (.3dm)

Autocad files (.dxf)

Coreldraw files (.cdr)