Final project Index:

Concept:

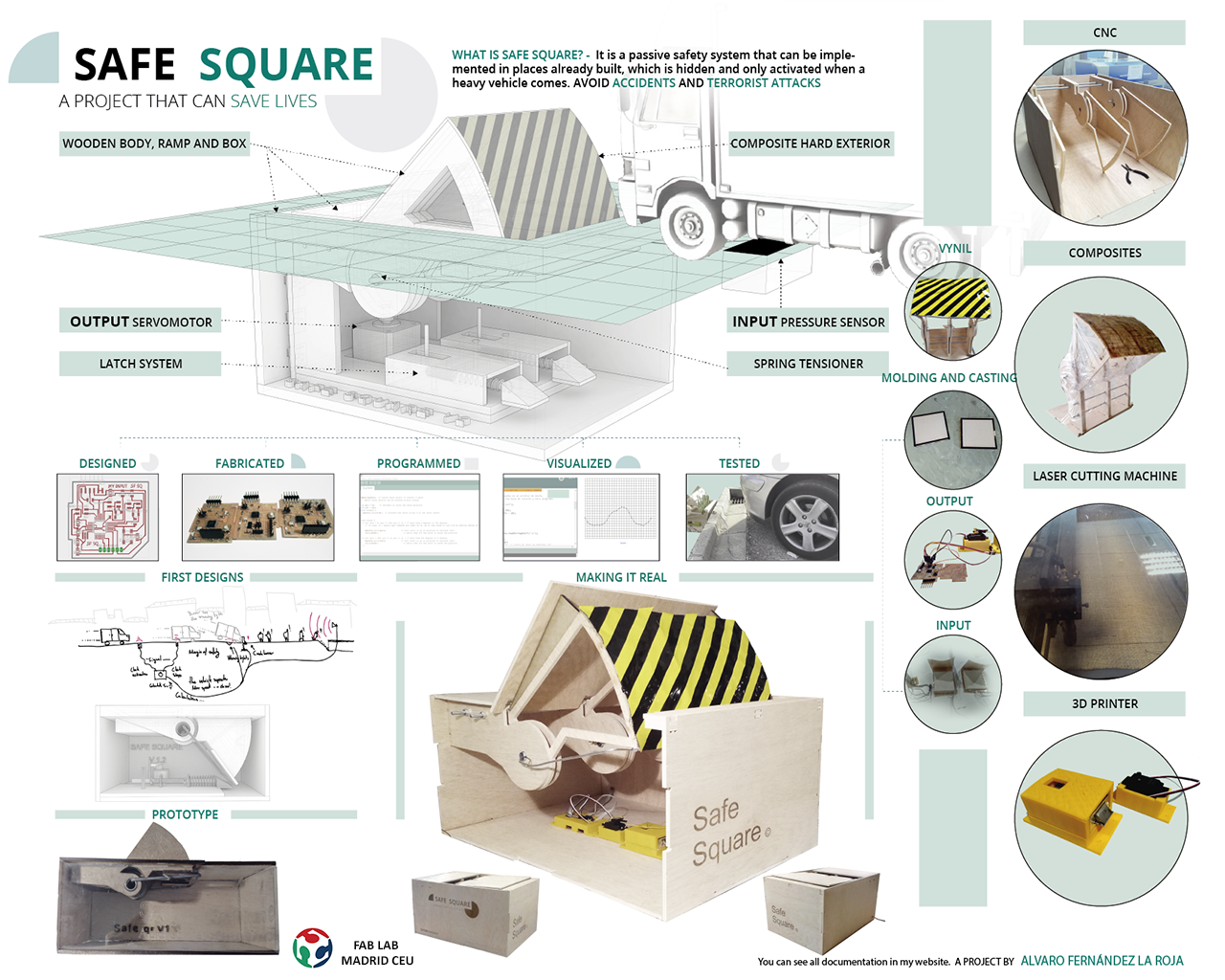

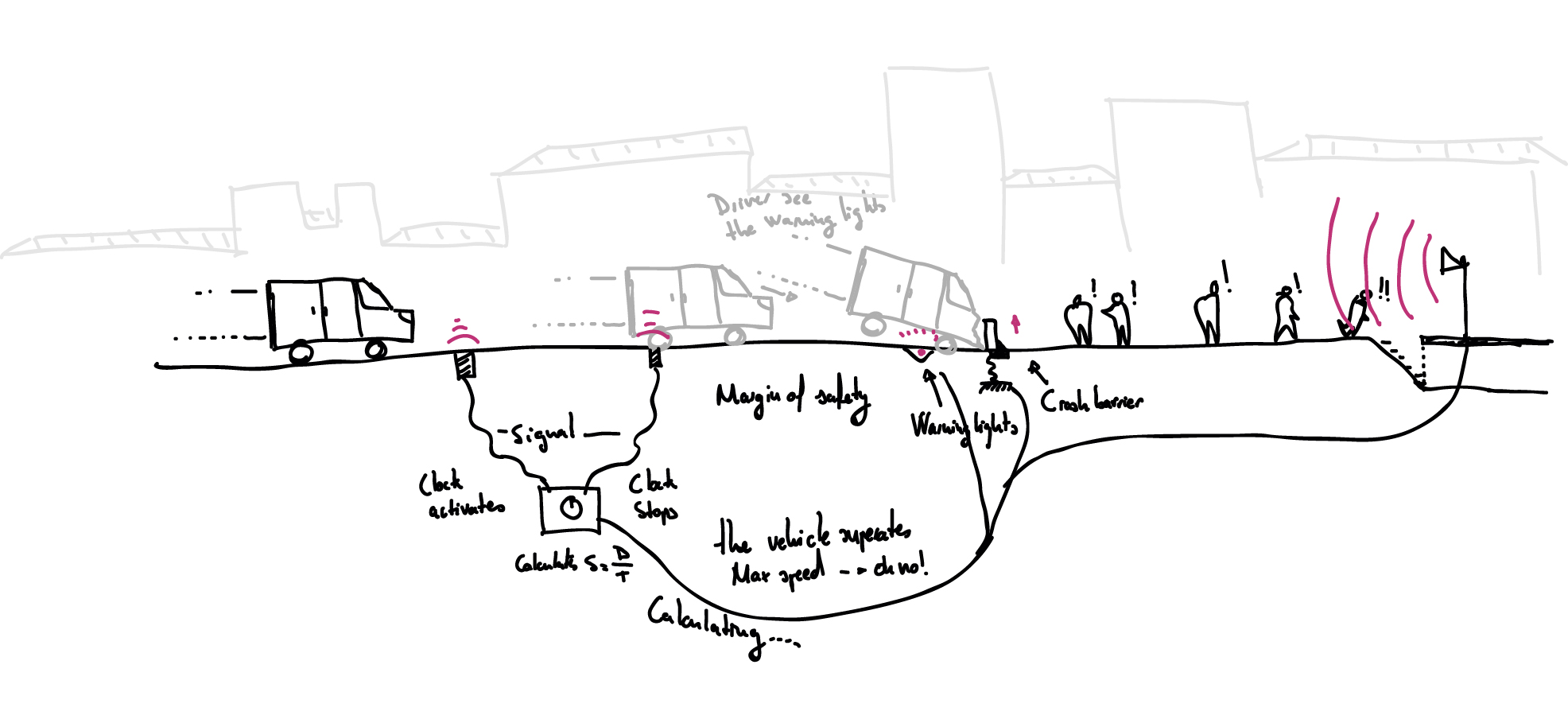

-My project will consist in an anti-run over security enclosure. The last accidents and terrorist attacks, produced in crowded areas,

makes necessary to protect public important spaces from possible accidents.

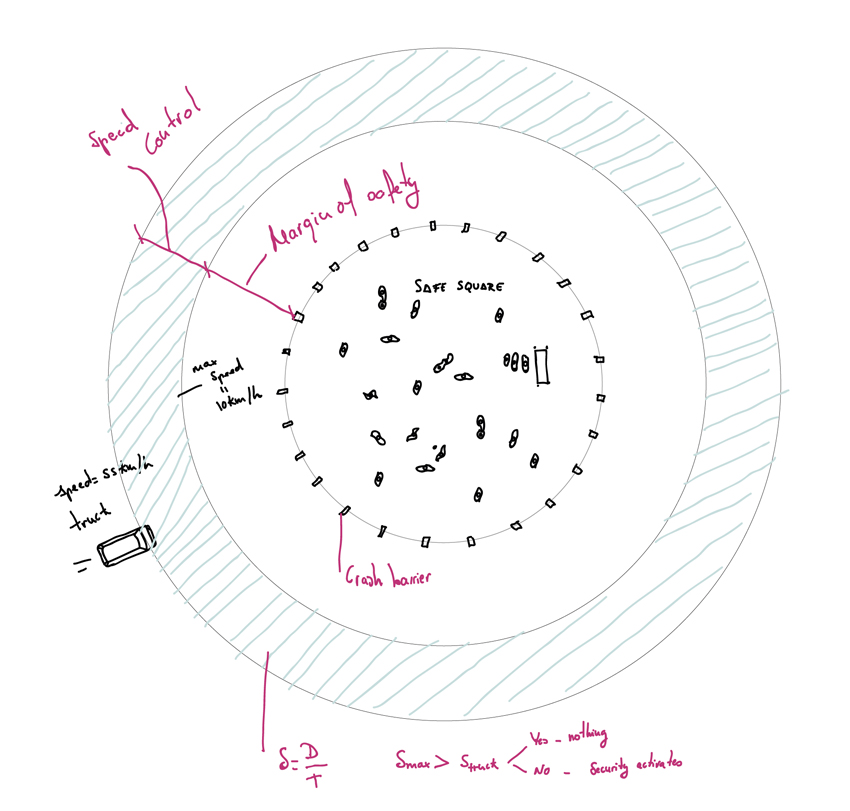

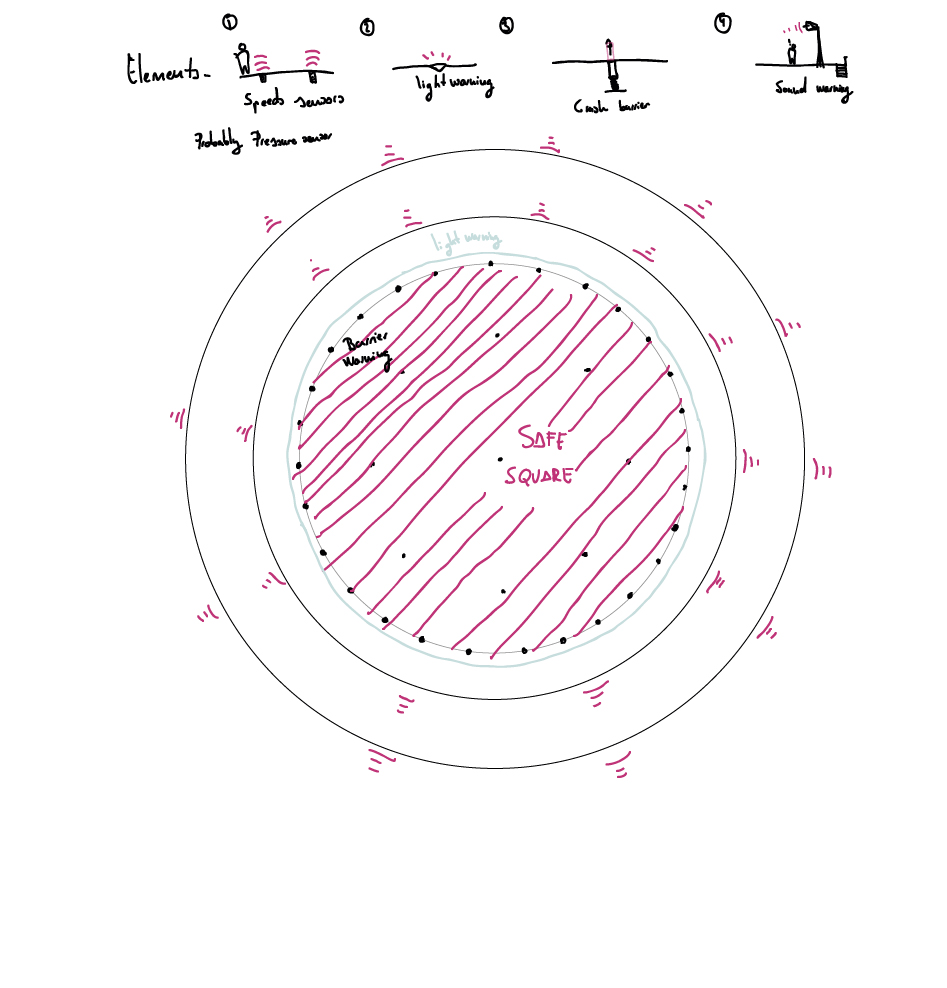

Around a circle or a square we will prepare a safety zone,

when people it's walking the security sistem is not activated but when a car or a heavy vehicle cross the detectors with high speed the security system it's activated.

avoiding the collision that may be caused, could thus be an urban prevention of accidents or terrorist attacks.

--- How does it works? ---

Safe Square and zones.

Safe Square and zones.

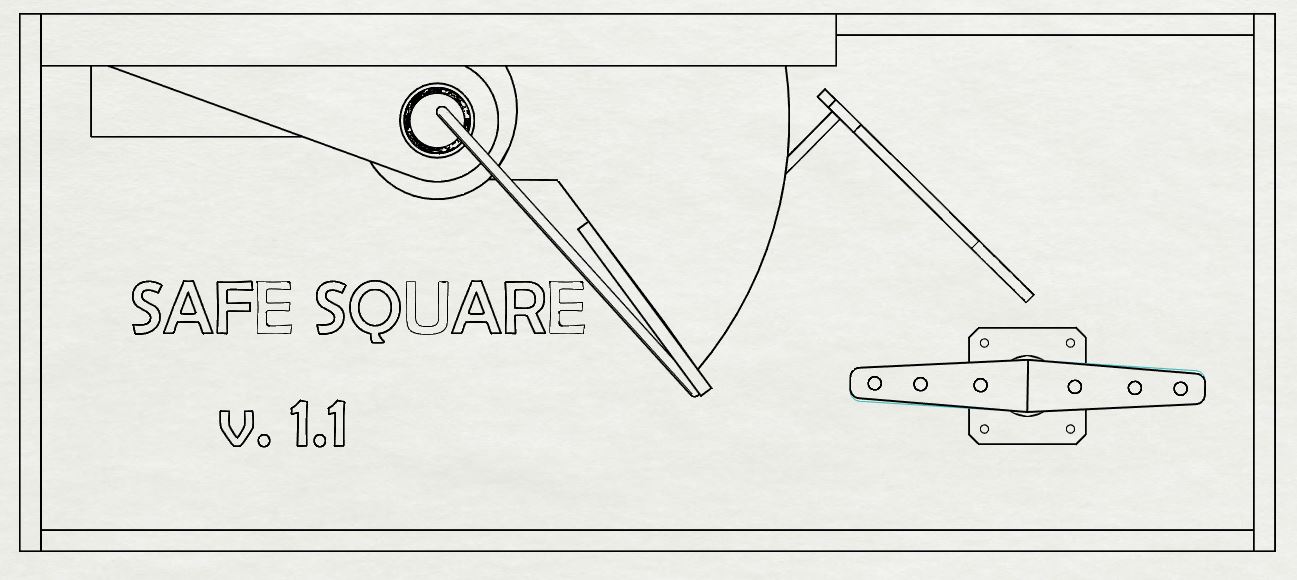

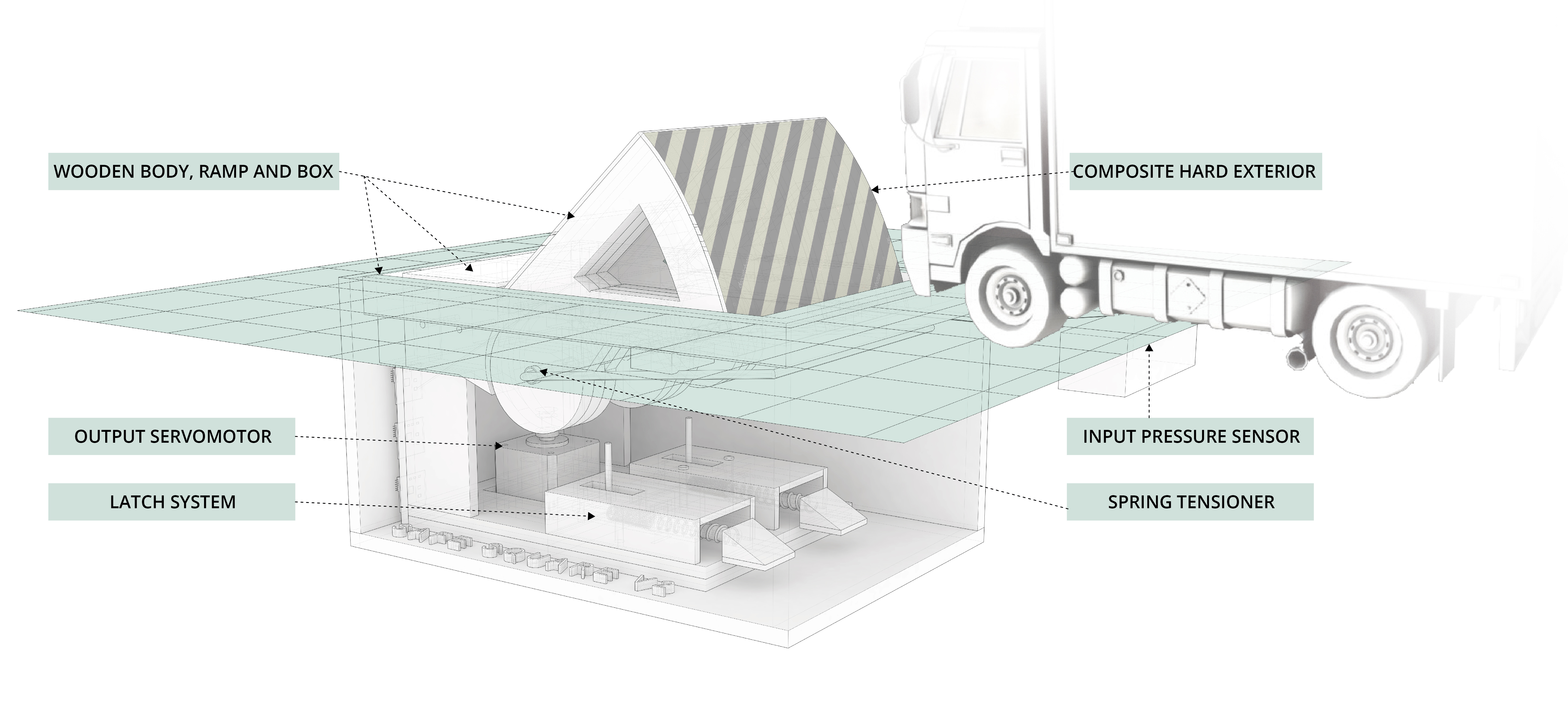

Elements and devices.

Elements and devices.

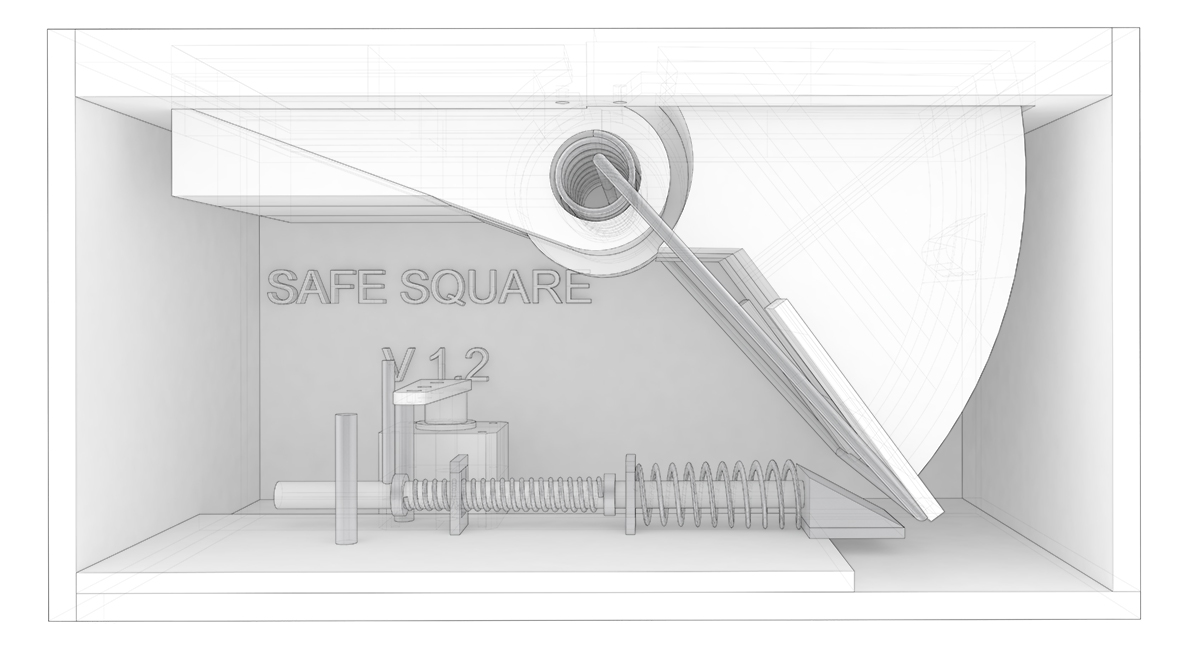

How does it works?

How does it works?

This will be an initial phase of the project, and in the future we will be able to make it more complicated or more simple

Update:

briefly summarises your project

This is the presentation of my project that I included in the James Dyson awards contest.

What It Does?:

My project is a device designed to be place in the plazas or main squares of cities in order to avoid accidental run-overs and terrorist attacks like the ones thar occured in Nice or London. It is an automatic bollard that rises when it detects a high weight.

The Inspiration

The inspiration came from the latest attacks in numerous countries where a heavy vehicle was used to attack pedestrian friendly zones. These frequent attacks have raised awareness for taking measures to ensure safety within these popular areas of the city. These type of attacks have been increasing and there is no doubt solutions have to be made in order to prevent them from happening again.

No adequate solution has been made and the city halls have only thought of placing large objects that do not take into consideration the general transit or the sensation of fear; these solutions are not the most adequate.

How It Works?

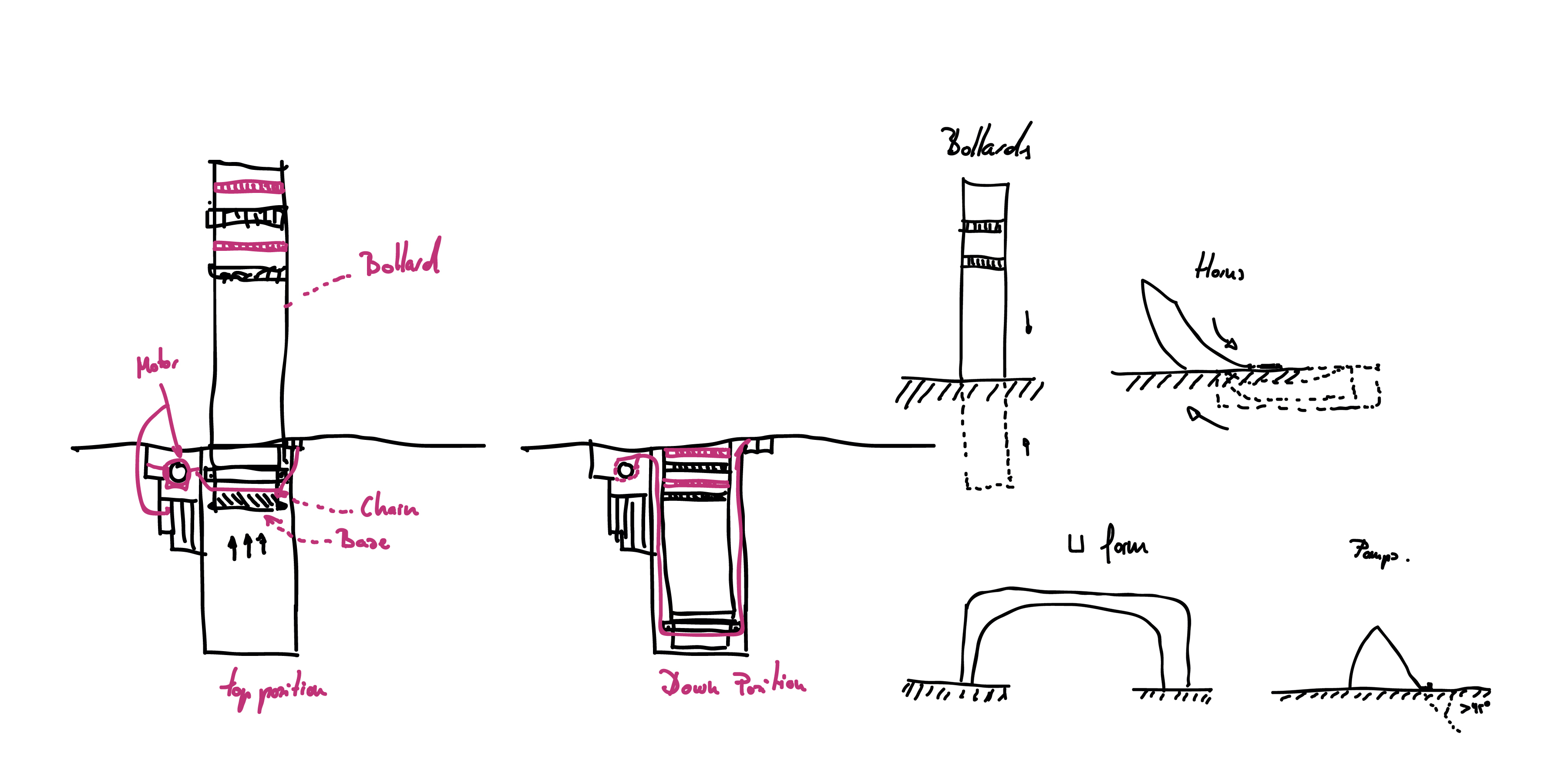

The operation is similar to conventional bollards where there is a resistant element that absorbs the kinetic energy of the vehicle and resists the impact, but in this case, there are some differences that I explain below.

It is hidden and integrated with the pavement.

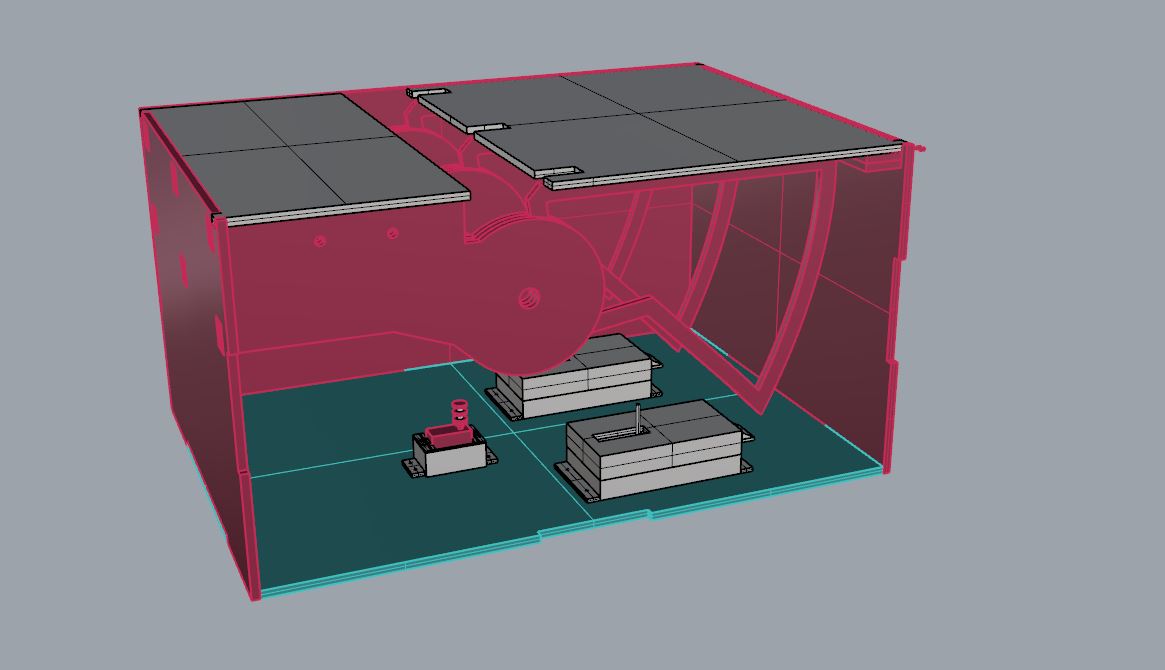

It has a spring system which rises when the micro-controller sends the signal.

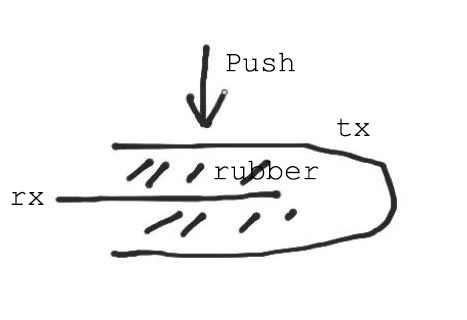

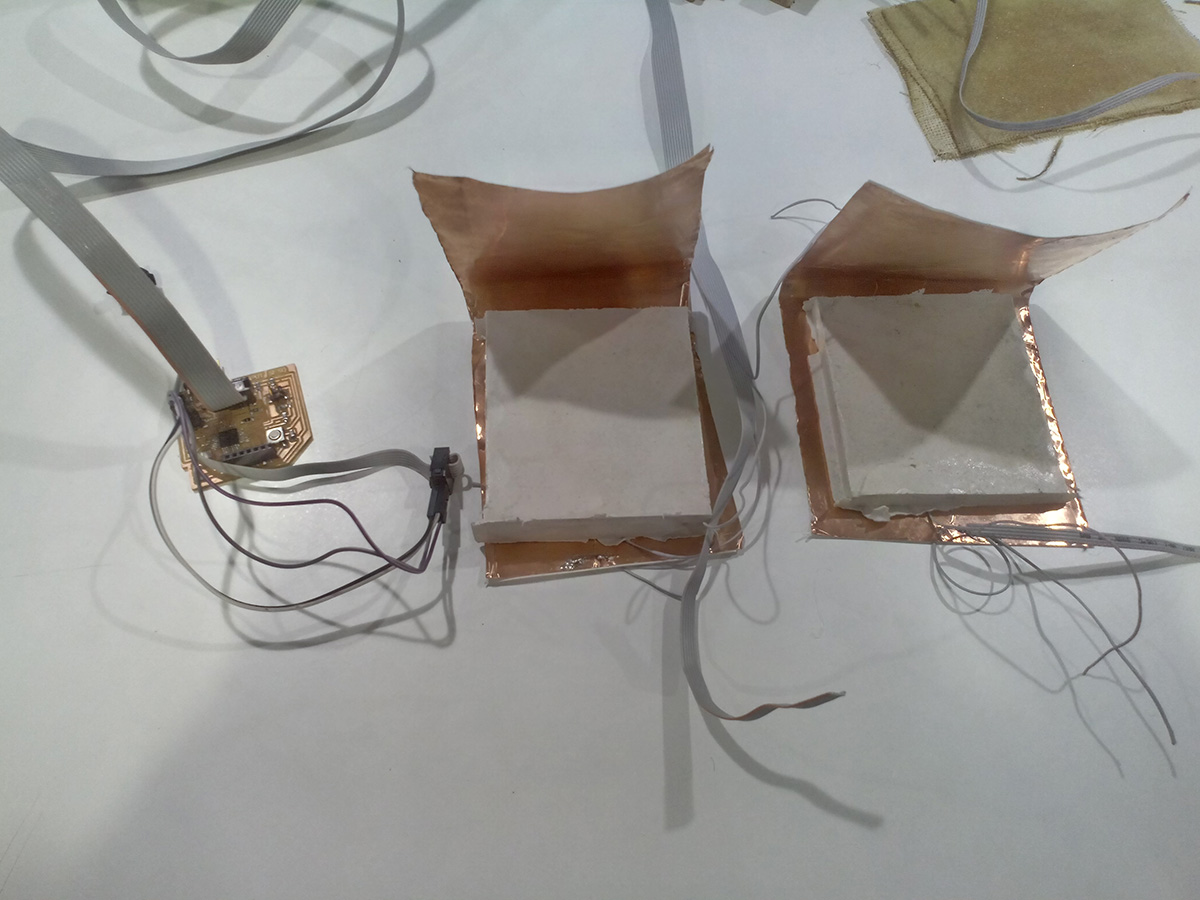

It has a pressure sensor, which only activates when it detects a heavy weight (a vehicle) and does not activate with people walking by or passing over it. This sensor sends a signal to the micro-controller that moves a small motor that releases the spring and lifts the bollard very quickly.

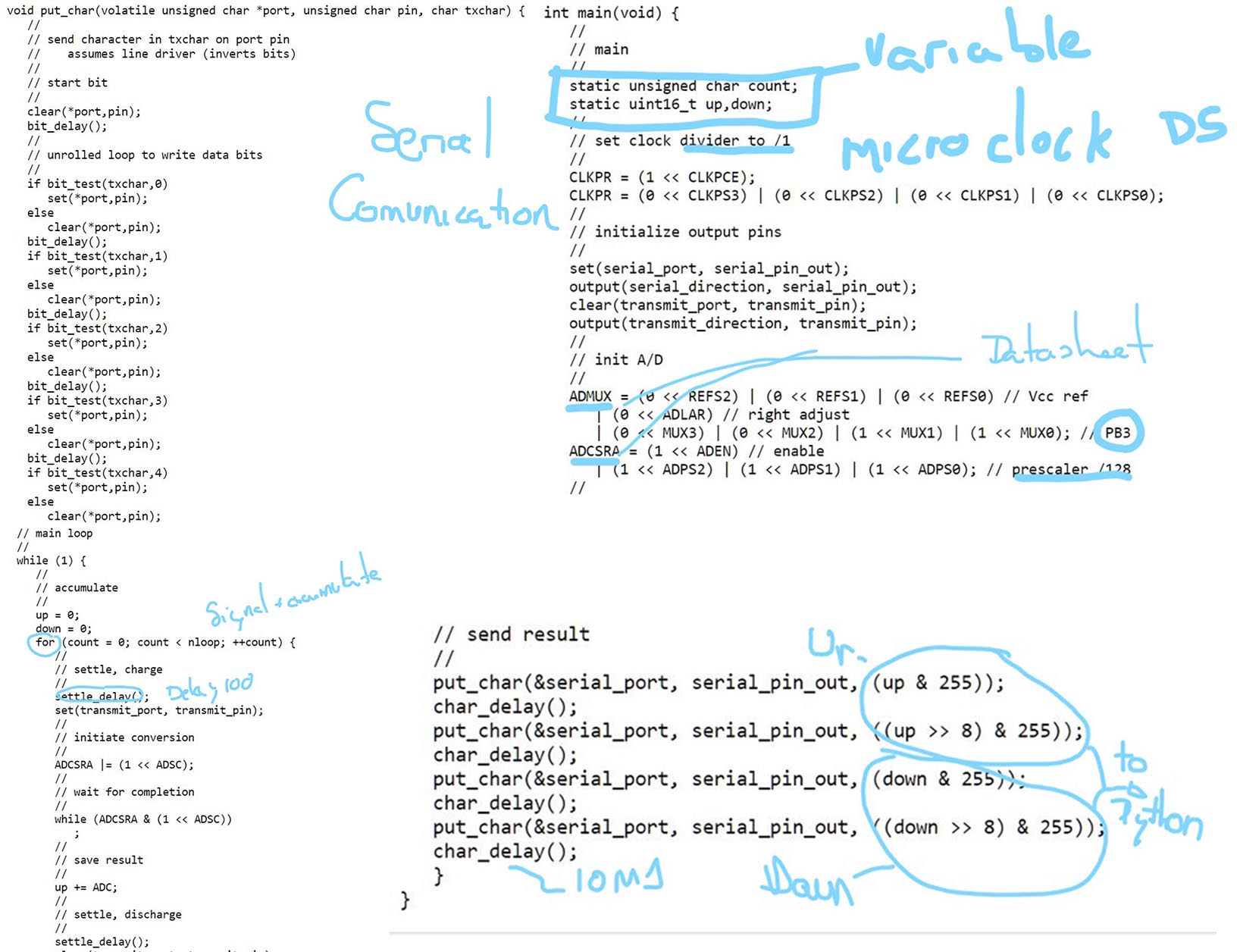

The sensor can be adjusted. The connection to the micro-controller and the motor is through serial networking and the frequency inhibitors do not affect it.

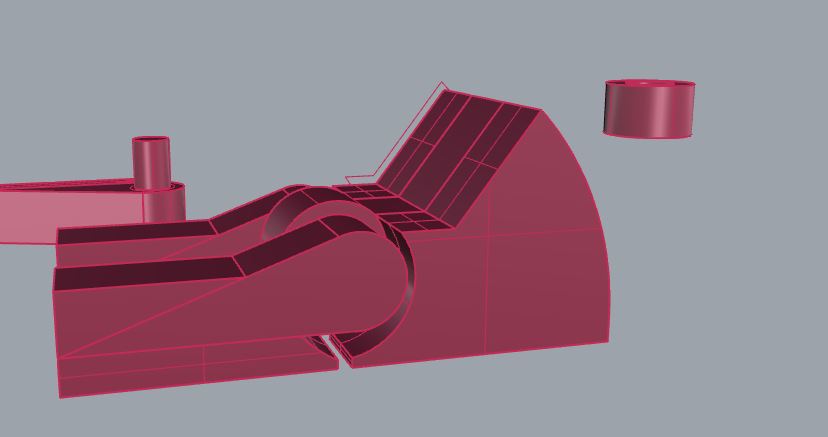

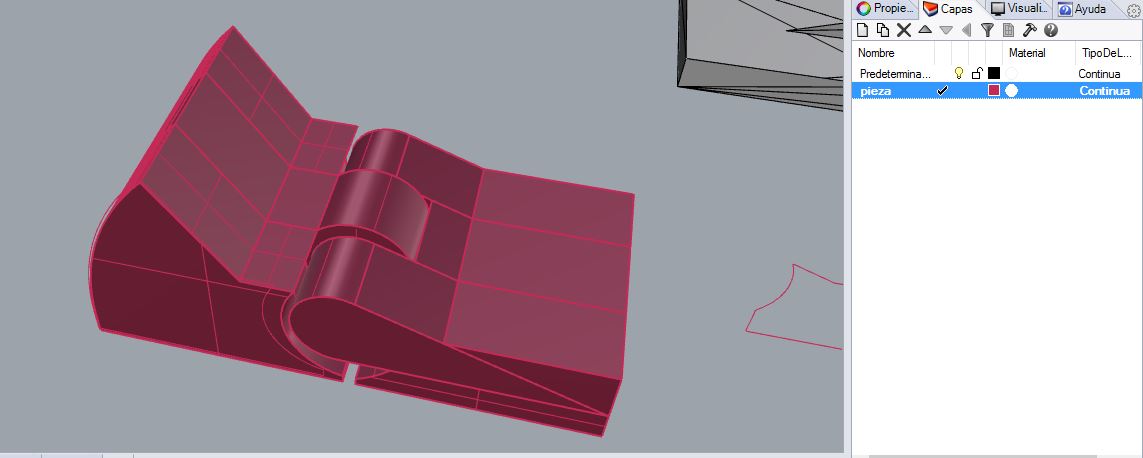

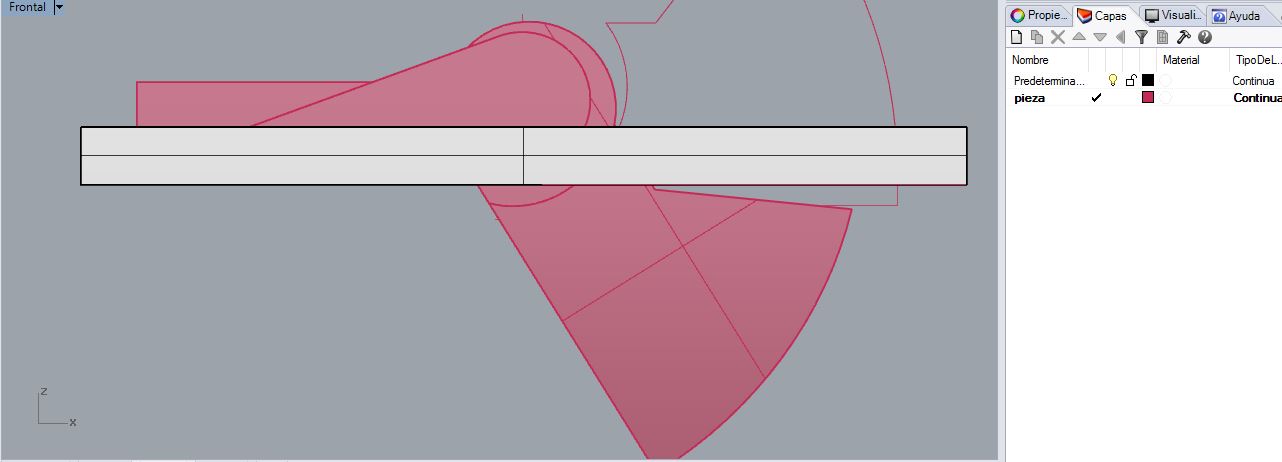

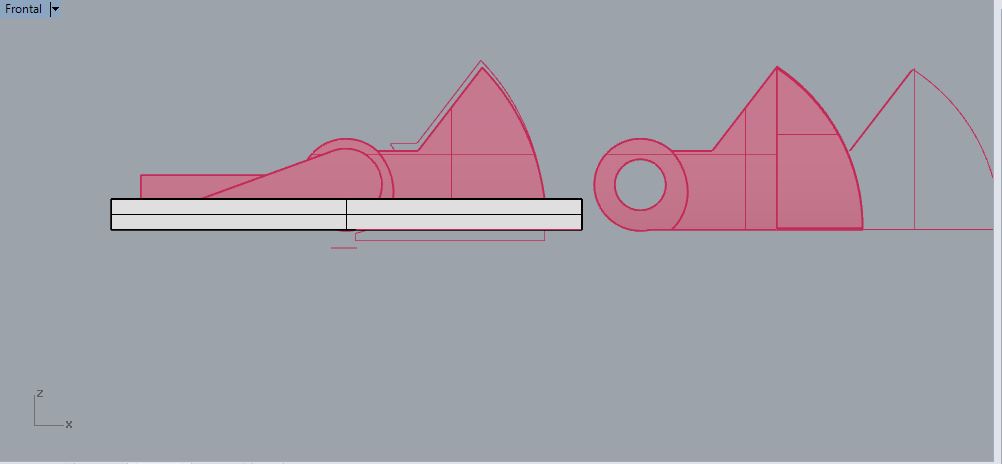

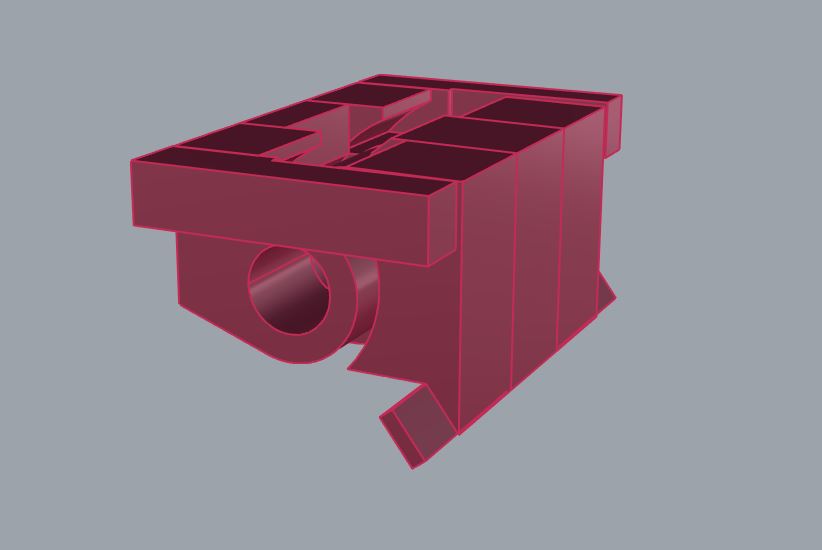

The bollard is shaped like a ramp and acts as a hinge, when it is hidden is at ground level. It is made of steel and the shape of the ramp helps to dissipate the energy.

Stages of Development

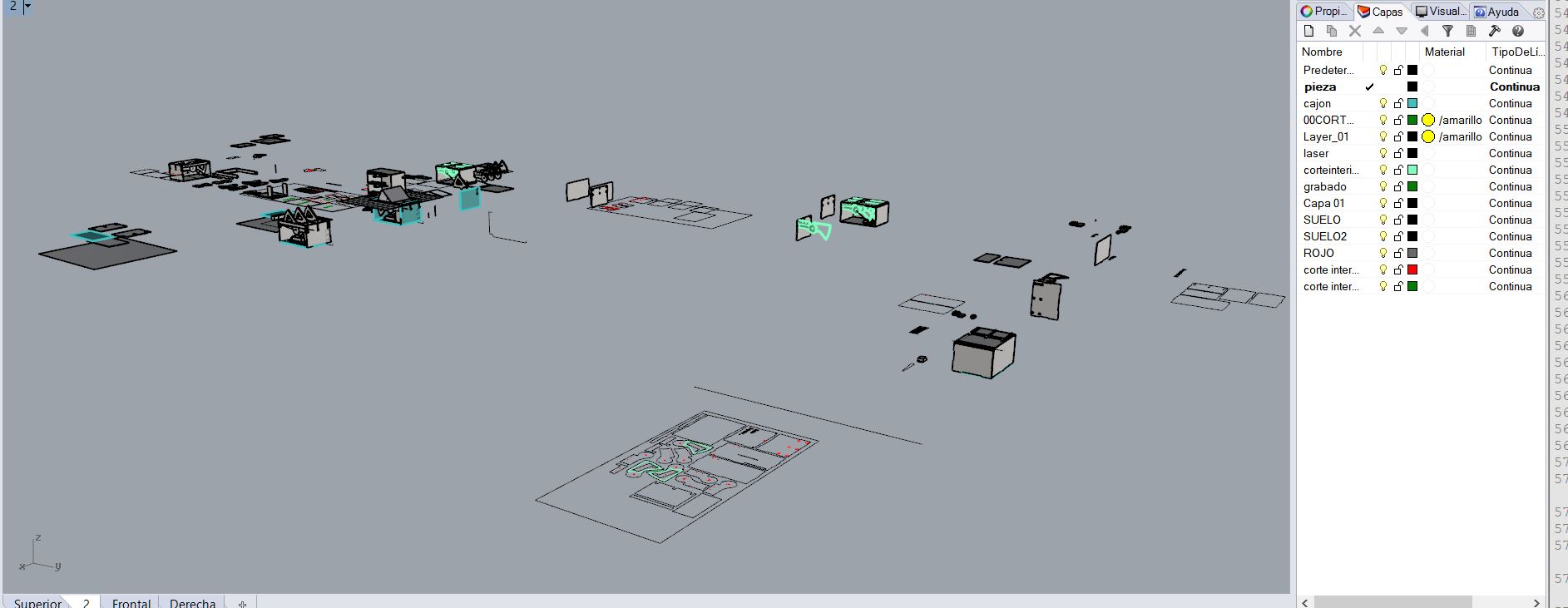

The project has been researched in parallel within the fields of design, electronic prototyping and programming.

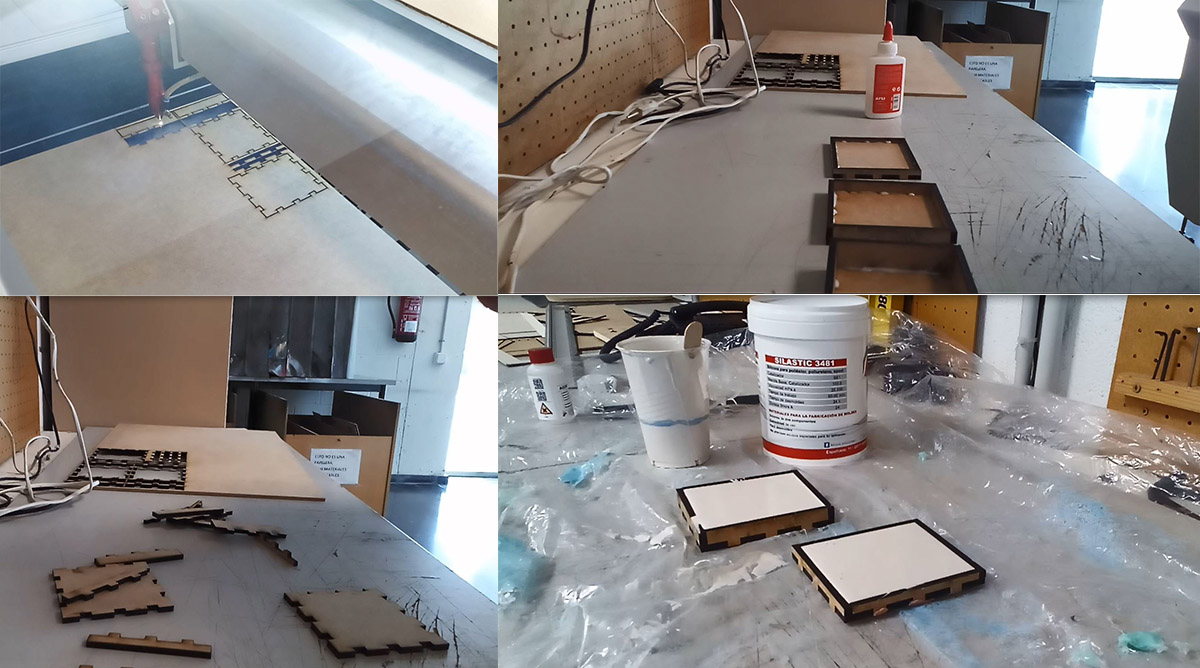

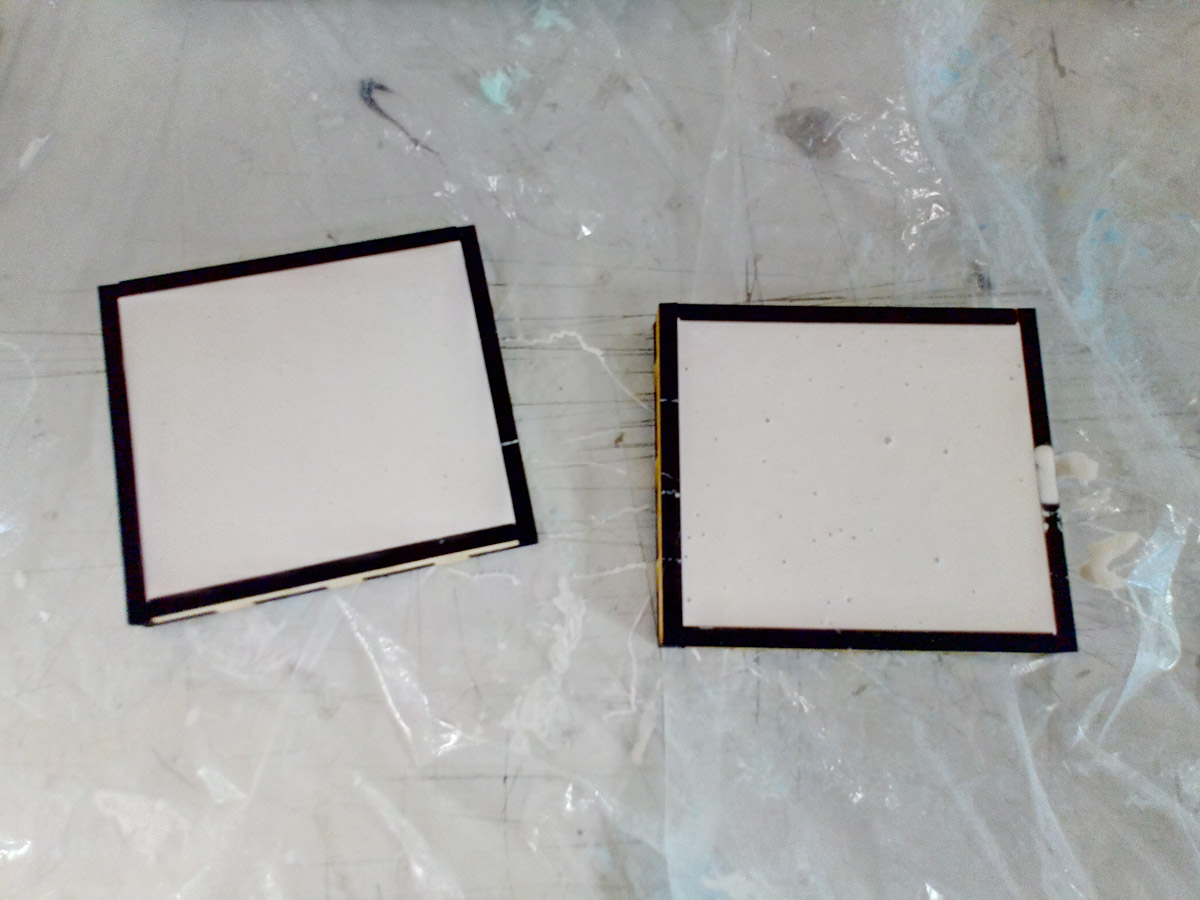

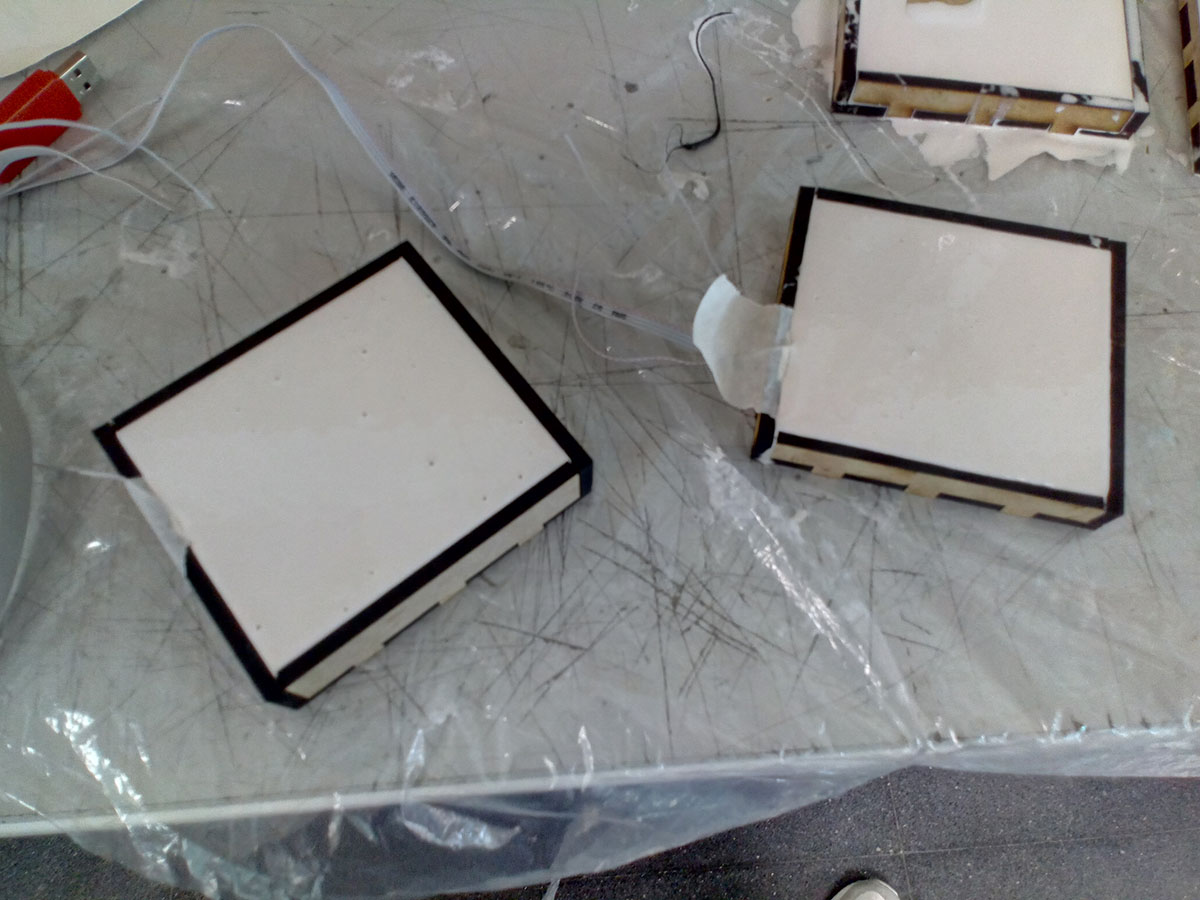

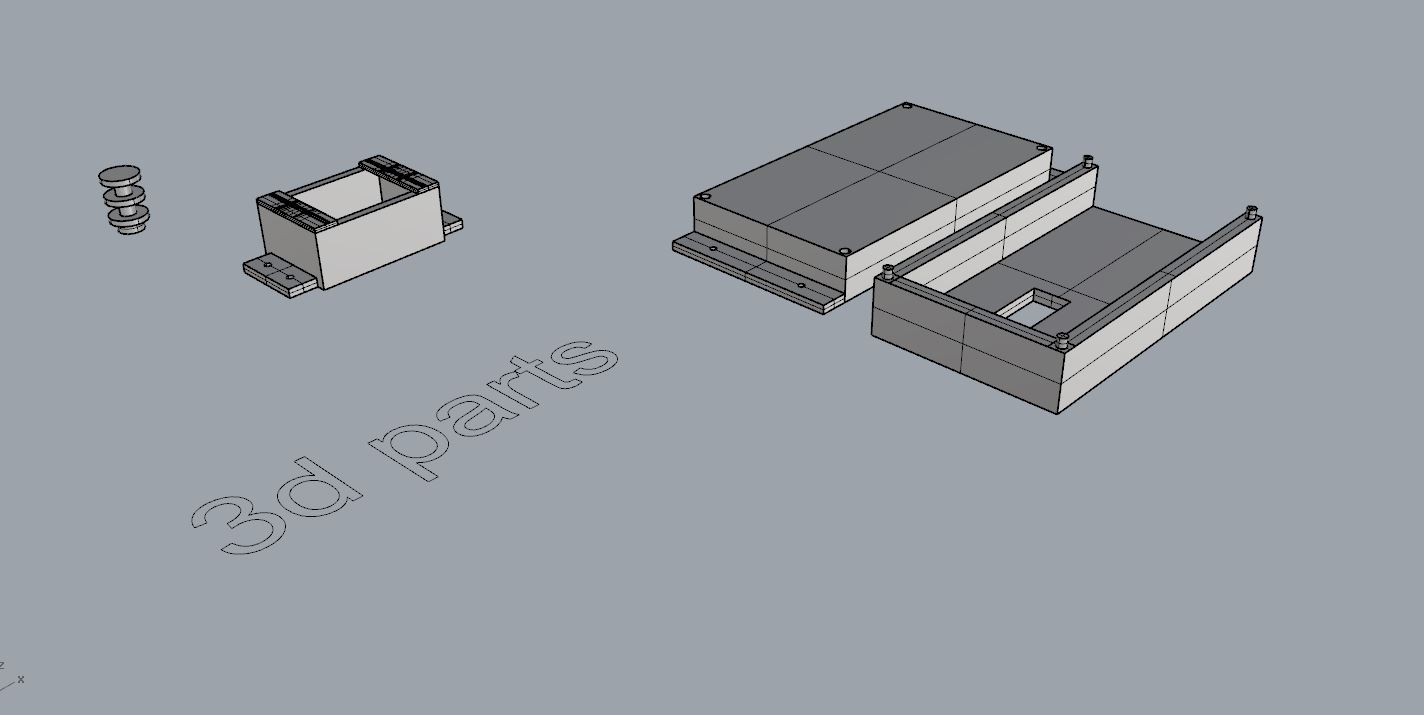

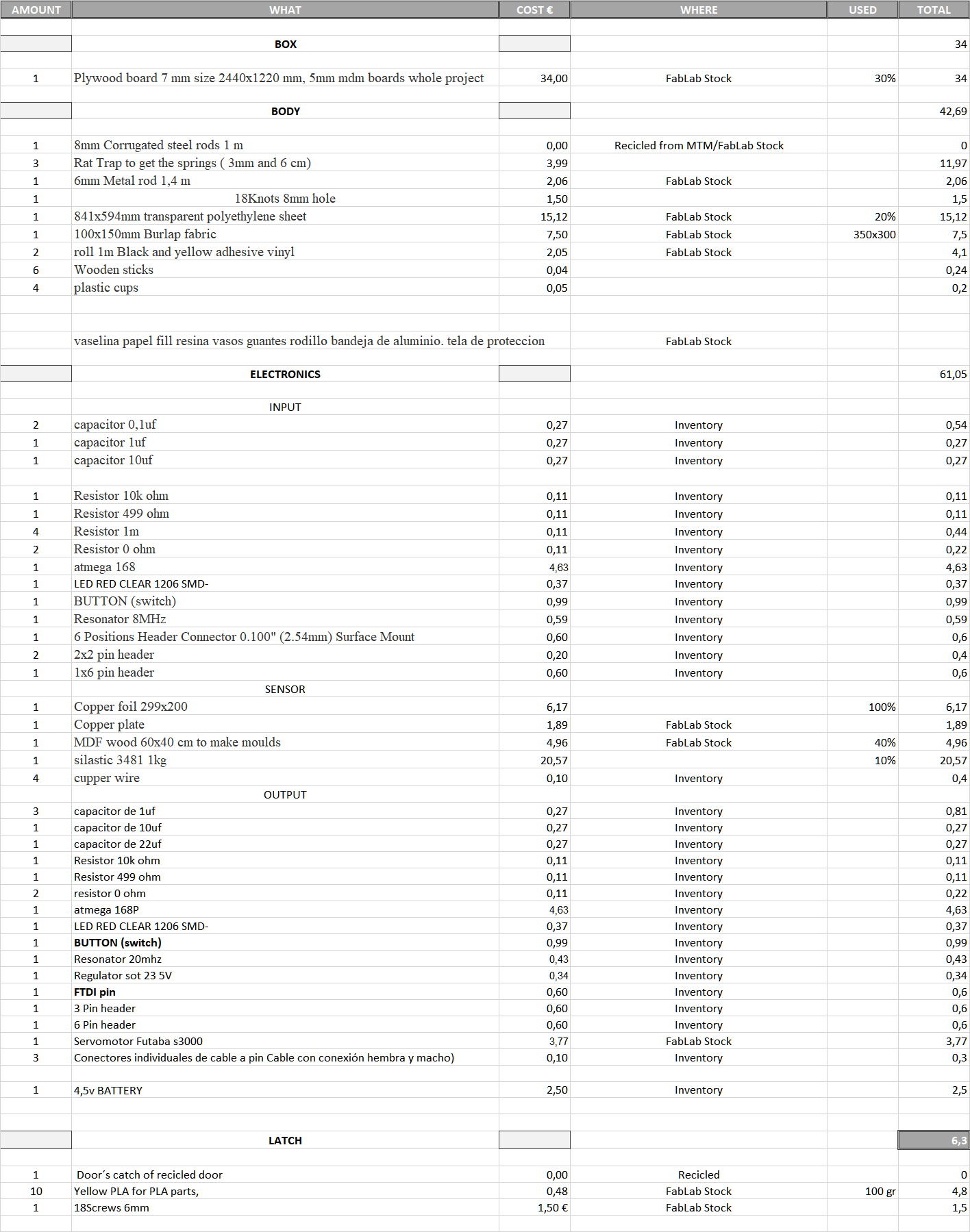

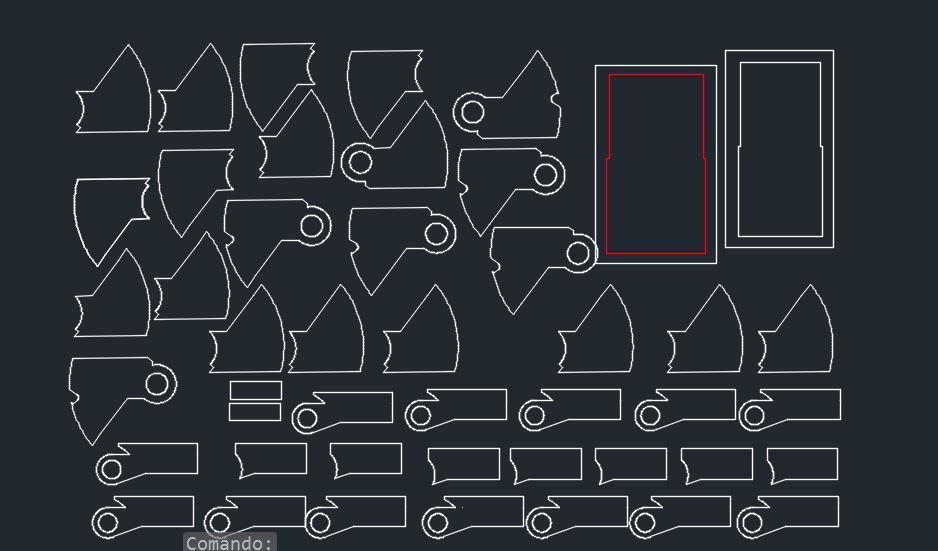

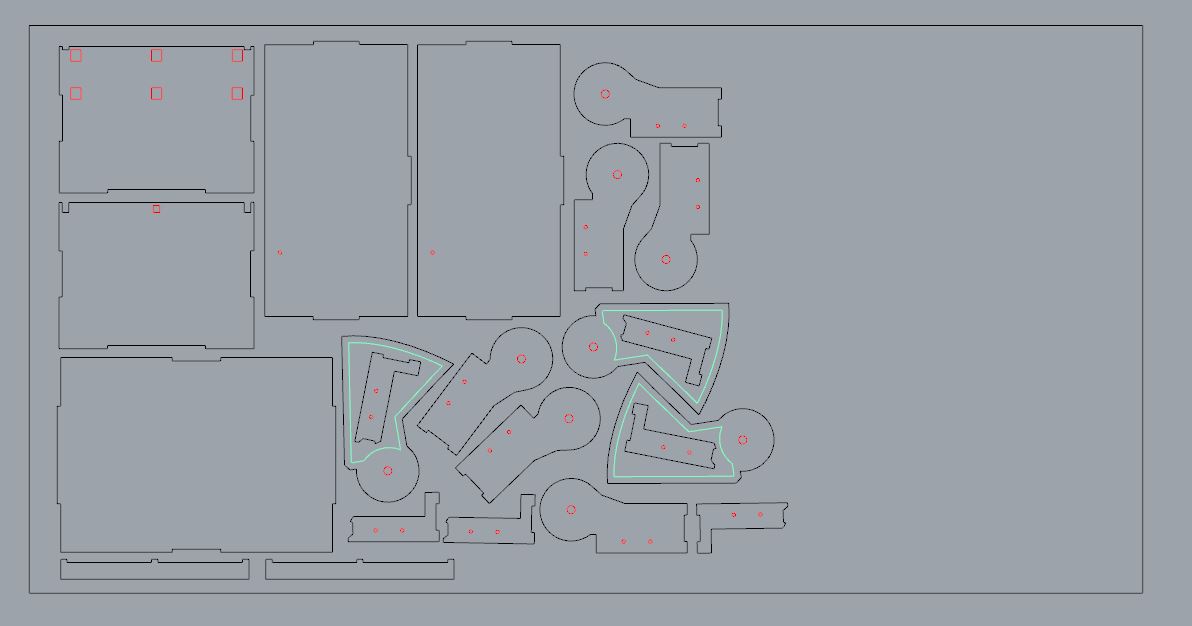

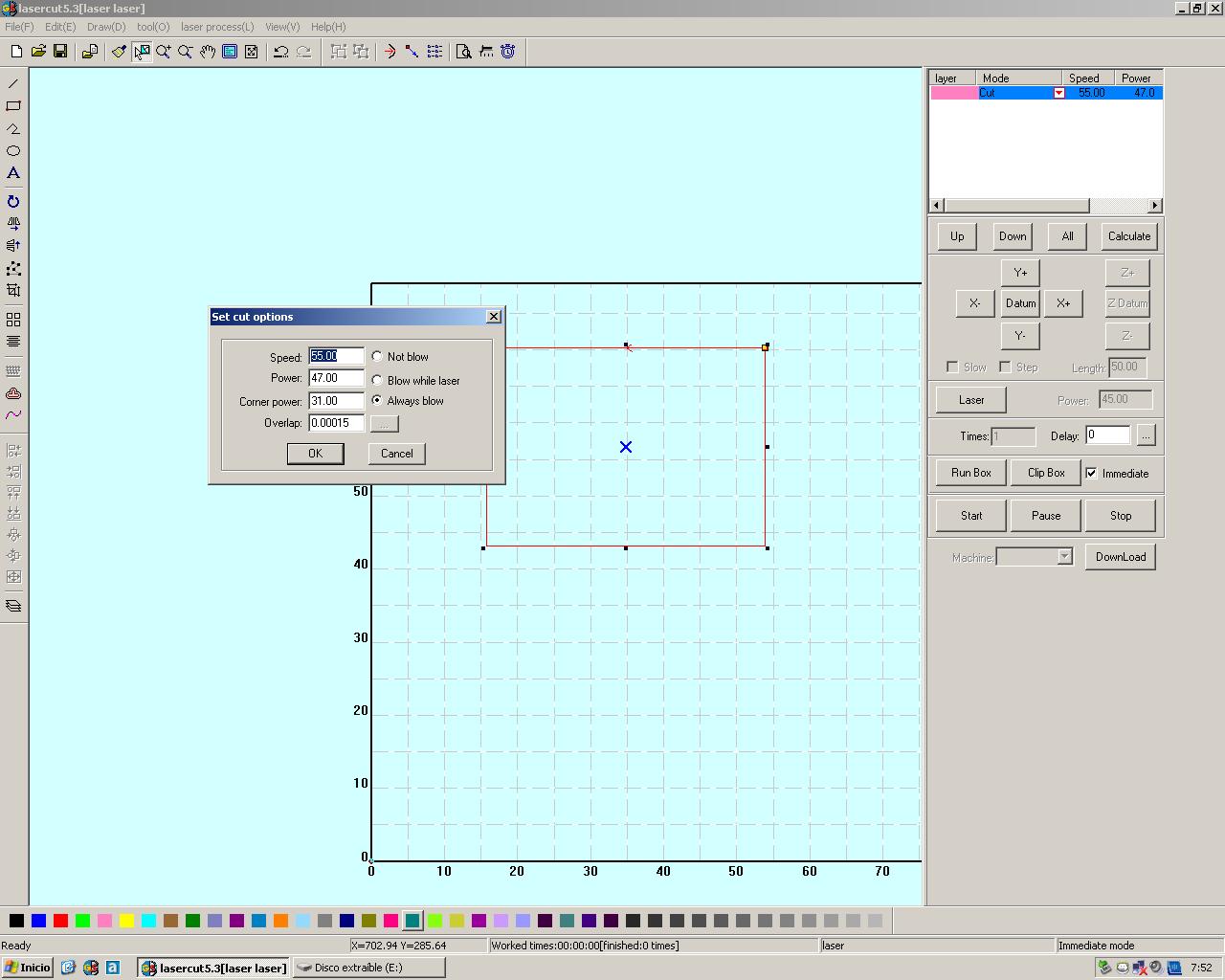

The first step was to perform a study on this type of elements and to sketch the general proposal, then I made the 3D design of the first version. The purpose of this era was to verify that it could function mechanically, I made a prototype using MD wood with a machine laser cutting, a spring inspired by a mouse trap and a locking system.

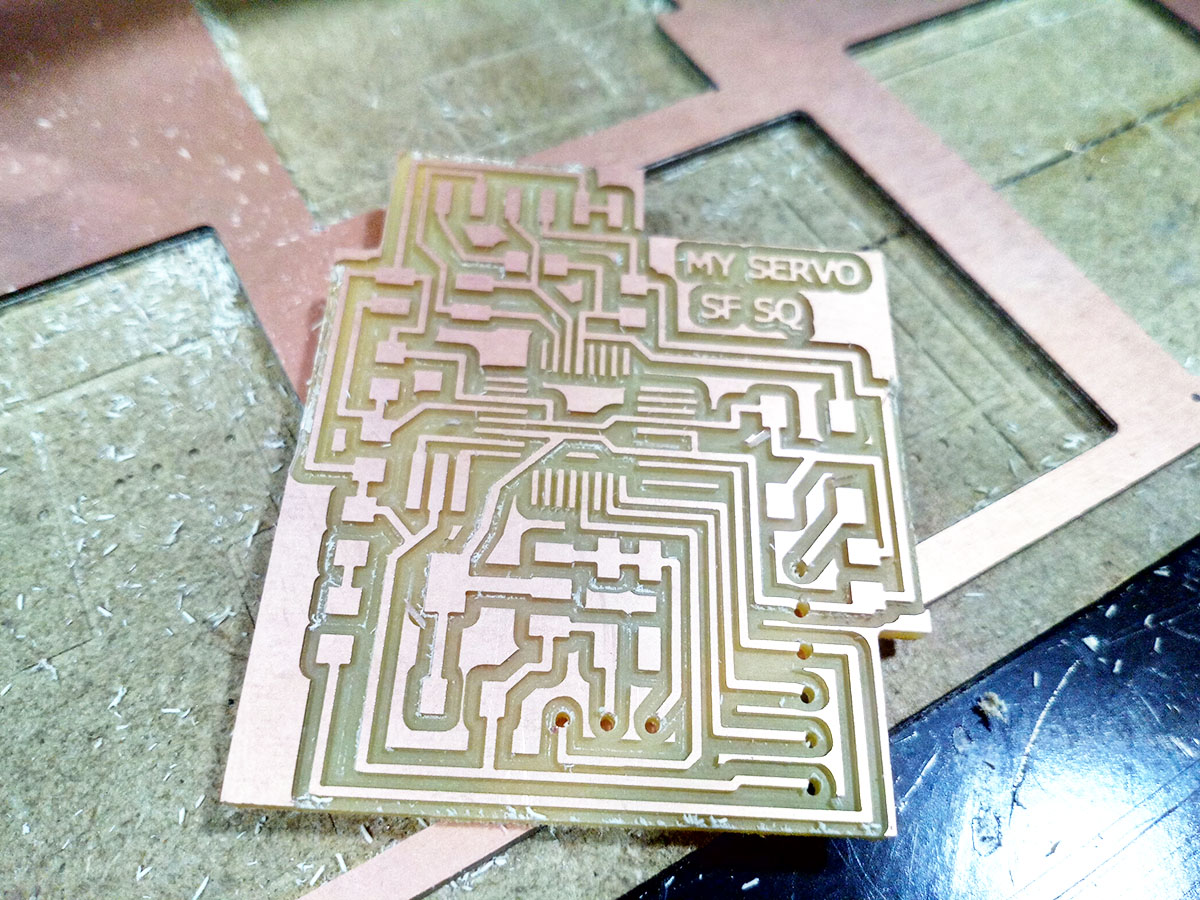

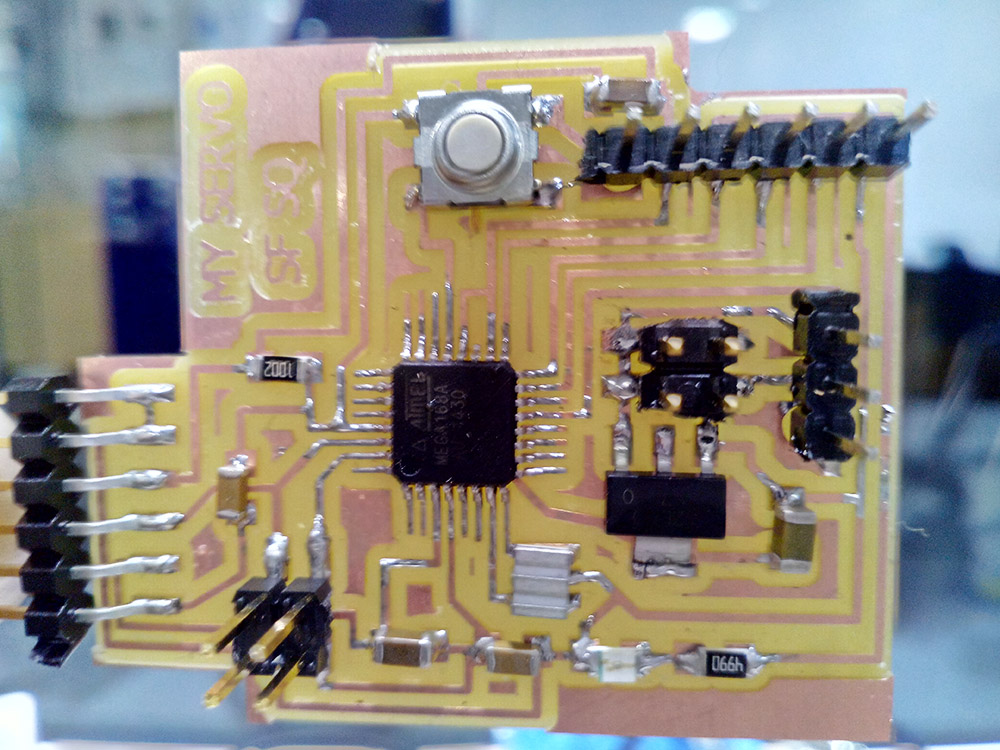

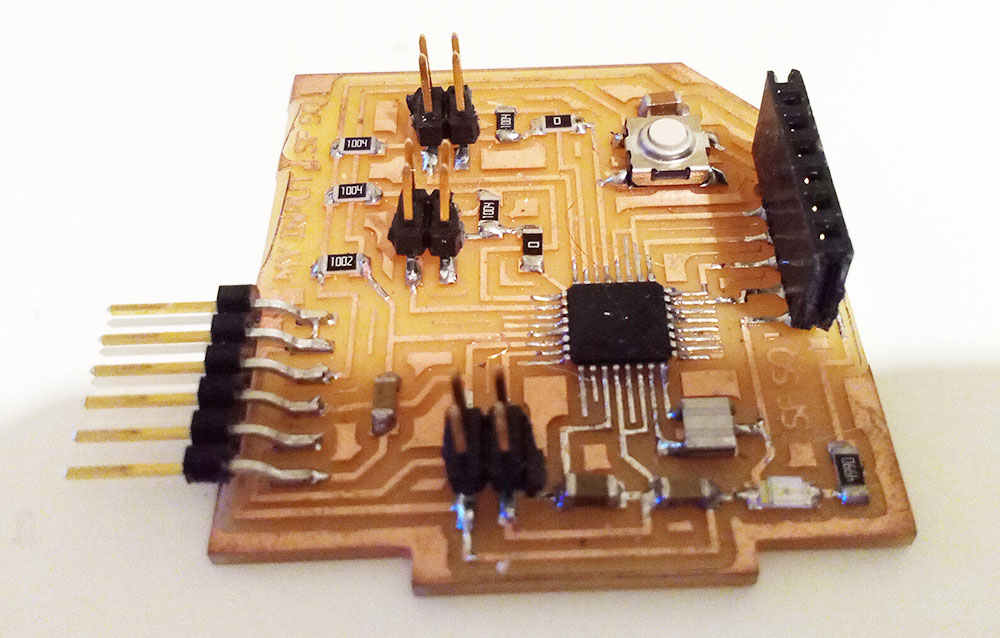

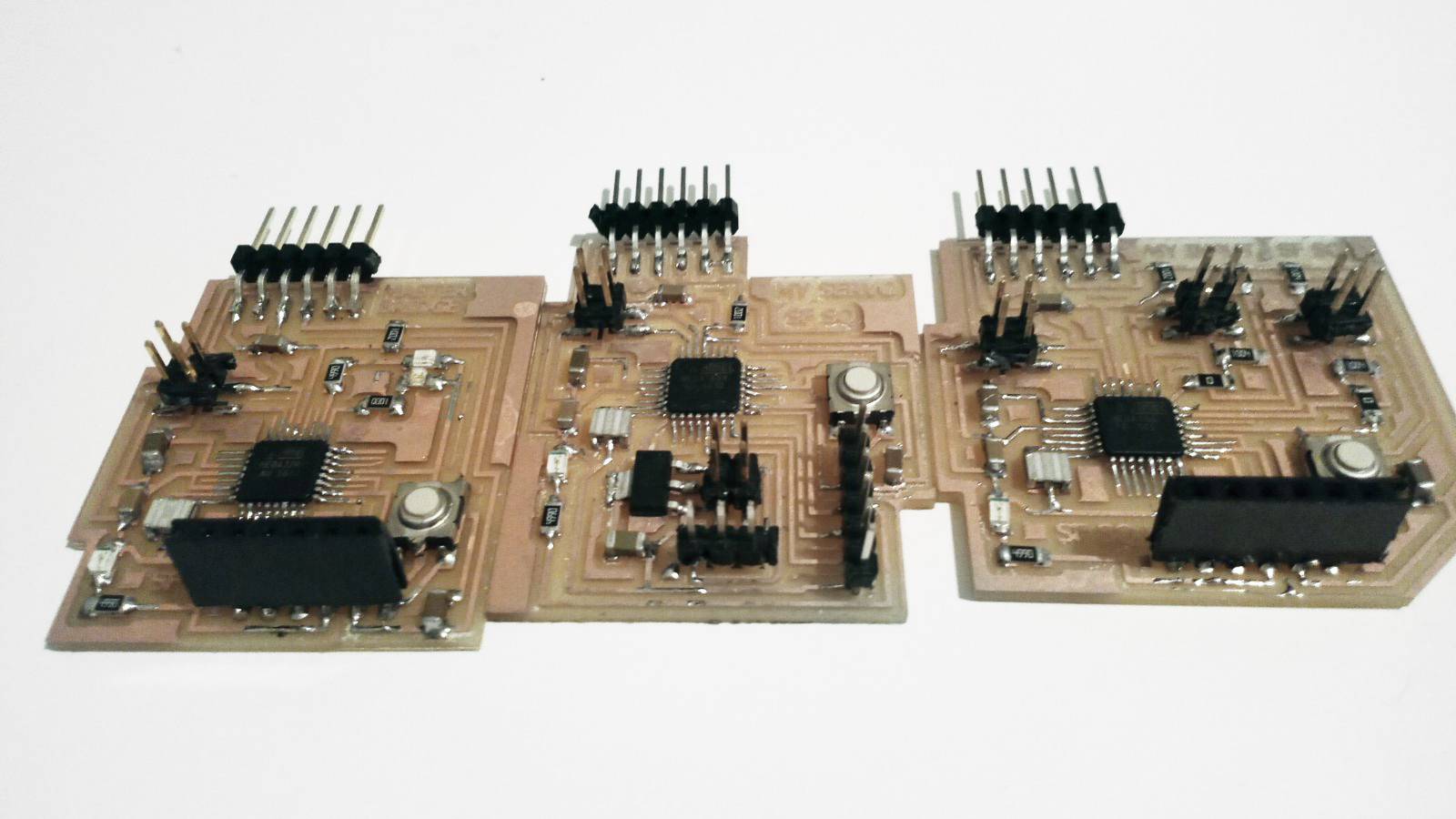

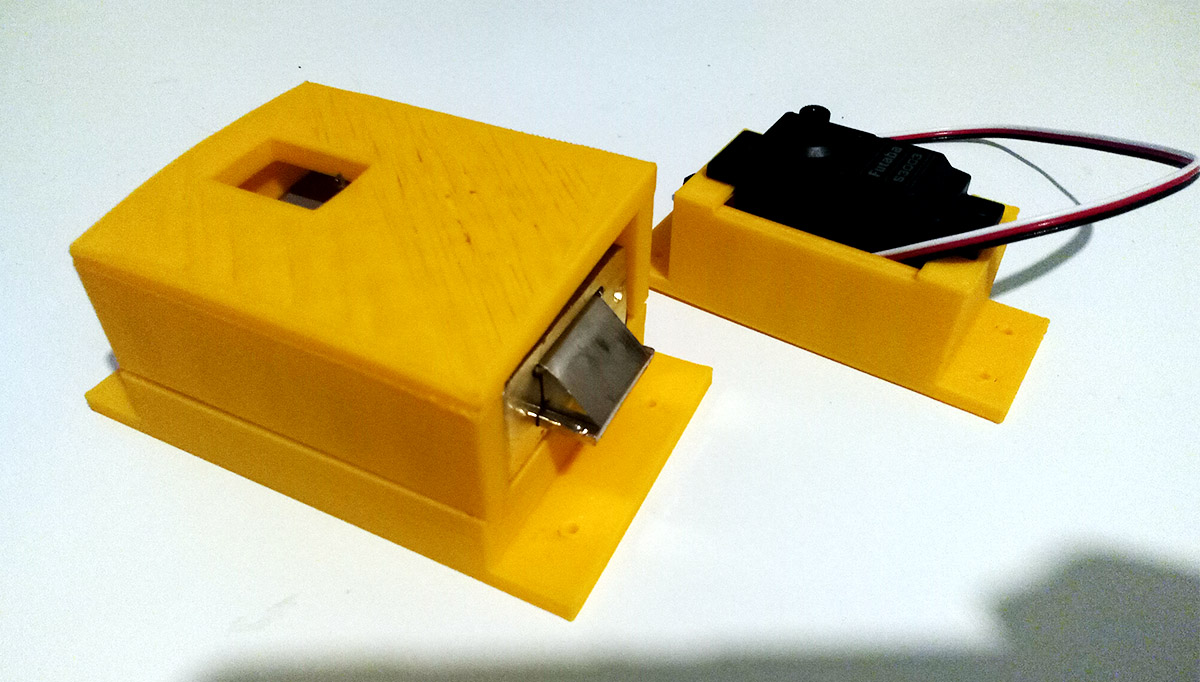

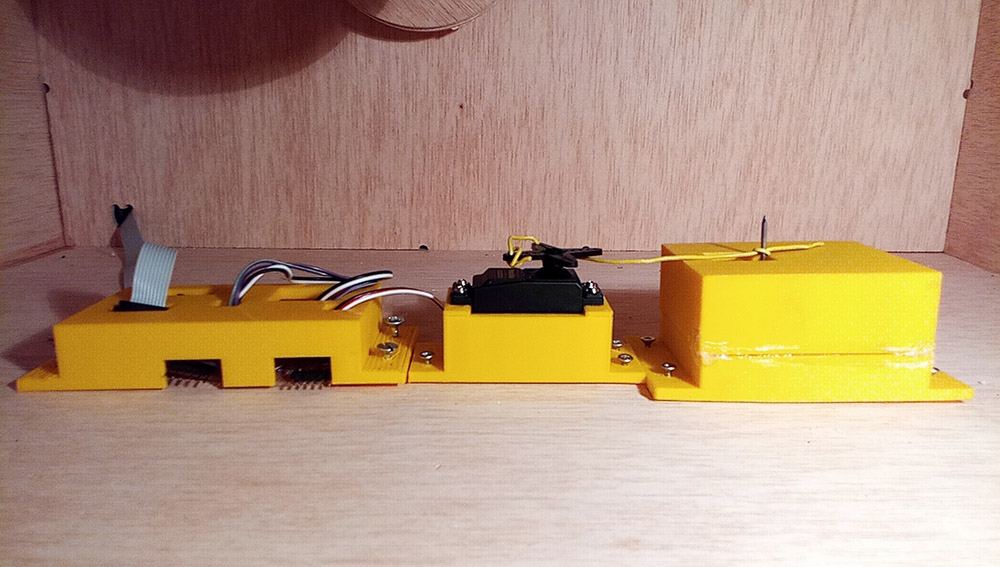

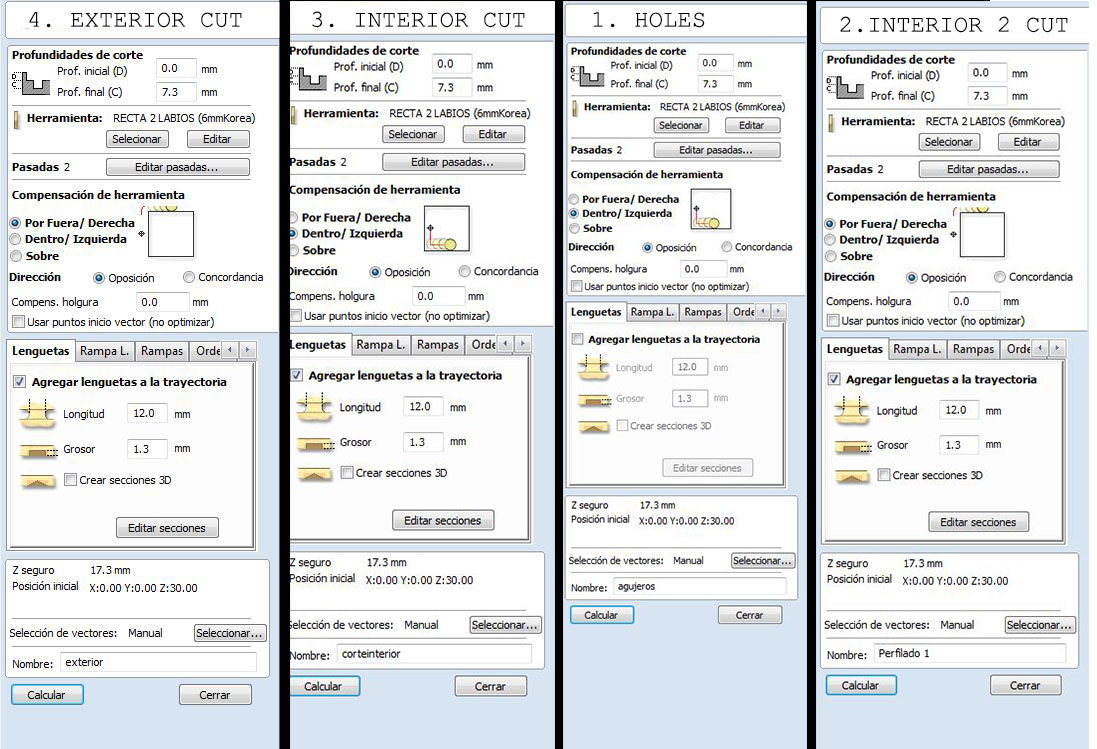

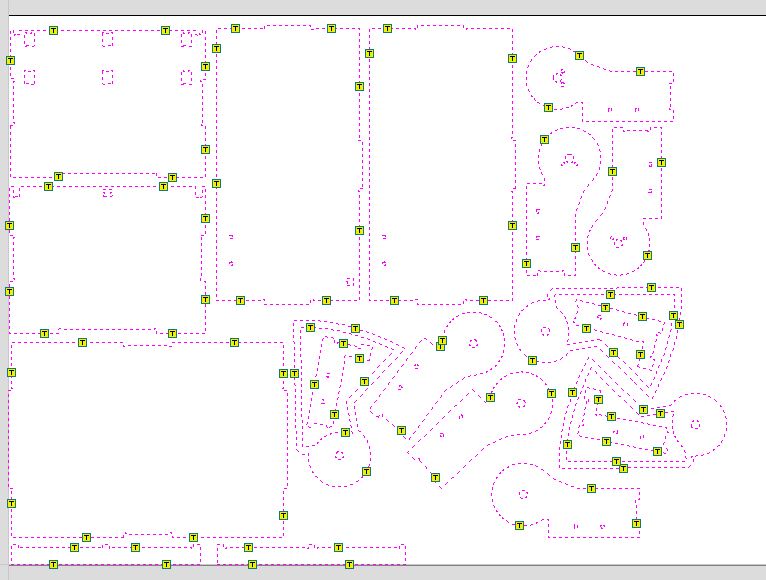

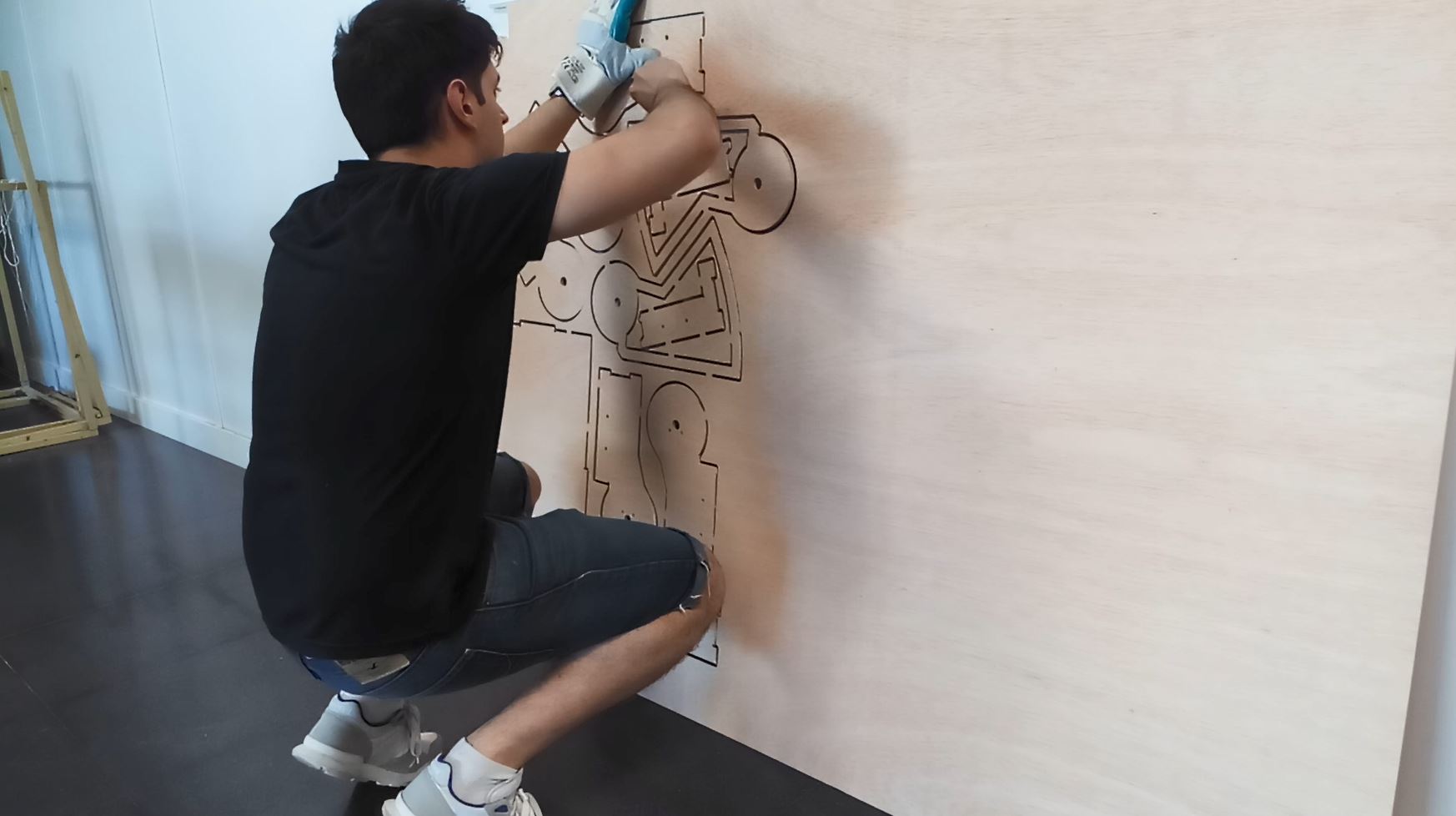

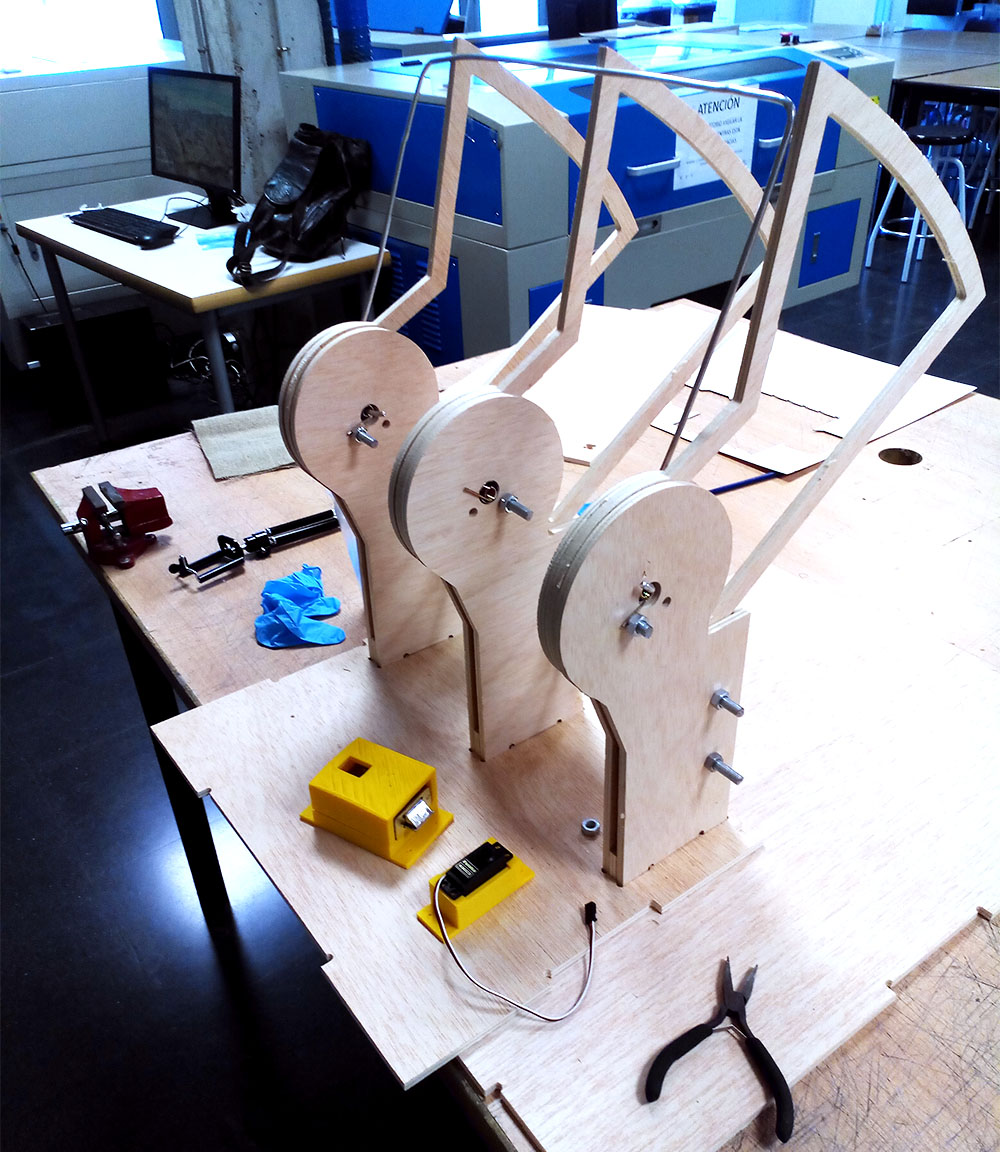

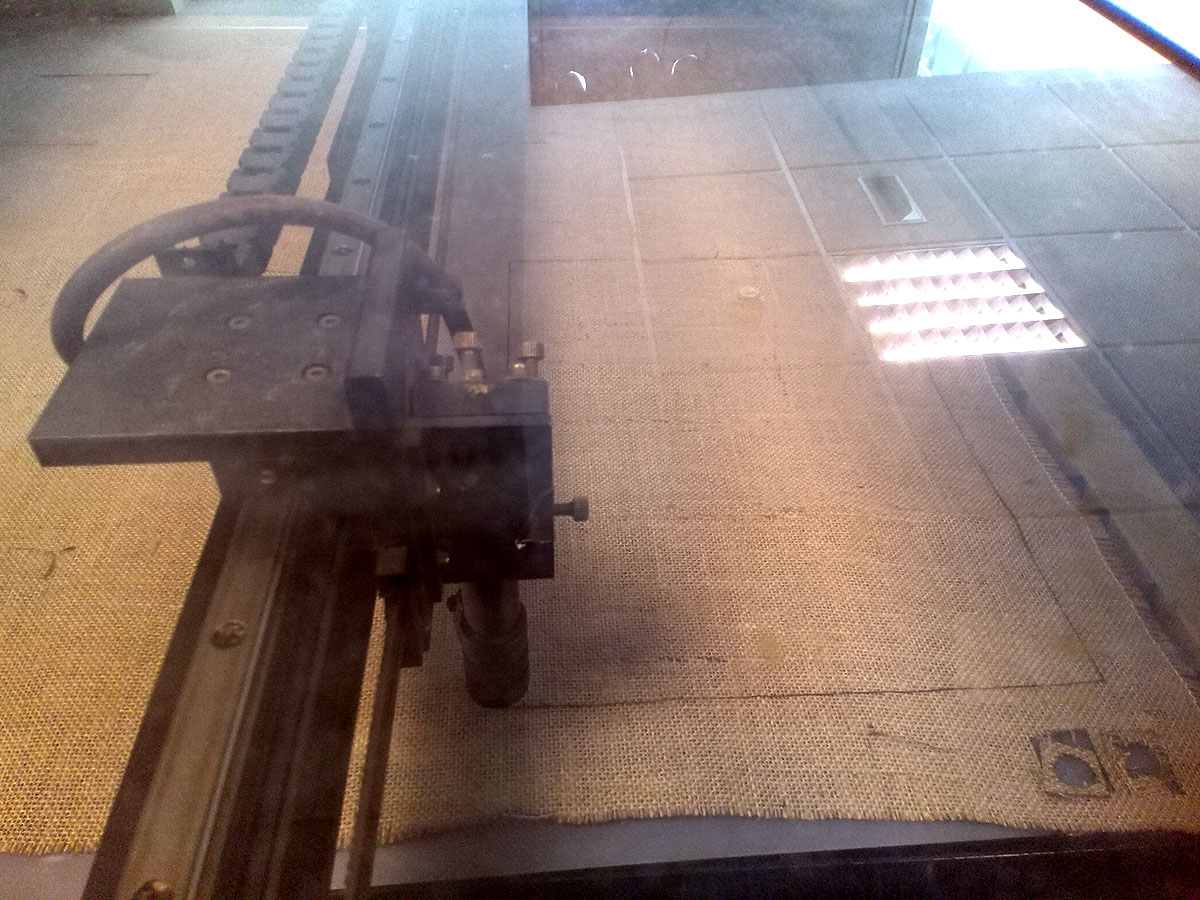

Later I began to fabricate the electronic circuits to solder a micro-controller and to connect a servomotor so that it was raised automatically by the springs when contracting the latch system, and milling the skeleton of the prototype (also made of wood) in a CNC machine, at the same time while making the sensor.

A sensor which is a manufactured capacitive pressure sensor fabricated by me. I programmed the micro-controller to communicate the sensor and the motor in Arduino. When I had the programming, I adjusted the sensitivity of the sensor, then I made an application in processing to visualize the results of the sensor. After several tests it worked correctly with a car, obviously the bollard is a prototype and the impact was not tested.

Process:

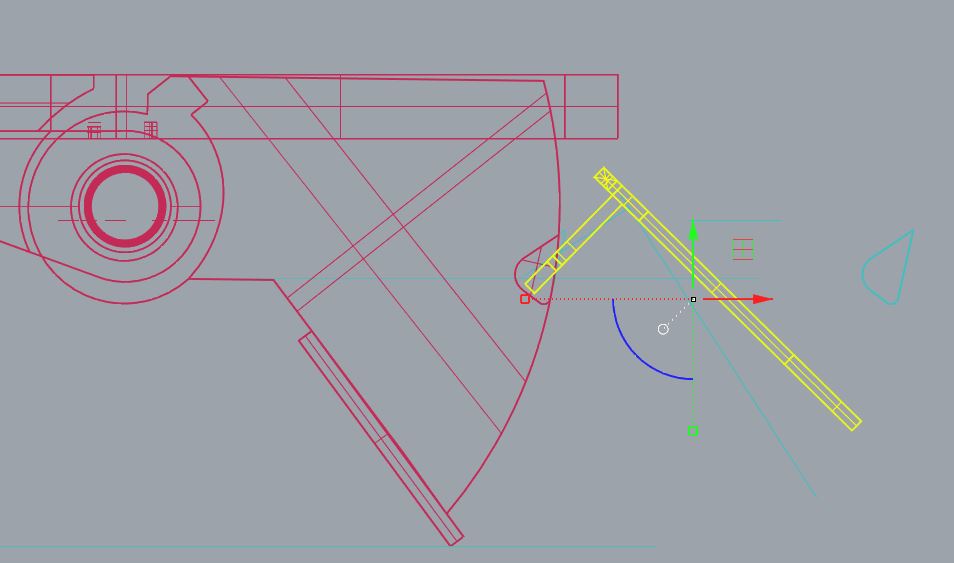

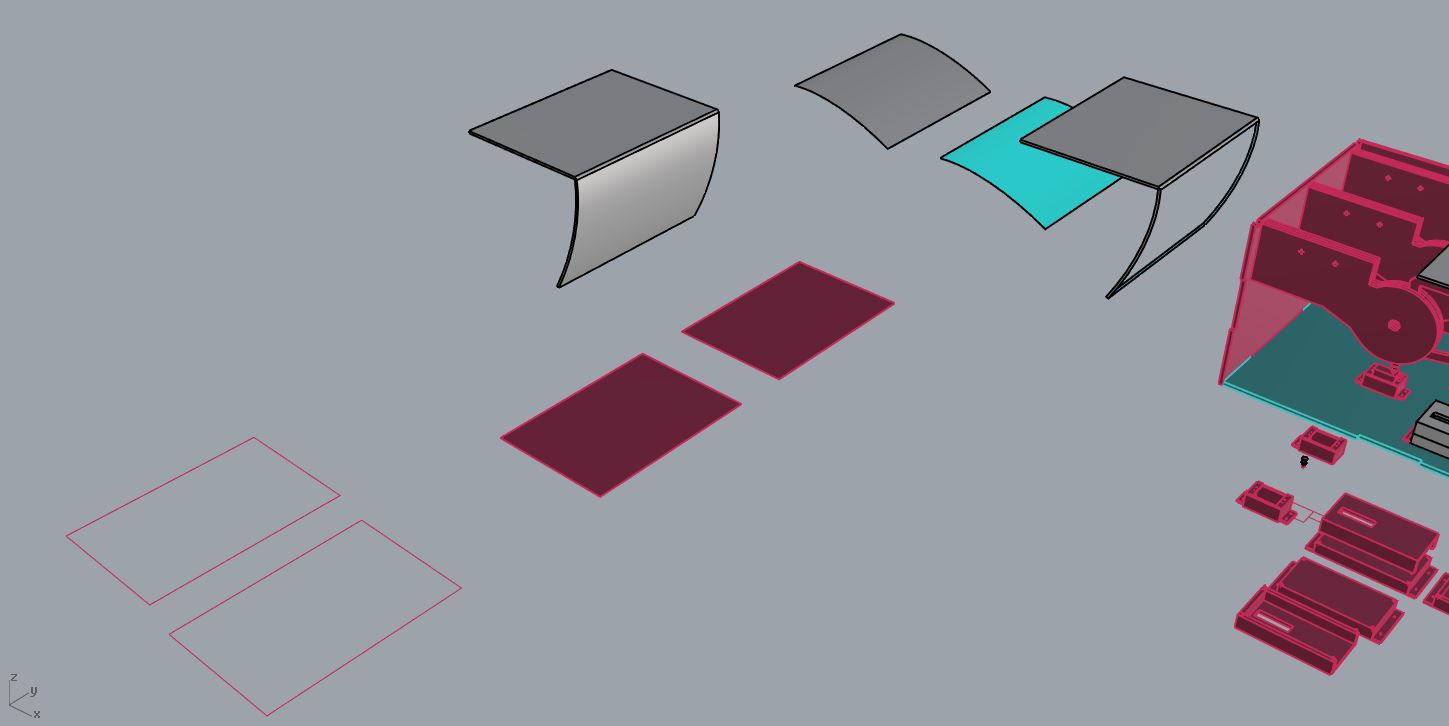

- Barriers Design -

For the Computer aided design and 3D printer, I decided to design the type of barrier I was going to use, I was looking for information on the type of barrier that would best fit to stop a truck or vehicle.

You can see this assignment in the following links.

There are different kinds of barriers listed here:

bollards, horns, and ramps.

bollards, horns, and ramps.

We will choose the ramps, for their greater effectiveness when it comes to heavy vehicles. An example of how one works is shown in this video:

A recreation of how the barrier works Copyright © 2015 Bremar Automotion. All rights reserved

A recreation of how the barrier works Copyright © 2015 Bremar Automotion. All rights reserved

The structure and resistance of the ramp Copyright © 2015 Bremar Automotion. All rights reserved

The structure and resistance of the ramp Copyright © 2015 Bremar Automotion. All rights reserved

Okay, knowing the type of barrier we want,It is time to design it, the concept is simple a hinge with a spring on its axis, which activates the safety mechanism and the spring causes the ramp to rise.

The main feature of my project remains hidden and unsuspecting camouflaged with the ground, and this is only activated when a real danger is imminent, while the passage of pedestrians or light vehicles like motorcycles or bikes do not activate it.

You do not need a motor to raise it and lower it as it is an emergency safety measure, you can dispense with the engine and put in place a spring mechanism, faster and cheaper.

- An example of a case study -

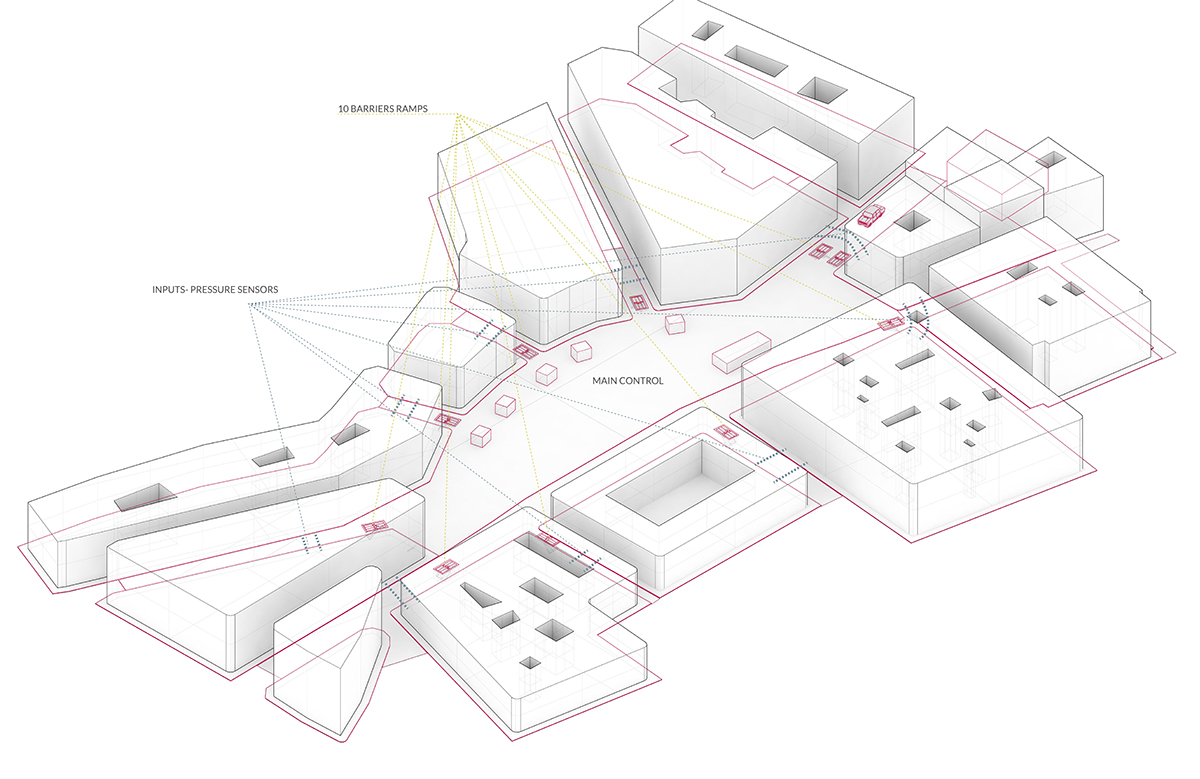

PUERTA DEL SOL, Madrid, With safe square.

And I will simulate the environment of my proposal.The chosen place is Puerta del Sol, the most famous square in Madrid, where events take place and protest march are celebrated.

Puerta del sol

Puerta del sol

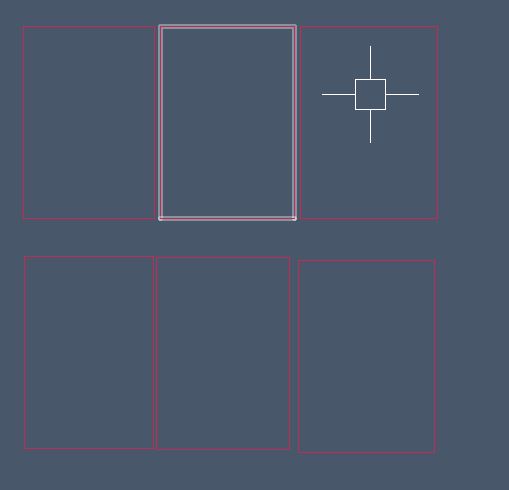

modeling the square.

It has several entrances with semi-pedestrian streets.

I have quickly modeled the scenario,

And I have placed my barriers in the square.

That's how it works.

modeling the square.

It has several entrances with semi-pedestrian streets.

I have quickly modeled the scenario,

And I have placed my barriers in the square.

That's how it works.

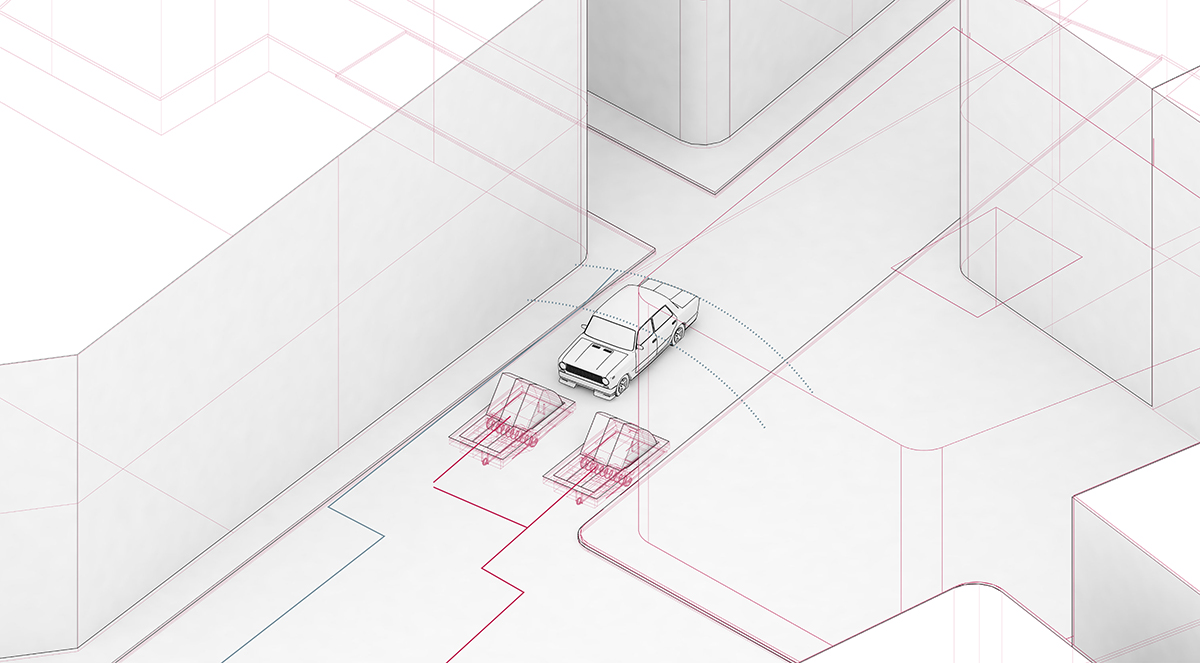

Puerta del sol with safe square.

And so it rises when there is danger near:

Puerta del sol with safe square.

And so it rises when there is danger near:

ramps up

ramps up

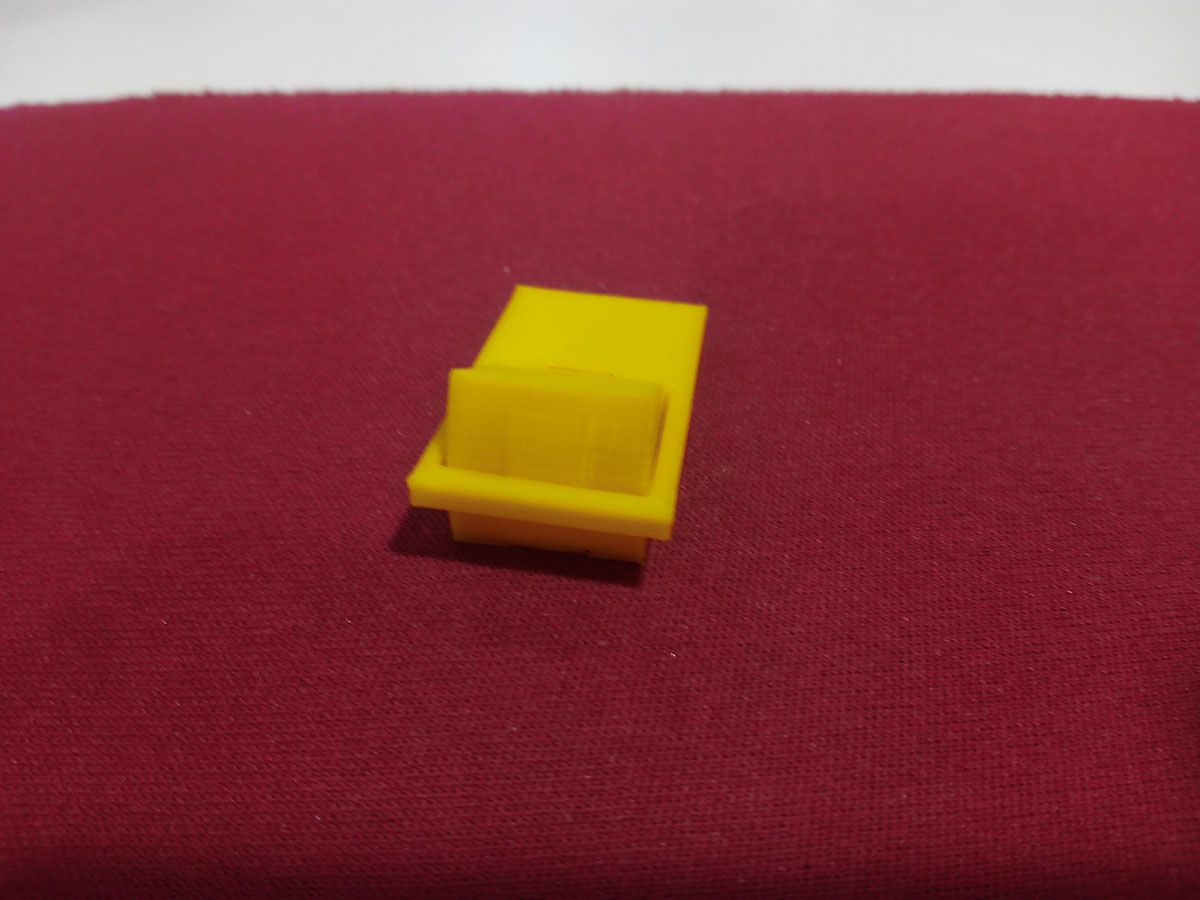

this is a prototype1, Very weak but works as hinge.

this is a prototype1, Very weak but works as hinge.As a prototype model it can work, it simplifies well what I want to achieve, it moves mechanically, it remains hidden in the situation of rest, it is solid and it holds.

The next step will be to create a larger prototype with a more advanced mechanical system and a suitable locking system.

Prototyped:

When I advanced a bit in the assignments I decided to make a new prototype, this prototype somewhat more advanced part of the design of a trap for rats.In a first prototyping and obviating accessibility problems, to test the mechanism we made prototype 2, inspired by the spring of the traps for rats

With a scale of 15cm and with different parts, 3d impression of the body, trap spring for rats, and metal fasteners.

For more information on the laser cut assignment click on the following button

For more information on the laser cut assignment click on the following button

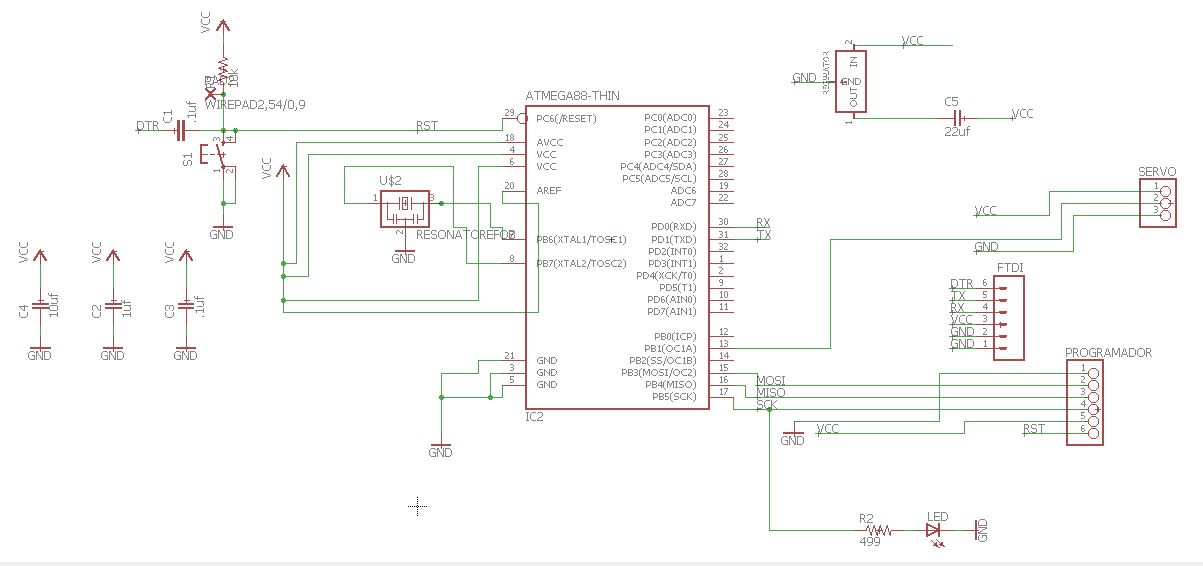

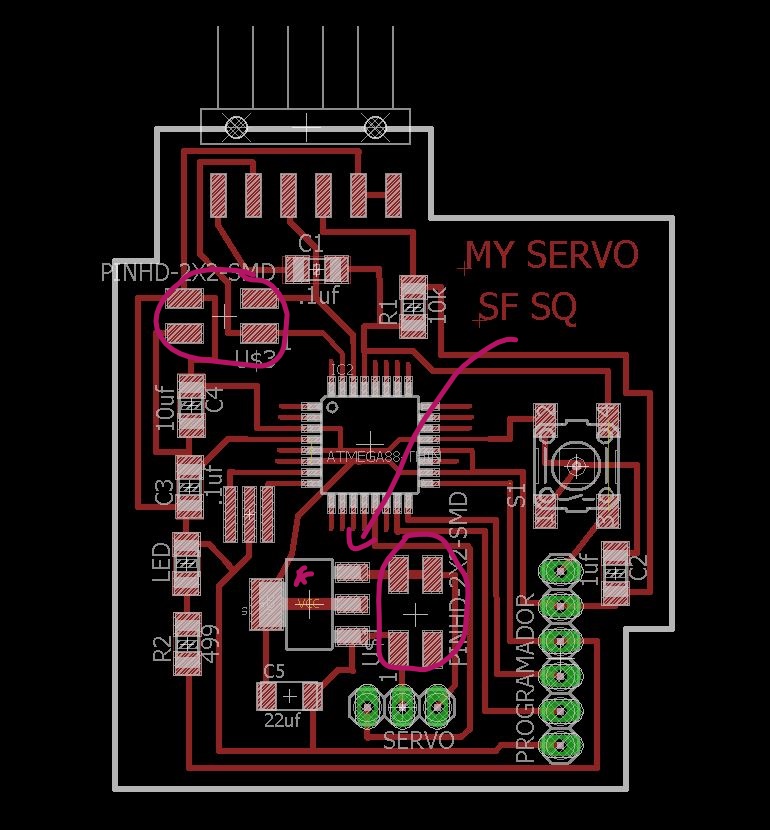

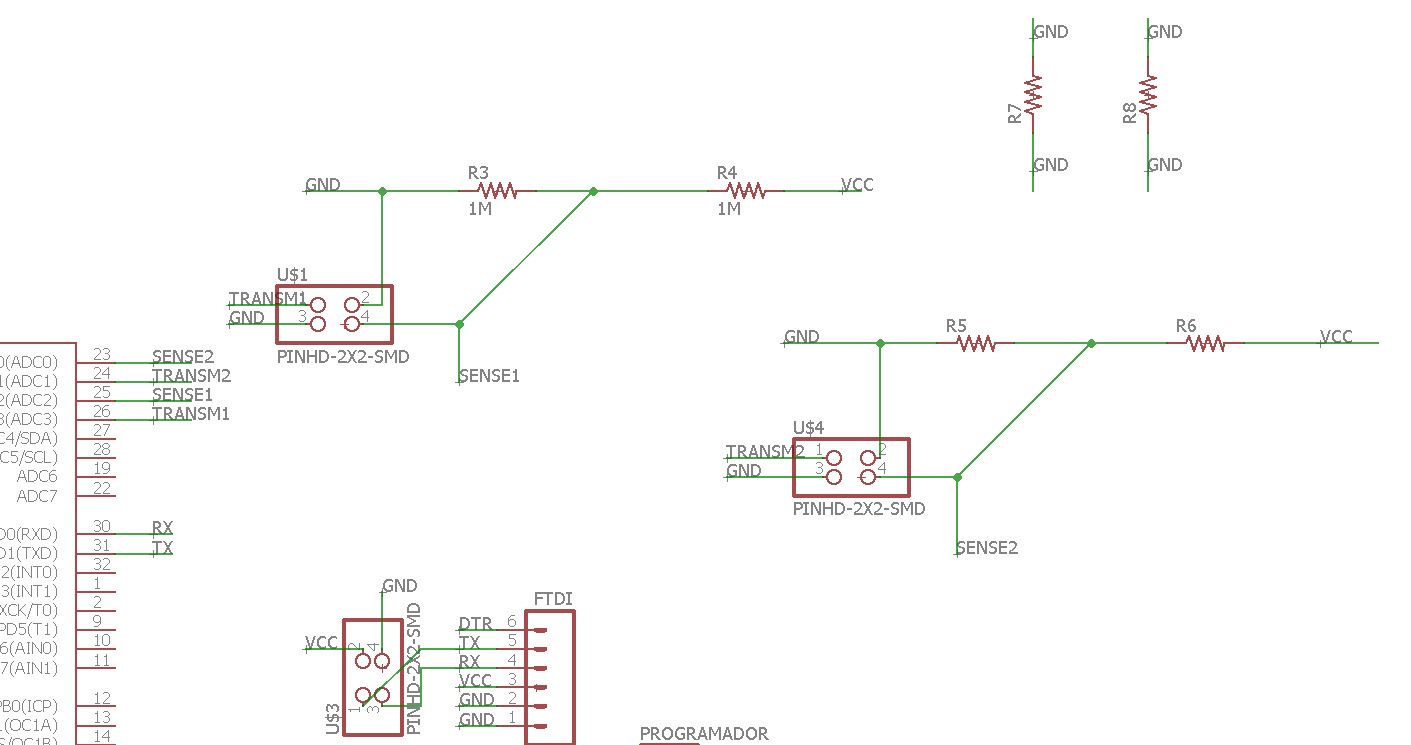

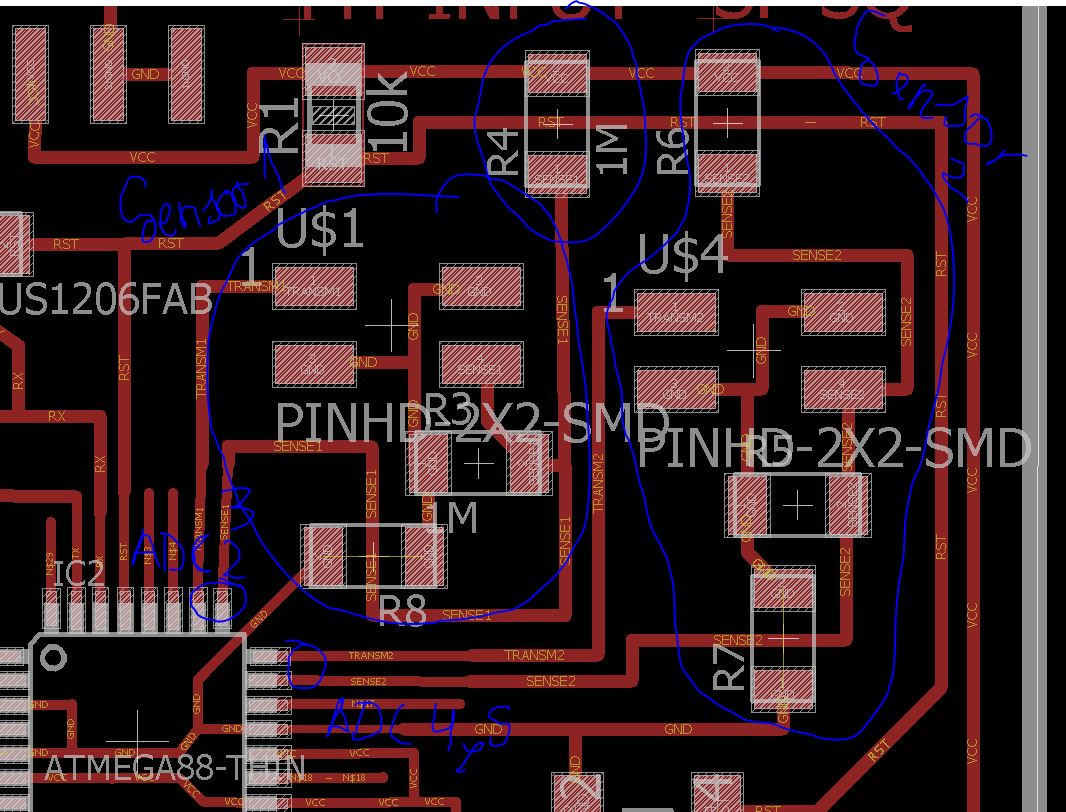

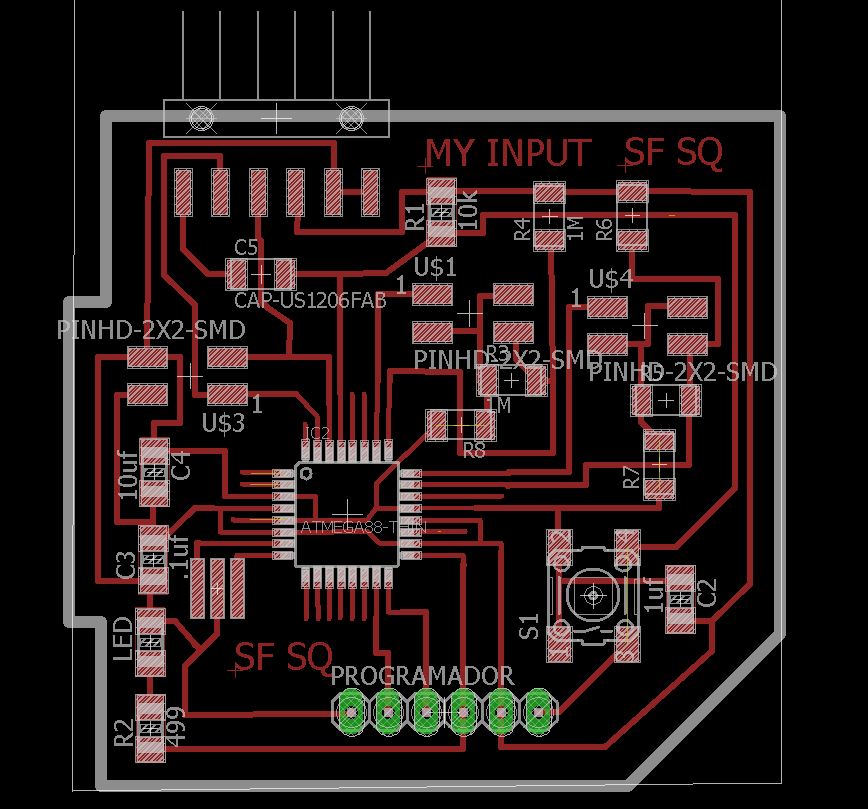

I will need an Output and an input for my final project, I also designed in networking a board to control it without PC.

I will need an Output and an input for my final project, I also designed in networking a board to control it without PC.