2016

Guitar pickup coil winding machine

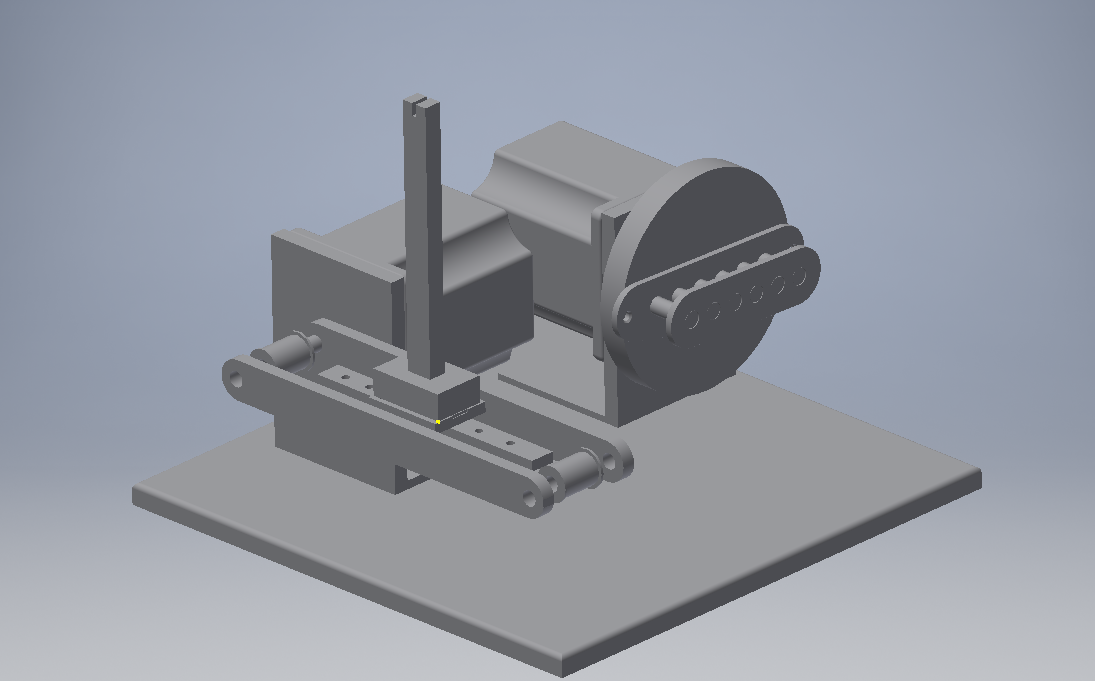

My Idea is to make a computer/controller driven guitar pickup coil winder.

The winder is equipped with two stepper motors and a logic that controls their movement. One stepper is responsible for turning the pickup bobbin enabling to make the copper wire coil winding. We need to control the speed and the number of rotations of the stepper. The second stepper is attached with a belt to a carriage of a linear rail producing a guiding system for the copper wire. Traditionally, the wire guiding is done with hand making consistently or similarly wound pickups extremely hard (re)produce.

What makes this project suitable for Fab Academy final project is the multitude of possibilities to use different production techniques and material together with electronics and embedded programming. It remains to be seen what parts need to be of the shelf and how much cane be manufactured in the lab.

This is the first sketch produced with Autodesk Inventor. As you can see, this still far from being a model that can be utilized to make the real product.

The model is put together from separate parts ( base plate, stepper motor, linear rail, etc...). That way it is easy to do some correction to each individual element,

Initial thoughts on the steps needed to complete the project:

Build stepper motor drivers (Done)

Make a controlling board for the steppers (Designed)

Design controlling software (Initial version done)

Design user interface (PC or LCD) (First version done)

Build the frame (laser cut, 3D print). ( Done)

Make bobbin with different techniques (laser cut, 3D print, milling) (Done)

Parts for the winder:

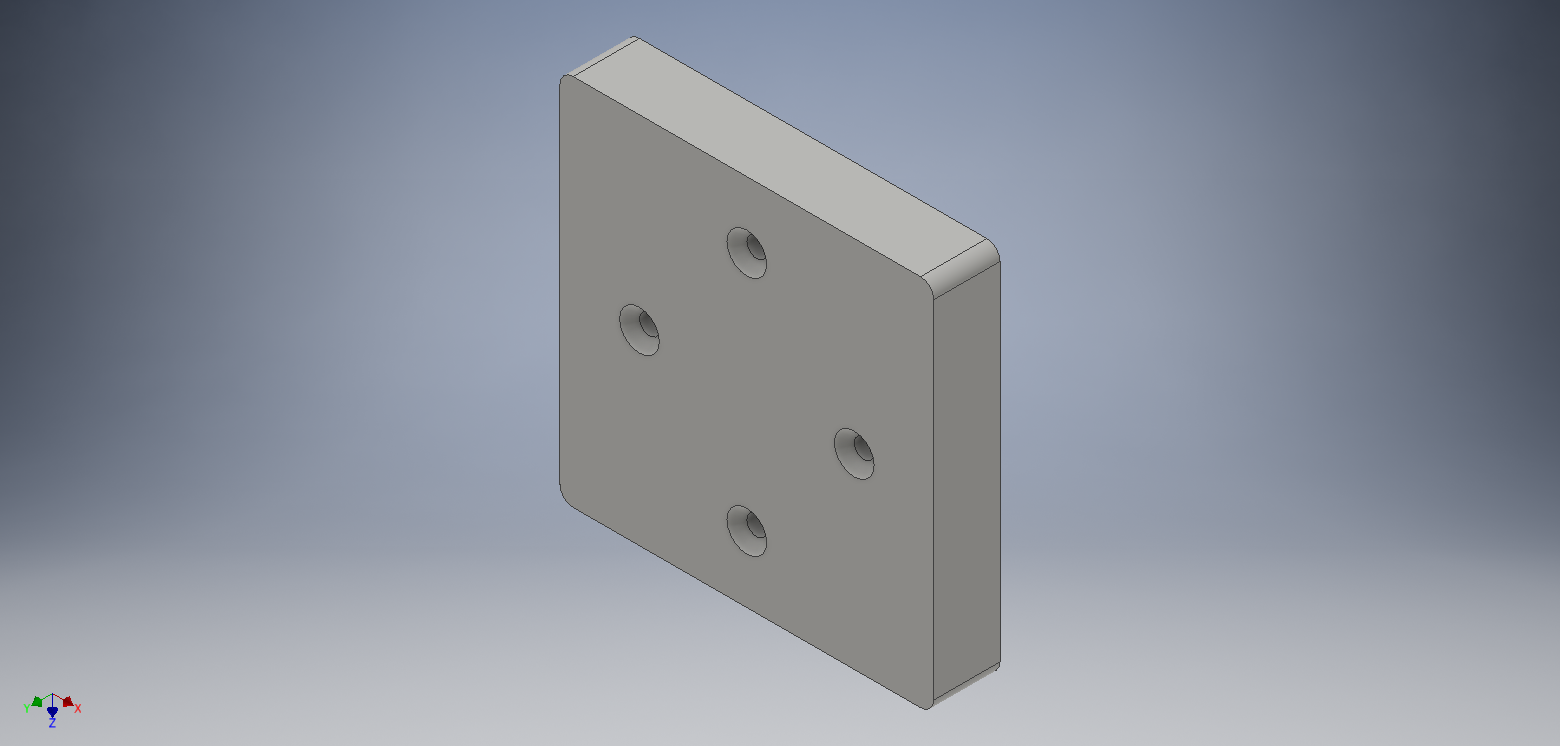

The Baseplate (Laser cut 5mm acrylic)

To go from Inventor to Inkscape to PDF for laser cutting:

- Create new drawing in Inventor

- Selcet Base and open the base plate inventor part (.ipt)

- Rotate the part so that it corresponds to lase cutting paths

- Export as pdf (this already might be enough but I needed to remove all the non needed graphical elements

- Import the pdf to inkscape and edit it so that it can be laser cut and save it as pdf.

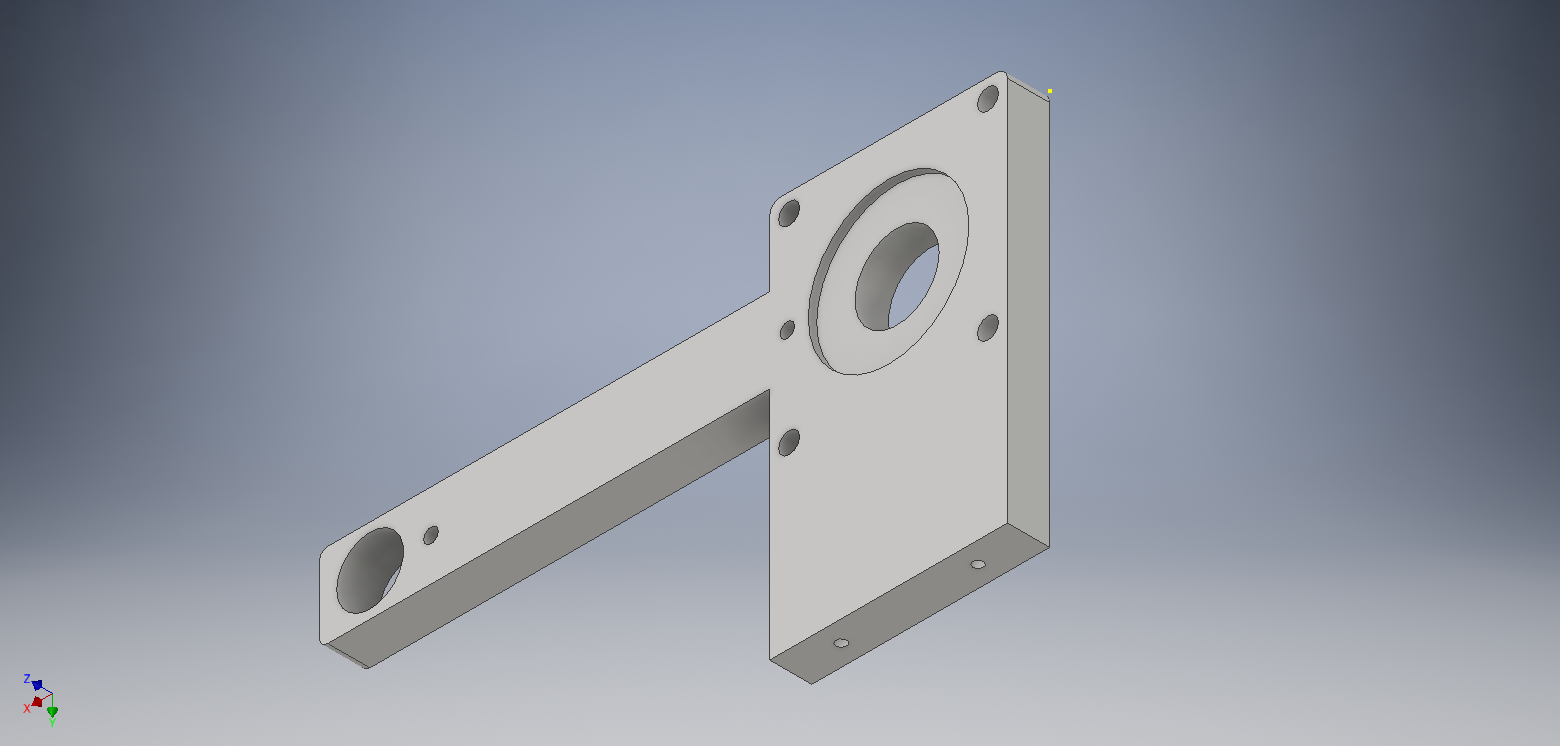

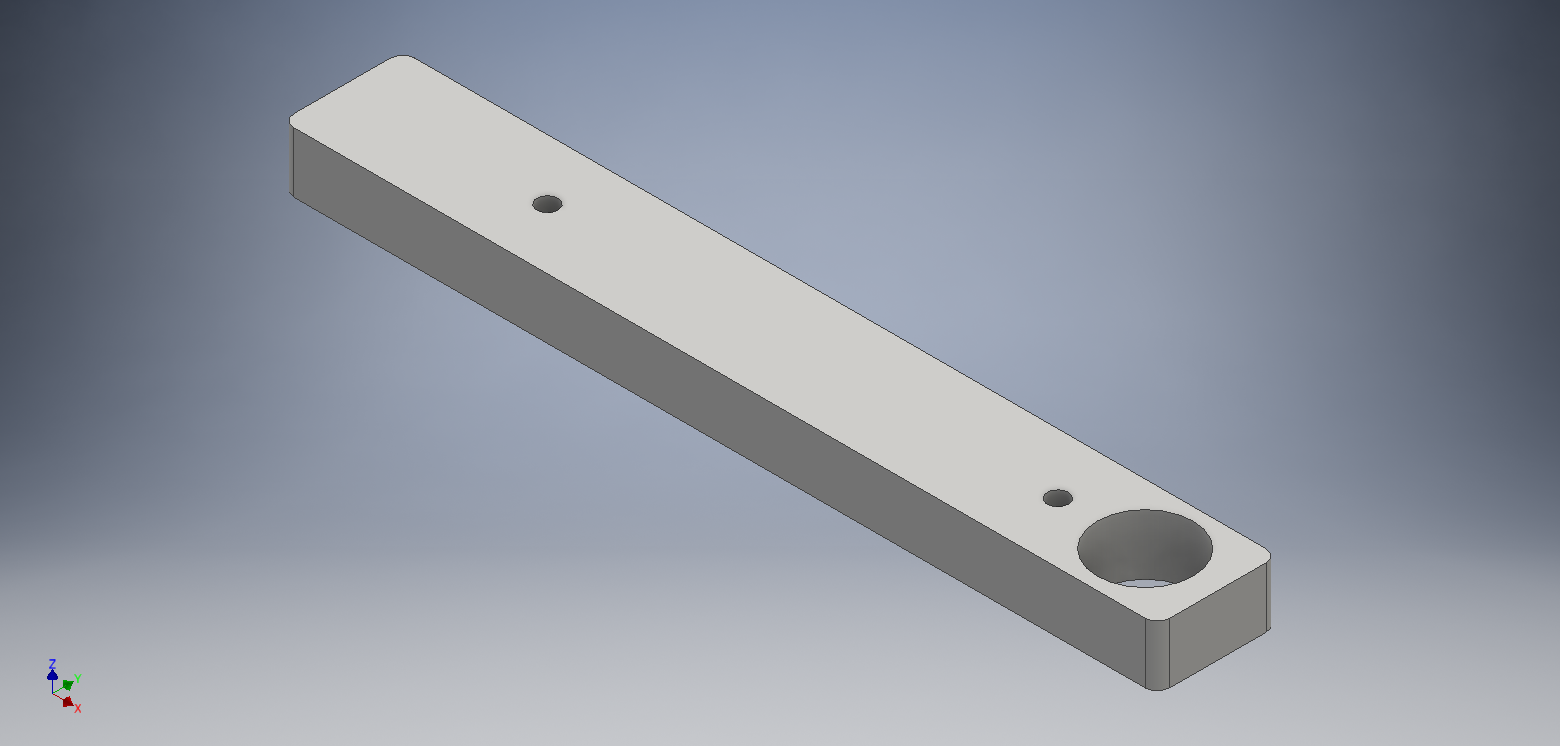

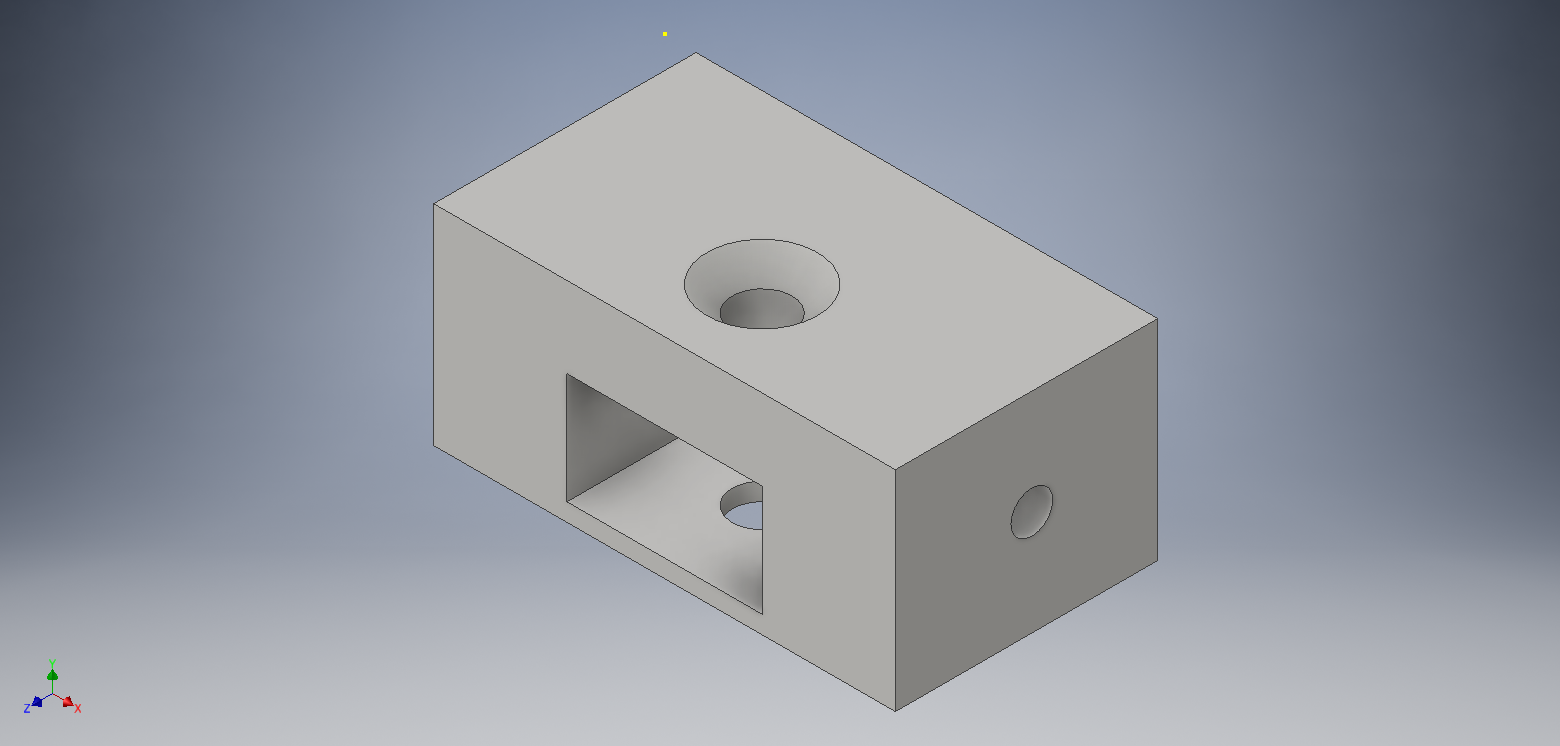

Motor holders: Milled with Roland SRM20. G code done with Inventor HSMxpress. Iused Generic Roland G-code output from the HSMXpress, The material is HDPE.

The bottom holders should be done with a column drill. I tried to speed things up an used hand drill and the screw barely stayed inside the body.

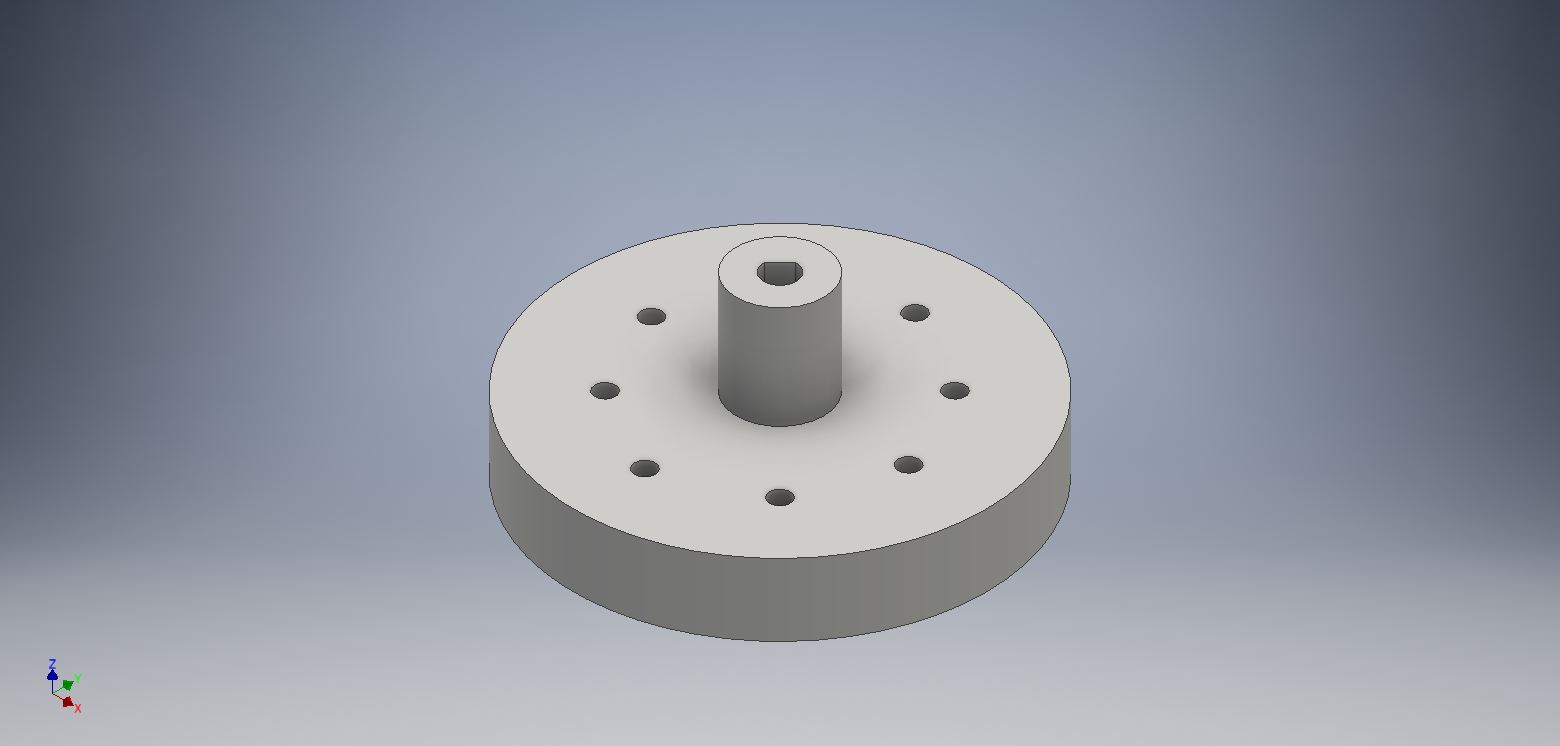

Holders for the linear input and disk for holding the coil bobbin. This one is designed for different types of guitar pickups. The parts are 3D printed with Stratasys Fortus 380mc. The material is black ABS.

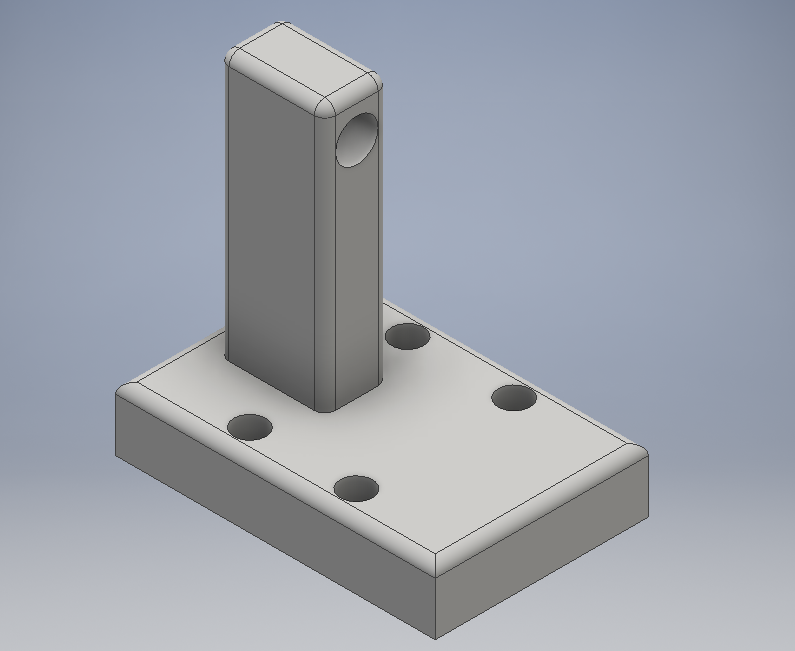

The underside parts are four feet and two parts the hold the motor holders attached onto the base plate. The parts are 3D printed with Stratasys Fortus 380mc. The material is black ABS.

I packetized the electronics from the Output devices -week. The other board's fastening holes were 90 deg off but was secure enough. Also, the heat sinks needed holes onto the lid plate. Other option would have been lowering the screw mounts. More heat dissipation is guaranteed with this design anyway.

Here is a simple GUI for the winding machine. It shows the rotations and has start button to engage the winding process.

Since we have 20 MHz resonator as a processor clock, we need to make same adjustment to Arduino IDE as described in week 8 to produce correct timing for serial communication etc.

BOM:

|

Item |

amount |

(EUR) |

Total(EUR) |

|

Stepper motor Nema 23 |

2 |

15 |

30 |

|

A4988 stepper driver module |

2 |

2 |

4 |

|

10mm HDPE (black) |

300 cm2 |

5 |

5 |

|

Linear rail with block |

1 |

10 |

10 |

|

PCB board |

30 cm2 |

3 |

3 |

|

ATmega 328p |

1 |

2 |

2 |

|

Misc .smd components |

1 |

5 |

5 |

|

3D printer ABS |

100cm |

5 |

5 |

|

Pulleys |

2 |

2 |

4 |

|

Belt |

1 |

1 |

5 |

|

Nuts and bolts |

1 |

2 |

2 |

|

Bearing shaft 1/4” |

60mm |

3 |

3 |

|

|

|

Total: |

76 |

What still needs to be improved:

- Microstepping for guiding stepper

- Improve the user interface

- Improve the speed (RPM of the winding stepper)

- Better wire spool holder

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.