Assignments:

- Propose a final project that integrates the range of units covered:

Have you:

1. what will it do?

2. Who's done what beforehand?

3. What materials and components will be required?

4. Where will they come from?

5. how much will it cost?

6. What parts and systems will be made?

7. What processes will be used?

8. What tasks need to be completed?

9. What questions need to be answered?

10. What is the schedule?

11. How will it be evaluated?

1. what will it do?

Is going to avoid outrages (accidental or provoked) in the main squares of the cities.It is a passive safety system that can be implemented in places already built, which is hidden and only activated when a heavy vehicle comes.

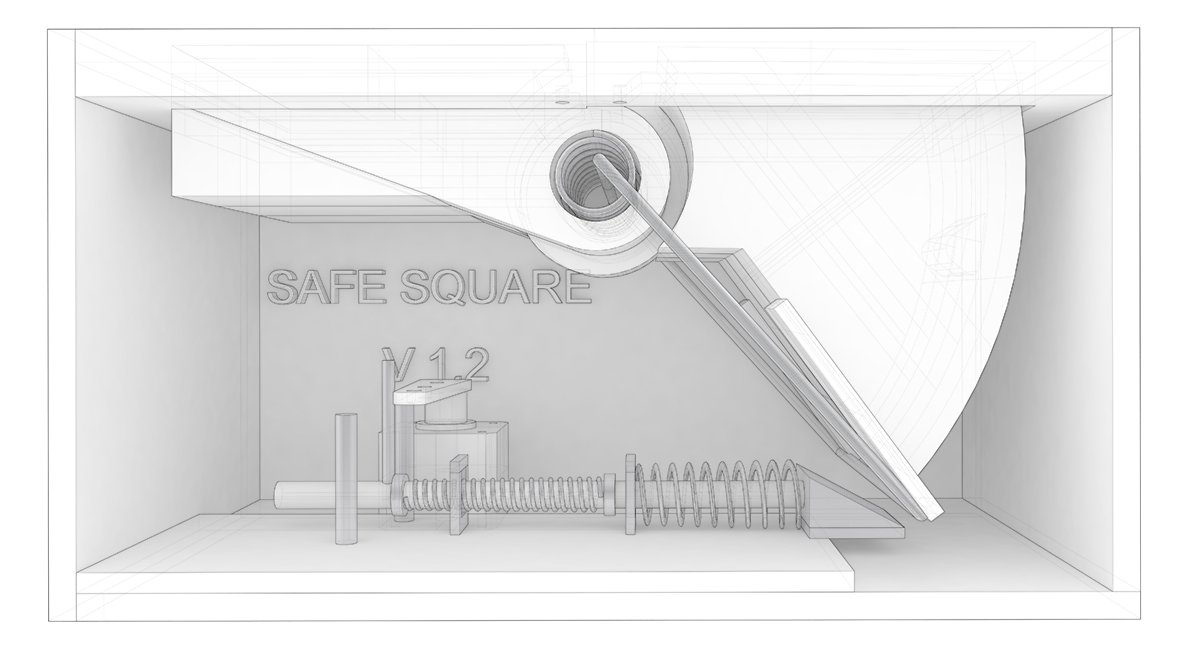

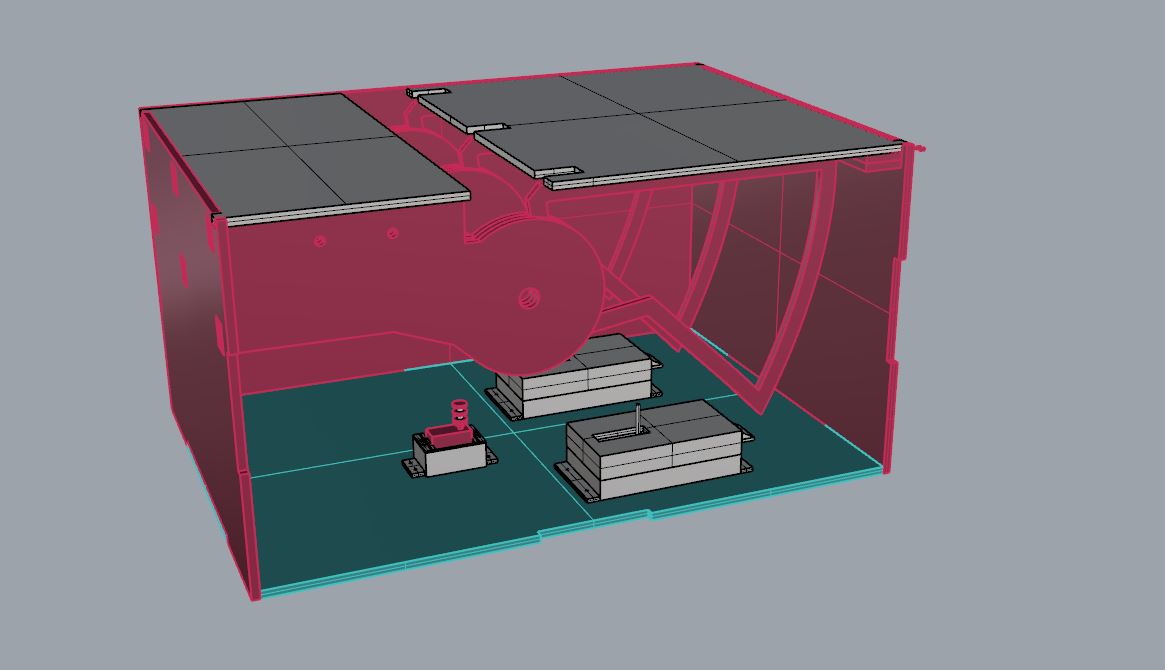

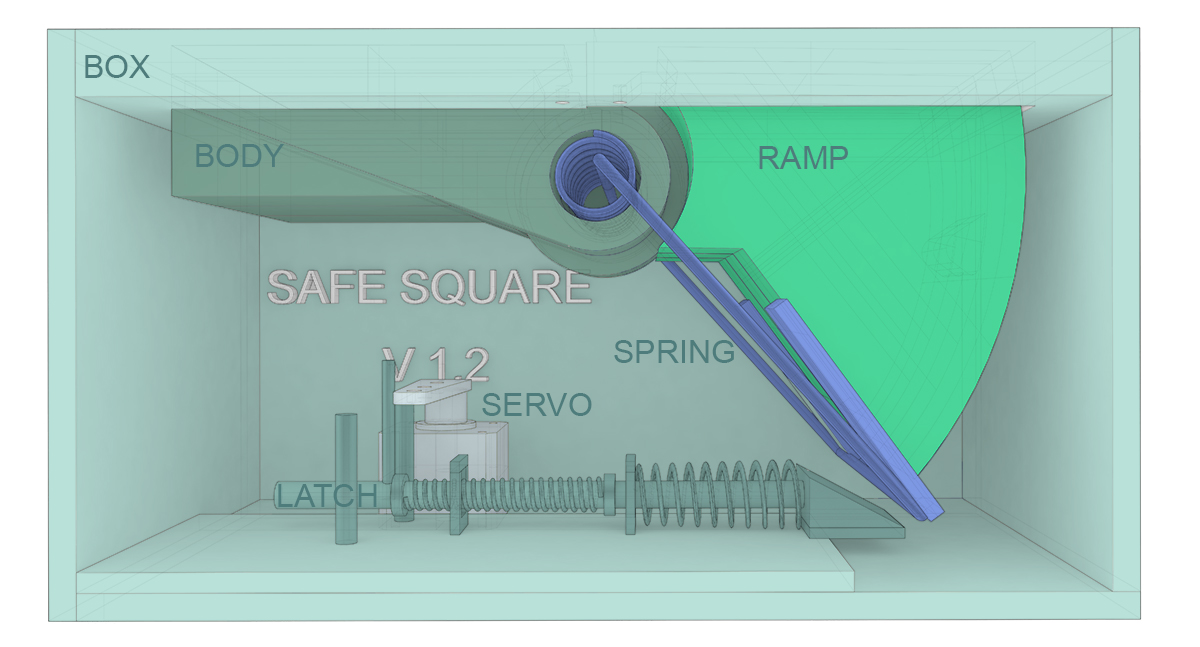

V1.2 of my project (prototype).

Right now with my means the most I can do is a prototype showing how a bigger one would work.

Final version of my project (big prototype scale 1/3).

2. Who's done what beforehand?

Bollards, automatic, manual, with barriers have long existed ....For example, this HEAD brand device is a real and proven safety device of this type.

This company is dedicated to making these and other bollards, and there are many more companies like this.

My final project in itself is not very different but it does focus on some very advantageous changes:

It is hidden, it does not disturb the normal circulation of non-dangerous light vehicles (bikes, segways ... etc.) Or pedestrians.

It does not create a sense of danger, the worst thing about terrorist attacks is that they cause fear, visible barriers with this function feed fear, not with hidden barriers.

It is cheaper in manufacturing, it is a Low-Cost device.

It has a faster reaction time than similar devices, it is not moved by a motor but by a prestressed spring.

3. What materials and components will be required?

These are the pieces of my final project:

1. Box: I need 1 wooden boards to make the device wrap Plywood board 20 mm size 2440x1220 mm, 5mm mdm boards

2. Body: The same wooden board .

3. Ramp:

4. Spring: 2 springs on the sides Link to amazon.

metal rod.

5. Servo: Servomotor still to be determined, sufficient force to move the catch Link

6. Inputs (sensors):Three boards to control the entire device.

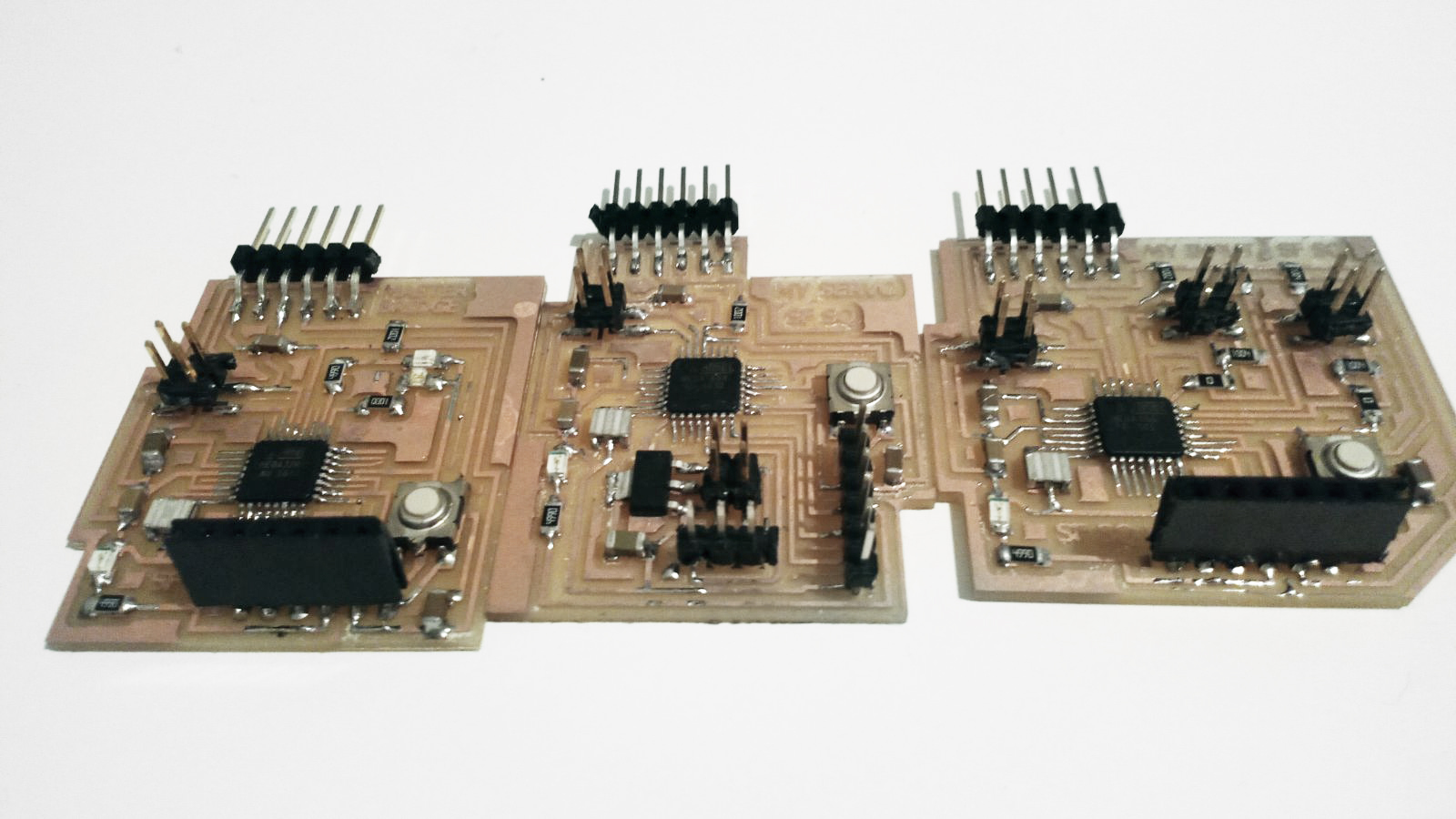

Input, servo and master.

7. Catch and springs: 2 door catch, pla material for the drawer

All the materials we manufacture are going to come from the inventory (plates, drawers, etc ...)

The woods and the composite used, we chose a good supplier.

The docks and the catch of the door, for obvious reasons we bought them.

We need a more powerful servo than the inventory we also buy.

4. Where will they come from?

Most items are taken from inventory such as electronics, materials are purchased from the best possible supplier.Some things like the door locks are recycled.

And rat traps or corrugated rods are expressly purchased.

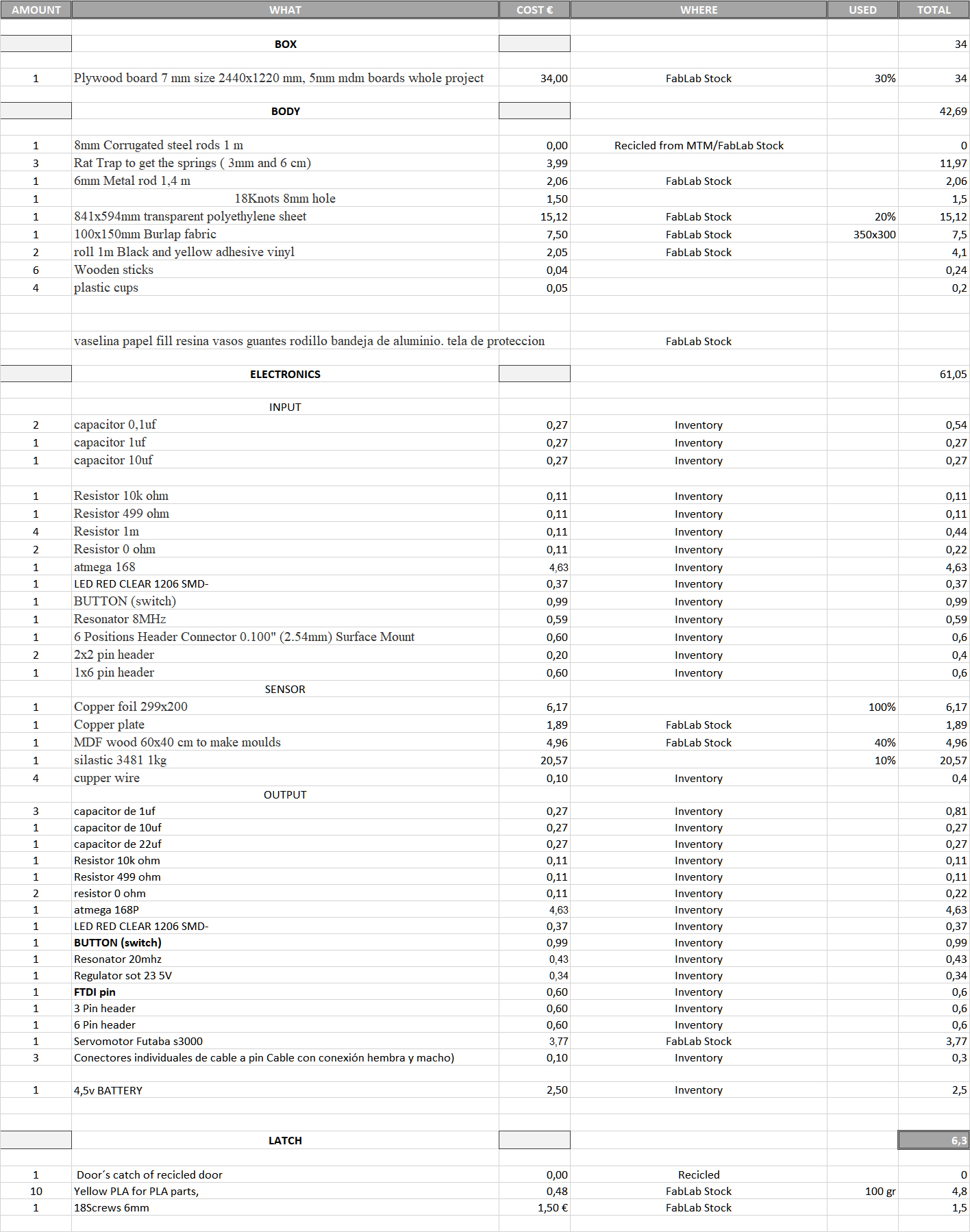

Look at the BOM.

5. How much will it cost?

Update approximate price of what was spent in the final project:* Attention, in the prices tries to detail accurately the cost but sometimes by purchase will buy surplus material, I will try to indicate the amount of material used.

FIRST ESTIMATION Plywood board 20 mm size 2440x1220 mm 56.46€

3 5mm mdm boards

2 springs on the sides 15€

metal rod. 20€ a large aluminium rod Link

Servomotor 22€

boards:

Input 10

servo 8€

master 7€

2 door Latch 6.44€Link

Approximate total cost: 161.90€

Max Cost: 188.56€

Conclusion: I have to start rethinking the type of materials to lower costs.

BOM update after completion of the final project:

6. What parts and systems will be made?

The parts of own manufacture will be the following:

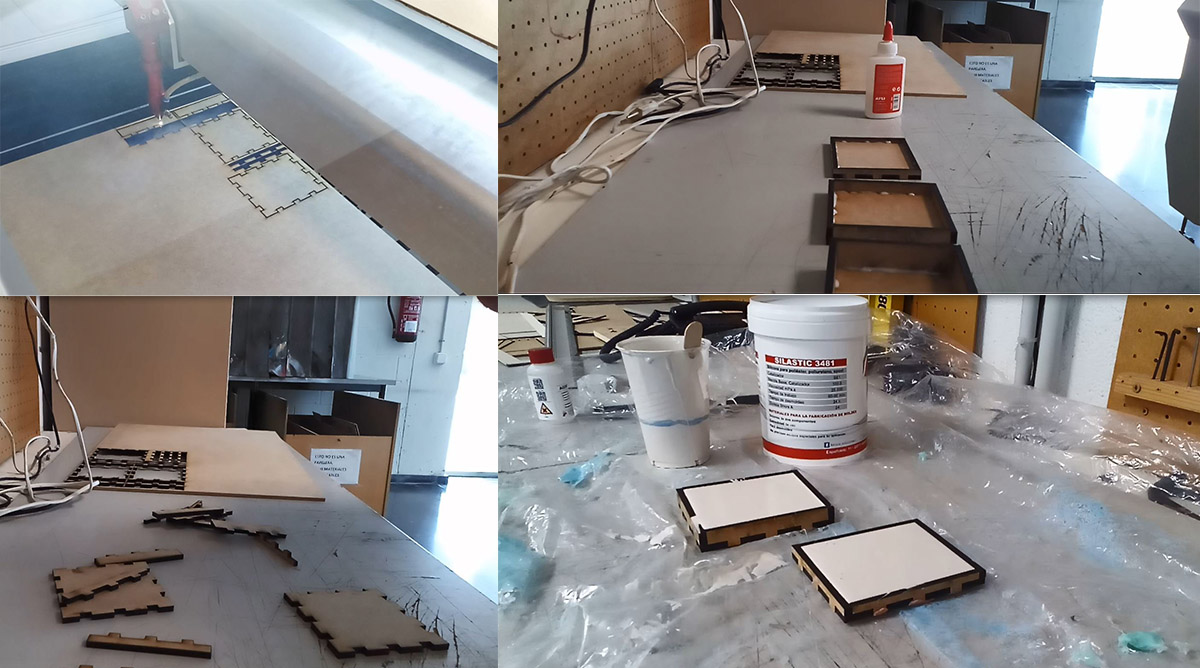

1. Box: Made with my own design in cnc in wood.2. Body: Made with my own design in cnc in wood.

3. Ramp: Made with my own design in composite from a 3d mold, and vynil exterior made.

5. Servo:Board manufactured by me.

6. Inputs (sensors): Boards manufactured by me using capacitive sensors.

7. Latch: Some parts, 3d Printer and Laser

7. What processes will be used?

CNC for box and body

Composite for the ramp.

Laser cutting machine for the sensor mold, for minor interventions and adjust the ramp.

Modela For the production of copper plates of the inputs, and the output, as well as the MASTER.

Molding and Casting for 3d Logo and Safe Square quality certificate.

Vinyl cutting machine for device signaling.

8. What tasks need to be completed?

Prototype:1. Test the 2 inputs at the same time.

2. Program and adjust the pressure value for the servo to activate.

3. Set the Catch system.

Moving from the prototype to the '' Real Size ''

4. Ramp the body and the box.

5. Acquire the necessary equipment: Springs, Motor, catch, sensor components.

6. Assemble and manufacture missing items.

7. Program and adjust the pressure value and perform test.

9. What questions need to be answered?

The least I control is networking.I do not take into account how the communication between my boards will be, the speed of processing until it works correctly

The manufacture of the composite ramp may present problems due to its complexity.

The impact resistance is something that I will not be able to control so that if I stopped on a truck I would need a ramp with a metallic structure.

The sensitivity of inputs needs to be improved and controlled.

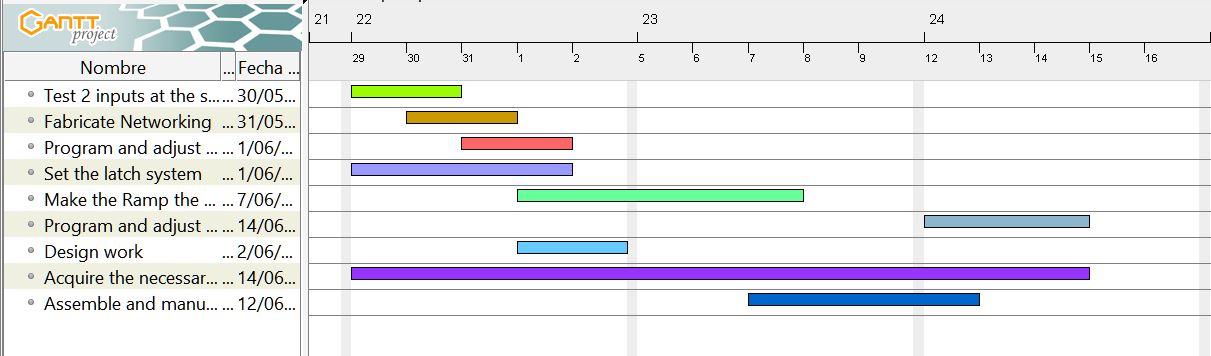

10. What is the schedule?

From today until the delivery of the final project I will try to adjust to this schedule.I have done a schedule with Ganttproject, in which I summarize the remaining tasks and the time that will take me.

Gantt Project.

11. How will it be evaluated?

The objective of my project is to be able to stop an accident or attack.But I have focused more on the functioning of the mechanism than on the resistance of the defense system.

The construction of a bollard or anti-truck ramp is made with metal structures and resistant elements that I can not fabricate.

I think the project has been a success if I get the following:

1.Correct input-output performance:

That when a heavy object approaches the inputs send the information of weight and speed, and with the programming the servomotor is activated.

2.Do not activate the system when there are smaller weights that are not dangerous.

3.The design will be a success if both the body and the box and ramp form a block and the pieces move correctly with each other.

4.If the latch is working properly and the ramp does not go up alone.

5.If it has the ability to stop an object at speed with a certain weight, not necessarily a truck.(because i haven't a truck).

FILES:

Ganttproject