Individual assignment: manufacture of a spindle clutch for our cnc machine on a lathe and cut a machine-bed:

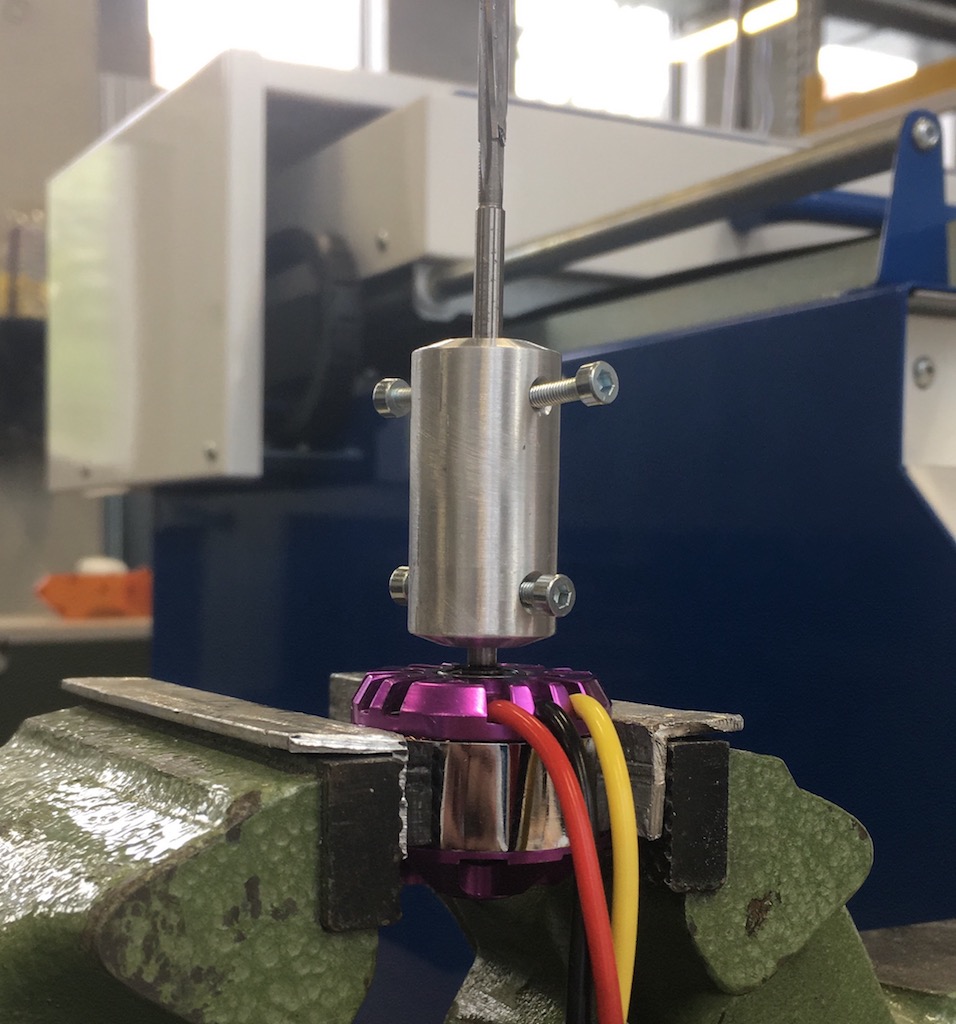

This "clutch" is tensioned between our brushless motor and between madchinentool. It is in principle the toolholder of our machine:

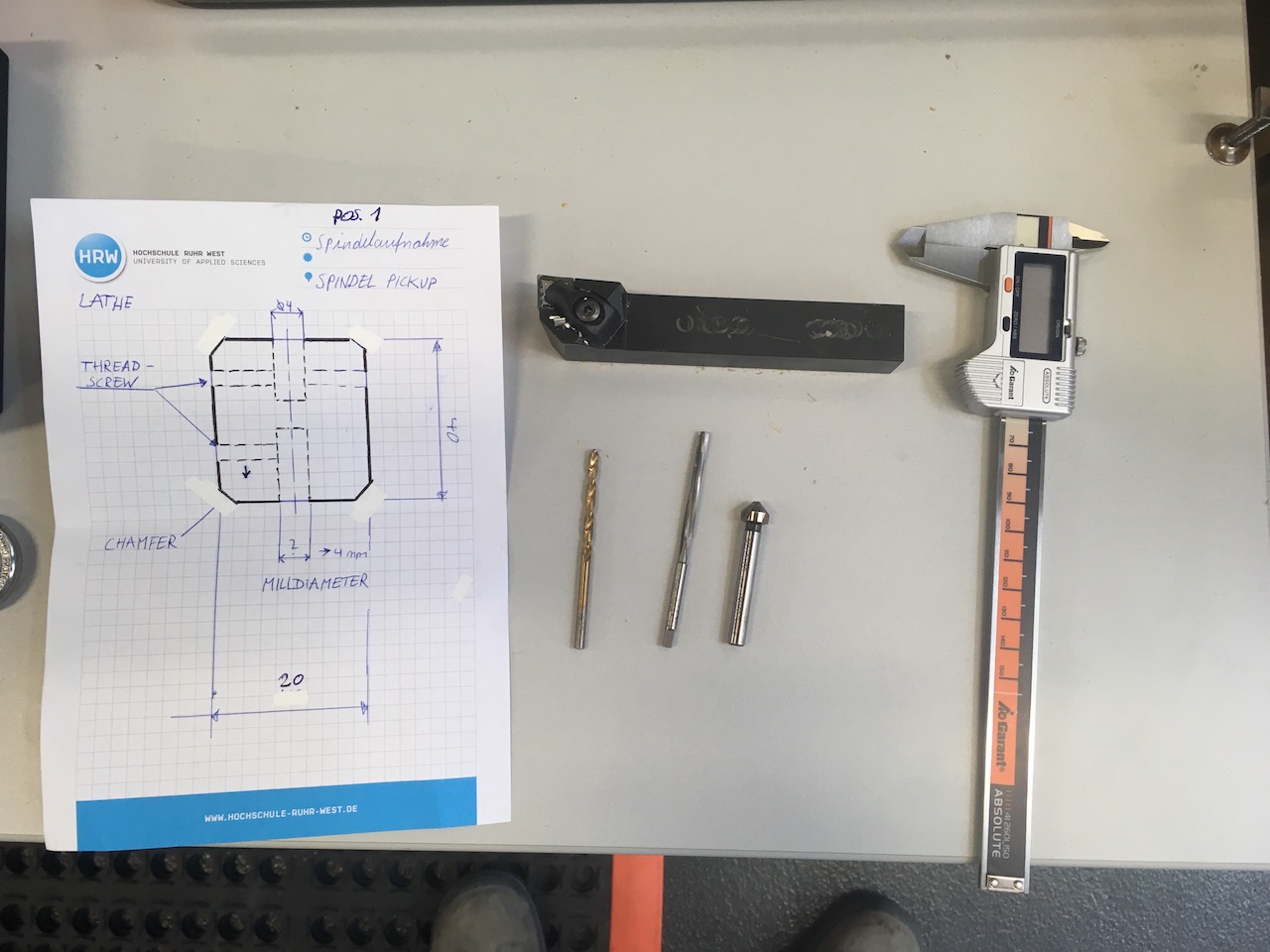

Required tools for this assignment:

Personal protective equipment

Aluminum round steel (40 mm)

Conventional Lathe with accessories and tools (chisel, coolant)

Drilling oil

Center drill

Metal drill 2,5 mm; 5,8 mm

Thread trimmer m3

90 degree tapered countersink

6mm reamer

Thread screws m3x20 (4 pieces)

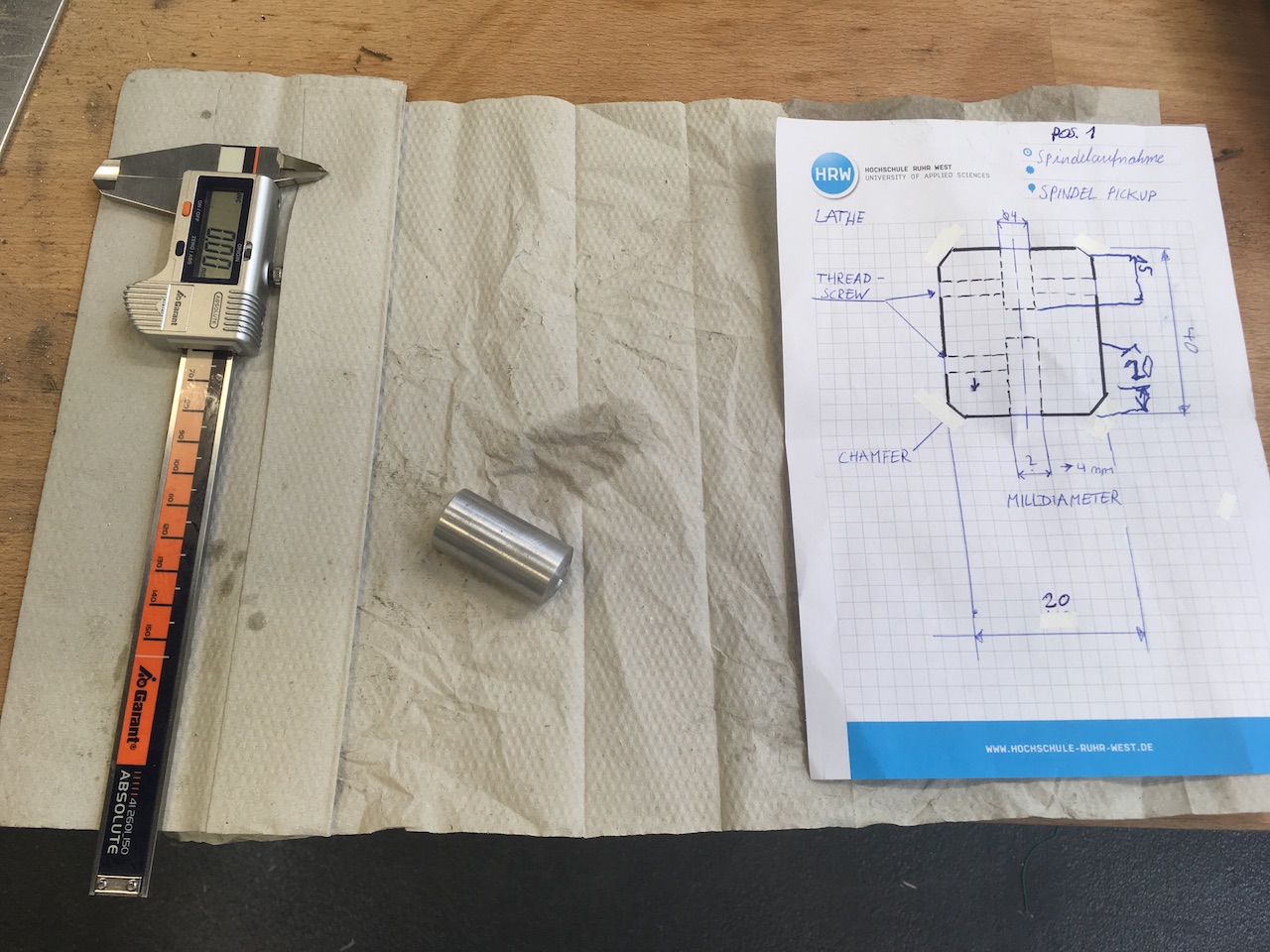

Sliding caliper

On the following photo you can see our Lathe, which is located in the second area (the technical area) of the HRW FabLab. I like working with the conventional lathe, because I am trained in this subject and always like to work on this machine.

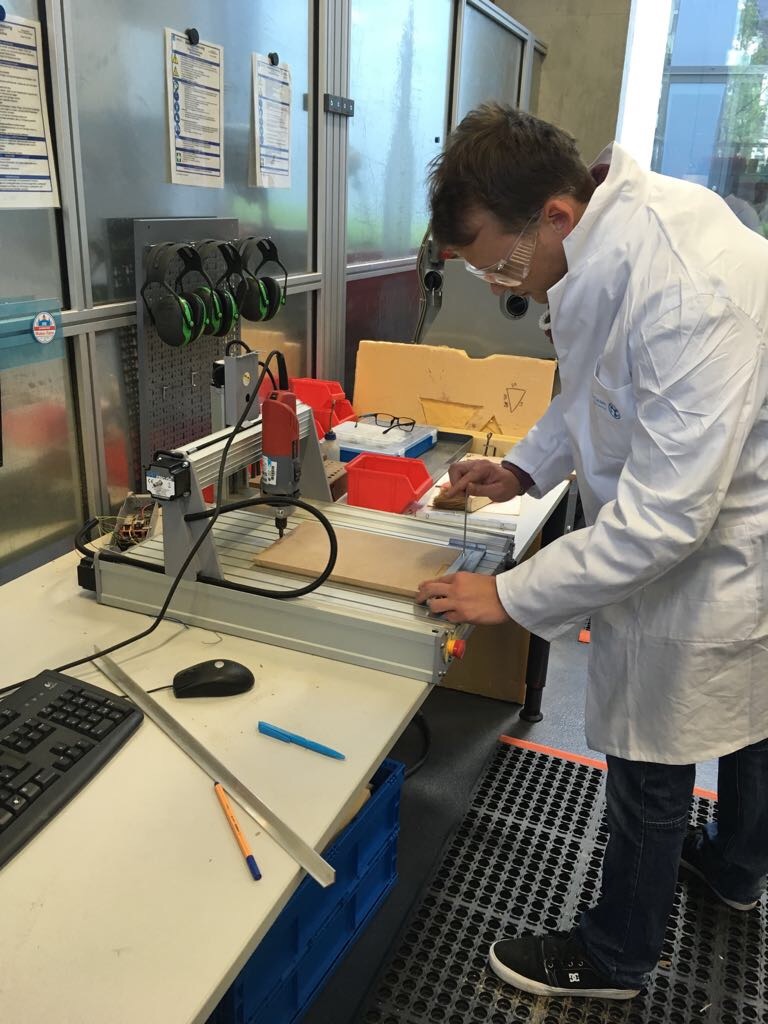

The following photo shows me with personal protective equipment (goggles, safety shoes and hearing protection). Never wear gloves or open hairs or clothing on rotating machine tools!

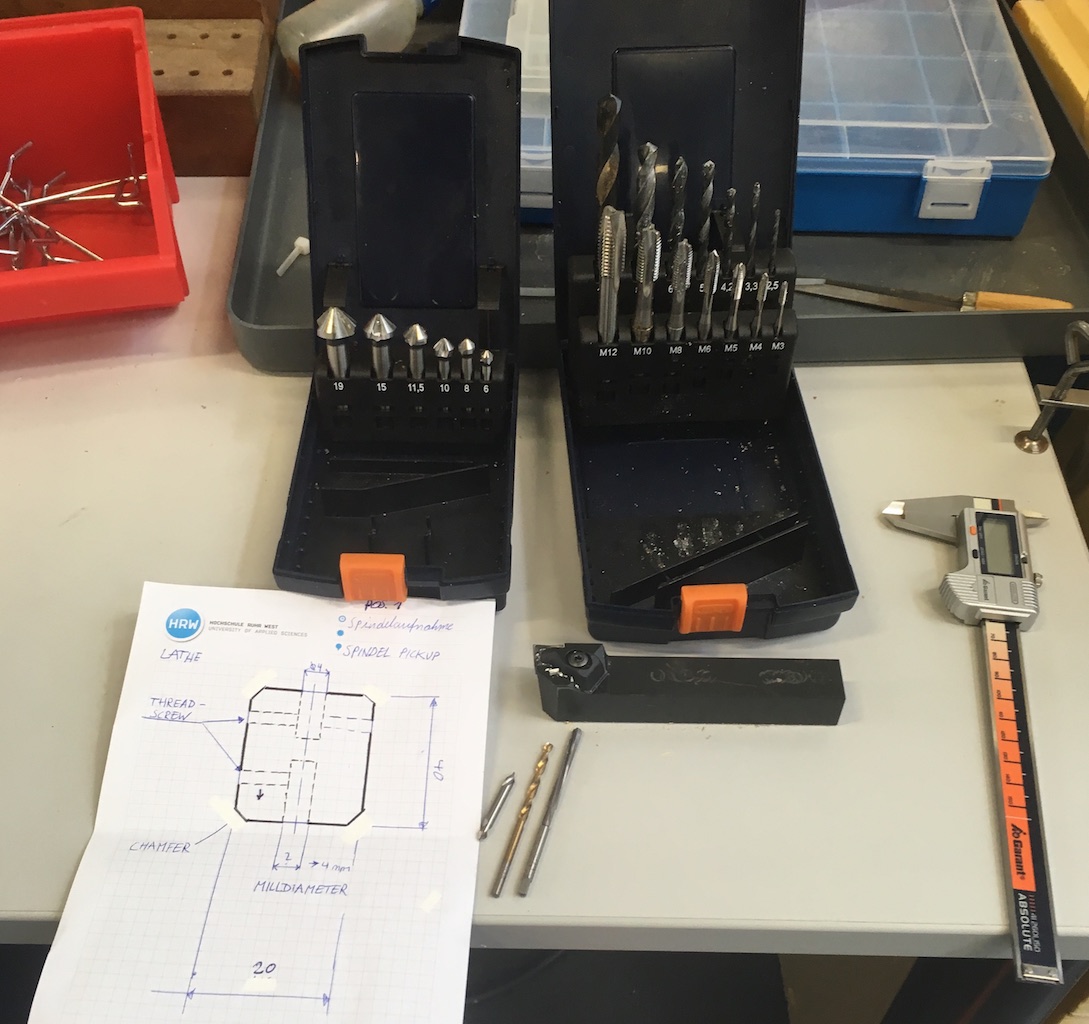

On the following pictures you can see the tools of my work: a measuring slide, reamer, a lower center drill, thread cutters and a corner chisel.

First I prepared the raw part: an aluminum rod cut-off and deburred - measure and test

The next pictures show the machining process with the lathe: longitudinal and pillar turning. At the end still center, drill, lower and rub:

Measure and test:

Since our ordered mills have a shaft diameter of 5.98 mm, I had to rub the clutch afterwards with a reamer to 6.00 mm diameter.

To avoid unbalance, the m3 cylinder screws were also exchanged for m3 thread bolts.

Cut the M3 threads:

For metric threads, the pitch of the thread must be pulled off the diameter and the size of the core hole is increased. The difference is the slope of the thread. For an M3 thread I have therefore pre-drilled 2.5 mm. The slope is thus 0.5 mm. The screw is 0.5 mm away per turn

Center punch helps to positioning the drill and ensures that the drill is at the right place without slipping:

Finally, I have milled some bags in a wood plate, so this plate fits on our machine. The printed trapezoidal bars are stored in these pockets.