- Materials, softwares and machine

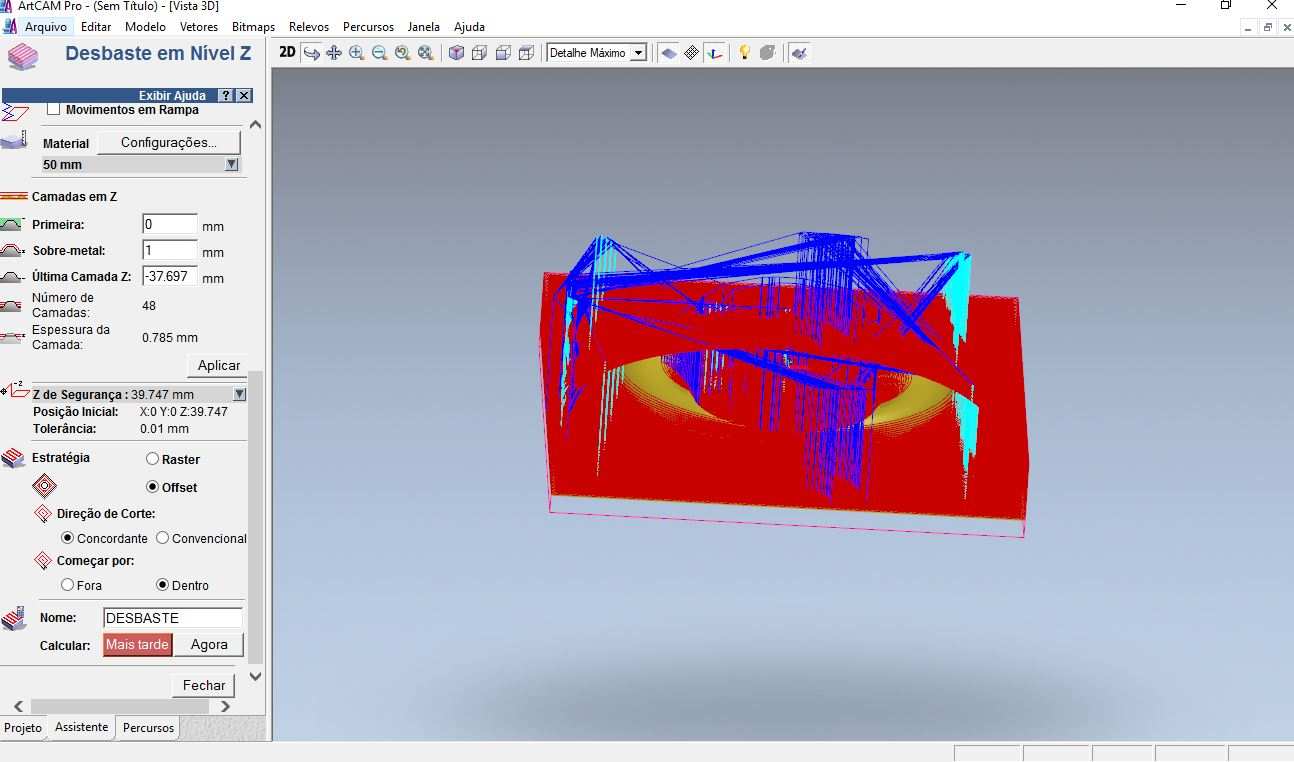

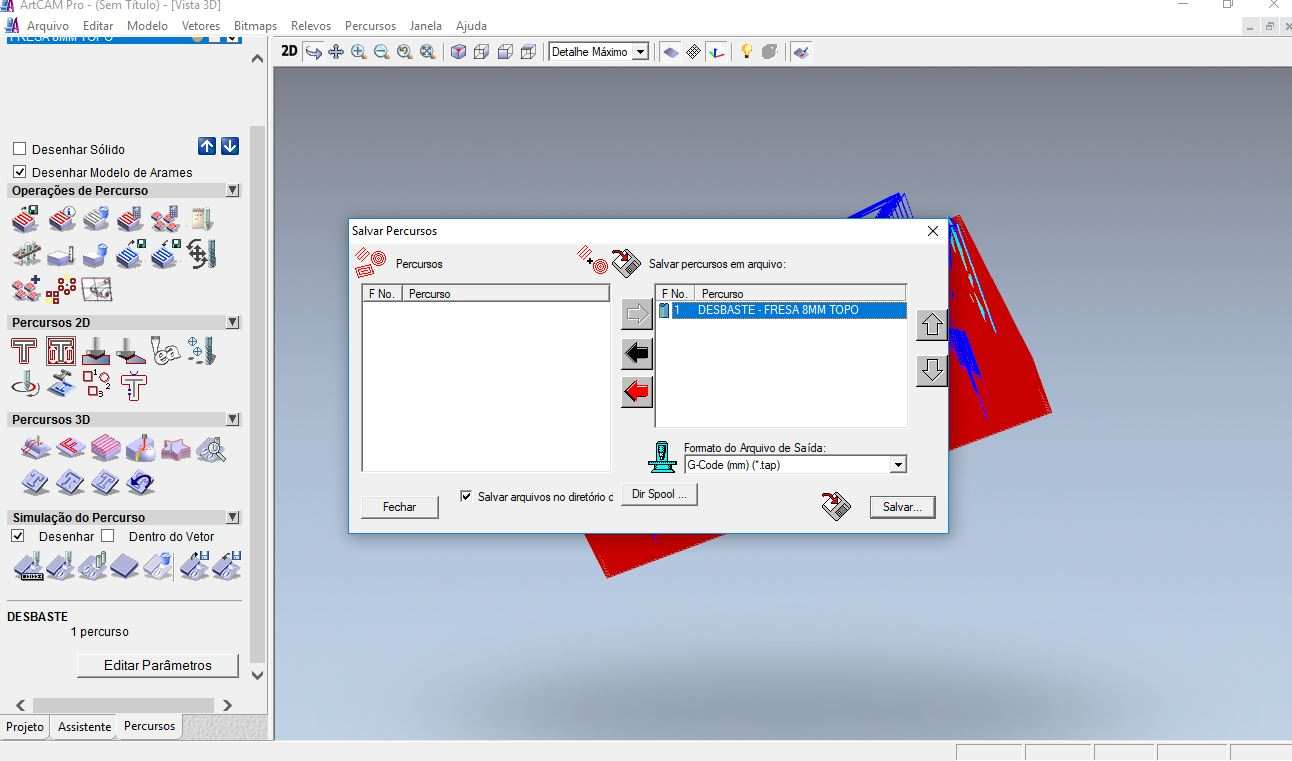

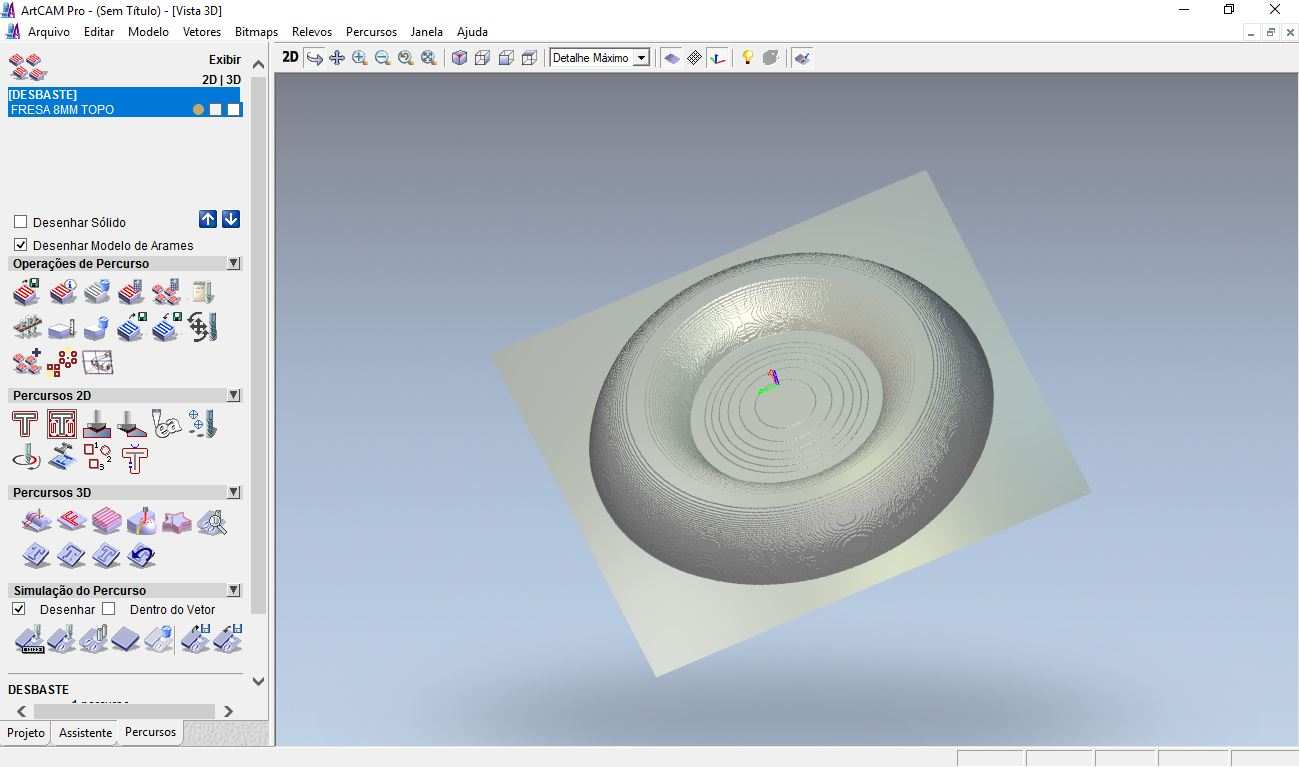

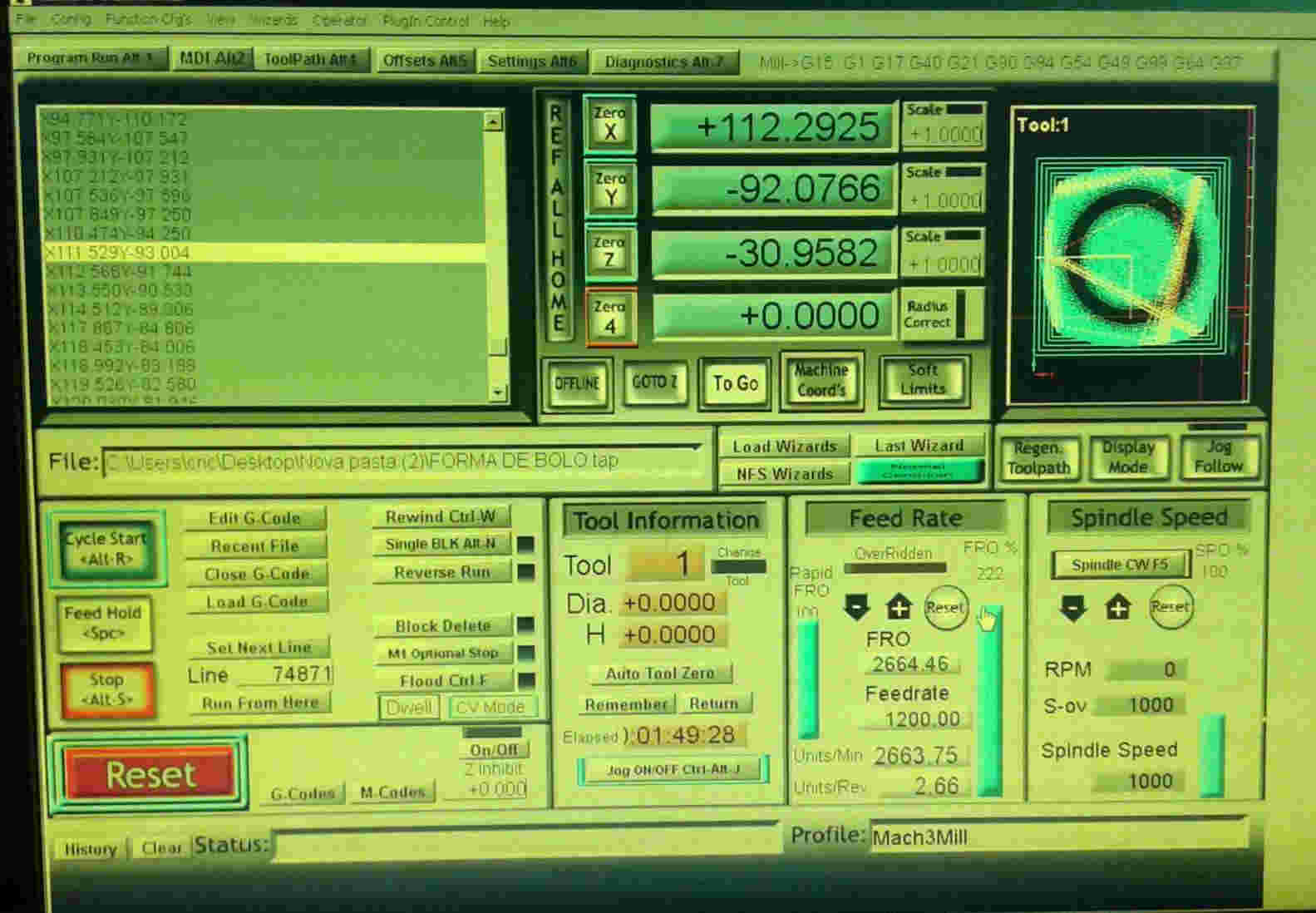

- Rhinoceros3D (CAD), Artcam (CAM/Gcode) and MARCH3

- Wood block 500 mm x 300 mm x 50 mm (Caesalpiniaceae wood.)

- CNC Mill

- Fabricating the base

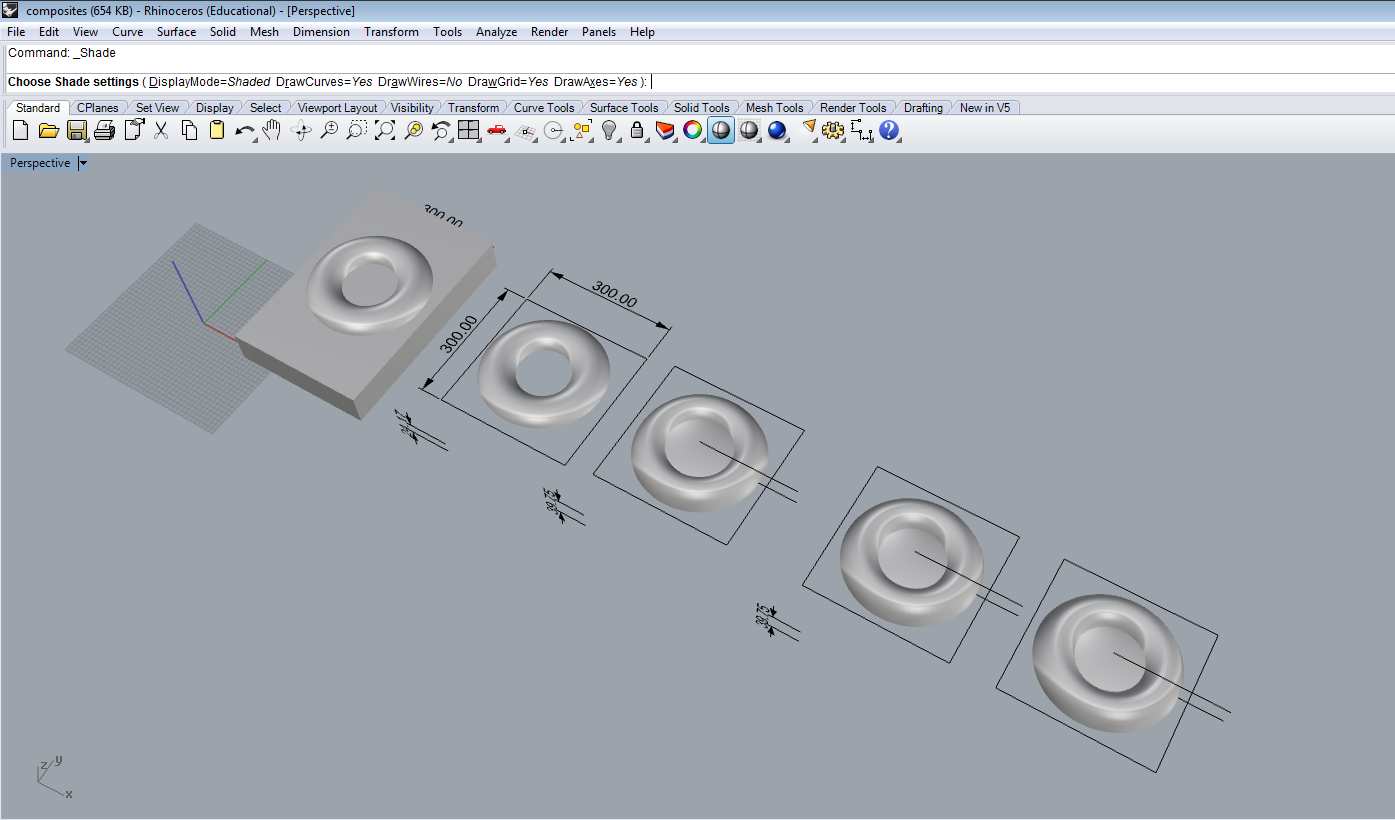

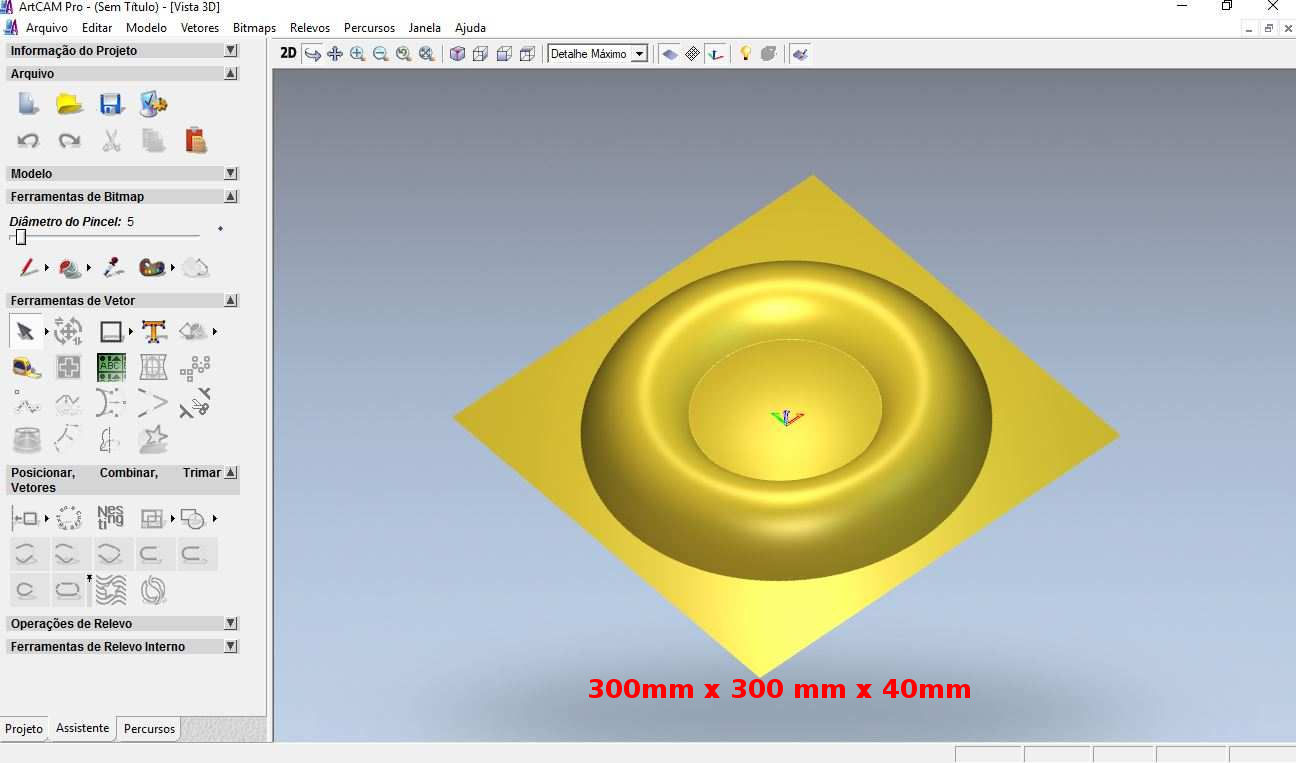

To do the composities I draw a simple torus (300 mm x 300 mm) in Rhinoceros 3D to mill it in a wood block.

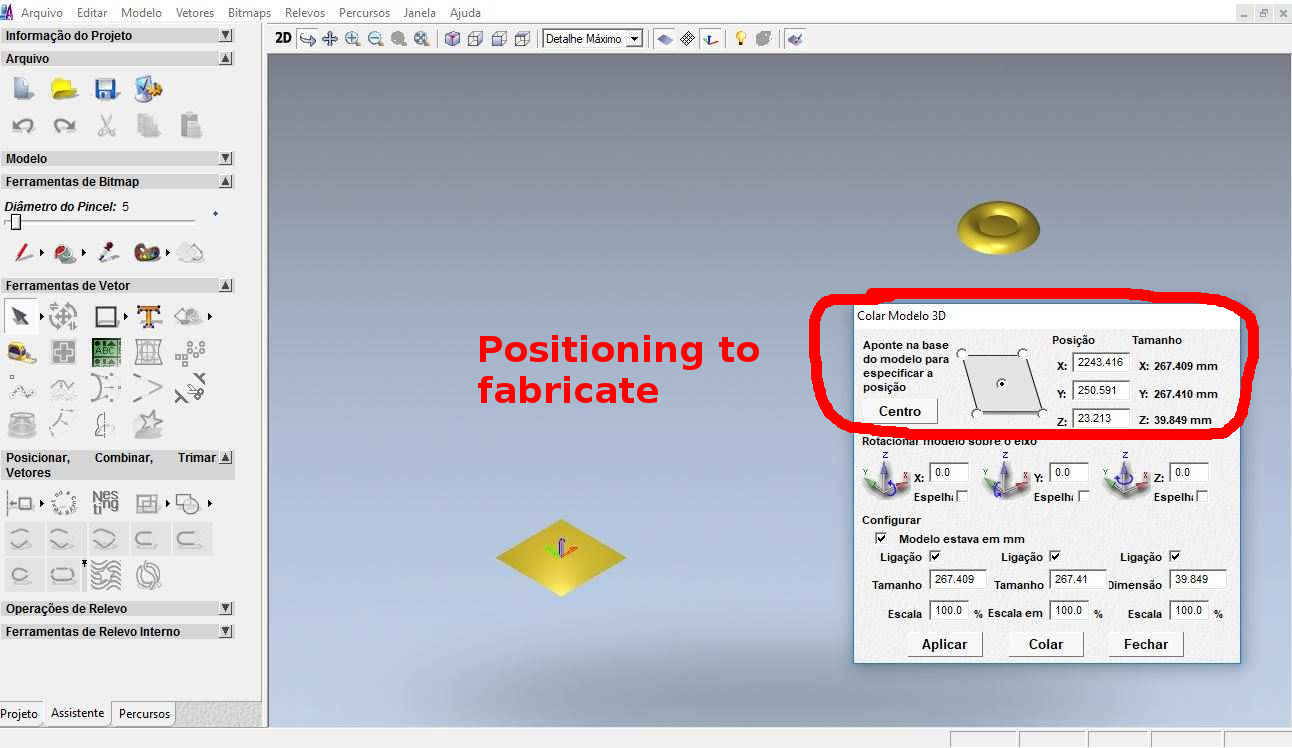

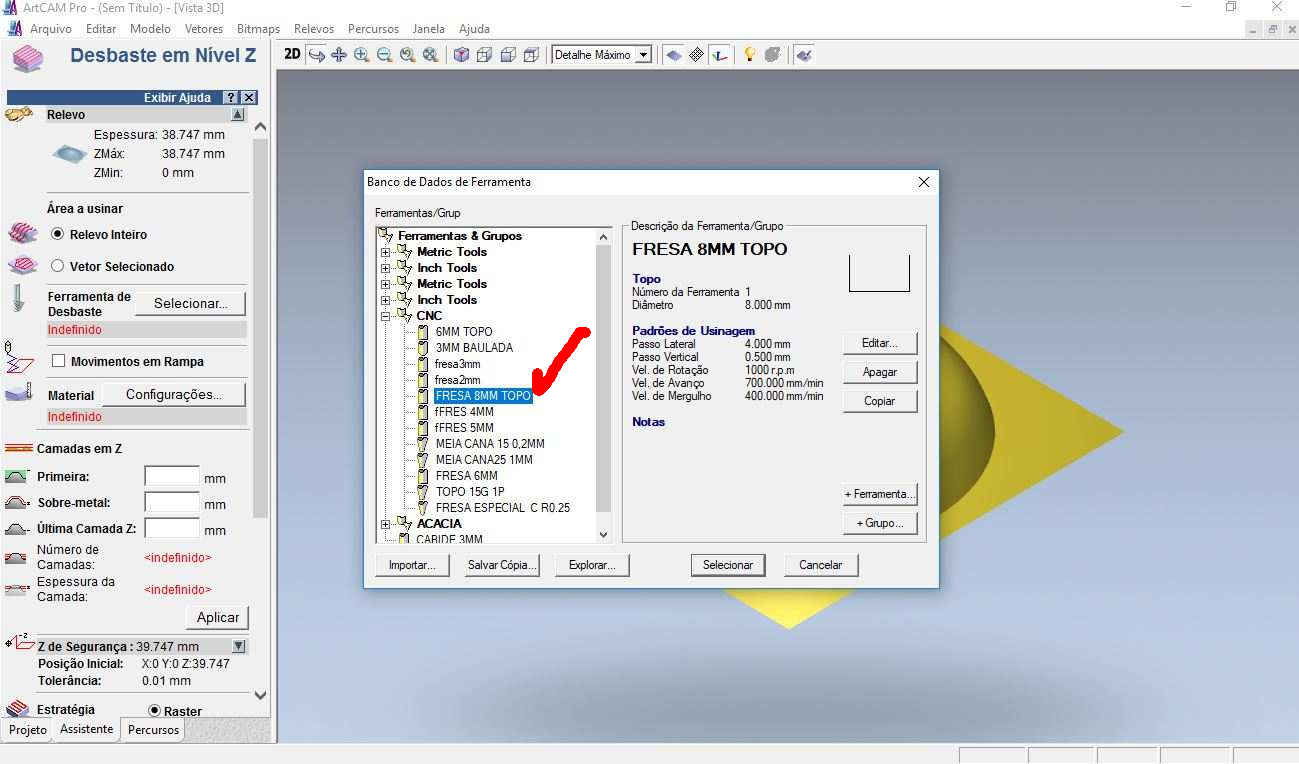

After that I Exported the .dxf from Rhinoceros3D to ArtCam to process the G-code

Composites Fab Academy - 2017 - Cleaning from Alex Angelo on Vimeo.

- Epóxy resin (SQ 2004 F)

"The base epoxy resin of the system is a liquid product, resulting from the reaction of Epichlorohydrin with Bisphenol A."(free translate from SQ 2004 and 3154 datasheet).

- Epóxy resin (3154)

"The modified polyamine based catalyst promotes better adhesion with good strength thermal, chemical and mechanical properties with low exotherm, having good solubilization in the resin with non-critical proportions, allowing homogenous cure with good speed and final properties controllable."(free translate from SQ 2004 and 3154 datasheet).

- Mold release wax

- Jute (vegetable fiber)

- PVC film

- Polyester fiberfill

- Vacuum cleaner

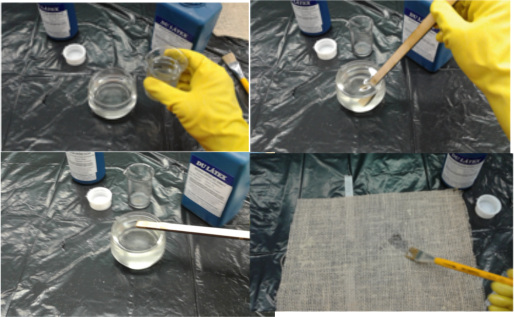

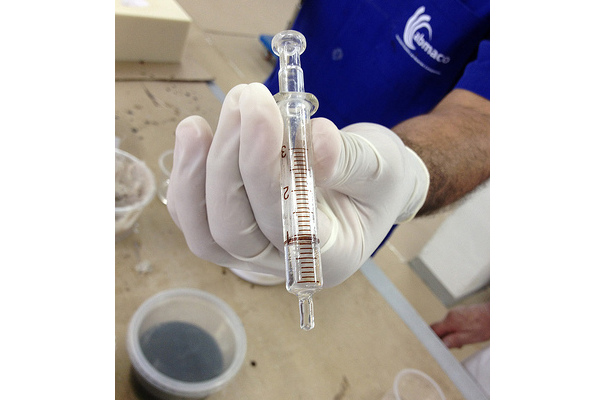

The resin and the catalyst should be mixed at a proportion of 2 : 1 respectively.

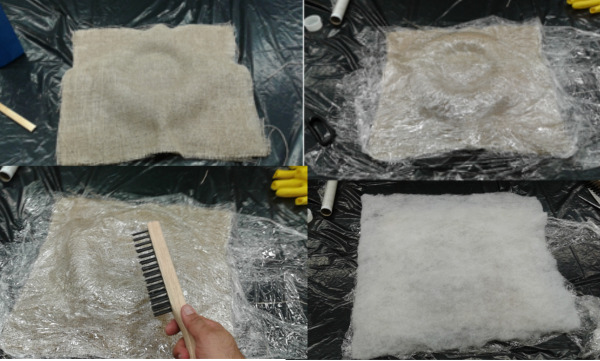

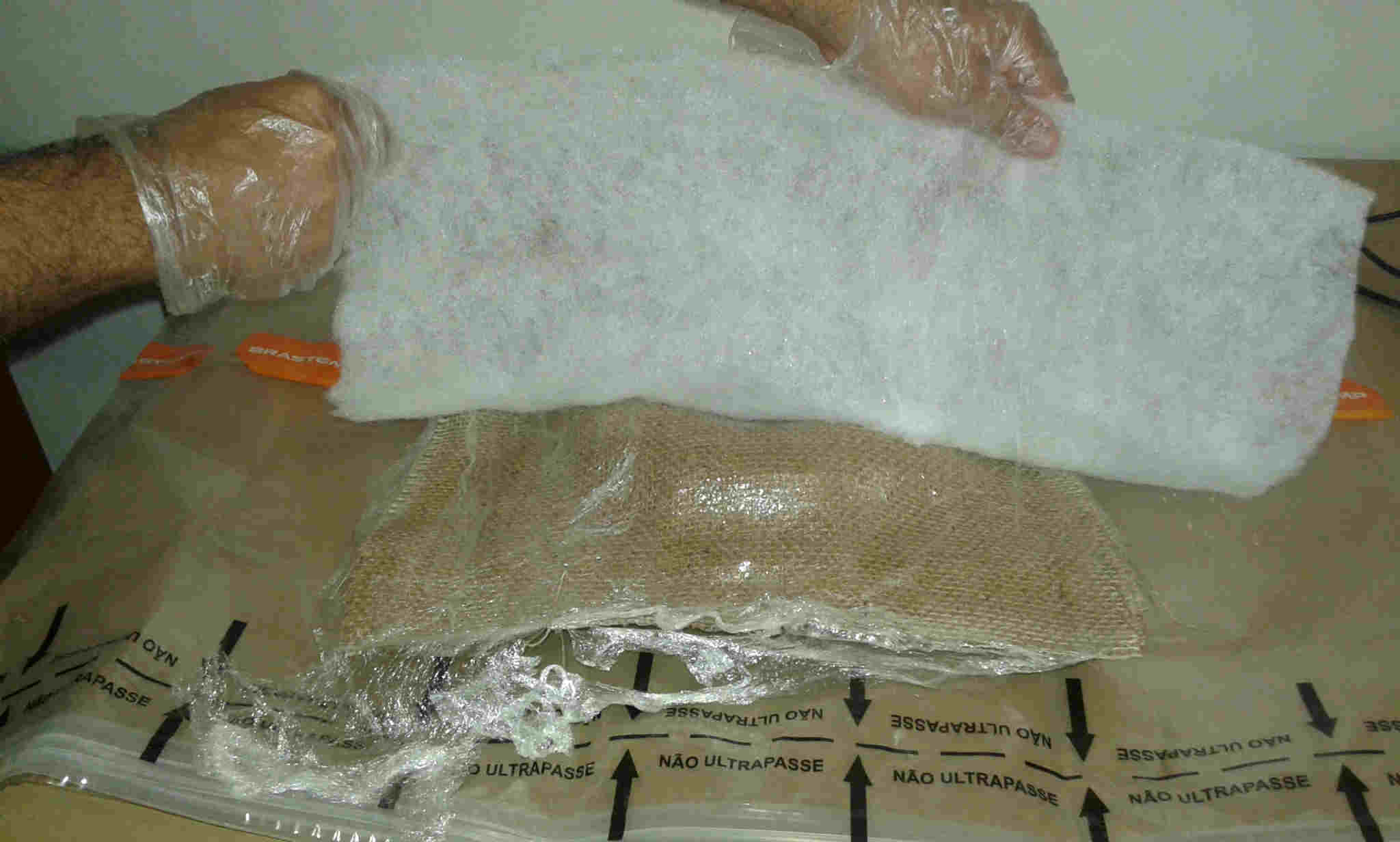

I cut 4 pieces of jute fiber and left them already positioned to receive the layers of resin.

After that I covered with PVC film and did holes to .

I cut 4 pieces of jute fiber and left them already positioned to receive the layers of resin.

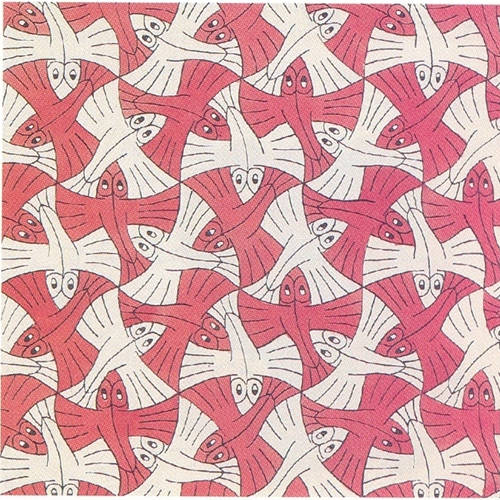

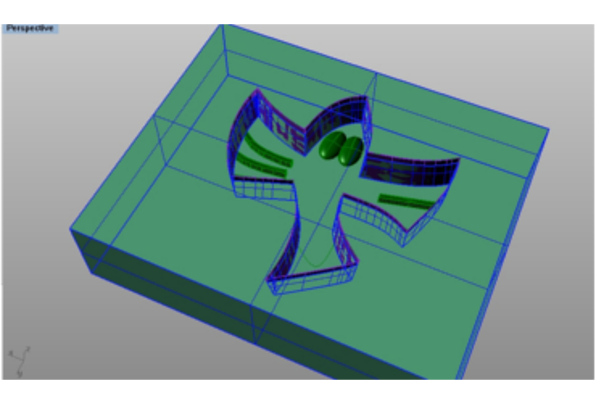

Inspired in Escher designs in order to make a 3D puzzle, I designed it in vector using Illustrator and imported it to Rhinoceros to do the 3D mold.

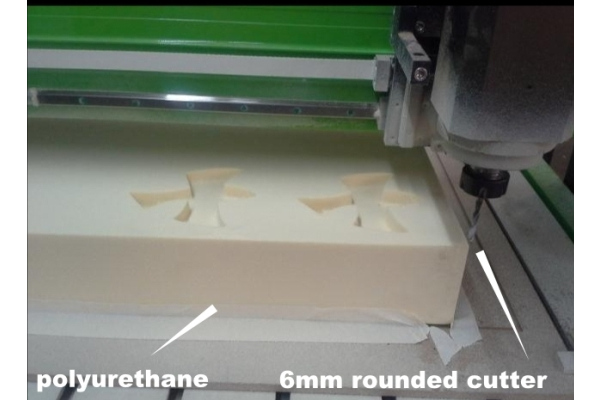

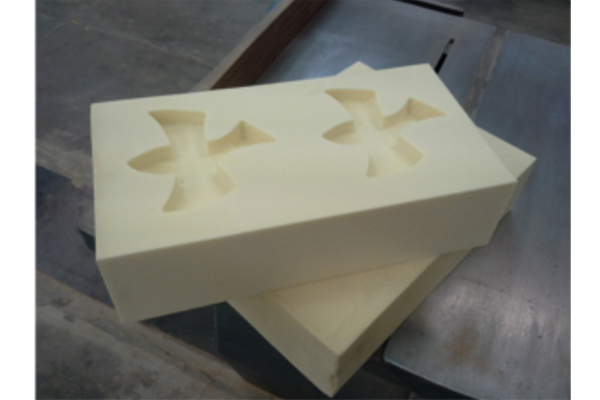

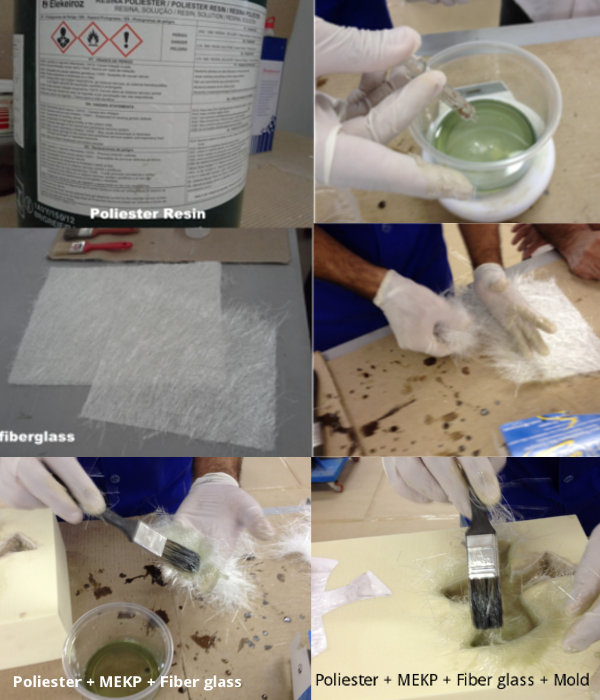

1. Mill the Polyurethane (Density/100)

2. I used polyvinyl alcohol to seal the mold and in order to demold easily (that didn´t really happened I needed to break the mold)

3. I prepared the GelCoat mixed with Butanox M-50 (MEKP) for the polymerizing the gelcoats resin. Info about Gel Coat here. Info about Butanox M-50 (MEKP) here.

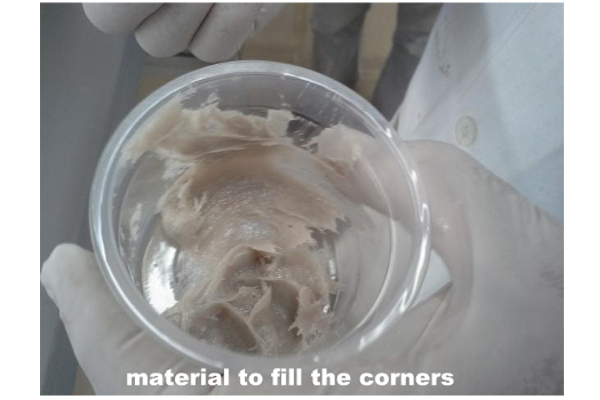

4. After that, I prepared a paste made with glass fiber mixed with MEKP in order to fill the mold´s corners. I used 50g glass fiber paste mixed with Butanox M-50/MEKP (1ml)

5. Then I cut a piece of glass fiber and mixed it with polyester resin and Butanox M-50/MEKP.

6.I waited until it polymerized, and needed to break the mold.The demold process was unsuccessful, the resulting piece was stucked in the polyurethane and I needed to break the Polyurethane mold. Maybe the polyvinyl alcohol was not appropriate to demold the piece from the Polyurethane.

Final result