WEEK 10 – OUTPUT DEVICES

Weekly assignment

Add an output device to a microcontroller board you've designed and program it to do something

For this week's assignment I've decided to make the hello.servo.44 board since I'm going to use a servomotor in the machine I've designed for the group assignment, and I wanted to start managing this kind of motors.

As usual, I started by making a list of components I needed to assemble the board.

BOM (one for each):

ATtiny44 microcontroller

20MHz resonator

20uF capacitor

10K resistor

6-pin ISP header

3-pin male header (to connect the servomotor)

4-pin male header (to connect the power)

5V regulator

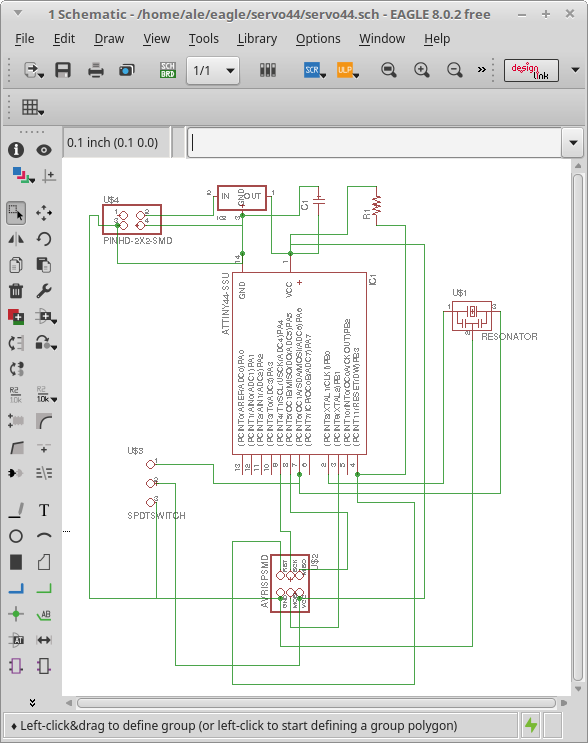

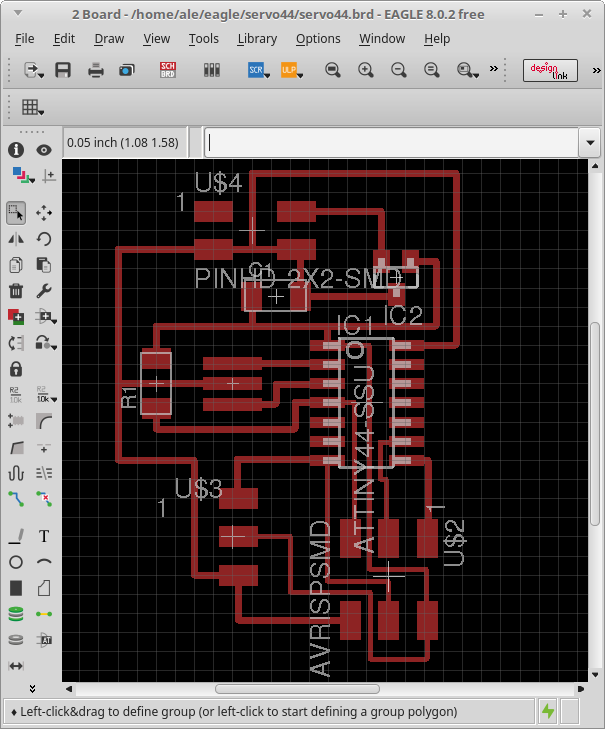

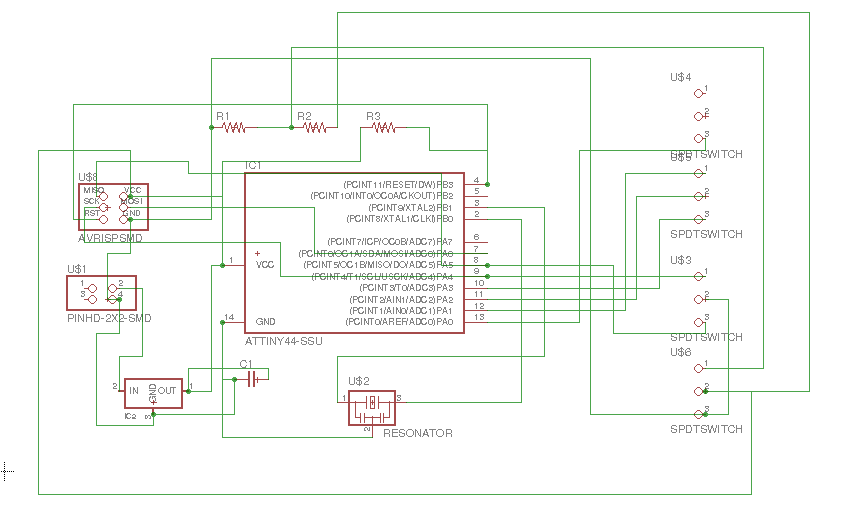

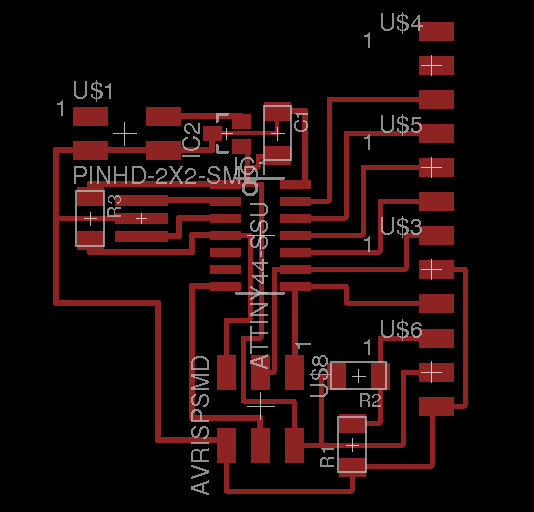

Then I moved to Eagle to design it. Starting from Neil's version I tried another regulator package (SOT 23) and so I had to redraw the related connection according to the minimum distance between pins and traces. Specifically I couldn't lay a trace between the in and out regulator pins, so I had to find other ways.

I also wanted to connect only one motor, so I included only one 3-pin header.

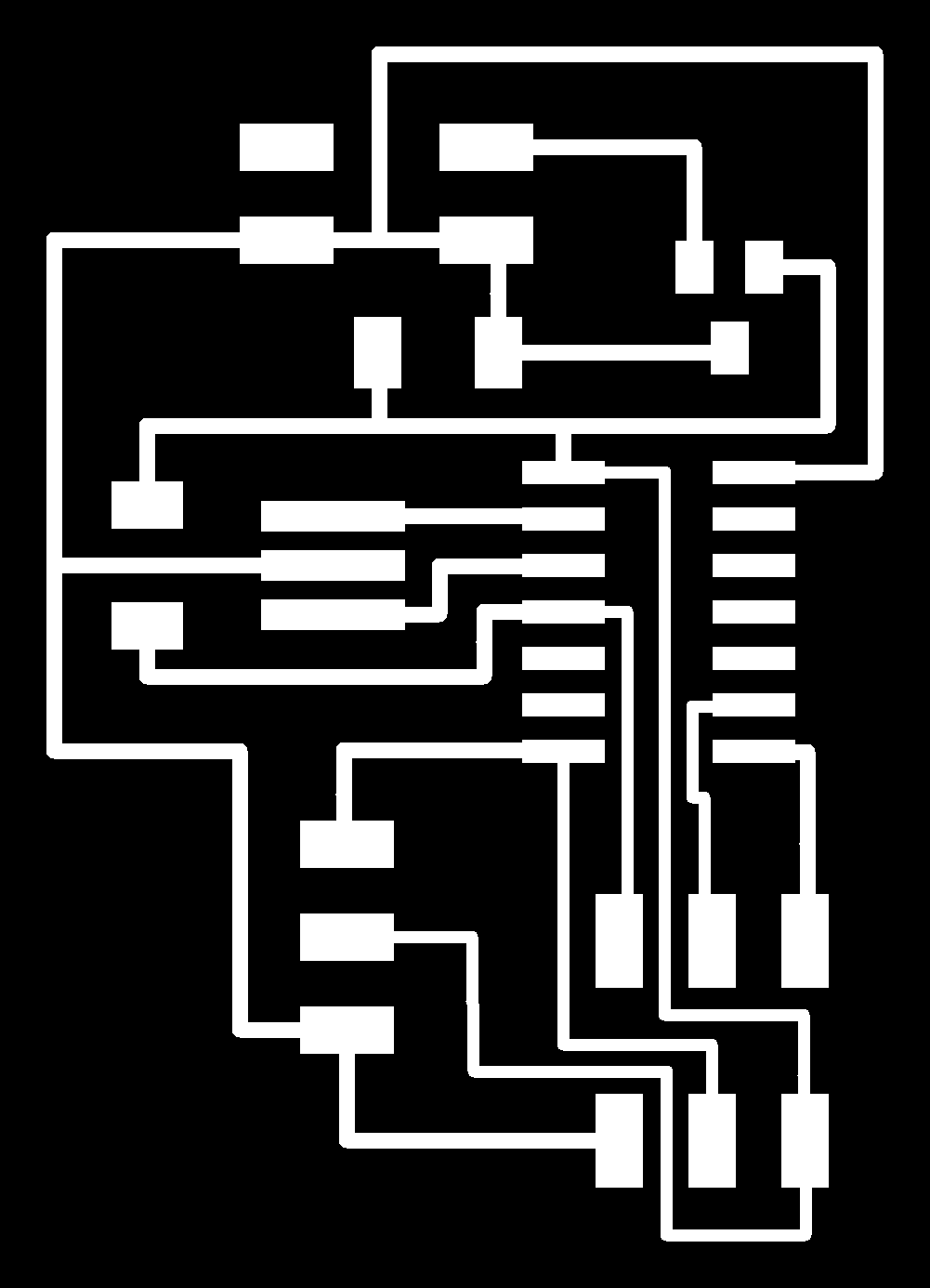

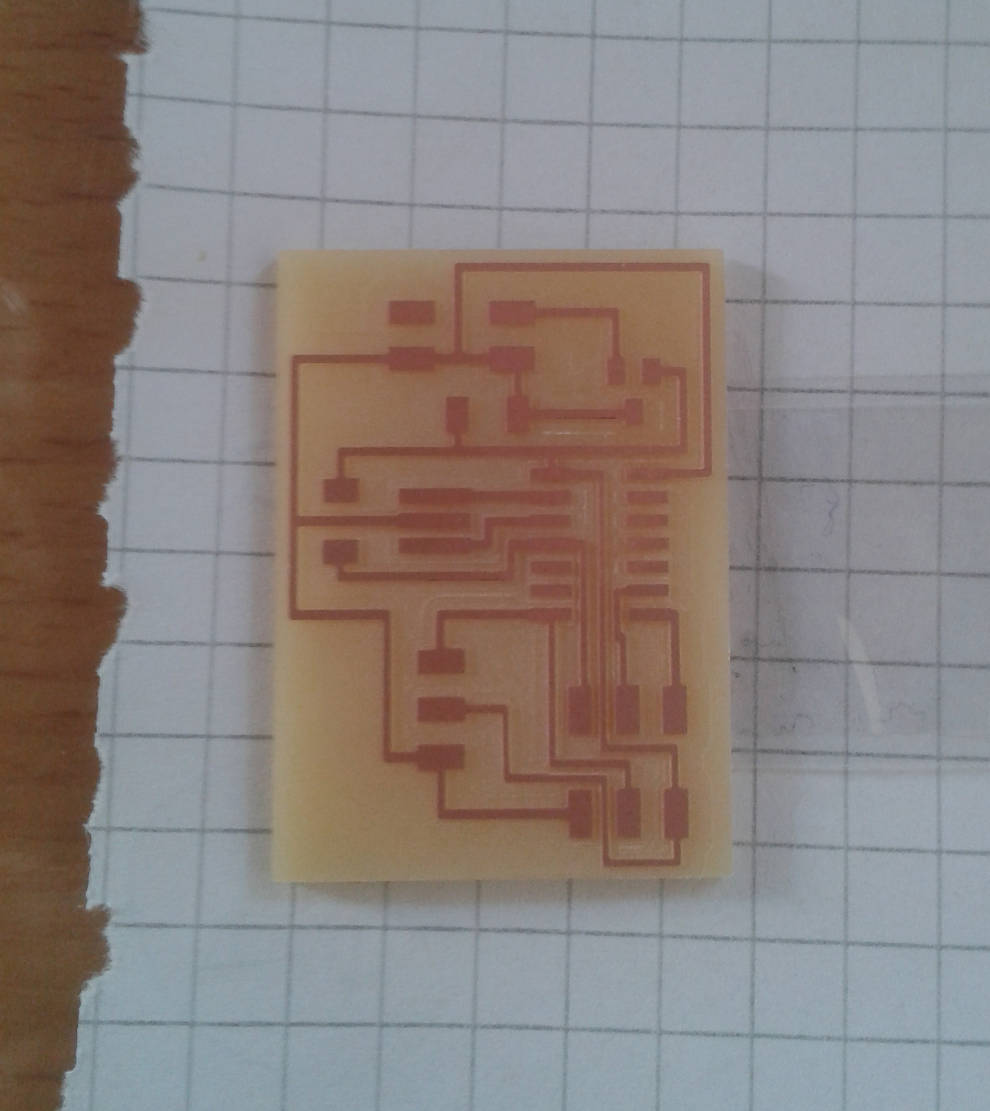

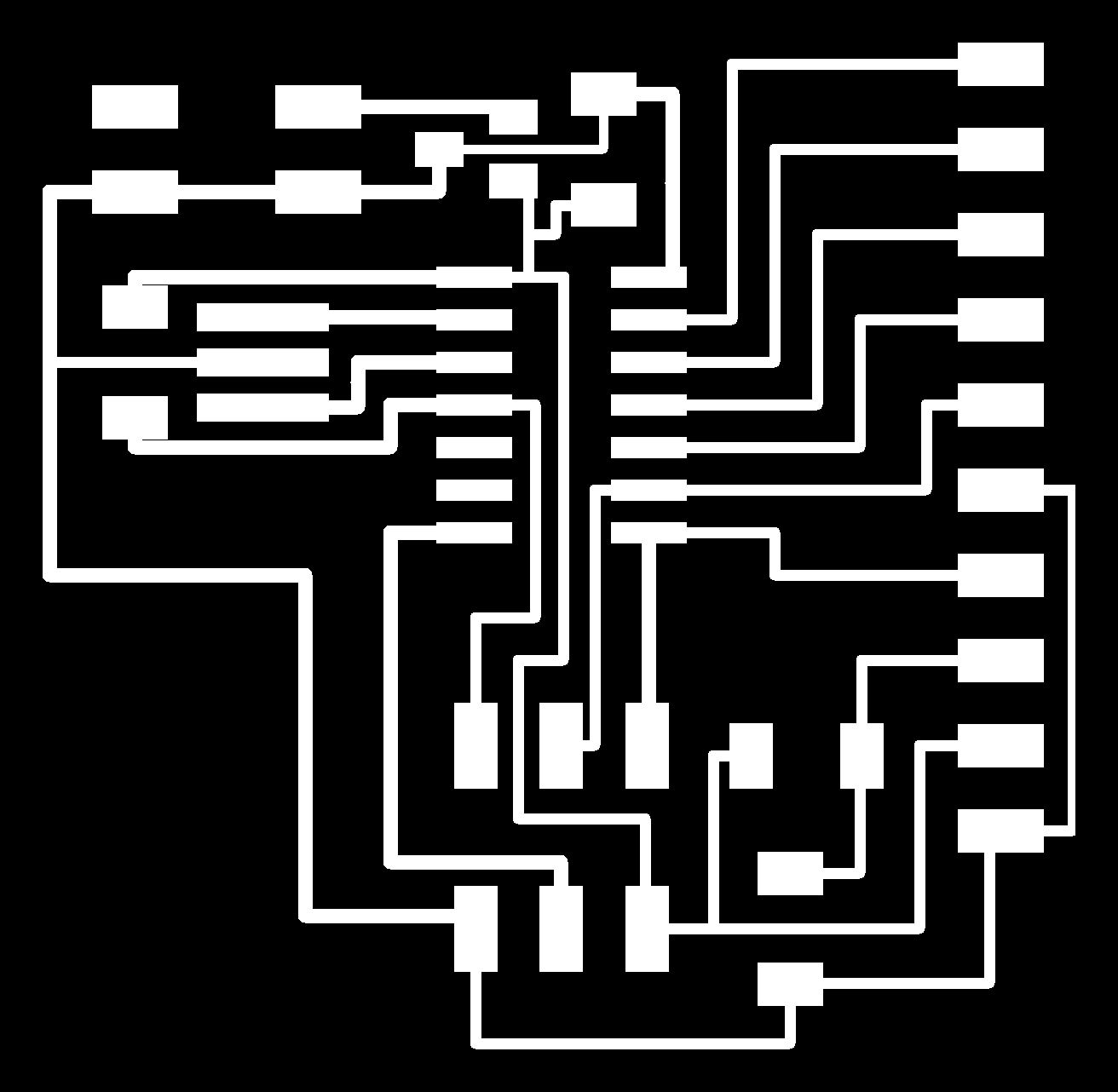

I created traces and outline .png files using Gimp and milled the board as I did in previous weeks

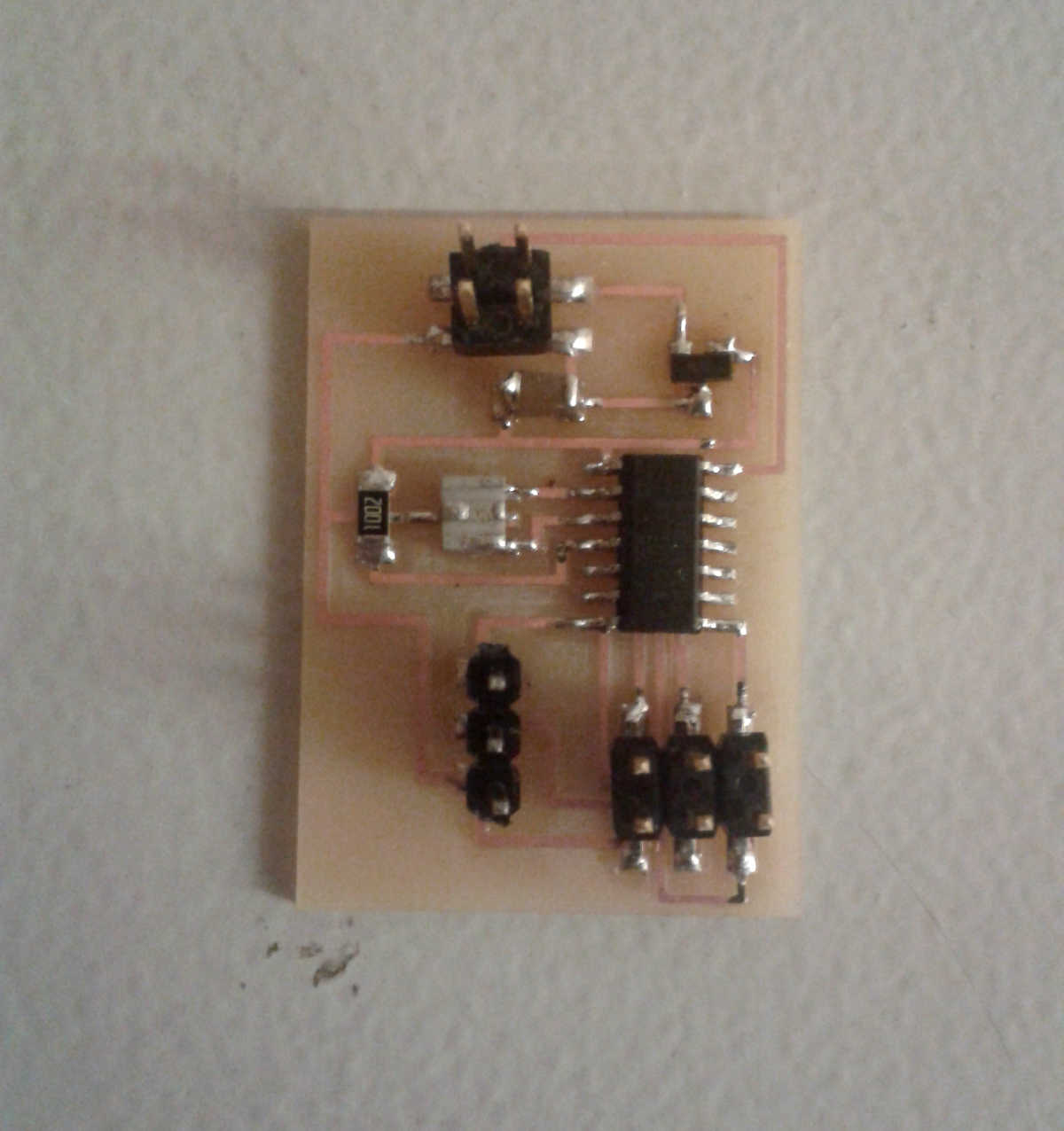

And then I soldered it

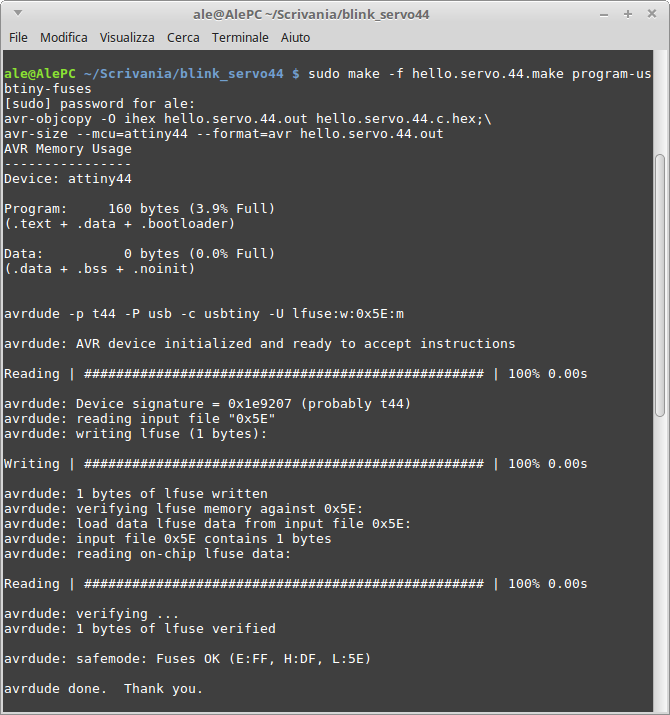

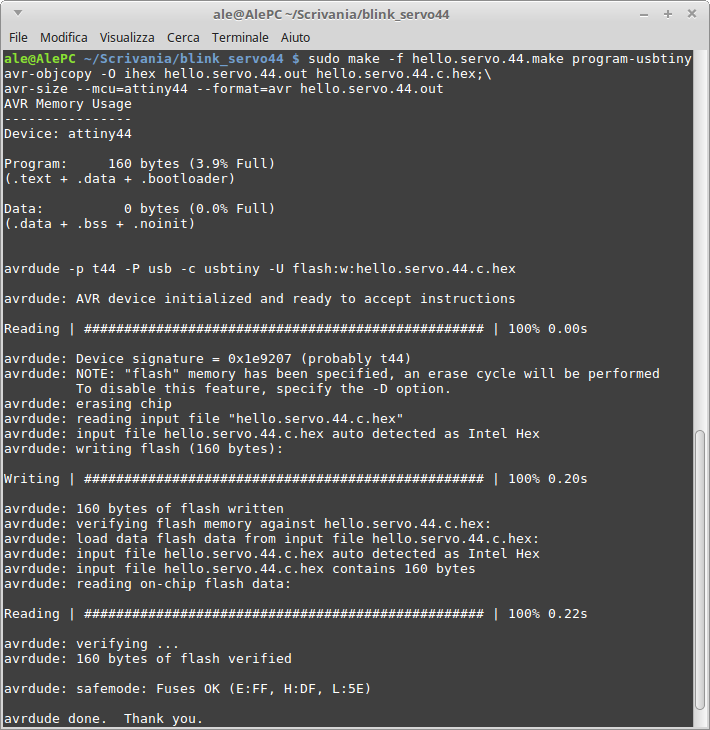

When I connected the hello.servo.44 board to my FabISP to program it I notice that the regulator heated up in few seconds. I found that it is normal for a regulator and I only tried to hurry to program it, so I could disconnect it as soon as possible.

Fortunately everything went well at the first attempt (never happened before!).

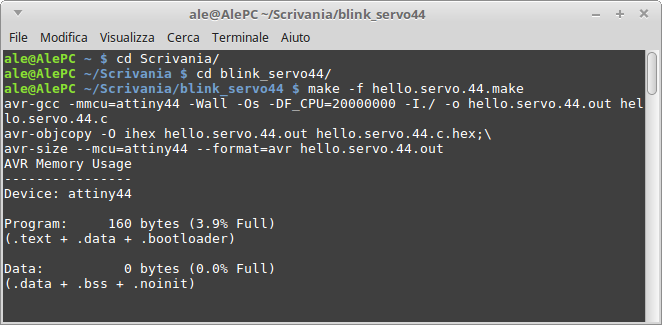

To quickly see if my board was actually able to move a motor I used Neil's C code for one motor.

Anyway I'm not enough pleased with my work, I want to study deeply motors (even stepper) and explore more programming. But this needs a lot of time...

Update 2/5/2017

LCD board

In my opinion LCD screens are very usefull devices so, since I had some time during the input device's week, I decided to make a LCD board

I started again from Eagle to design the board

The LCD screen I used has 16 pins but I needed only 10, so I designed my board with only those pins I was going to use

In Eagle I couldn't find the specific kind of pin header I needed, so I laid more and then I removed the surplus (only two on the top) on Gimp once I moved to set traces and outline files

To do this I only had to select the area I wanted to keep and then click on "crop to selection"

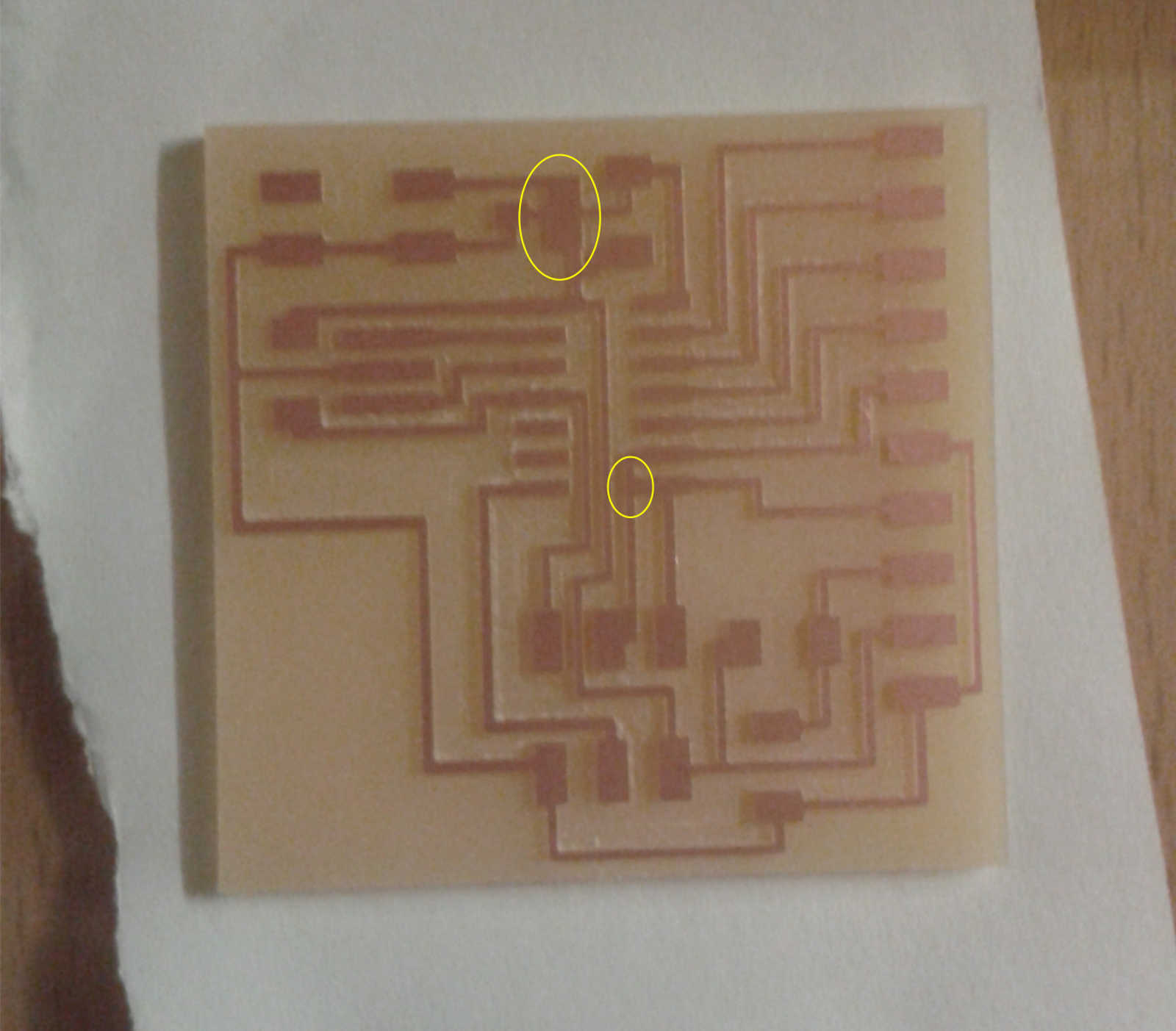

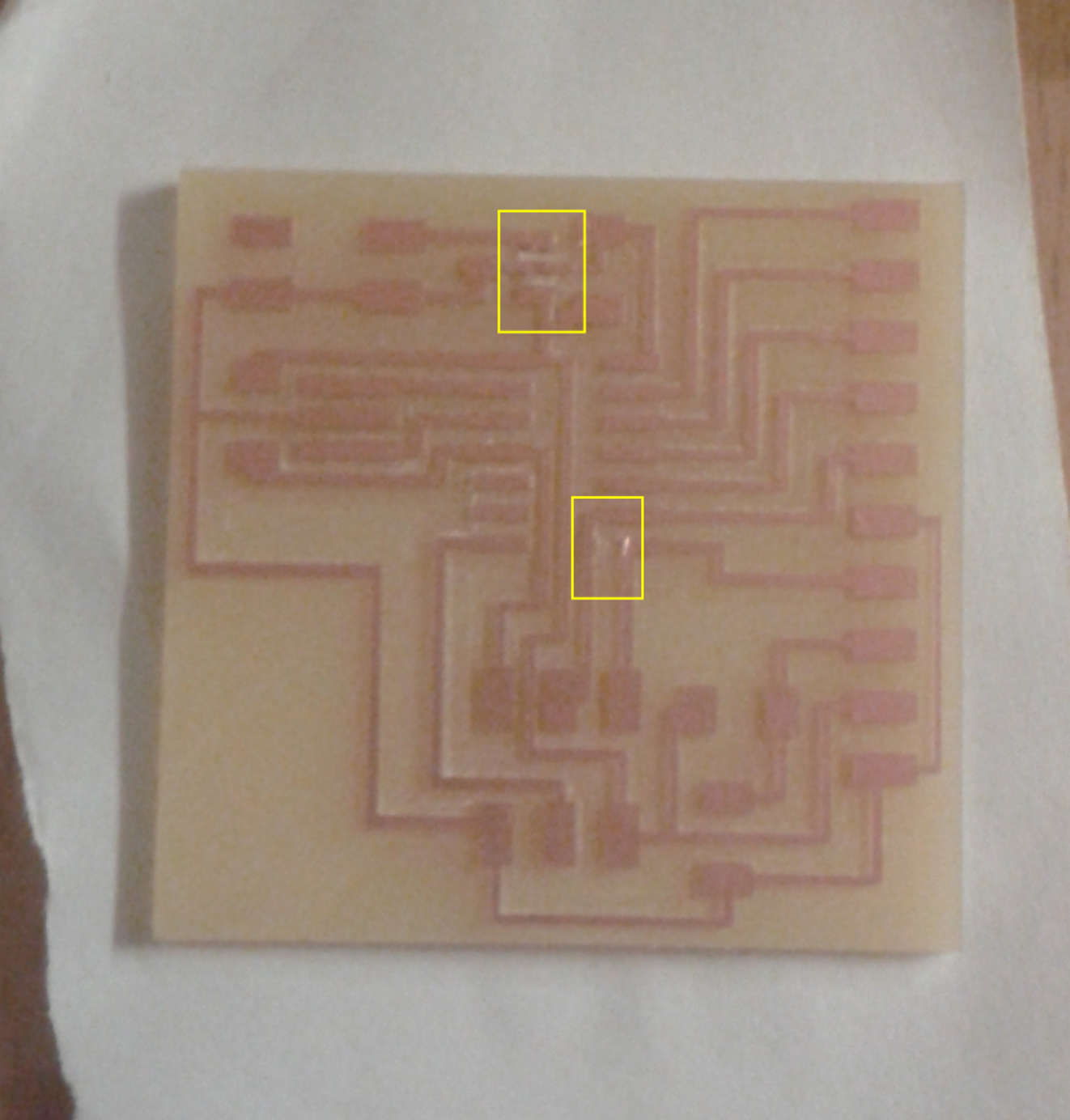

After the milling process I had a bad surprise, three pins were connected to some traces they should not be

So I removed these connection by hand with a cutter and tested with the voltmeter to be sure everything went fine

Making the connection cable

Due to my board design I couldn't connect it directly to the LCD screen, I necessarly needed a connection cable. But I already knew when I designed the board, beacause I used LCD pins from 1 to 6 and from 11 to 14

So I had the opportunity to solder my first cable

I checked all connections with the voltmeter, and since they worked I covered them with hot glue to isolate any connection to each other. After that I covered everything with the insulating tape

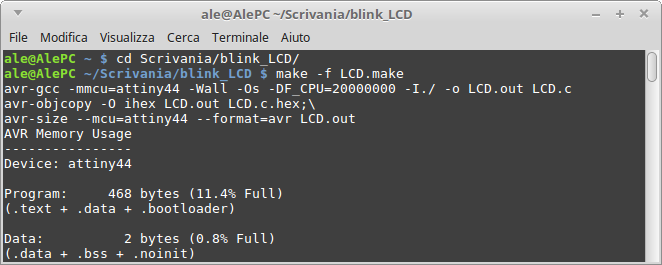

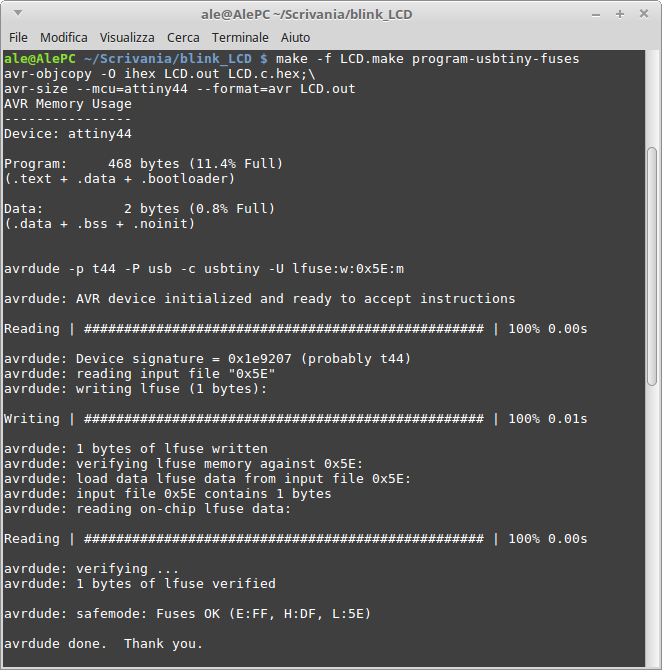

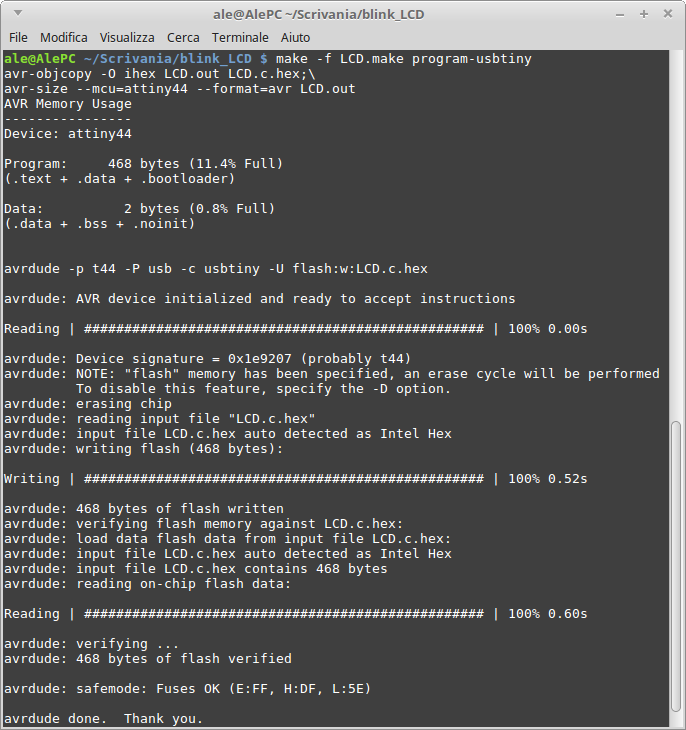

Then I moved to program the board using Neil's C code and make file

Eagle and program files here