Electronic Design

This week I had a interesting story of drama and love with the Modela MX-20 of Fablab León. I lost several afternoons fighting with it. I have to admit that still didn't get the perfect workflow, mainly with the outer mask for cutting, as I didn't make the correct space to avoid cutting the circuits lines.

Lesson

Academany Fab-2016.03.02D Lesson 06: Electronics Design from Fab Academy on Vimeo.

Electronics Design

http://academy.cba.mit.edu/classes/electronics_design/index.html

Designing a electronic board using a ECAD program

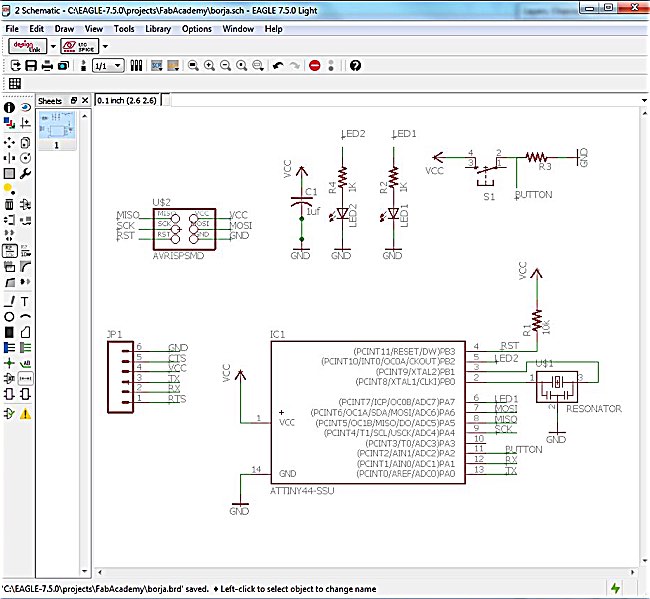

First I went to the most safer goal, and with eagle I modify with the parameters marked a made board. I really wanted to make from start from KiCad as didn't have some of the limitations of free Eagle and to know a new program. But as me and others students found, there are still some issues with the fab library in this program. These problems are being fixed fast by the great people of Fab Academy community. But as I run in problems cutting the board I postpone to a future update.

Introduction to ECAD programs

My Guru Nuria Robles, that is also lead one supernode make and interesting meeting for introduce us to Eagle Design and solve some problems starting with our board designs.

This is a screenshot of the event that I borrow of the conference from my co-student Marta Verde. I thought of making a video recording of the session for screencast. But my full Desktop was a mess.

As I was aware that I maybe will be have problems making this assignment, I tried to make as simple as possible. Just adding 2 leds and a button.

I have problems with joins that seemed connected without problem at the schematic and didn't appear at the board, so I knew that something was wrong. With the help of auto diagnosis I could fix everything

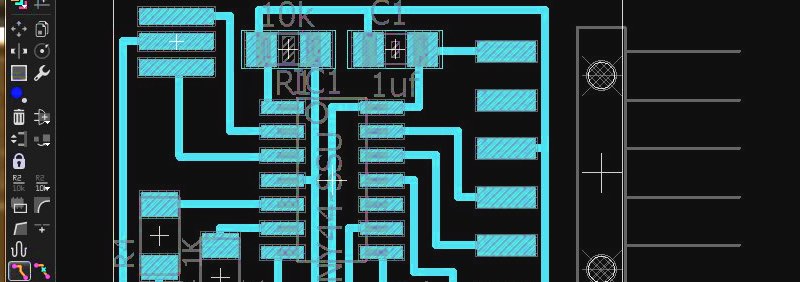

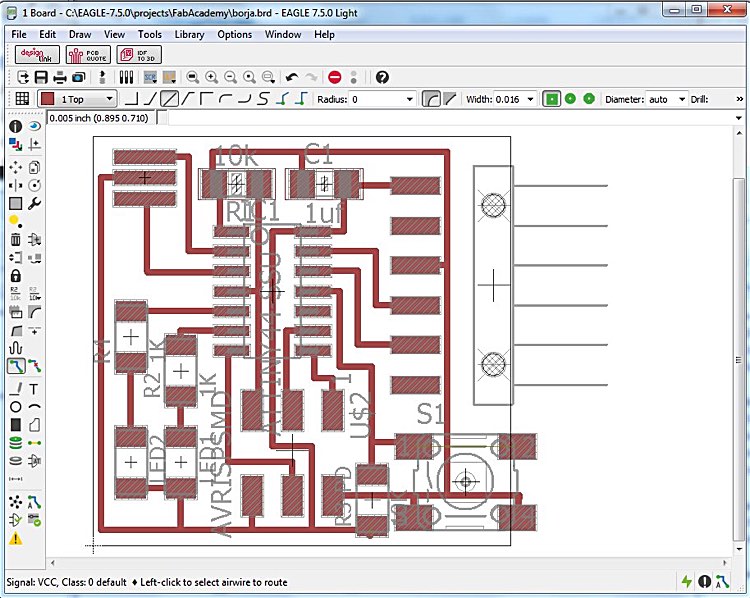

View of the board made by Eagle. I had to manually fix some paths as the autopath function make same mess and not the smartest routes. Also I checked that paths have enough distance between them with at least 41 mm

Milling the designed board

FabModules

This week I used Fab modules at different machines and systems, so it assure my confident on them. Sometimes the best setting is that if it works, don't touch or update it. Also I finished to install them in the fablab macbook I usually work inside the fablab.

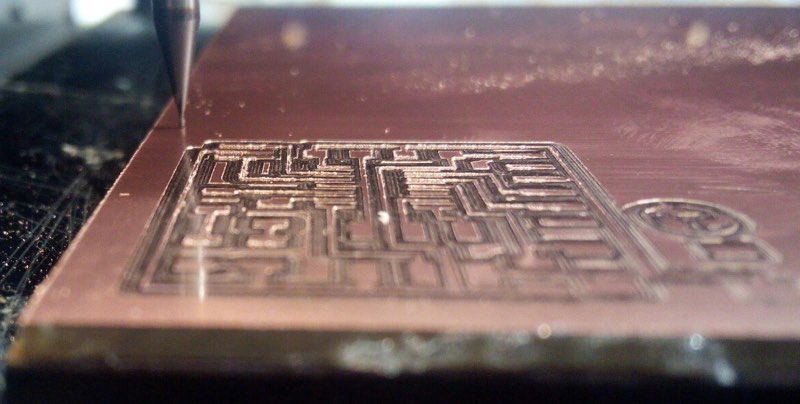

Milling with the Modela MX-20

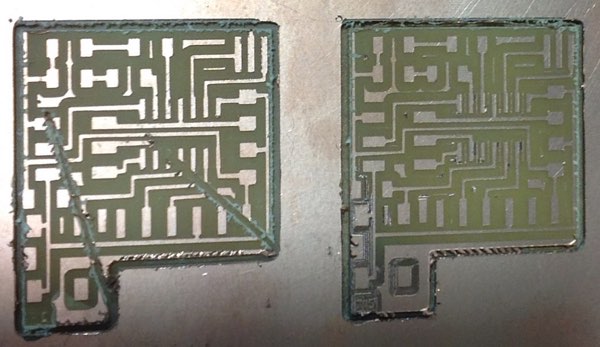

In this photo we can see the little differences of milling with the old fab modules (right) and the newest html5 fab modules (left). For my opinion the old ones have a little sharper paths.

The diagonal cut of the right board is made because the Modela did strange movements if is controlled in Linux without the proper special hacked cable (DB9-DB25). In Mac with html5 modules you use another cable (USB-DB25).

Also the cutting mask is was more narrow that it should be, so the outside paths were spoiled by 32" milling bit.

On Monday I tried to mill again, this time with a bigger and wider mask, but I have a new problem, still to find. When milling the paths it didn't make well. As I changed the full board including the sacrificial layer, maybe some irregularities could make this happen.

I checked, that the milling bit was touching the board, and for my appreciation, I didn't notice that any big irregularity. But without a precision measure level, I can be absolutely wrong.

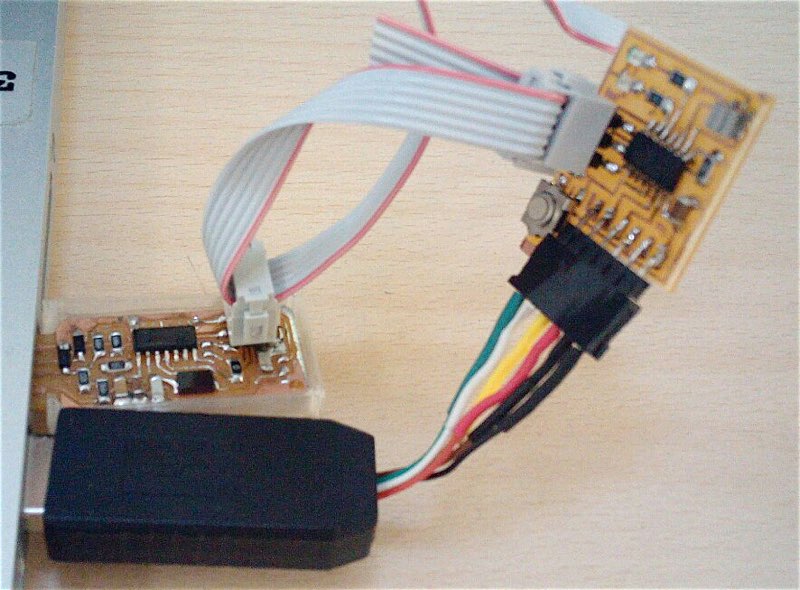

Finally on Tuesday I could some some problems and cut the previous board, and start soldering.

Soldering the board

Preparing the components

As the inventory in Fablab Leon is nice ordered and have everything, I didn't have any problems getting all I need. Not any special issue.

Soldering

Well, even I'm improving still a long way ahead. Still I'm able to burn a path if I don't have enough care, and make dirty joins. And of course when an element has more pins and the paths are thinner more complicated is for me

But I could make enough good connections after solving some missing links with the help of the electronic tester, to connect the board to a computer and see that it can be programmed

Any case the board has a design flaw that I introduce myself as I misunderstood the helpful advices of my instructor Nuria Robles and I cut more than needed in the zone where the header of 6 line pins are situated. They are on free fall and can be broken. It's clearly that I have bad moments and ideas with the cut mask.