Assignments:

1. Complete your final project. Track and document your progress.

Complete your final project. Track and document your progress.

--- Have you answered these questions: ---

1. what is the deadline? How much time do I have left?2. what tasks have been completed, and what tasks remain?

3. how will I complete the remaining tasks in time?

4. what has worked?

5. what hasn't?

6. what questions still need to be resolved?

7. what have you learned?

1. what is the deadline? How much time do I have left?

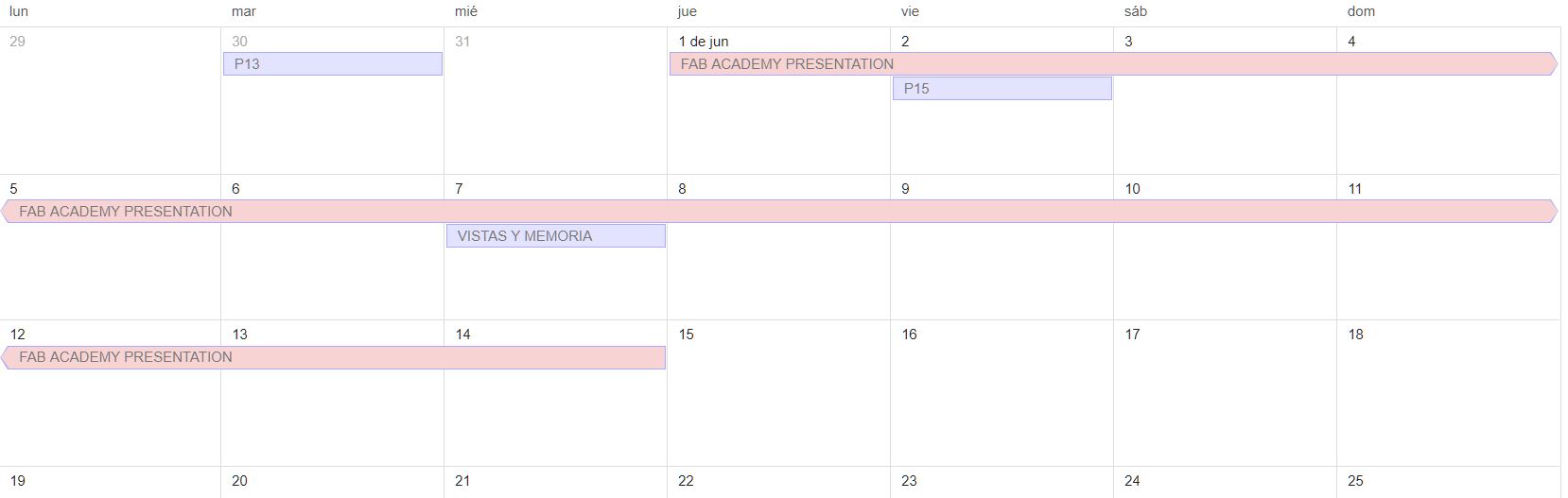

I have a week or two ahead, I still do not know when it will my turn,I am going to use all my time to finish the final project, indispensable requirement to obtain the title.When I started this week was June 1st, the presentation of my final project is on June 14th, just waiting to know the exact date.

Update:

Confirmed on the day of the presentation is June 14th I will have to hurry to finish all the documentation and tests so that my project is perfectly understood.

Remaining days.

2. what tasks have been completed, and what tasks remain?

in the absence of these days this is what I have:

Electronics:

boards, I have to see if I have to re-do the output board because the pads were a bit loose, I will try to re-mill the output board if it gives me time.

Programming:

I have the program that reads the sensor data, and I have a program that moves the servomotor, but separate, it is necessary to calibrate the sensor and to do the networking between input and output and test it.

Many things can fail.

I have to test all programming until now I have a sensor that gives values, I have to create the copper plates of the sensor and put the rubber and test the sensor.

3d print:

I have the design of the boxes to integrate the boards, the motor and the lock, it is necessary to adapt it to the final height of the project and to print it in the makerbot.

Structure:

All the parts are milled, ready to assemble, the next step is to make the composite, once it is dry I can mount the box and see if everything works well.

Mounting:

The main body is assembled, it is necessary to make adjustments and tighten it sufficiently so that it rises without problems.

in the absence of these days I still have left,

re-do the output board because the pads were a bit loose, I will try to re-mill the output board if it gives me time. do the networking between input and output and test it.

others: documenting the website, leaving the slide and the video that is in process of the previous week finished, make the composite, pieces of pla for the integration of the parts, adjust the ramp to be hidden, improve programming faults and use the sensor, measure the pressure of a car and calibrate the weight.

Record the laser logo on the box.

Finish mounting the prototype and leave it closed.

Prepare the presentation.

3. how will I complete the remaining tasks in time?

dedicating enough time, completing the priority tasks and then the secondary tasks, it is important that the project performs its function and is shown well but there are goals more important than others.

The first thing to do is the composite, to be able to assemble everything else and have the body closed.

The next priority would be to perform the programming of input and output through networking.

After making the sensors, make the planes of the molds, cut the copper plates and pour the rubber on the plates, the paste will take a day to dry if everything goes well.

With these three priorities you could start to test the project and start improving or doing other things.

While I am performing the tasks I can combine them with making parts in 3D printing of the PLA for integration or cutting to make the design file and cut the vinyl for the frontal.

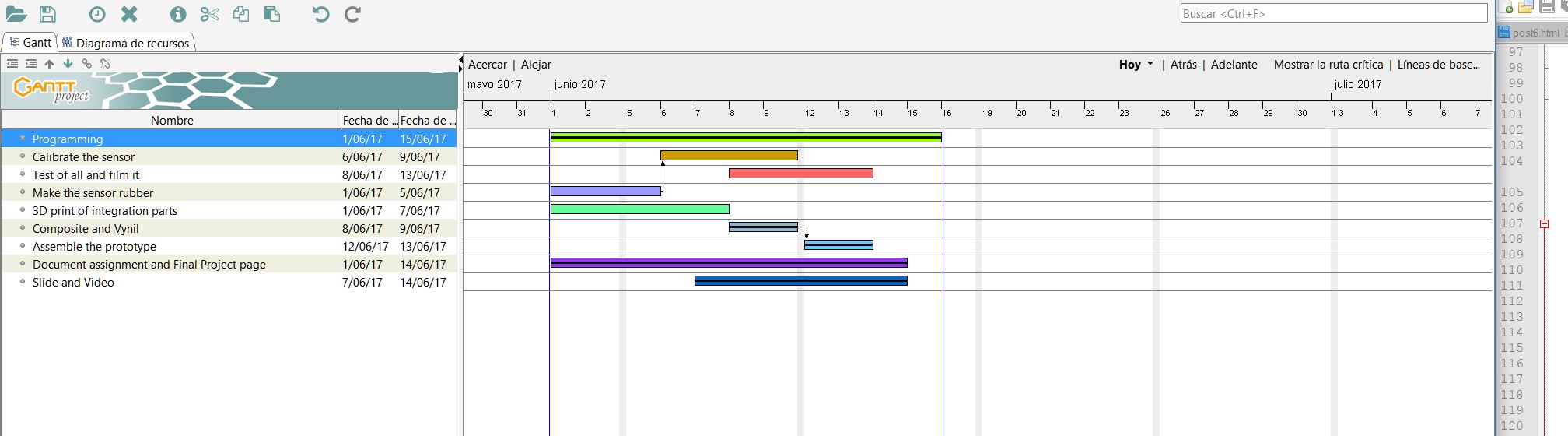

My schedule

In this time management table I have taken into account several more factors.

Priority is given to tasks that make others depend on them, such as composite and make the sensor.

I have flexibility leaving plenty of time to tasks that will not take me so long, I will use the time that I can win in unforeseen and complications.

I will work in parallel, if some task is too complicated for example programming, I will dedicate time to another one that can be done at any moment like documenting ... etc. and I will ask for help and advice on this difficult task.

4. what has worked?

Mechanically the device works, it is necessary to adjust subjects like height, lifting force and resistance but the CNC milling has been good.

The boards of input and output also with some weak pins in the output.

the spring system is working properly.

5. what hasn't?

Update:

I have been having several problems, when making a copper sensor, one of them was not working, the plates were not correctly in contact, during the test of the car the other sensor was shredded by the weight of the car directly on the several times.

The programming has given errors many times and I had the problem that the delay did not send the result and activate the output, it has been difficult to solve this because I lacked the knowledge to do it.

When the sensor passed a value the input sent a "8" and the output had to read and move the servomotor, in this process either slowed the sending to the output or sent the signal so fast that could not make the journey.

The rubber of the mold the first time that I realized it did not fit well the mixtures and it did not work, being very little quantity it was difficult to measure and I was wrong.

I made the mix again and made another sensor rubber a day later.

6. what questions still need to be resolved?

There is a fault of adjustment of route by what will have to raise the ground by means of triangles with mdf, para futuros proyectos hay que mejorar el diseño.

The sensor is a voltage differential, which measures the difference between one pin and another, when I tried the device with the car happened something I did not expect.

The material of which the wheels are made conducts the electricity of different form, when passing the car on the sensor not only did not lower values but increase that did not happen when placing a weight on the sensor, it worked because I had this in mind the programming but still depending on what is in contact with the sensor may give unexpected results.

7. what have you learned?

I have tried to make the final project a summary of all the assignments so that we can remember everything we have seen during this time.

I have learned to make a new type of composite.

I have done molding with another type of component.

I have learned from the tolerances and the possibility of making holes for screws in the parts of the 3D printer.

I have remembered how a vinyl was made, and how to use a product to adhere better to smooth surfaces.

I have learned to give orders from an input and that the output interprets them.

I have learned a lot of programming and working with if variables in arduino.

Also to read and better understand C programs like Neil's which are based on final programming files.

I have learned above all that nothing is finished until it is, and that you always have to go with enough time because there are unforeseen.

Summarise and communicate the essence of a project:

What It Does:

My project is a device designed to be place in the plazas or main squares of cities in order to avoid accidental run-overs and terrorist attacks like the ones thar occured in Nice or London. It is an automatic bollard that rises when it detects a high weight.

The Inspiration

The inspiration came from the latest attacks in numerous countries where a heavy vehicle was used to attack pedestrian friendly zones. These frequent attacks have raised awareness for taking measures to ensure safety within these popular areas of the city. These type of attacks have been increasing and there is no doubt solutions have to be made in order to prevent them from happening again.

No adequate solution has been made and the city halls have only thought of placing large objects that do not take into consideration the general transit or the sensation of fear; these solutions are not the most adequate.

How It Works

The operation is similar to conventional bollards where there is a resistant element that absorbs the kinetic energy of the vehicle and resists the impact, but in this case, there are some differences that I explain below.

It is hidden and integrated with the pavement.

It has a spring system which rises when the micro-controller sends the signal.

It has a pressure sensor, which only activates when it detects a heavy weight (a vehicle) and does not activate with people walking by or passing over it. This sensor sends a signal to the micro-controller that moves a small motor that releases the spring and lifts the bollard very quickly.

The sensor can be adjusted. The connection to the micro-controller and the motor is through serial networking and the frequency inhibitors do not affect it.

The bollard is shaped like a ramp and acts as a hinge, when it is hidden is at ground level. It is made of steel and the shape of the ramp helps to dissipate the energy.

Update:

Moving forward with final project testing:

I have made progress in the development of my final project, as you can see in this video I already have the body mounted, with the servomotor and the boards of the input and output, and I am doing tests of how the lock system works.

Today, June 12, I made the final tests with a real weight, that of the car, I placed the sensor in a parking lot and I decided to do tests to see if I could get my project to work, after many attempts and to adjust the code from the sensor to the weight of the car I got it to work.

this is the first fail.

this is the final result. FILES:

Ganttproject2