Week 17

Applications & Implications

For the period of the past 17 Weeks, I learnt different skills from which will be used in developing my final project. Below are some of the questions which I will answer

What will it do?

My Final Project Proposal which is Electric Door Mat is an equipment which will maintain cleanliness in offices and residential houses by dusting their shoes before entering. It might replace the traditional door mats. It will have brushes which will scrab off dust as they rotate at a higher speed.

Who's done what beforehand?

I got the idea just in Gearbox Nairobi - Maker Space where I attend my classes to protect their neatly pinned down carpet from durt. The space receive many visitors and so so many peolpe walks on the carpet, this would see them replace the carpet so frequently. Elsewhere, I checked through DIY to improve my idea bur all I got were traditional mats and so I had to think hard

What materials and components will be required?

The Materials needed here include;

- - MDF board or Acrylic with bigger thickness for frame

- - Brushes

- - Stepper Motors

- - Gears

- - Saction component

- - Simple electronic Board with weight sensor

Where will they come from?

From the local Market and Electronic Shops around

How much will it cost?

The cost will be;

| Materials | Quantity | Amount |

|---|---|---|

| MDF | 4x8ft sheet | 500 |

| Round Brushes | 3 | 150 |

| Stepper Motor | 2 | 3000 |

| Resistors | 2 | 30 |

| Weight Sensor | 1 | 300 |

| Microcontroller | 1 | 300 |

What parts and systems will be made?

I will be able to make the structure out of the materials. I will also make the Electronic board.

What processes will be used?

The process to be used is the inludes almost all the skills learnt during the course period.

What tasks need to be completed?

Below are some of the tasks to be accomplished

- - Physical structure of the Machine

- - Electronic PCB; designing, milling, populating testing and programming

- - Assembling all parts and components

- - Testing concept

- - Finalising assembly

- - Testing Machine working

- - Adjustments & Improvements

- - Evaluation

- - Presentation

What questions need to be answered?

Coming at the end

What is the schedule?

The shedule was abit challenged following some difficulties and the fact that I was alone, my hands were full and could not follow the schedule as expected

| Activities | Time | Status |

|---|---|---|

| Designing | 3 | 150 |

| Building of Structures | 4x8ft sheet | 500 |

| Round Brushes | 3 | 150 |

| Stepper Motor | 2 | 3000 |

| Resistors | 2 | 30 |

| Weight Sensor | 1 | 300 |

| Microcontroller | 1 | 300 |

How will it be evaluated?

The evaluation will not be so difficult. Different parts will be tested by Engineers around in terms of Electronic fitness, Mechanical correctness of various parts, Environmental suitability and generally everyone around can try it out if at meets its purpose

Projects can be separate or joint, but need to show individual mastery of the skills covered

It was a challenge to me since I didn't have agroup to work with but fortunately I got friends in Gearbox either working or Interns whom I could consult from time to time and also deeply involves afew to help me in areas I had lots of difficulties. I also depended heavily on the Regional Supervisor/ Instructor Luis Carvao who used to take several hours helping out in difficult areas via Teamviewer, Skype, Whatsapp, Facebook, emails or even phonecalls. The physical distance between us was several thousand Kilometres away but I could feel the heat of his push to move ahead until things work

Where possible, you should make rather than buy the parts of your project

Like said above, I will do make most of the parts and only buy materials needed

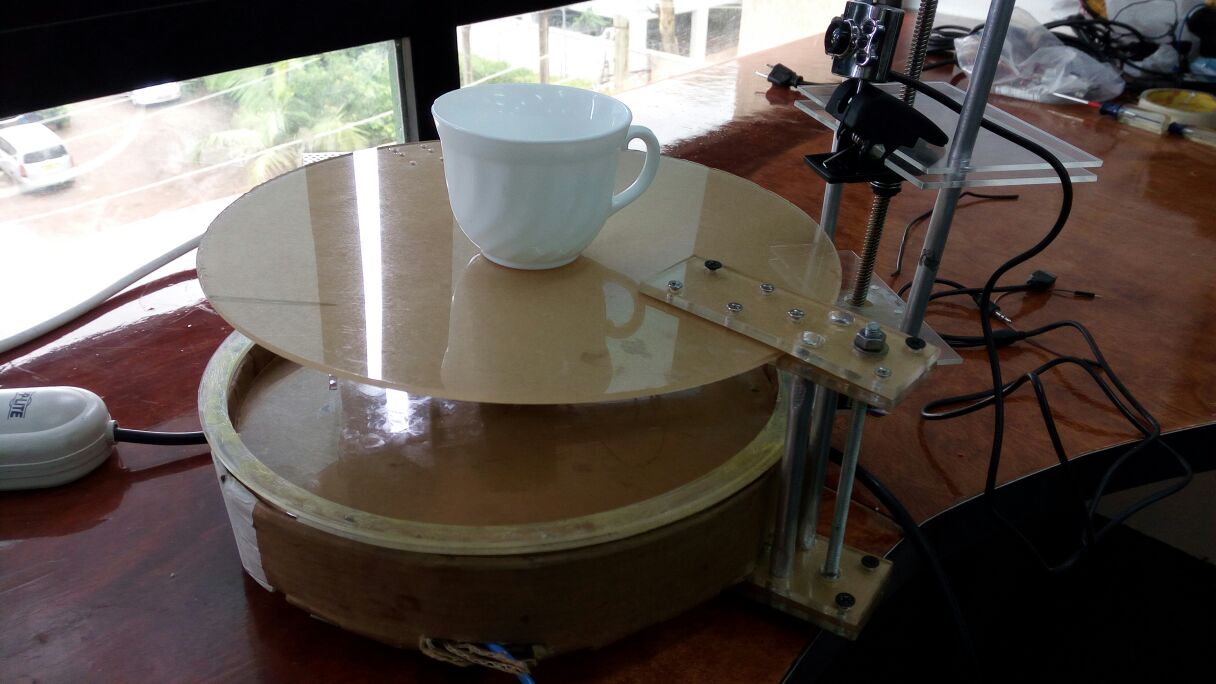

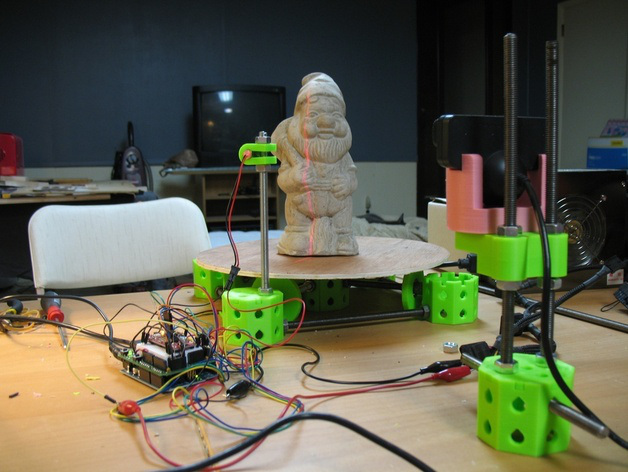

3D Scanner

I had to switch at last minute from my initial Final Project Proposal above of Electric Door Mat and take this 3D Scanner as my Final Project. This was a project I did in week 9 and 10 for Machine building and the decision was reached after consultation with Luis - my regional Instructor and it was informed by the fact that I didn't have a group to work with and so was taking much time in each step of the building save for the other assignments. I employed several skills I learnt from the past weeks in developing this final project. Below are some of the questions which I will answer

What will it do?

This 3D Scanning Machine is an equipment which will be used to take 3D images of objects using the camera which rotates around the object and moves in the Z- axis as well thereafter using a Construct me or Autodesk Sketch will process the images by stitching them nicely to make a single 3D image.

Who's done what beforehand?

Above are some of the 3D Scanners ever Developed in the Past

Alot of other people out there have tried out the idea and alot of DIY projects have listed them however many of those peolple have been doing the scanners with revolving table while I opted to try out the one where the table holding the object will remain staioned while the Camera moves. Below are some of the links to the sites of people who have tried made such before.

What materials and components will be required?

In choosing materials, I had to be keen on how the material will bring in the usage of the past skills learnt while at the same time remain the most suitable material of choice. Below are the list of Materials needed;

- - Acrylic sheet

- - Plywood

- - Stepper Motors

- - Motor drivers and other electronic components

- - Fabduino/ Gestalt node

- - Power supply

- - Rollers

- - Counter weight

- - Camera

- - Alluminium rods

Where will they come from?

From the local Market and Electronic Shops around

For Electronic, I will purchase them from Nerocus while Acrylic and plywood, I will the local stokists and hardware around

The aluminium rods and motors were shipped in together with other component from Fab Foundation

How much will it cost?

The cost will be;

| Materials | Quantity | Amount |

|---|---|---|

| Acrylic | 4x8ft sheet | 500 |

| Plywood | 20 x 50cm | 150 |

| Stepper Motor | 2 | 3000 |

| Fabduino Components | 1 | 300 |

| PowerSupply | 1 | 2500 |

| Motor Drivers | 2 | 1000 |

| Alluminium rods | 2 | 000 |

| Rollers | 1 | 500 |

| Camera | 1 | 1500 |

| Total | 10000 |

What parts and systems will be made?

I will make most parts of the structure using the above materials. I will also make my PCB - Fabduino board.

What processes will be used?

I will involve several processes ranging from Machine building, to PCB making and to Image stitching

What tasks need to be completed?

Below are some of the tasks to be accomplished

- - Physical structure of the Machine

- - Electronic PCB; designing, milling, populating testing and programming

- - Assembling all parts and components

- - Testing concept

- - Finalising assembly

- - Testing Machine working

- - Adjustments & Improvements

- - Image taking(Scanning) and stitching

- - Display of results

- - Evaluation

- - Presentation

What questions need to be answered?

What makes the difference on the quality and process between a Scanner with fixed table and that with moving/ rotating table?

What are the easiest ways of stitching images

What is the schedule?

The shedule was abit challenged following some difficulties and the fact that I was alone, my hands were full and could not follow the schedule as expected

| Sn. | Activities | Time | Status |

|---|---|---|---|

| 1. | Idea Conceiption and Acceptance | by week 2 | Completed |

| 2. | Designing Physical parts | by week 4 | Completed |

| 3. | Designing PCB | By week 7 | On Progress |

| 4. | Building of Structures | By week 9/td> | On Progress |

| 5. | Assembling of Parts | By week 14 | On progress |

| 6. | Testing of Concept | By Week 16 | Not done |

| 7. | Adjustments | By Week 17 | Not done |

| 8. | Scanning First Object | By Week 18 | Not done |

| 9. | Local Presentation | By Week 18 | Not Done |

| 10. | Final Adjustment &Presentation | By Week 18 | Not Done |

How will it be evaluated?

The evaluation will not be so difficult. Different parts will be tested by Engineers around in terms of Electronic fitness, Mechanical correctness of various parts, Environmental suitability and generally I will make presentation to everyone within the Maker Space (Gearbox) to see if the Machine meets its purpose, Listen to their comments, and document the important ones for improvemnt.

Projects can be separate or joint, but need to show individual mastery of the skills covered

It was a challenge to me since I didn't have agroup to work with but fortunately I got friends in Gearbox either working or Interns whom I could consult from time to time and also deeply involves afew to help me in areas I had lots of difficulties. I also depended heavily on the Regional Supervisor/ Instructor Luis Carvao who used to take several hours helping out in difficult areas via Teamviewer, Skype, Whatsapp, Facebook, emails or even phonecalls. The physical distance between us was several thousand Kilometres away but I could feel the heat of his push to move ahead until things work

Where possible, you should make rather than buy the parts of your project

Like said above, I will make most of the parts and only buy materials needed save for Components like Camera and Motor Drivers