Moulding and Casting :

let's mold a cat!

Assignment for this week

- Design a 3D mould, machine it, and cast parts from it

----------------------------------------------------------------------------------------------------------------------------------

What I have done?

Specific material and softwares used during this assignment

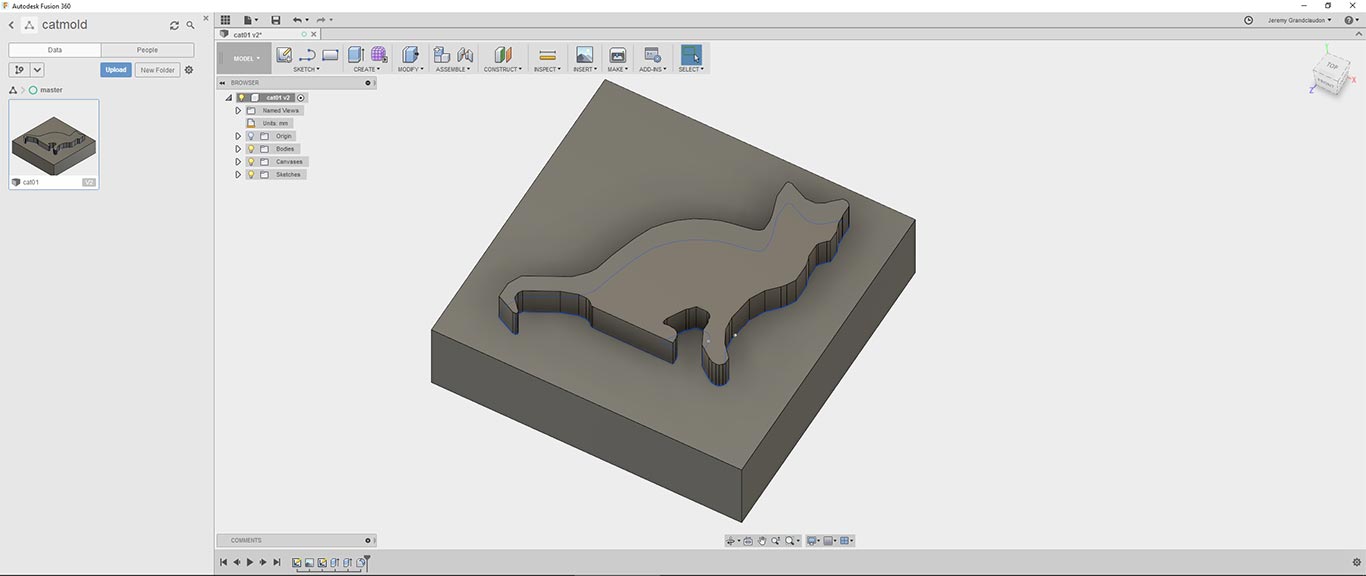

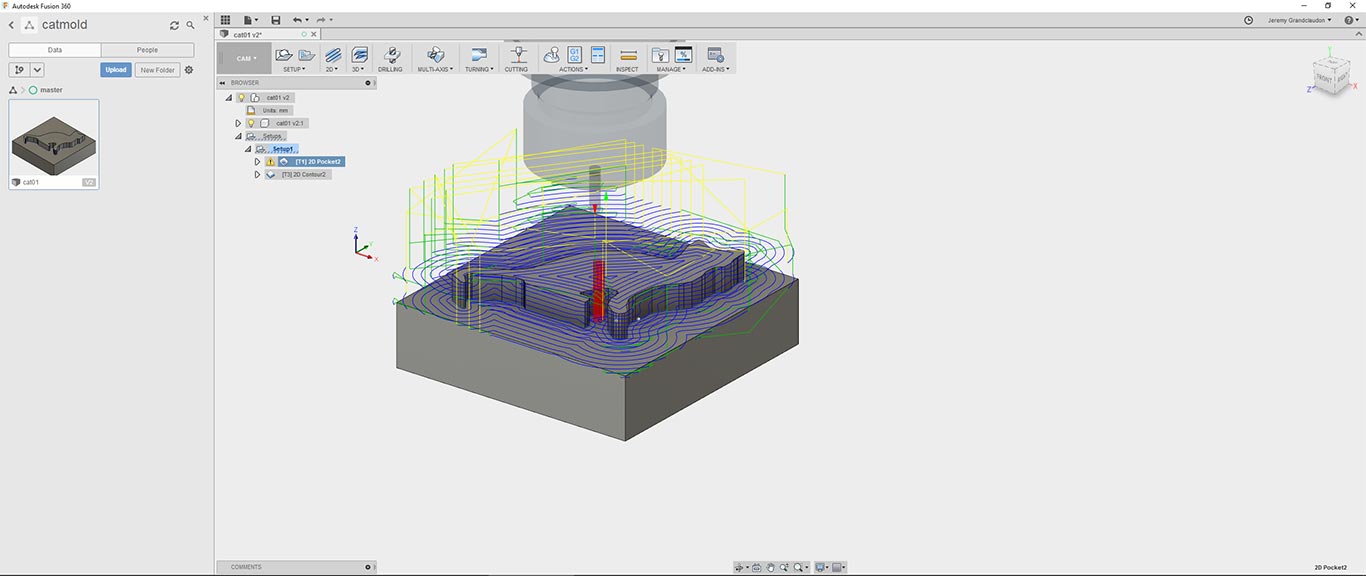

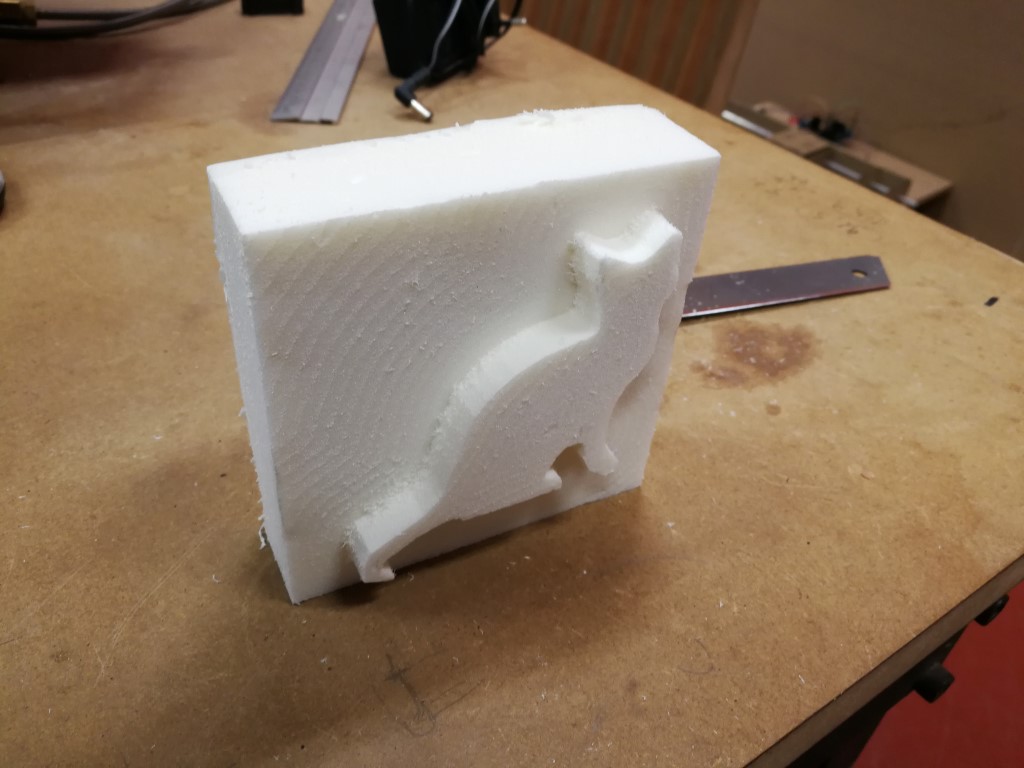

Designing and machining the master mold

For this assignement, I have decided to make a mold in order to produce chocolate cat! The master mold will be make from extruded polystyrene and machined with a CNCI have made my design on Fusion360 :

Prepping the mold for casting

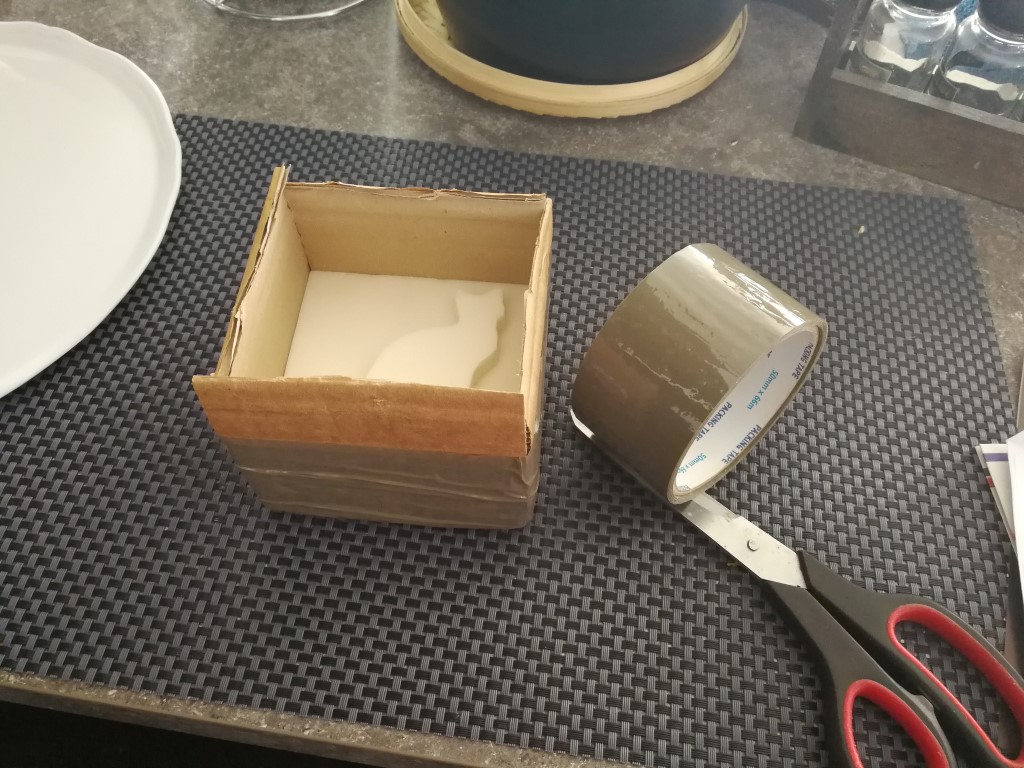

I have now my master mold, I can produce the silicone mold. I will set-up 4 pieces of cardboard with to create the formwork around it

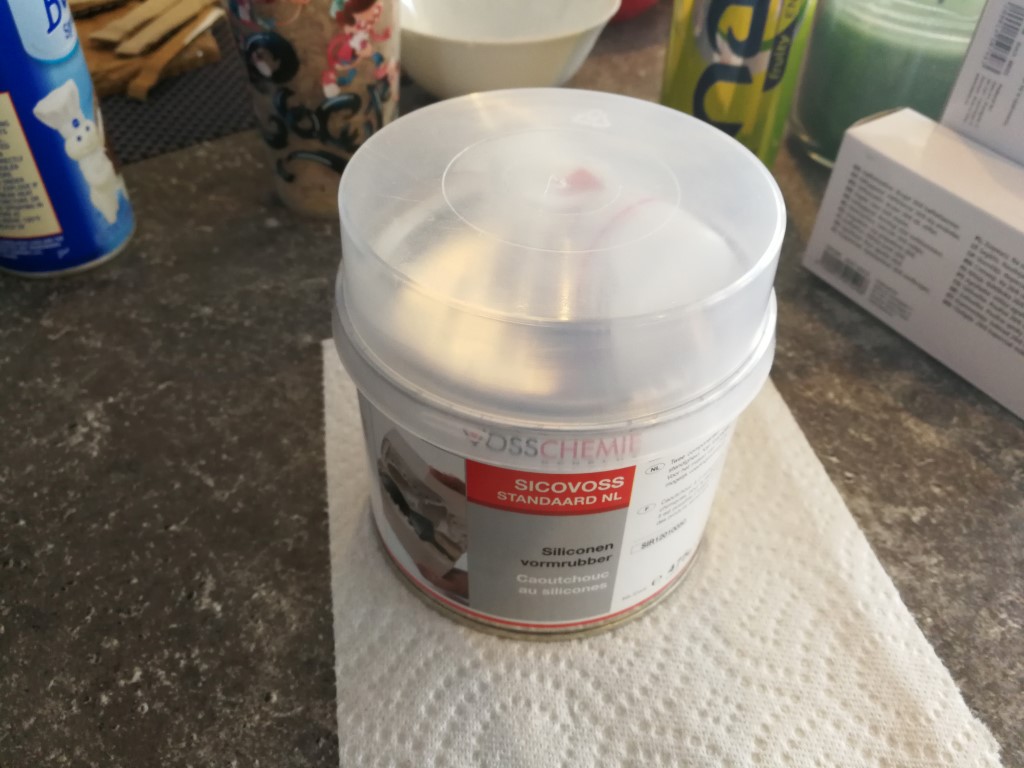

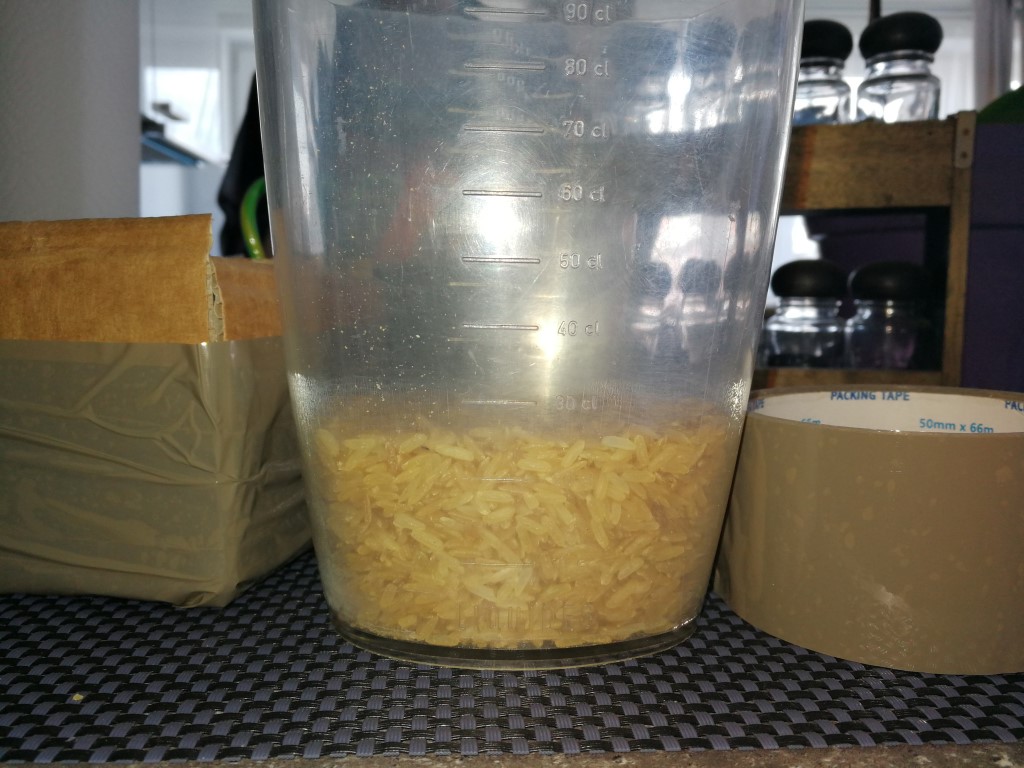

Now that's the fun part : I have to find the right amount of silicone to fill the mold. The final mold needs to be at least 10mm thick to ensure that the mold doesn't tear.

I can use Fusion 360 to get the answer but let's try it the old fashion way.

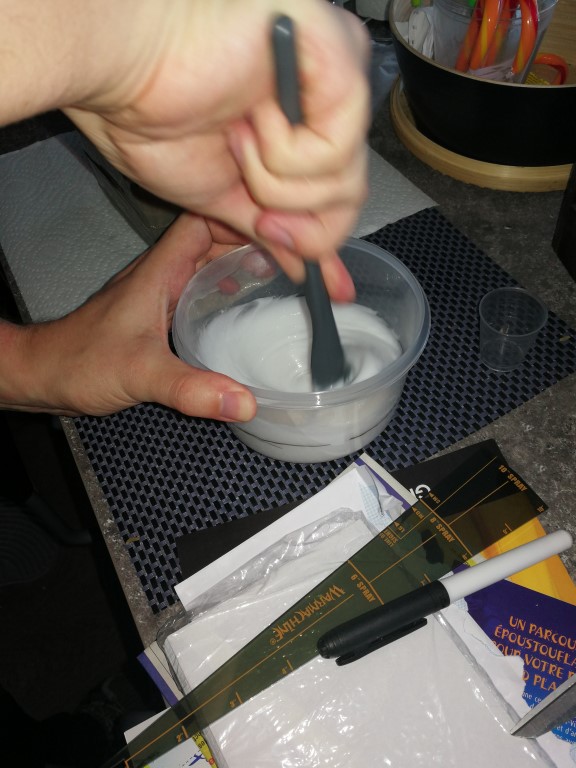

Now that I have that quantity, I also know that I need 12.5ml (5% of the amount of silicone) of silicone hardener I need to put into the mix.

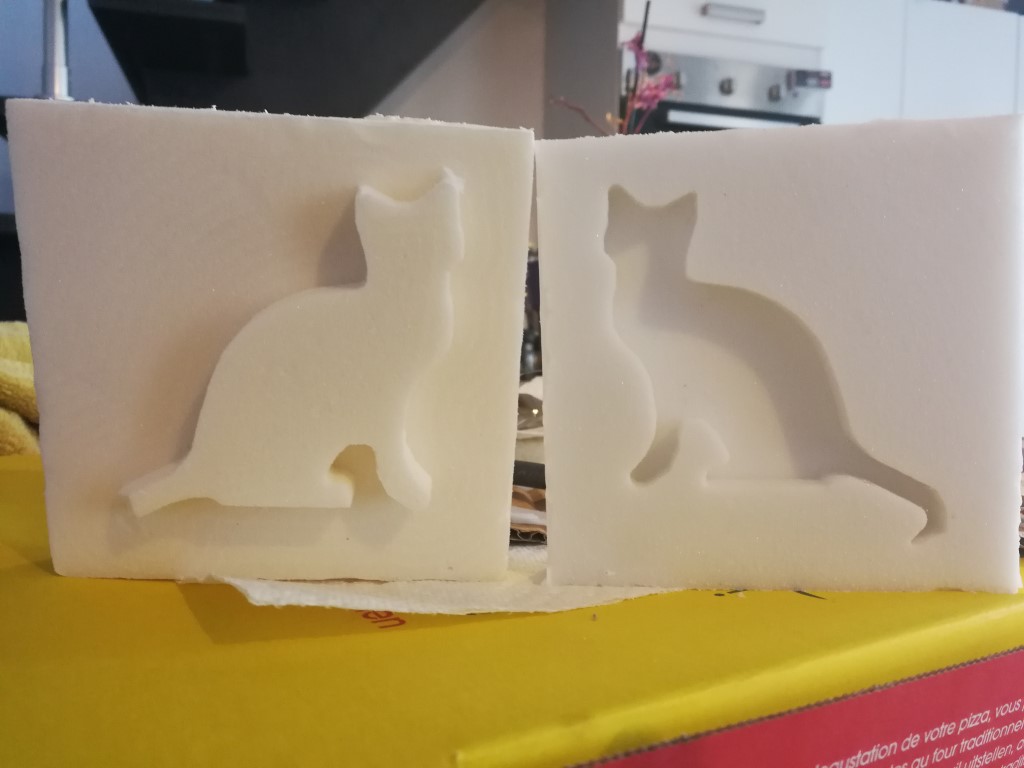

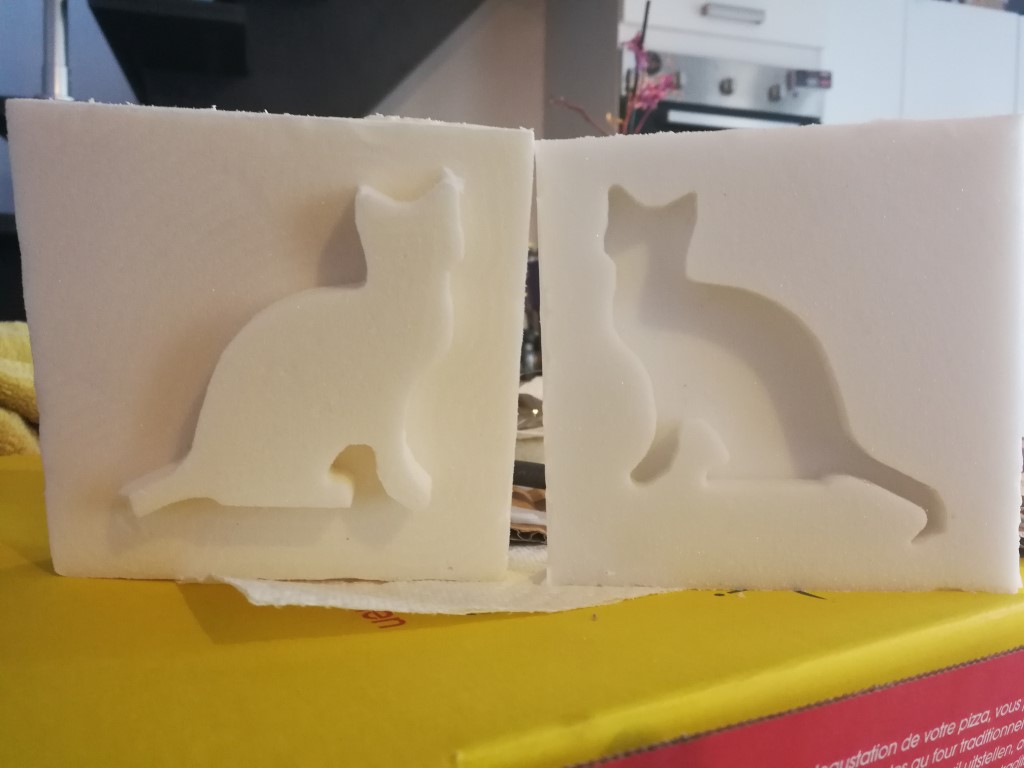

Release and first try of the mold

24H later, It's time to see if everything went fine. I was a little stressed :)

It's time now to test the silicon mold and what's better than chocolate? I will try to produce a chocolate cat from the mold

I'm not a very good cook but let's go!

Lessons learned and possible improvements

Now that I understood and tested the whole process, It much easier to see the flaws of my firt mold :- I should have design the mold in full 3d not in 2.5d

- During the design, I have to think how to avoid any sharp line or form,like the tail of the cat, to facilitate the unmolding

- I don't need to make the mold so thick, next time I can save some material (quite expensive by the way)

Update

During a review, my instructors have pointed out that my master mold (the cat) was in 2.5d and not 3d.So I have use something in 3d (yeah for the kiwi and thanks Ben!) and the same teps have been taken in order to complete the assignement at 100%.Once the mold is dry (24h), I will updated the page :)