Week 17 - applications and implications

Assignment

propose a final project that integrates the range of units covered, answering:

projects can be separate or joint, but need to show individual mastery of the range of skills covered where possible, you should make rather than buy the parts of your project

What will it do?

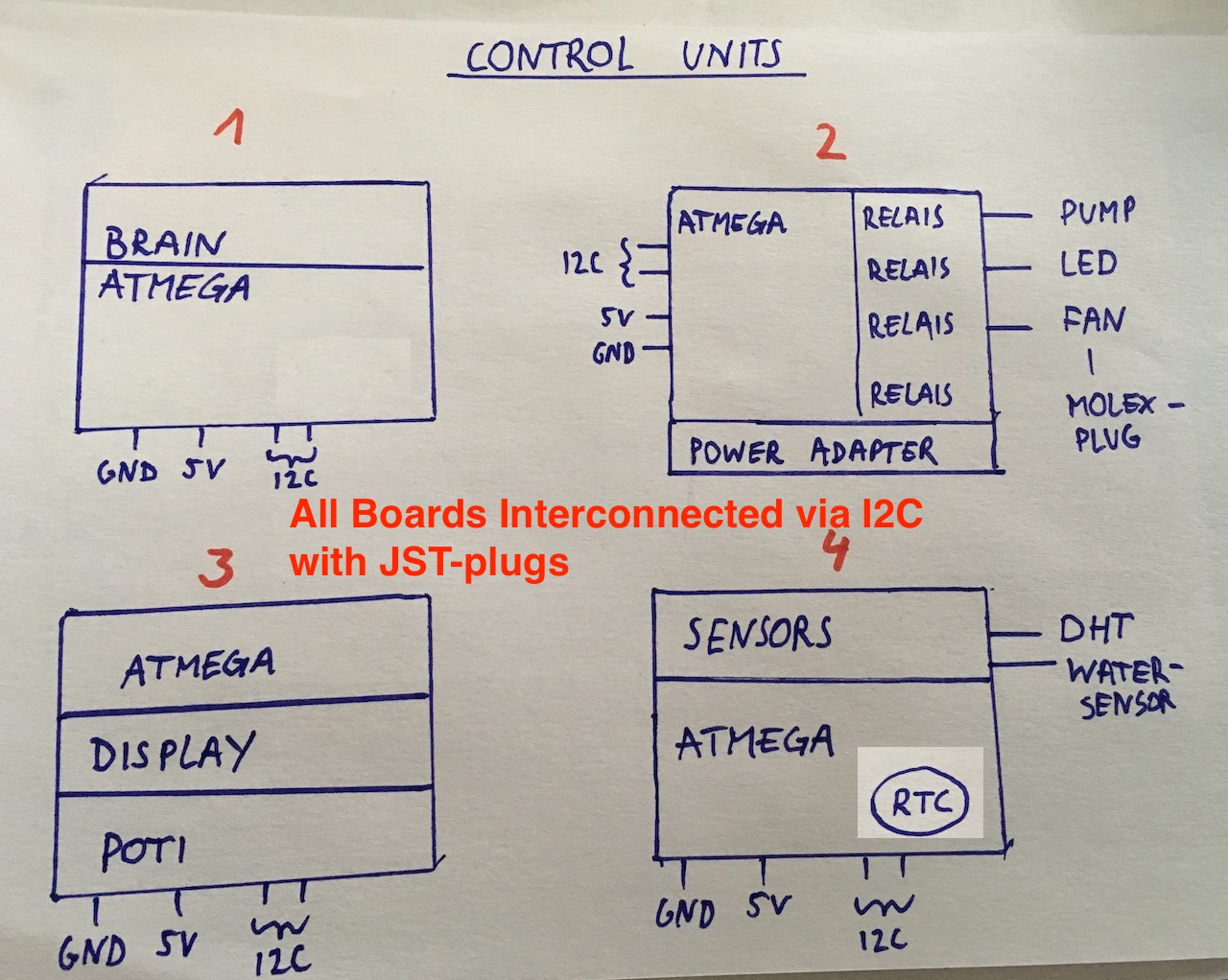

My final project will be a hydroponic growbox. The electronics consists of a total of 4 control units which can communicate via the I2C protocol. The Growbox has an LED lighting which is to be controlled with a relay control unit and has a integrated power adapter.

The individual control units have integrated an ATMEGA 328P-AU, which could controls the pcbs. On the first control board are the relays, which control a pump, the lighting and a fan

The second control unit (also with ATMEGA 328 P-AU) has the sensor system. To measure the temperature and humidity in the Growbox, a DHT22 temperature and humidity sensor is used. A water sensor is also planned.

The third board also has an ATMEGA 328 P-AU, a display and a potentiometer to visualize my sensor data.

The fourth board, the so-called "Brain" is supposed to have a real time clock and is the "Master-board".

On the following illiustration you can see the concept:

who's done what beforehand?

In the internet there are numerous growbox projects. The most inspiring for me, however, is the great Aquapioneers Growsystem from the Fabacademy last year. The system differs from my planning because the system is an aquaponic system that includes an aquarium with fish. Through the exudations of the fish, the plants are fertilized. The difference is that I as mentioned already no fish would like to breed and my system. Furthermore it is smaller, more cheaper and easier to manufacture.

In my system there is only a nutrient solution and a pump in the tank, which can be used to fertilize the plants with oxygen and fertilizer

Main differences to this project:

Last year, I had the opportunity to visit the green fablab in Barcelona and get in contact with the guys of Aquapioneers.

HRW Fablab in Green Fab Lab Barcelona 2016:

Farther inspiration for me is the MIT Media Lab Open Agriculture Initiative (OpenAg).

The open Agriculture Initiative is on a mission to create healthier, more engaging, and more inventive future food systems. They believe the precursor to a healthier and more sustainable food system will be the creation of an open-source ecosystem of food technologies that enable and promote transparency, networked experimentation, education, and hyper-local production.

OpenAg brings together partners from industry, government, and academia in a research collective that's creating collaborative tools and open technology platforms for the exploration of future food systems (Source. https://www.media.mit.edu/groups/open-agriculture-openag/overview/).

The following photo shows my results from last year:

What materials and components will be required for my fab-able system?

Where will they come from?

More datails on Final project - electronics

How much will it cost?

This is difficult to answer. However, I go from about 150 $. When the project is finished, I will upload an updated list.

What parts and systems will be made?

What processes will be used?

What tasks need to be completed?

What questions need to be answered?

How do I get a high safety factor for the electronics in the wet room area? In this case, I may decide to offer the electronic components outside of the growbox.

The LED lighting can plug on top inside the box, which I have already test and it has led to no problems.

What is the schedule?

Due to my visit at the Fab13 my deadline is the 9.7

How will it be evaluated?

At first I will put different plants in the box to test the function. At the beginning I will take plants, which are very insensitive eg garden cress or pea-plants. The effects of the environment in the box, I will gradually adapt to other species, so I can also grow more exotic plants like moroccan mint in the box.