Week12 molding and casting (Apr 20)

design a 3D mold, machine it, and cast parts from it.This week i want to make a mold about fablab and I use the tool and material are follows.

CorelDraw

MODELAPlayer4

VPanelForSRM20

Mitre Saw

Sandpaper

usually we make the mold form flexible material so that cast will be easily removed. //Because the flexible material is hard get it and I found the ABS in the lab so I chose this material to make the mold. in order to the cast is easily removed and add the oil on the wall of mold.

mold release

ABS

Paraffin

Phosphor powder

Design model-->Roland Mill Setting-->Milling-->Sanding-->preparing Material-->Casting-->Finish

Milling process includes two part: make three paths of Surfaceing /Roughing/Finishing and operate machine to set origin point of user coordinate system before milling.

1.Design model

In order to make my work more meaningful, I decided to make a FabAcademy logo .Using the Rhino software, I make a 3 D model of Fabacademy logo. I'm not very familiar with the Rhino software, so it is a little difficult to me at the time of making. I spent lots of time, but I finally did it. Then I realize that I should spend more time for the Rhino software for a deeper understanding.

2.Roland Mill Setting

This is my first time to use Roland Mill to make a 3 D, so I need times to learn how to use Roland Mill production to make a 3 D. By importing, the STL file to the MODELA Player, then respectively to make three paths of Surfaceing /Roughing/Finishing.

3.Milling

In my fist times to mill, I forgot to set Origin Point so that I miss corrected position. Setting Origin Point is very important because it is the key of the right milling. Always set the Origin Point before Milling.

4.Sanding

Got the mold and found the edge is very sharp, so needed to sand the edge of mold.

5.preparing Material

The material includes ABS/Paraffin/mold release and Phosphor powder.

6.Casting

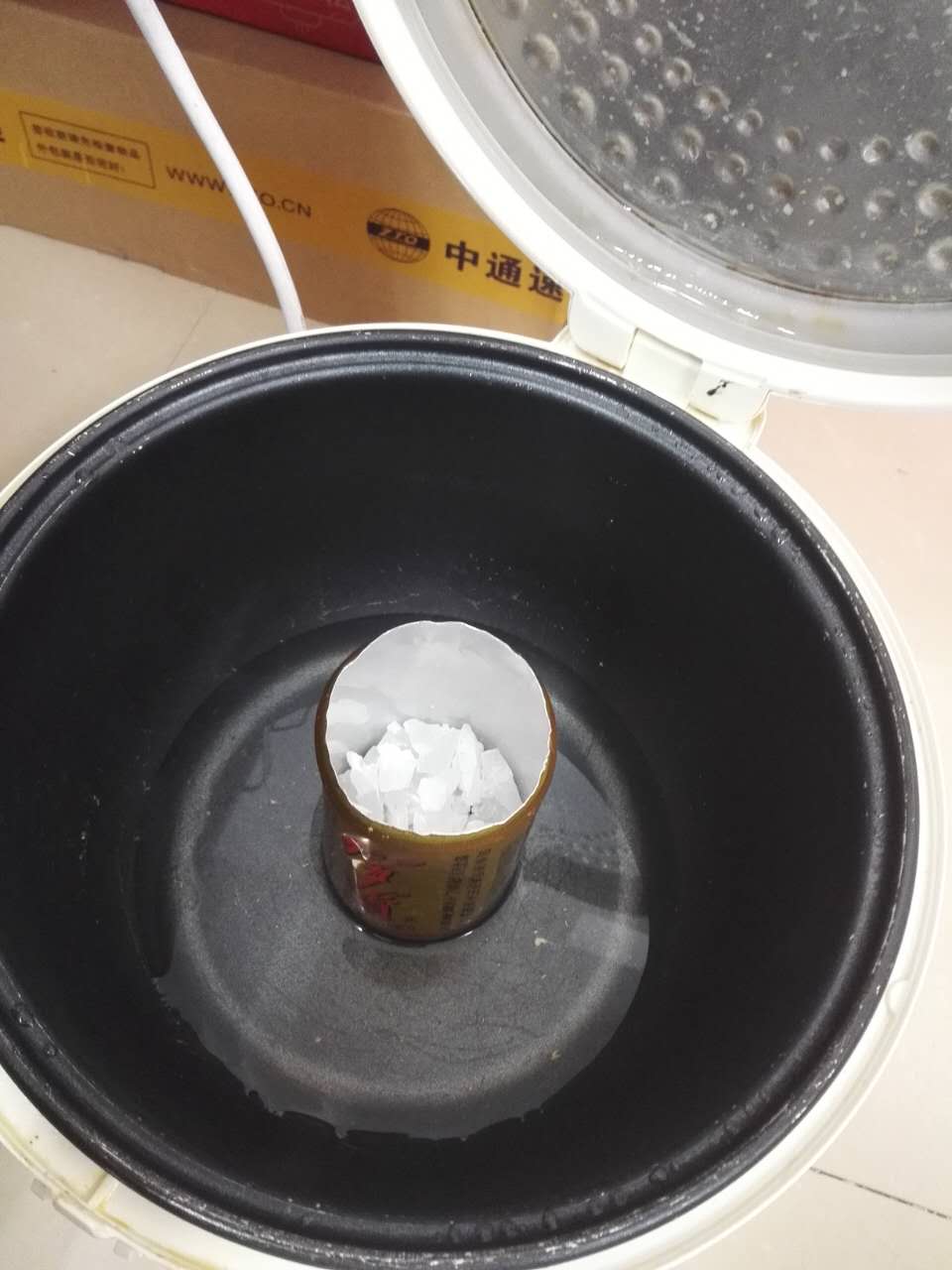

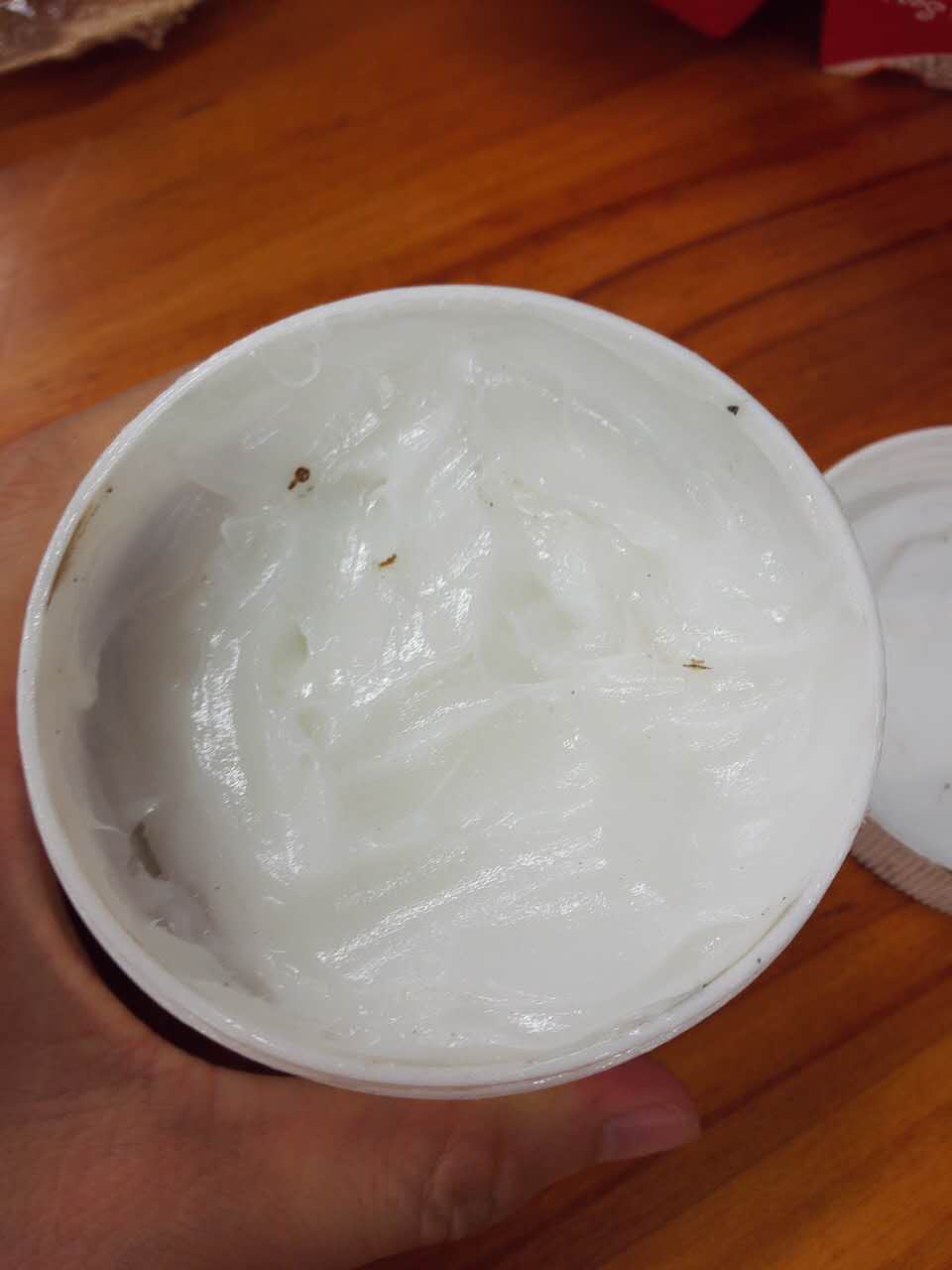

The melting point of paraffin is about 100 degrees, which is the hot spot after boiling. When it is become100 degrees the paraffin began to melt. For the sake of safety and temperature control and the highest temperature of a electric pot is to 103 ± 2 degrees ,so I choose to use the electric pot to melted wax.

Thank you for my instructor give me the suggestion and I buy some rubber material online immediately when my instructor tell me that try to use flexible material to make the mold.

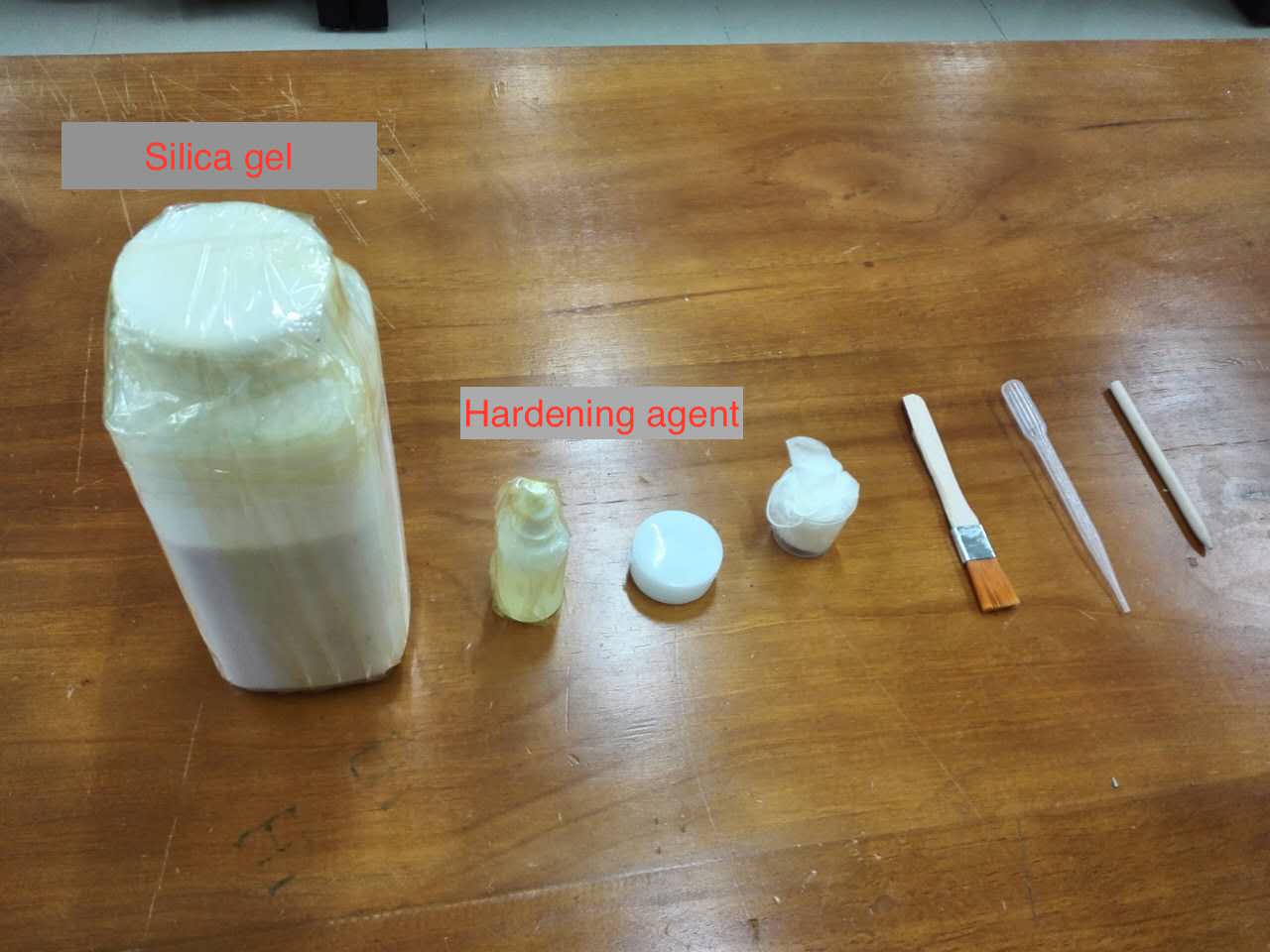

Silica gel and Hardening agent:

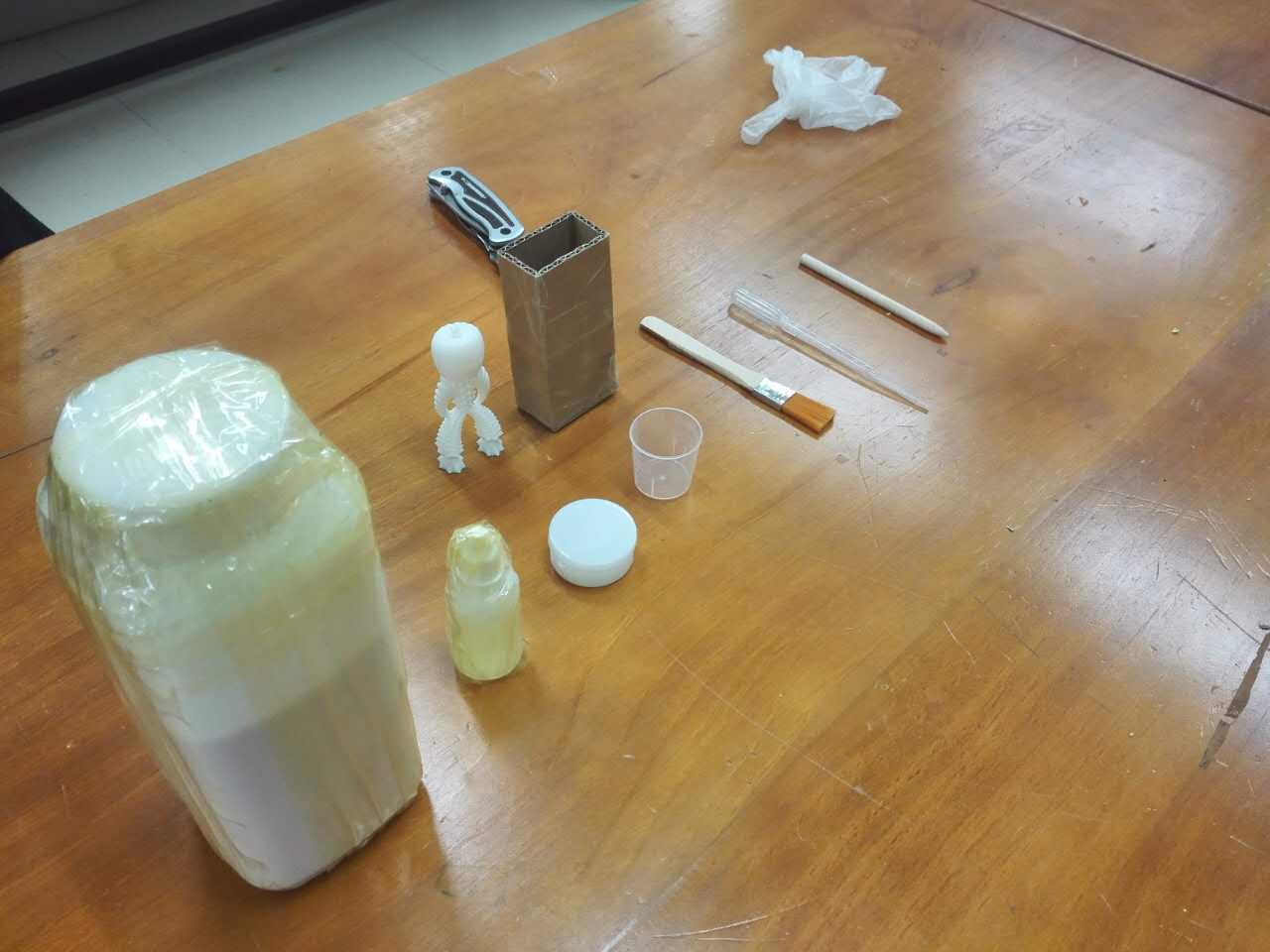

Make a frame:

Need to pay attention to something when make the frame.Have to remember to reserved vents or it will cause the mold and cast appear some Bubbles and the mold and cast will be failure.

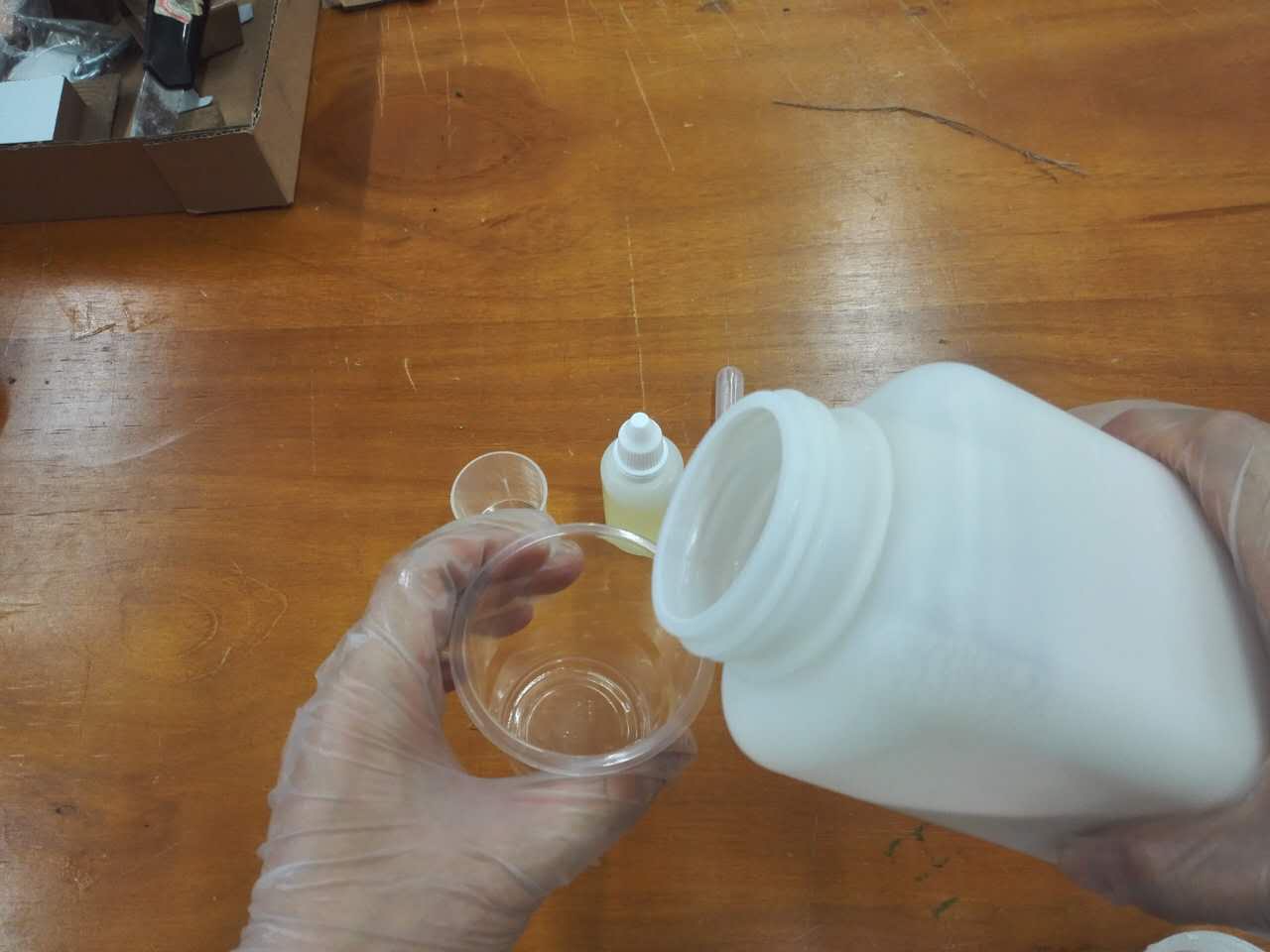

Prepare some materials:

Need to prepare Plastic cup, Wood stick, sucker, measuring cup,Silica gel and Hardening agent.

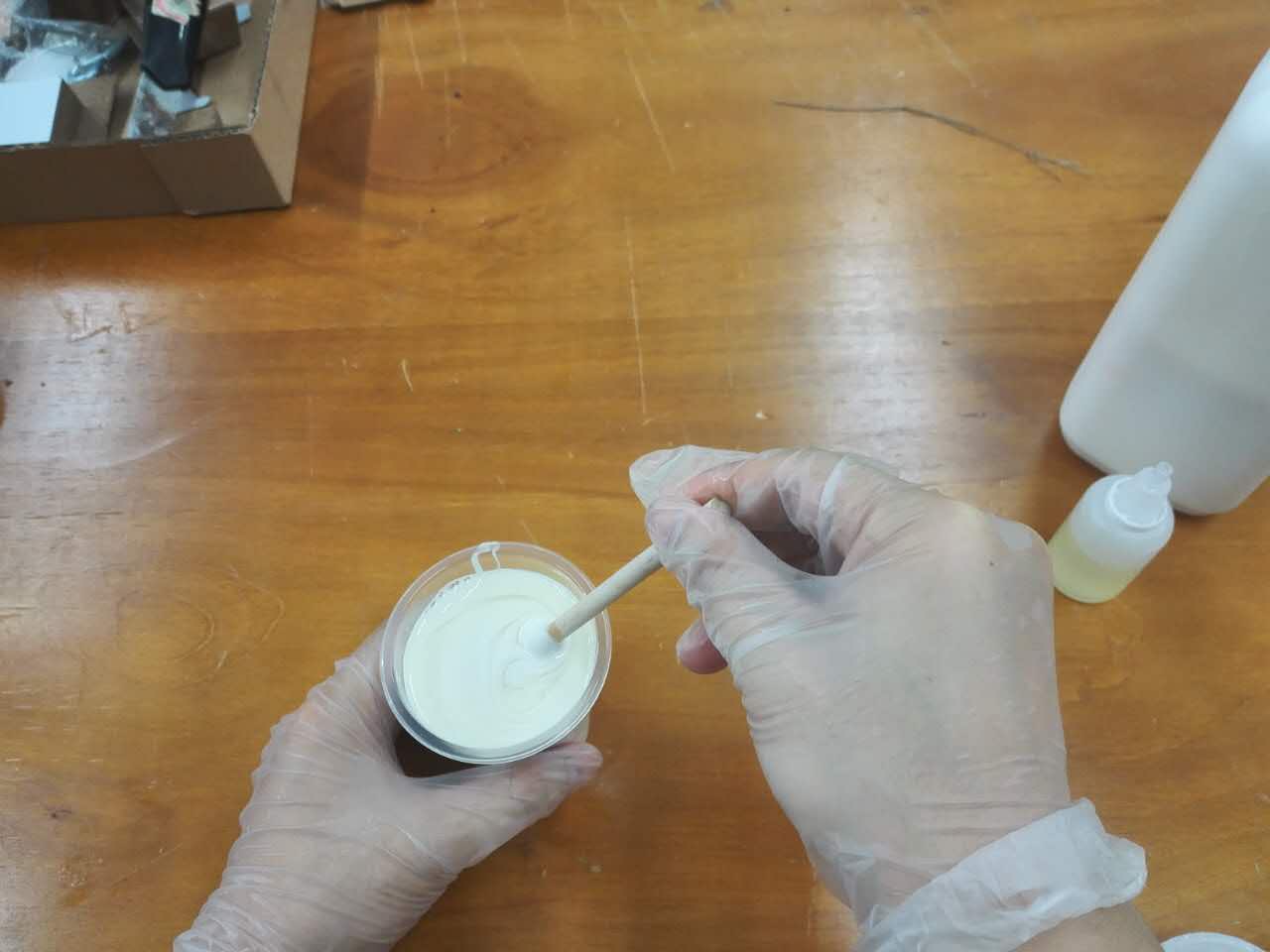

Use Silica gel and Hardening agent, one hundred parts to two and mix them.

Put the Mixture into the frame slowly.

Vacuuming:

Failure:The mixture hasn't uniform distribution,Maybe the frame is too small.

Make a frame:

Put the Mixture into the frame slowly and fill the fame as one side.

Wait 30 mimutes, Put the Mixture into the frame and cover the top as second side.Divided into two step in order to let the mold solidified quickly.

Mold completely solidified:

success!!

Mold.stl

1.If does not pay attention to the Paraffin melting point, it is very dangerous.

2.Set the Origin Point is very important for Milling.

3.Understanding of material properties is very important .

4.Roland Mill is very powerful to mill small stuff.