Final Project - Building the Box and Housing

HRW OpenHydroponicGrowbox

Building the Nutrientsolutioncontainer and the housing

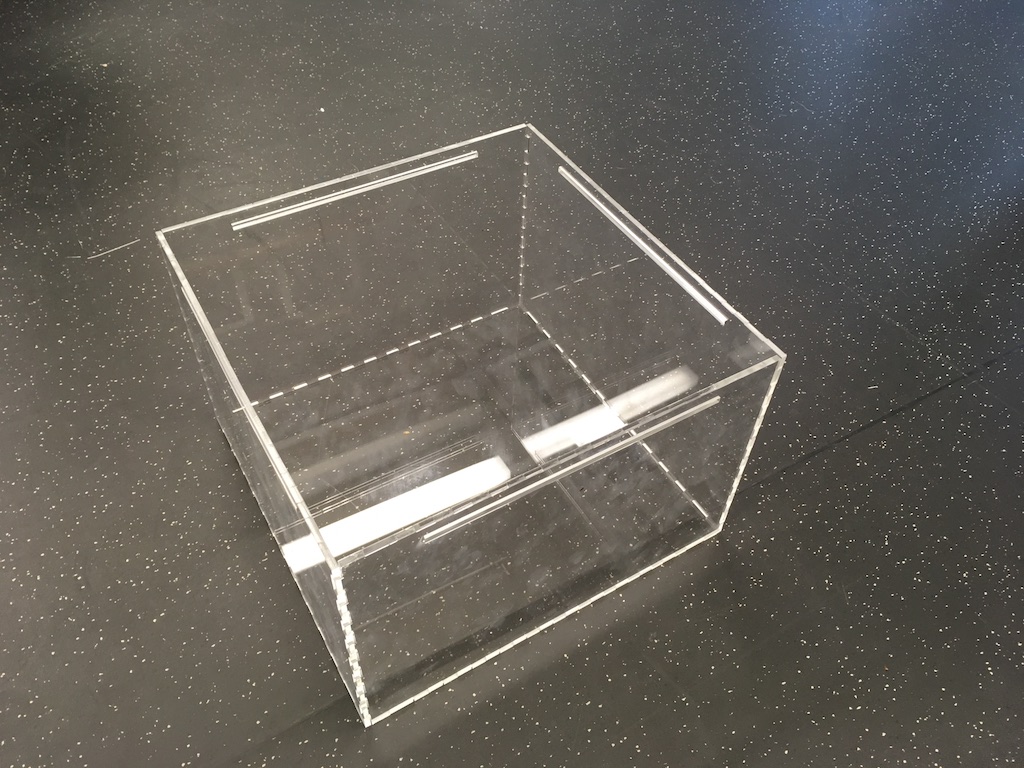

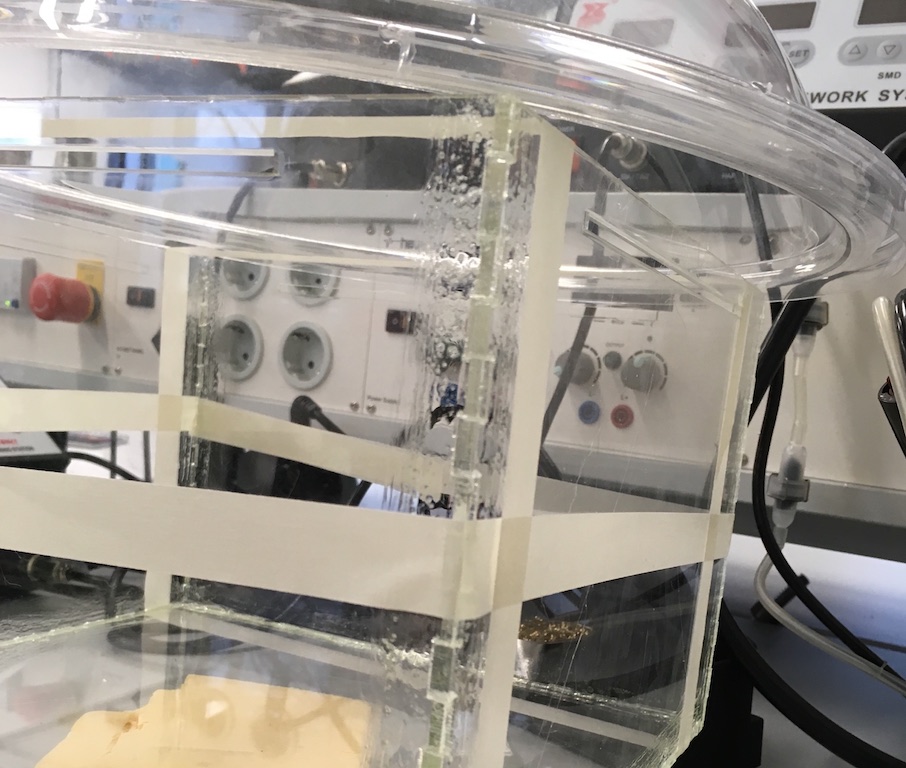

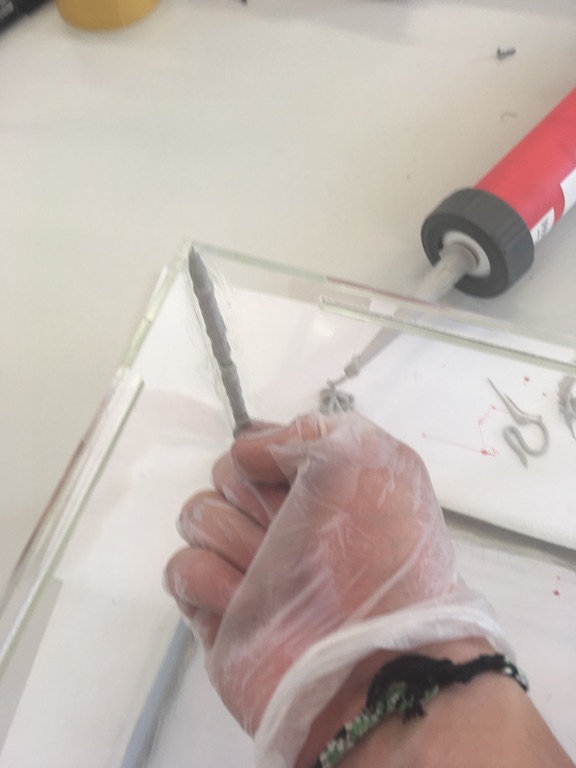

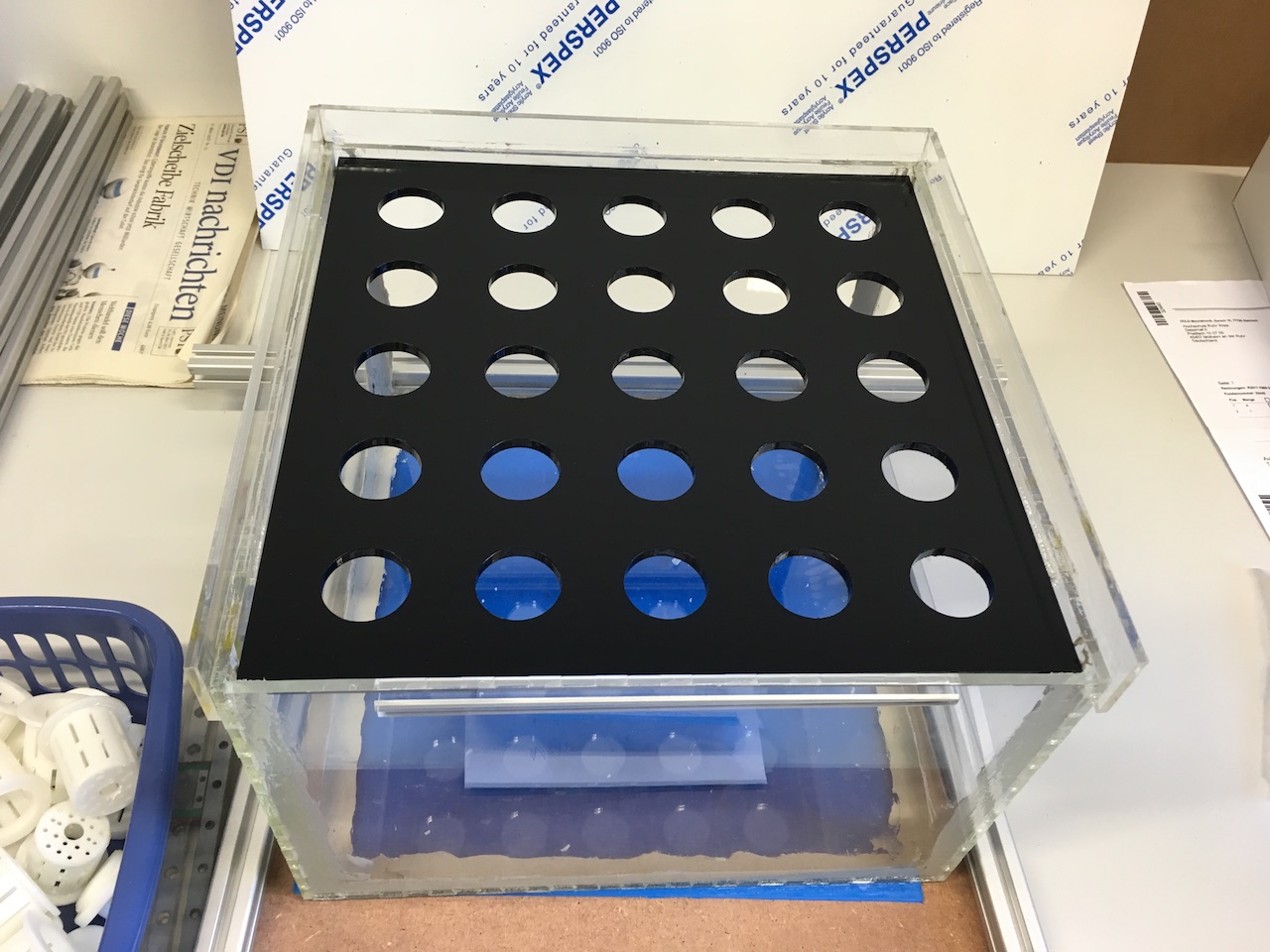

Building the Nutrientsolutioncontainer

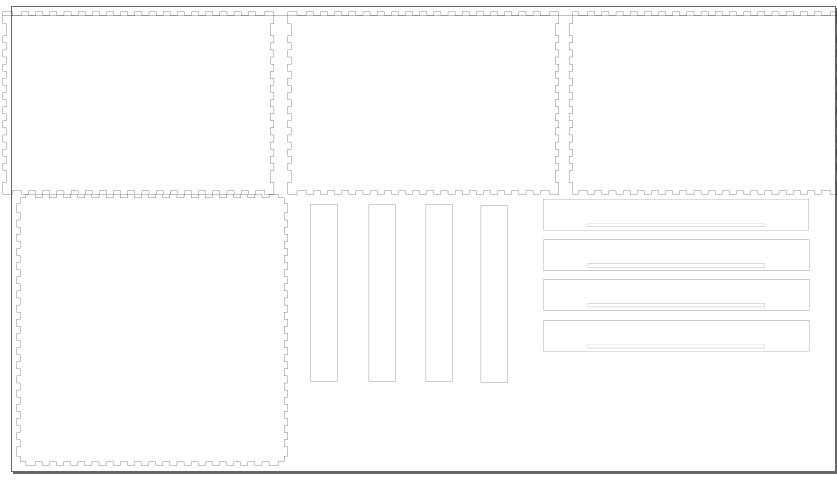

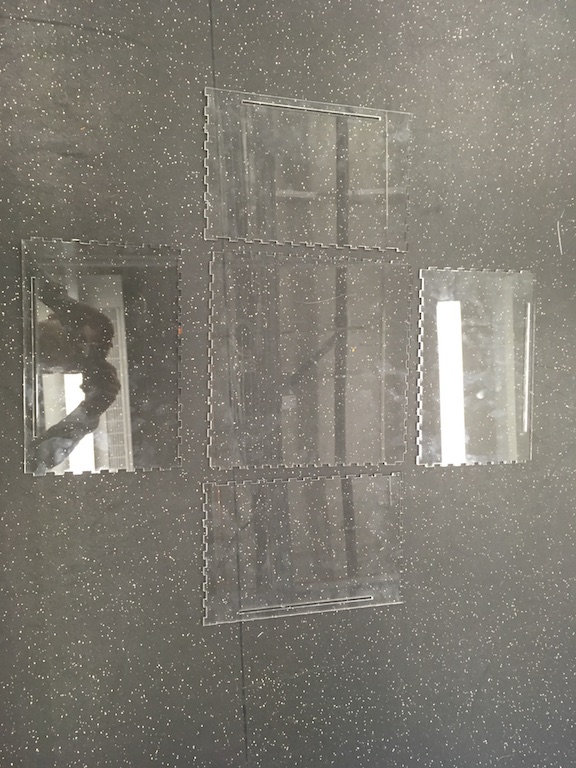

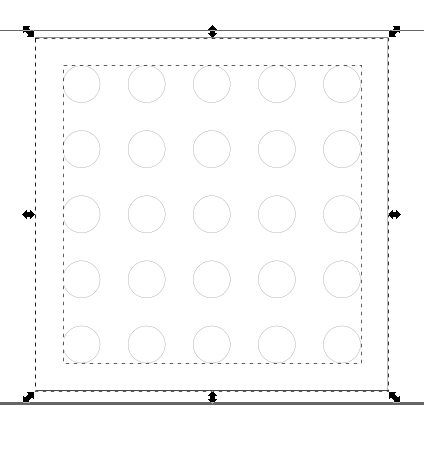

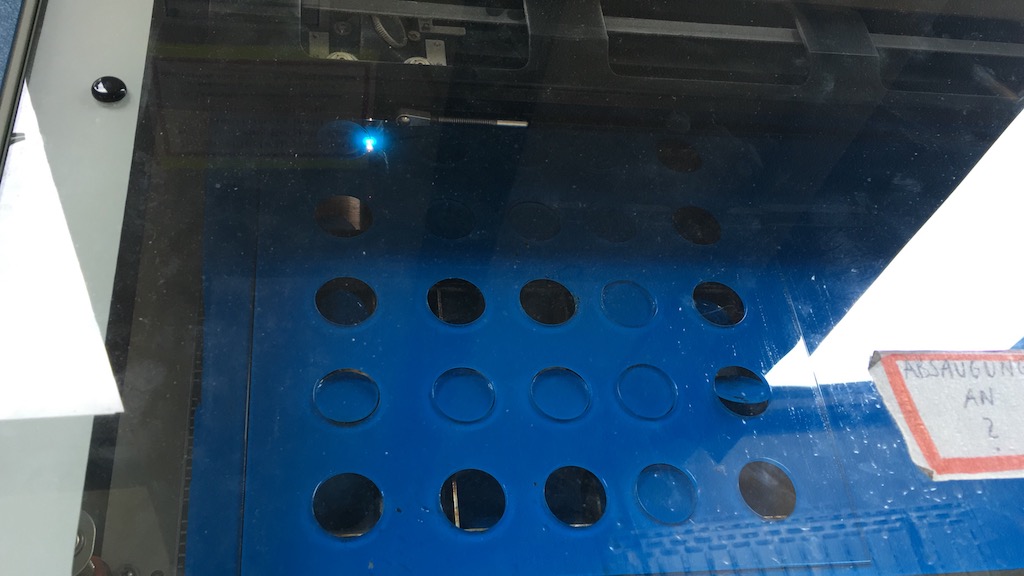

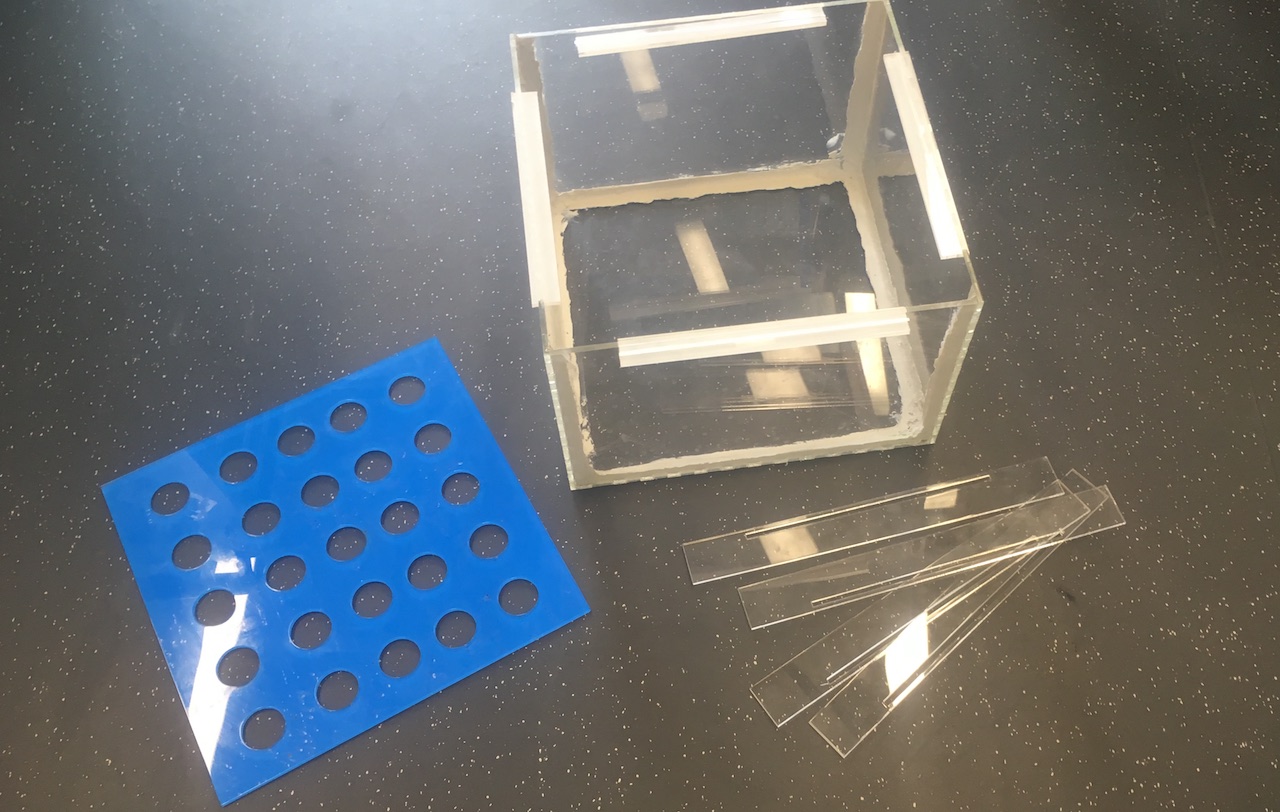

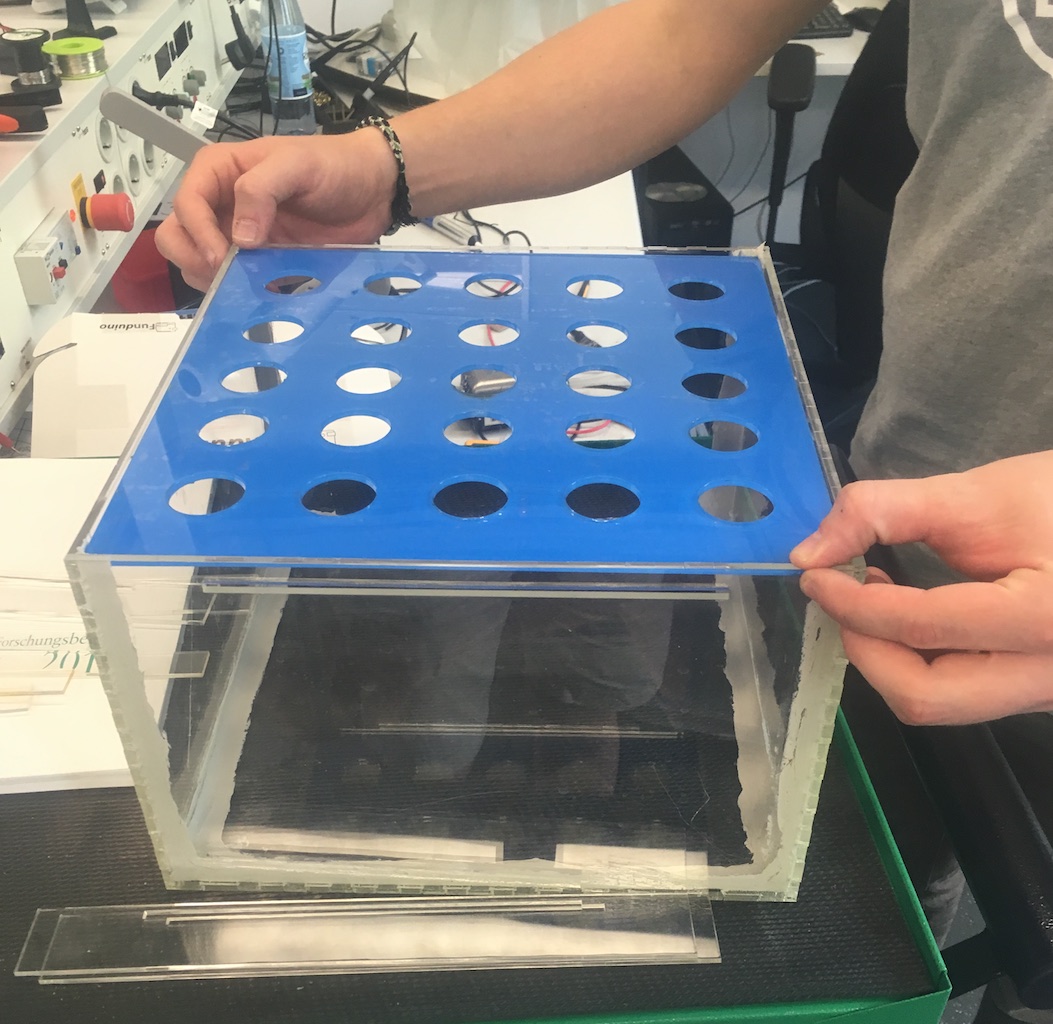

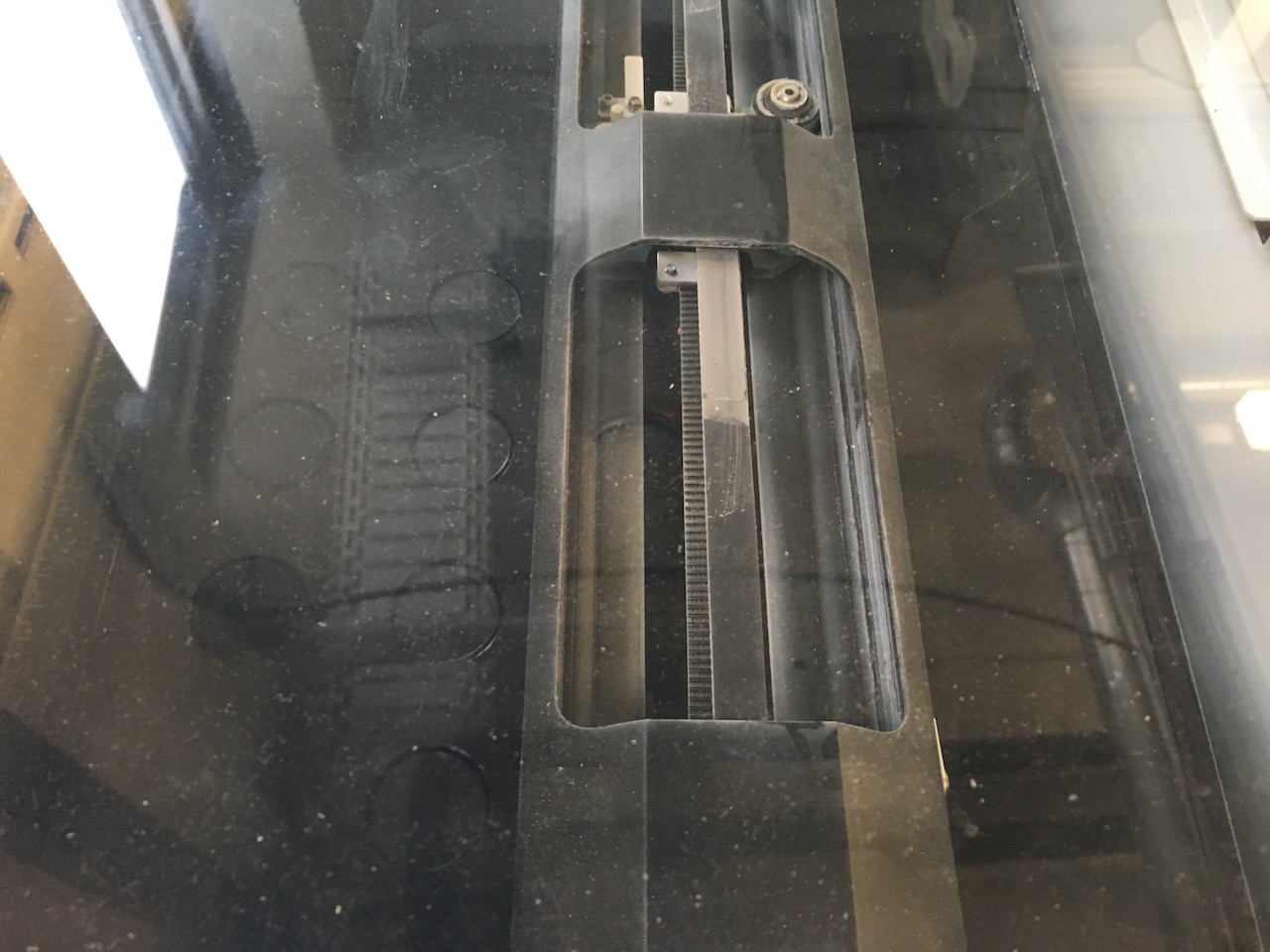

First I created a box with the software Inkscape and modified it and then lasered with the help of the lasercutter. The box is made of 4mm thick acrylic. The holders and modifications are designed with Inkscape. the svg-file can be downloaded in the download-section:

First I created a box with the software Inkscape and modified it and then lasered with the help of the lasercutter. The box is made of 4mm thick acrylic. The holders and modifications are designed with Inkscape. the svg-file can be downloaded in the download-section:

Power: 100%; Speed: 40%; Frequency: 5000

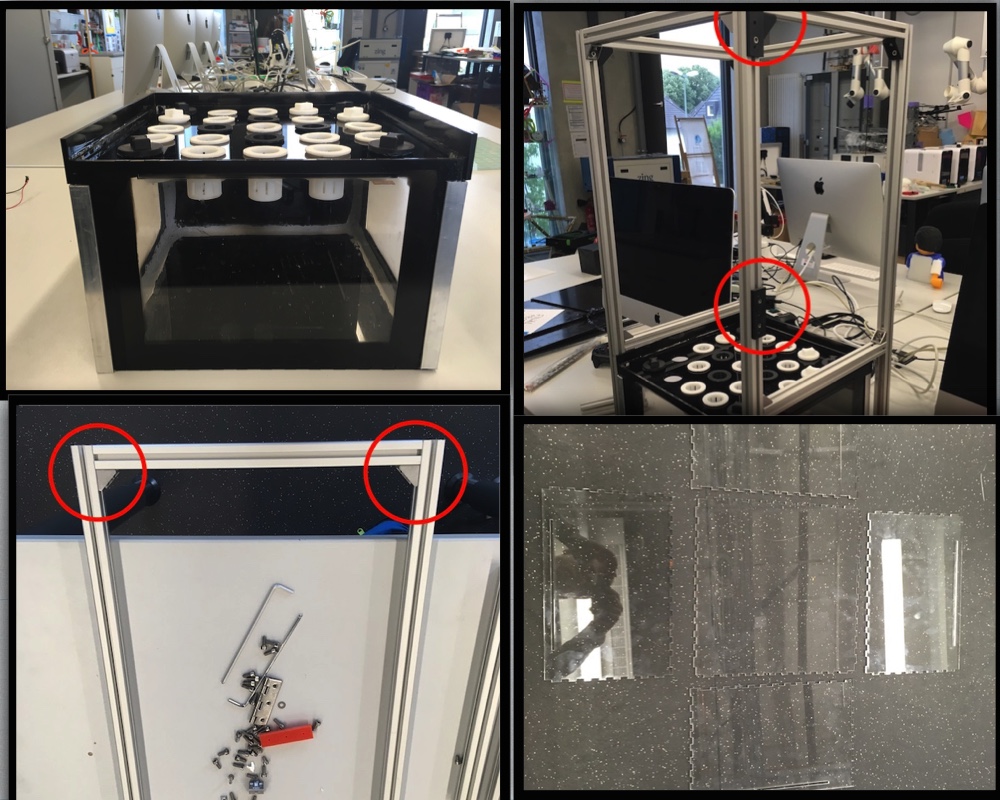

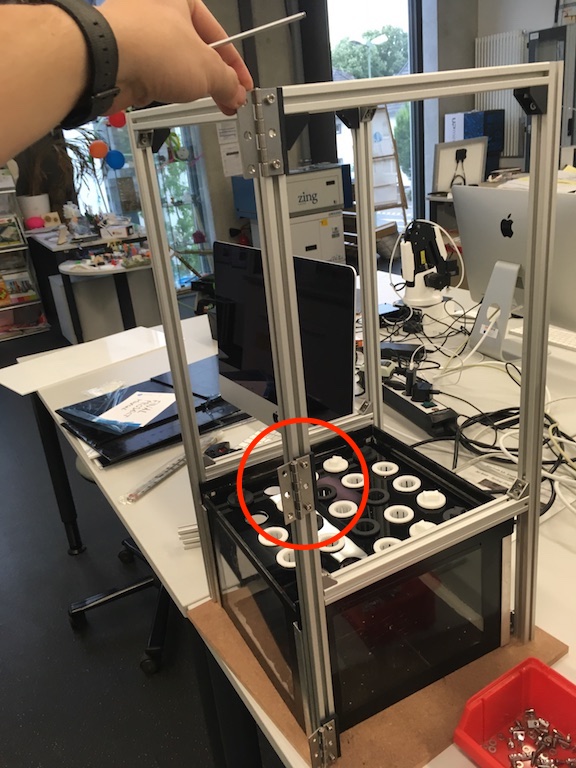

With some black color and aluminum profiles I have the container still a more beautiful finisch procured:

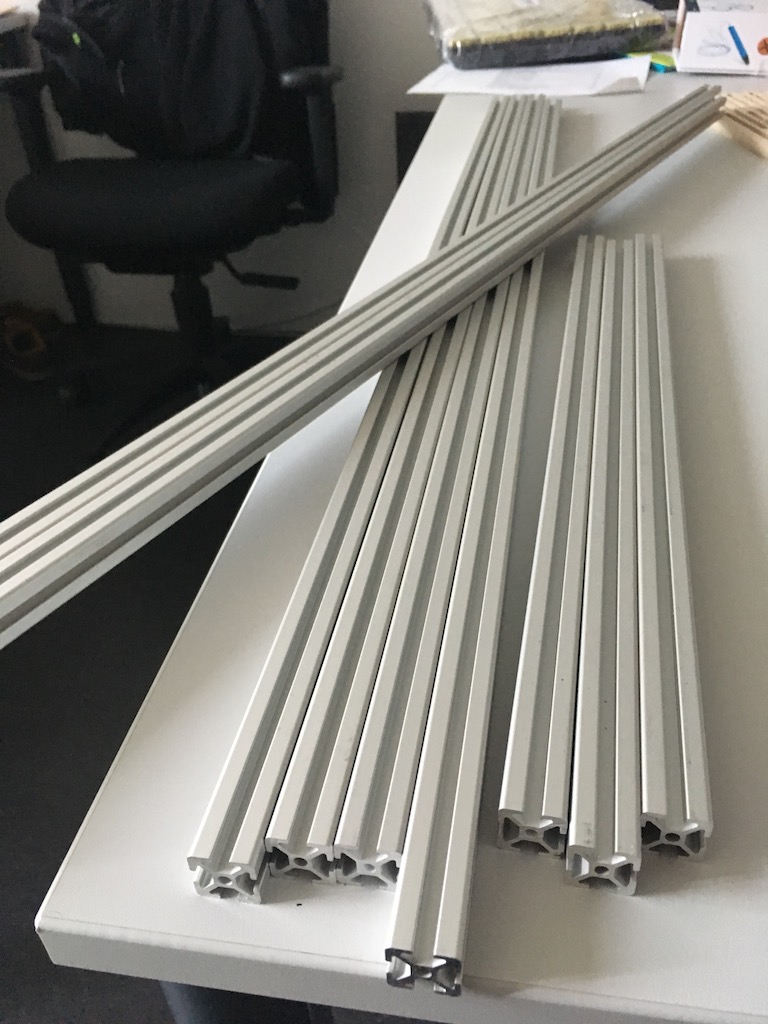

Building the Housing

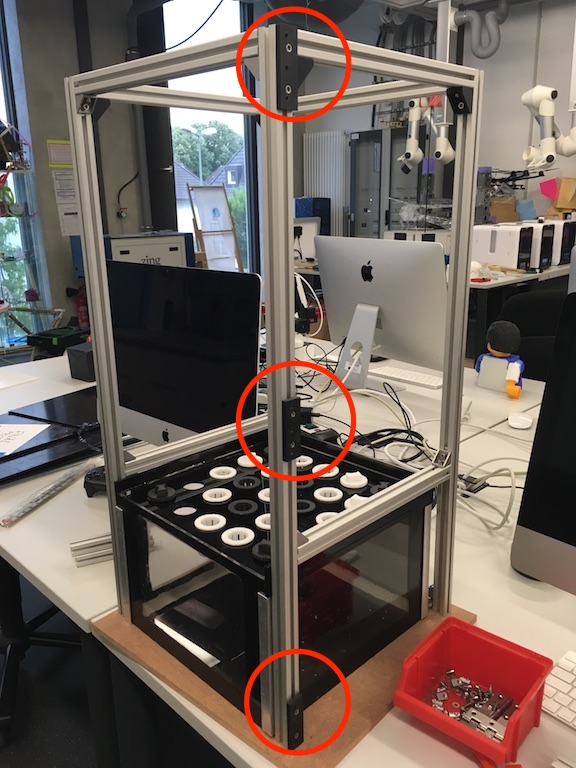

For the enclosure of the box I use aluminium profiles (20 x 20 mm with a groove width of 6mm). The profile is anodized.

The connections are mountet with some aluminiumcorners from DIY-store (fasteners):

The size of the enclosure is 70 cm high and 35 cm deep:

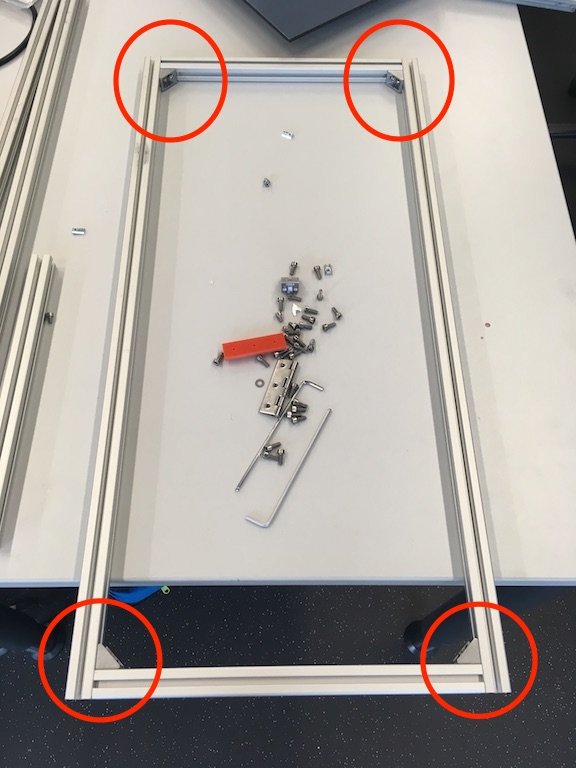

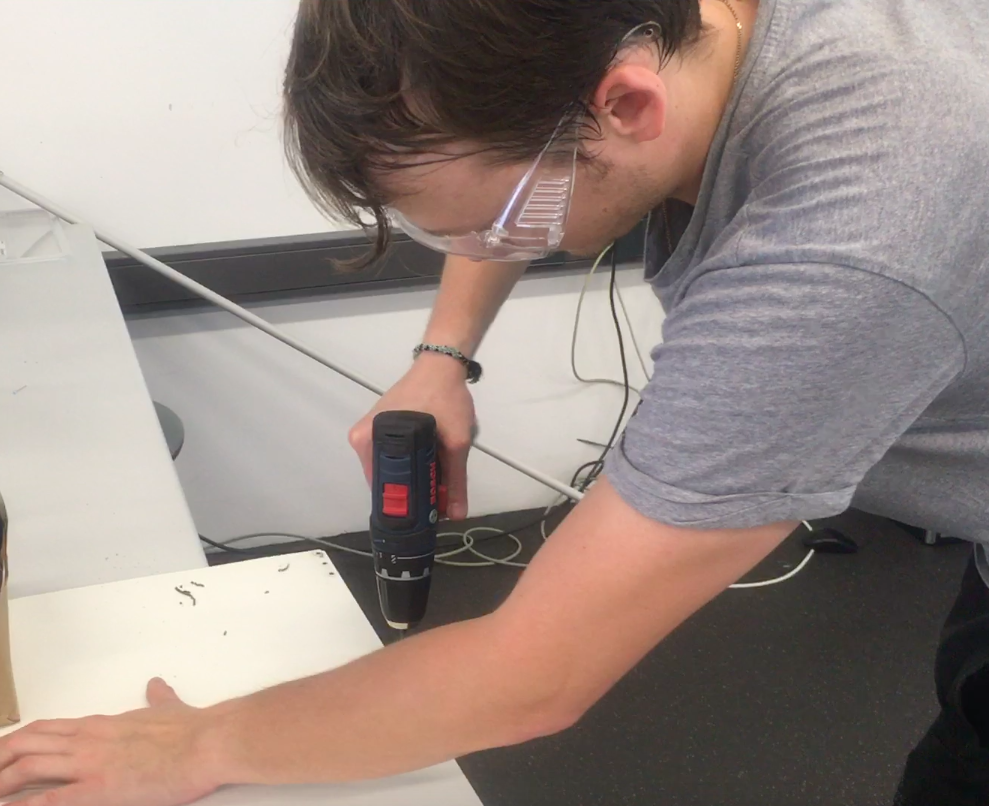

Building the Frame:

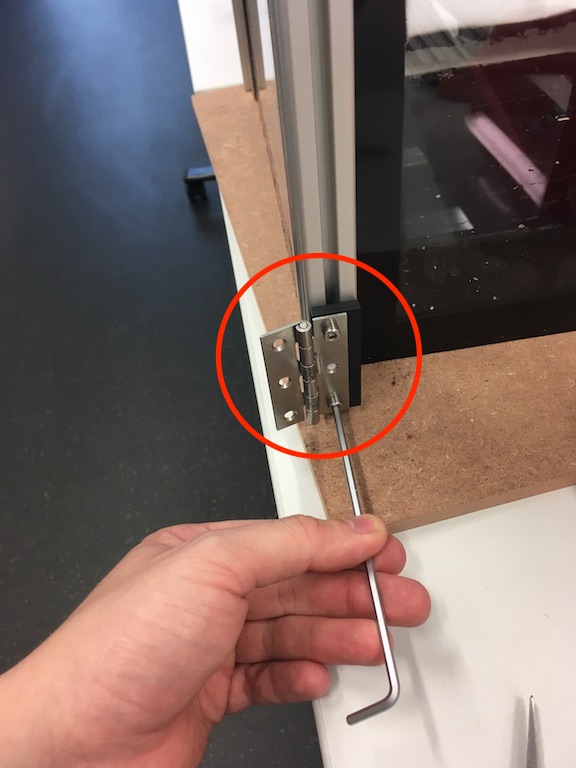

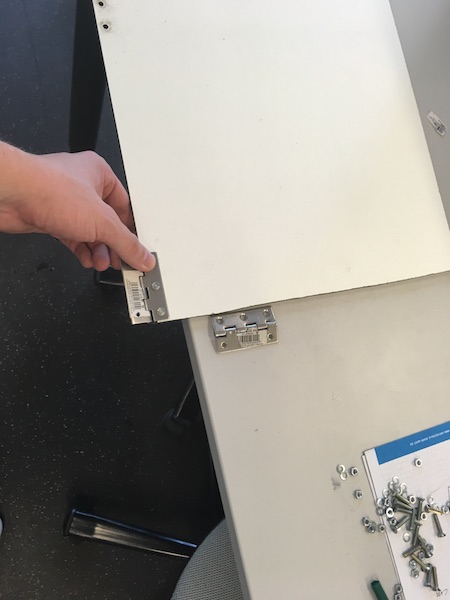

Hinges allow opening and closing of a door for the enclosure

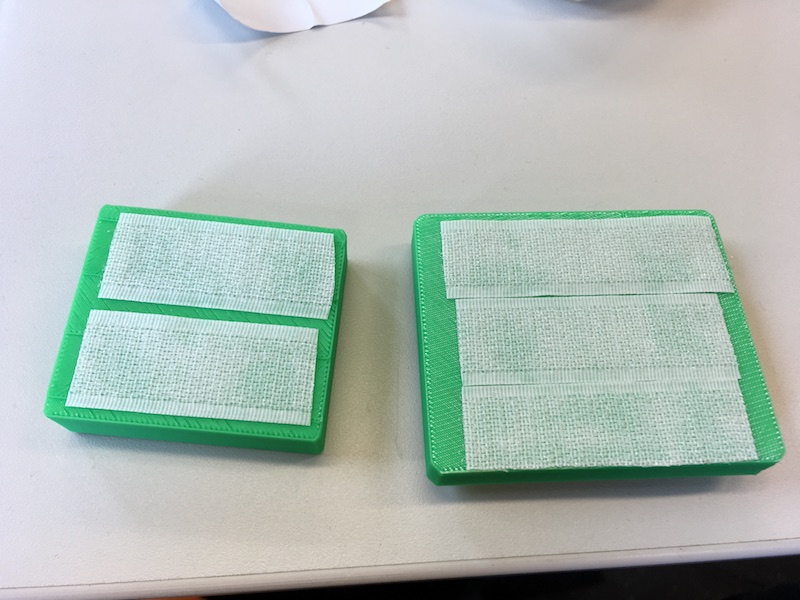

In order to attach the hinges to the aluminum profile, some adapter has also been made with the 3d printer (you can download the adapters in the 3d-printing section):

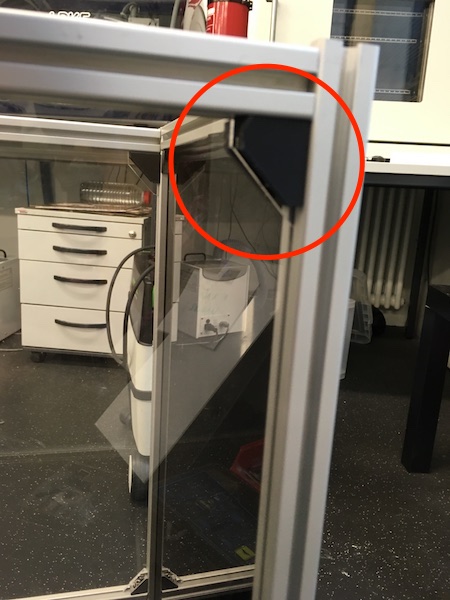

With the lasercutter I have cut the sides in black and transparent acrly:

The corners were worked with the lasercutter so they fit under the mounted angles:

It fits perfectly under the corners of the construction:

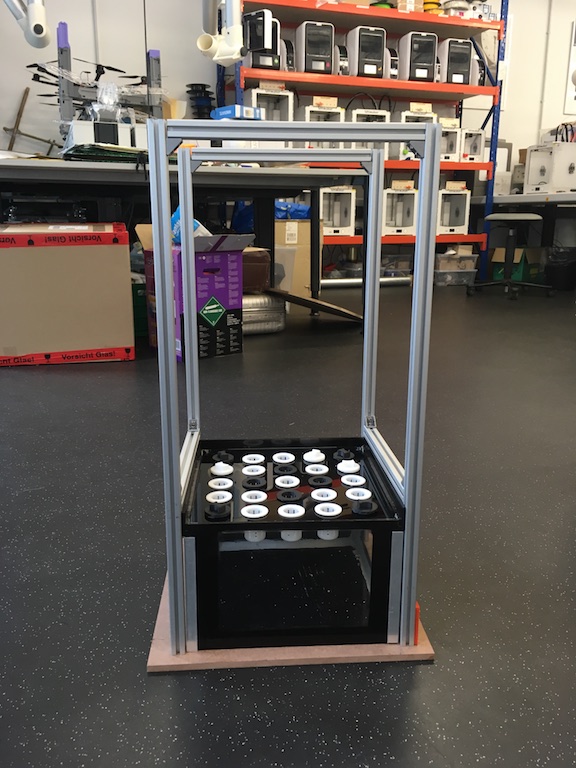

Here you can see the ready assabled Growbox without a door:

With the help of velcro tape I can put my contrullunits on the backside of the Box:

Here you can see the development of the door:

For this construction I used M4 countersunk head screws and the hinges:

That is the ready assambled Growsystem (frontside view).

For the Vinylcut FabLab-logo I used again my design from computer-controlled cutting week. You can also see that I have mounted the 3d printed handle grip at the left side of the door:

Growsystem (Backside view)

Download-Section:

Hydrobox.svg

Hole-plate.svg

Adapter for hinges.stl

The box is made with help of makercase