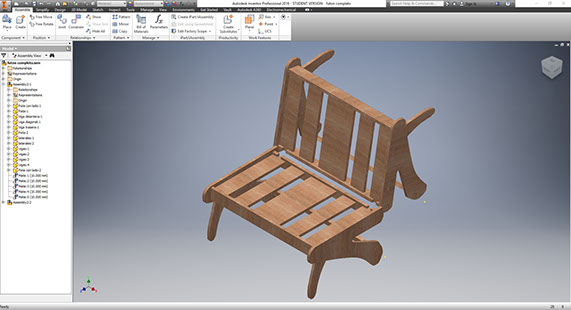

After designing and making all the probes in Inventor,I decided to take the archive to the Router CNC en a 2.44 x 1.22 m and 18 mm so that it can be resistant and durable

After cutting alll in the Router CNC I decided to assembly without glue or screws and the I sat down to test the resistance and VOILAAAA!!! It supports me and that made me very happy.

I decided to put some wood sealer so that the woood could look better and natural, also it helps to protect the wood and for me that made look better.

Once all this treatment I assembly everything and to make sure I used a special glue and then I install the mechanism so that it can work as a Futon

Here are the archives of the FUTON in Inventor and DXF

Here is the assembly of the mechanism and the final result o it

To be sure of the model, I decided to cut it first in MDF so that I can see the design and how it will probably work

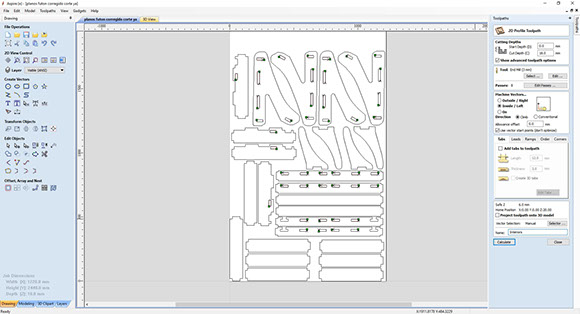

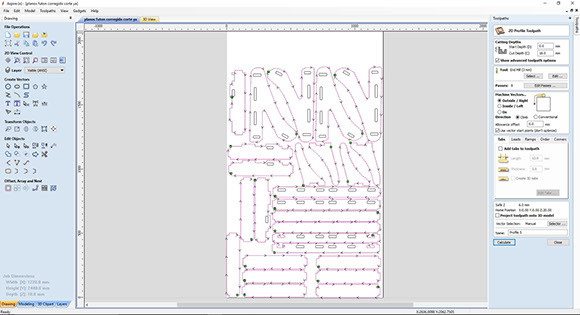

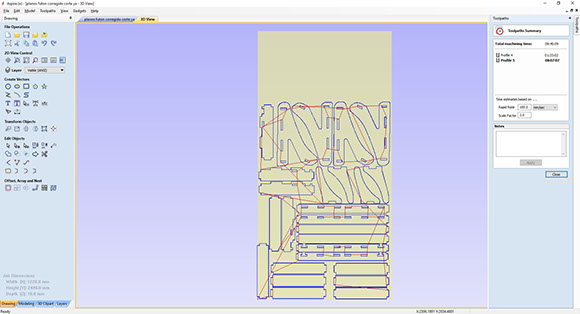

Here is how I programmed the cuts, and the passes I wanted for the wood. Also in this software I can calculate the time it will probably take to cut all the archive.

Here is how I set the cutting parameters:

Feed: 60mm per second,

Mill speed: 10,000 rpm

I used a two flutes end mill

For this assignment we have to do something BIG. Cause we spent a lot of time working at FabLab Puebla, we need something to rest and to continue and I decided to look for a chair.

I look for some designs at pinterest, instructables and nothing was enough for me.

So I got inspired and I design a FUTON and somebody gave me a mechanism for futons so I decided to used it.

Week 7

COMPUTER-CONTROLLED MACHINE

Elias Prado Morales

Fab Lab Puebla, México

aeliaspm@gmail.com

Fab Academy | 2016