Mechanical Design :

Let's make a drawing machine!

Assignment for this week

- MECHANICAL DESIGN (week 1 of 2) : Make a machine, including the end effector, build the passive parts and operate it manually.

- document the group project and your individual contribution

- Link to this week’s home work page

----------------------------------------------------------------------------------------------------------------------------------

What I have done?

Specific material and softwares used during this assignment

- Material :

- 1 MTM kit

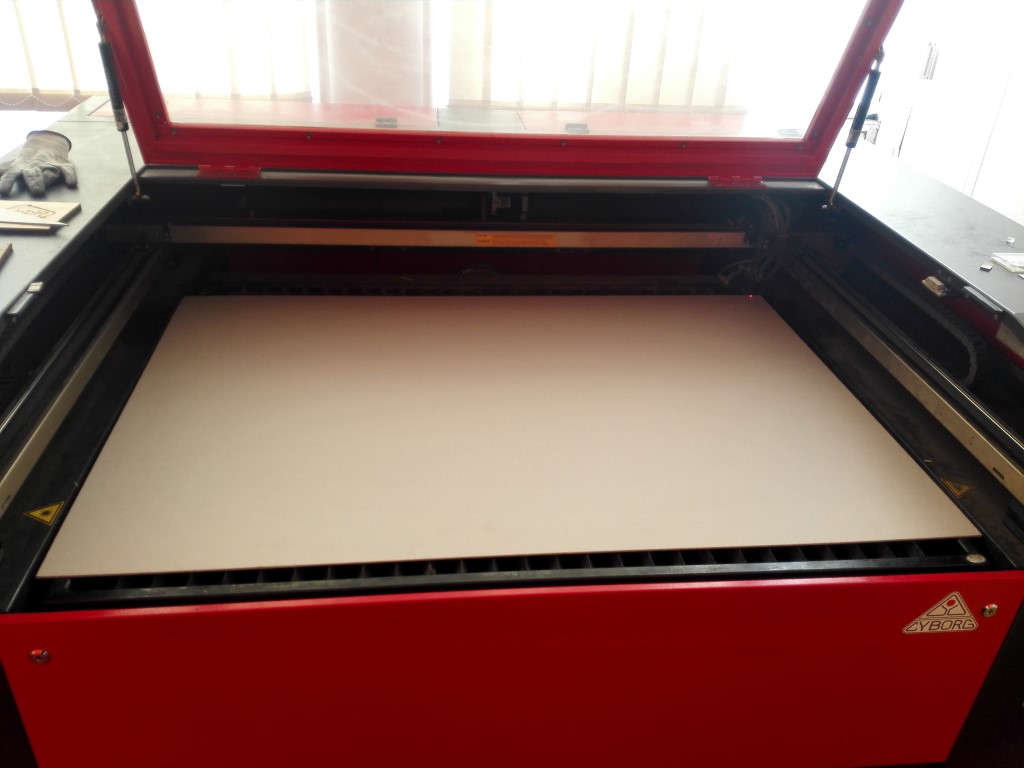

- Laser Cutter

- 5mm thick Grey Cardboard

- 3mm thick Honeycomb Cardboard

- Software :

- Rhino

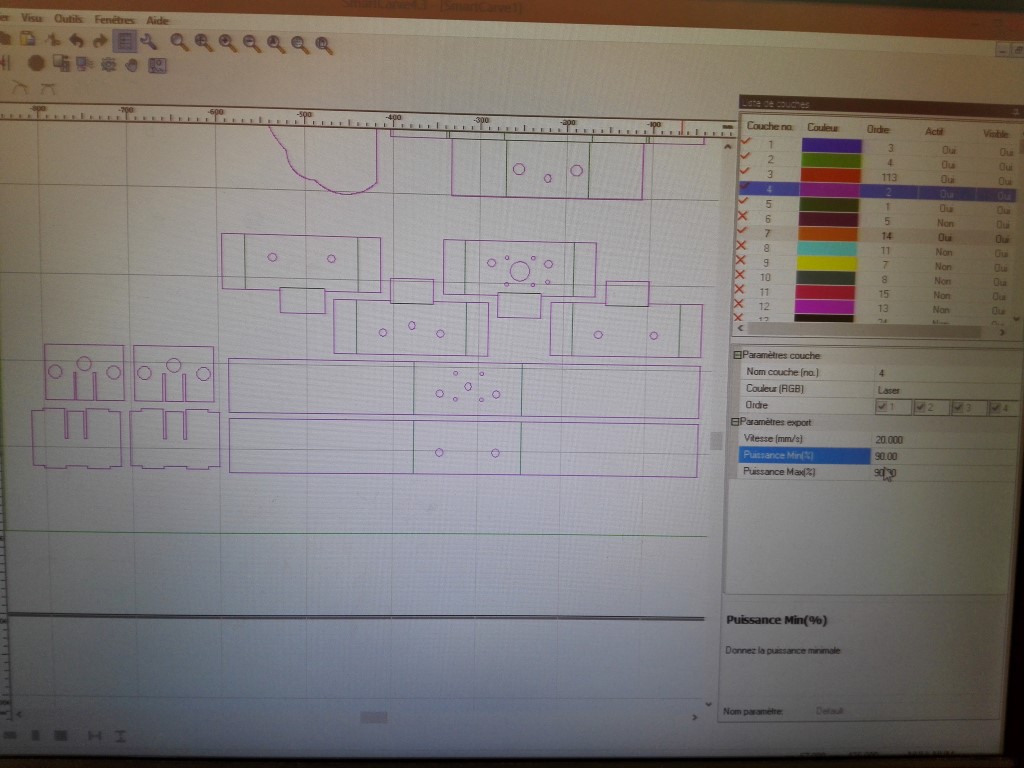

-Smartcarve

- 1 MTM kit

- Laser Cutter

- 5mm thick Grey Cardboard

- 3mm thick Honeycomb Cardboard

- Software :

- Rhino

-Smartcarve

Build a machine... well which one?

The very first step for this assignment was to decide what to build. The debate was fierce but we decide to start on a kind of drawbot machine.A quick decision was taken about the kind of drawbot : not the classic XY, CNC like but more like a polargraph : two motors, a end effector with the writing tool and the cable or whatever to make everything move

First trials

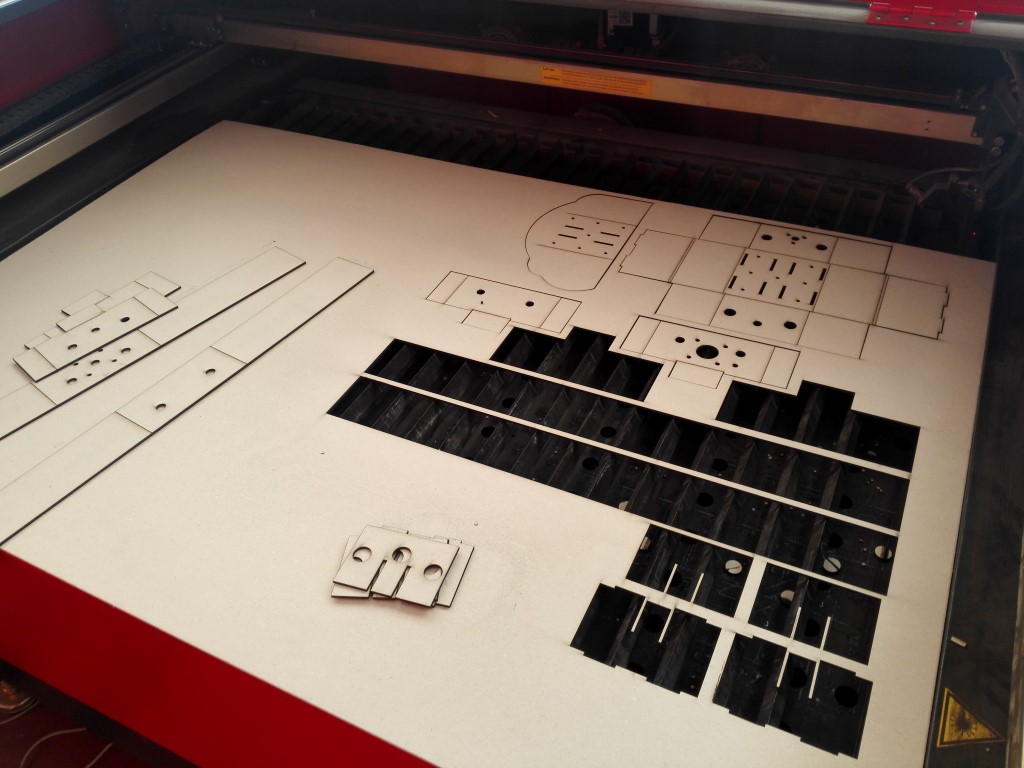

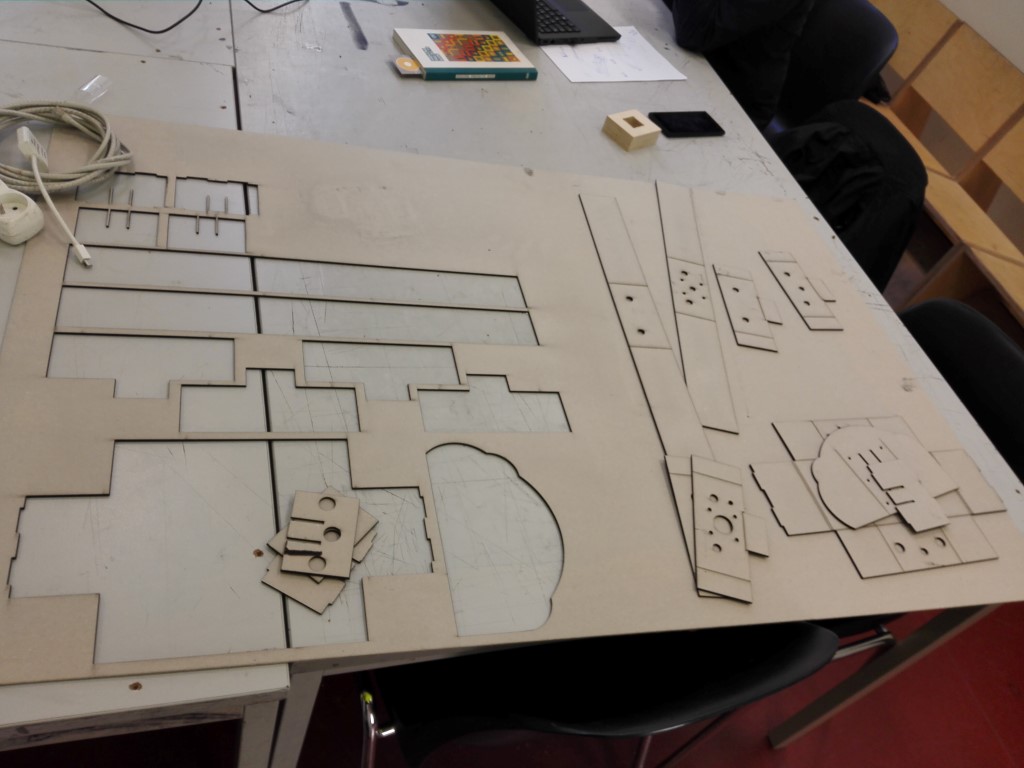

The job was divided between us and I'm in charge of laser cutting the 5mm grey carboard. The file was prepared by David from the rhino file since the parametric plug-in doesn't work anymore on the MIT page. (It was kindly provided later).The cutting went pretty smooth, the grey cardboard is not very fliendly for laser but still fine. But as you can see in the pictures below, I've got a surprise at the end.

First issues

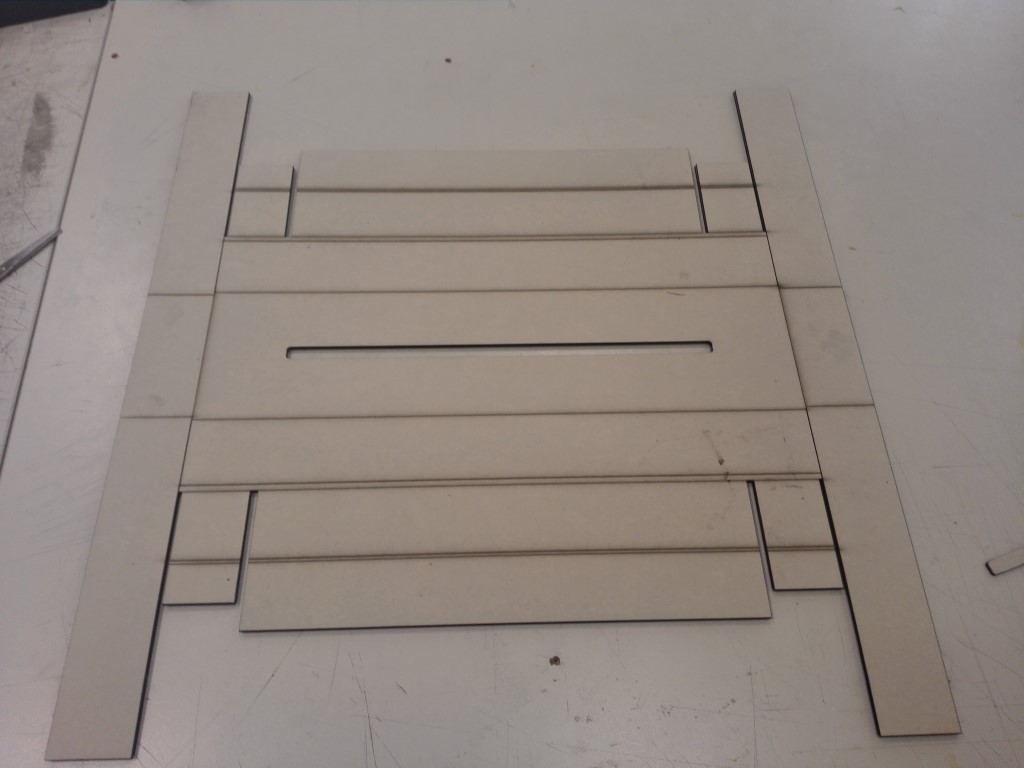

The cardboard was to thick and during the assembly process, it was quite clear that nothing will ever move with this.. So we have redo the same process but 3mm thick withHoneycomb cardboard and the pices were roughly moving together by hand this time.More informations about the next part can be found in our BXL group page

A quick look of our first prototype!