computer-controlled machining

Tools

1.-end mill 1/4'

Meterials

2.-plywood 15mm

SOFTWARE

3.-shopbot 3

4.-Autodesk inventor

5.-vcarve Pro

MACHINES

6.-shopbot

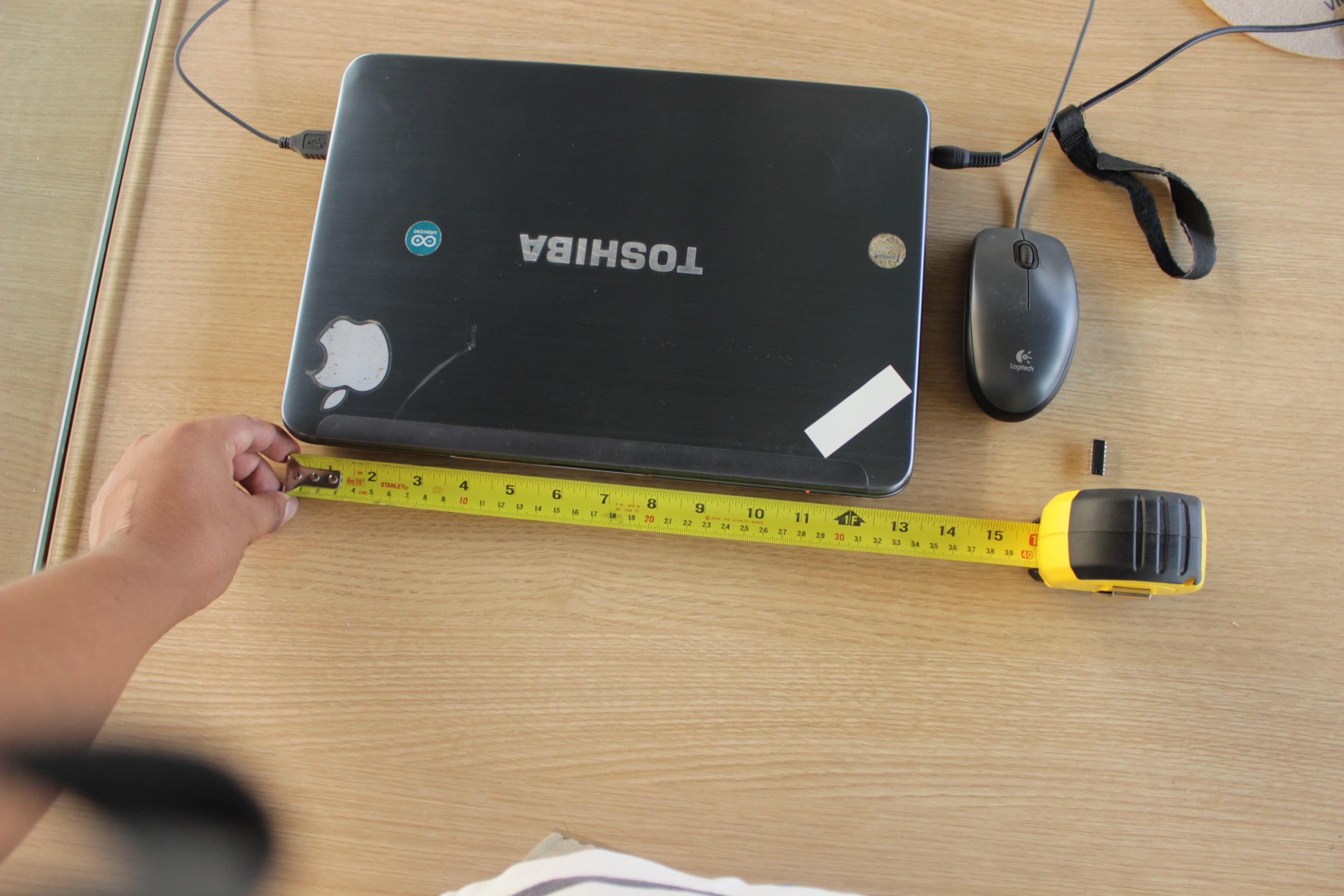

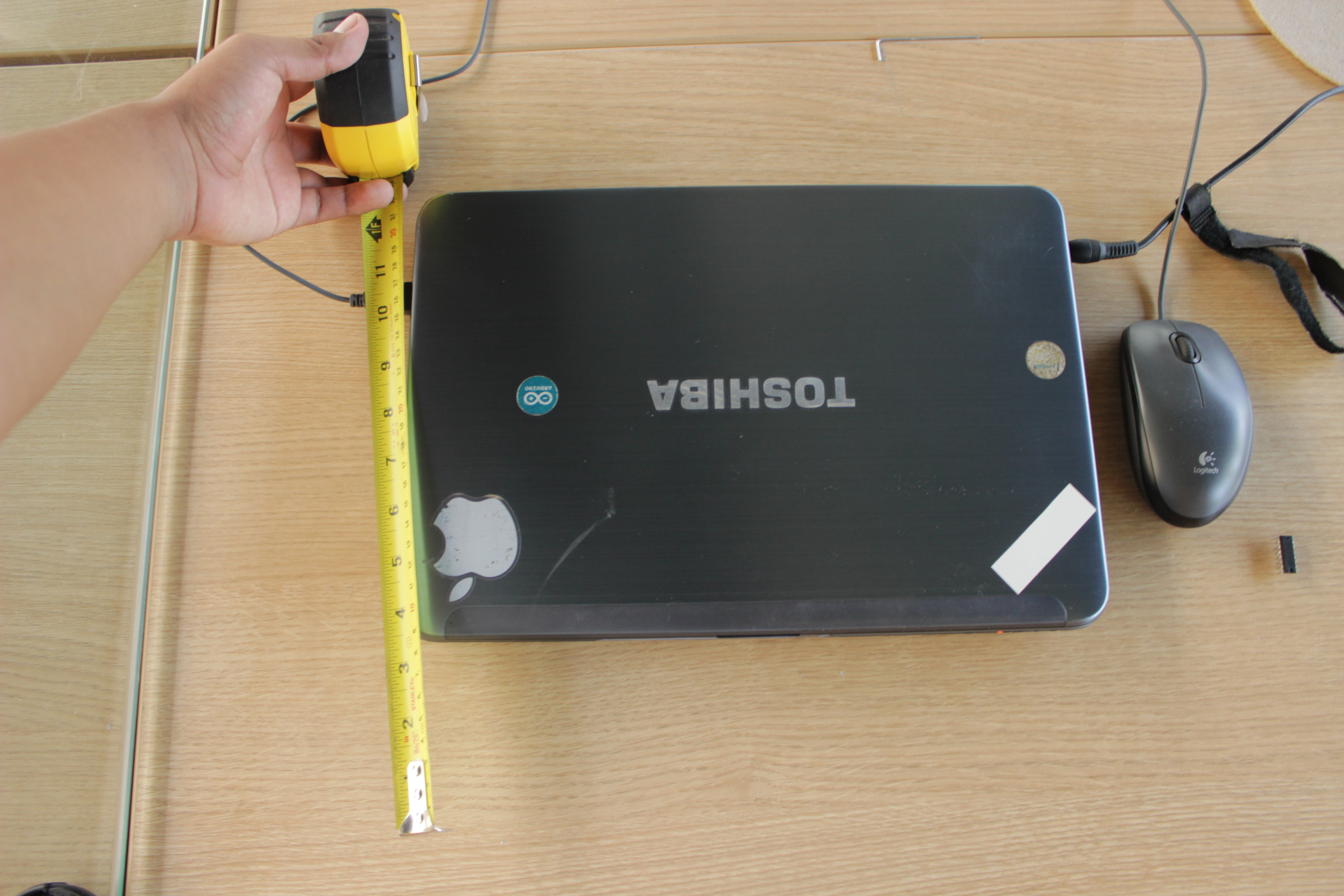

I want to make a suport for my laptop so, First I take the measurements of a laptop

width and length of my laptop

stamation of inclination of the laptop

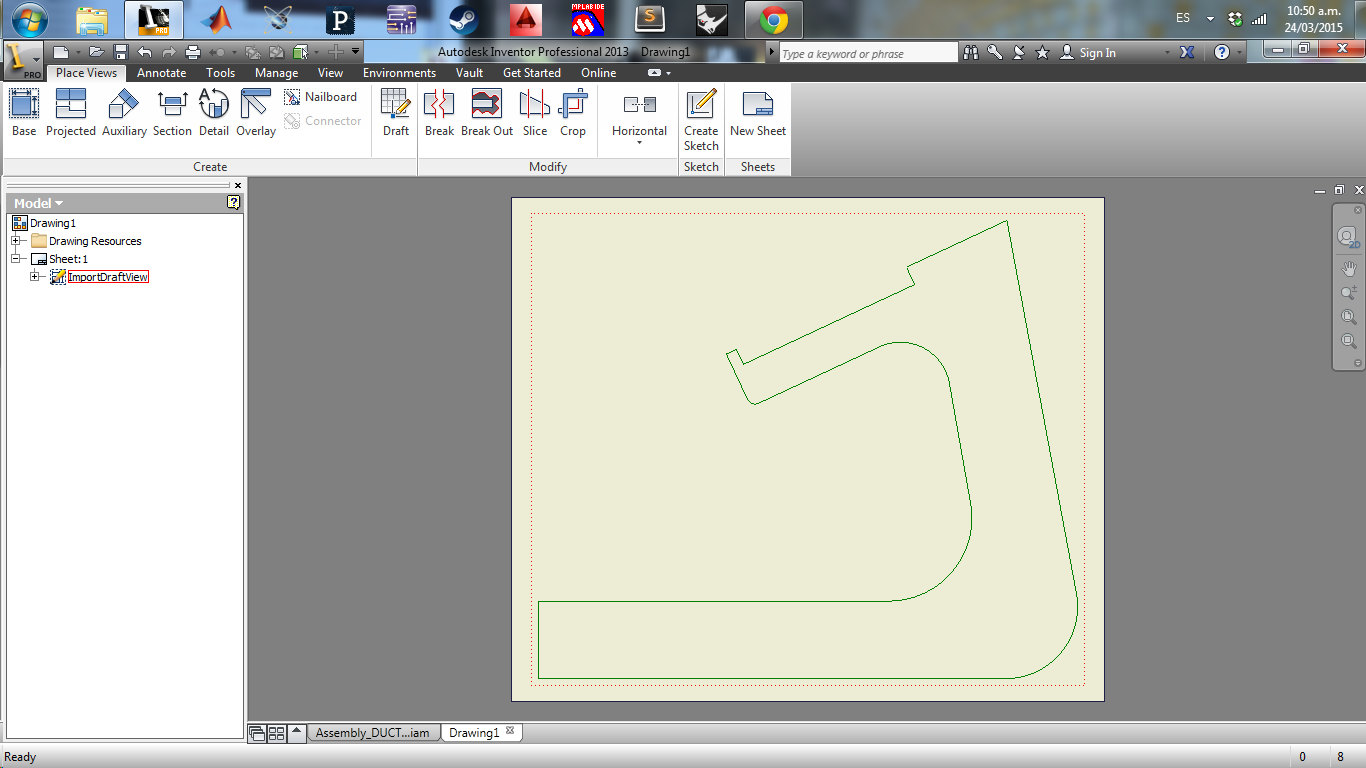

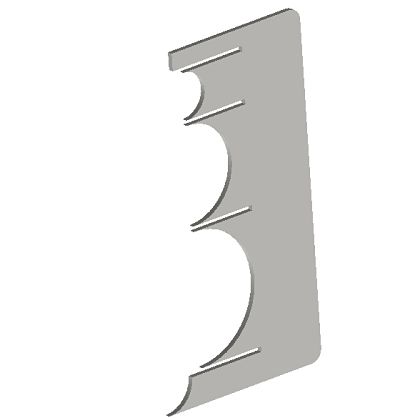

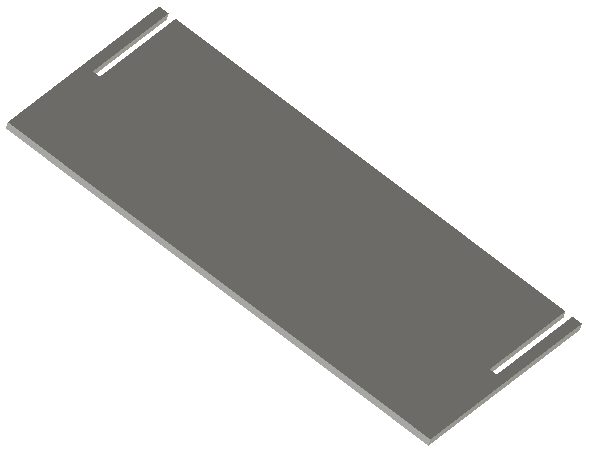

I build the pieces based on the measures for this I use INVENTOR CAD software

the structure is simple, 3 parts and two equal parts

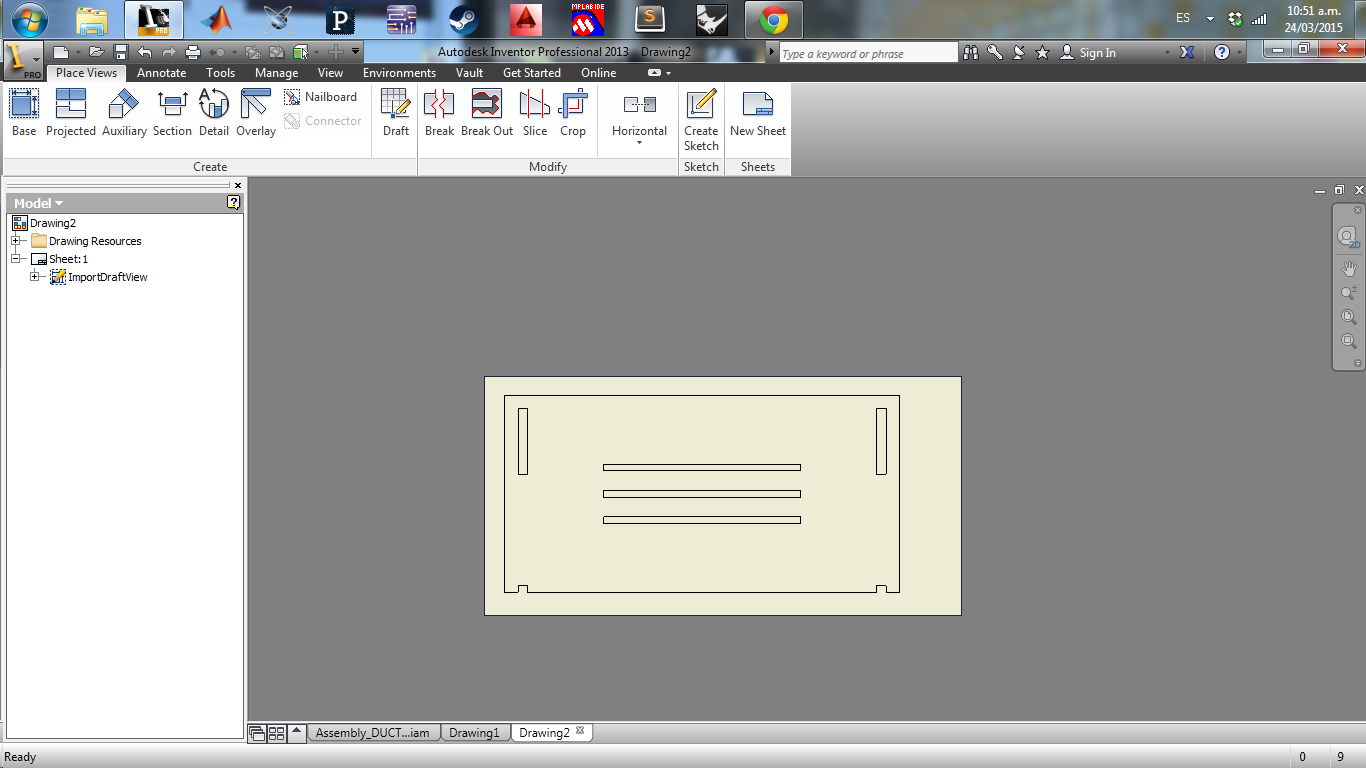

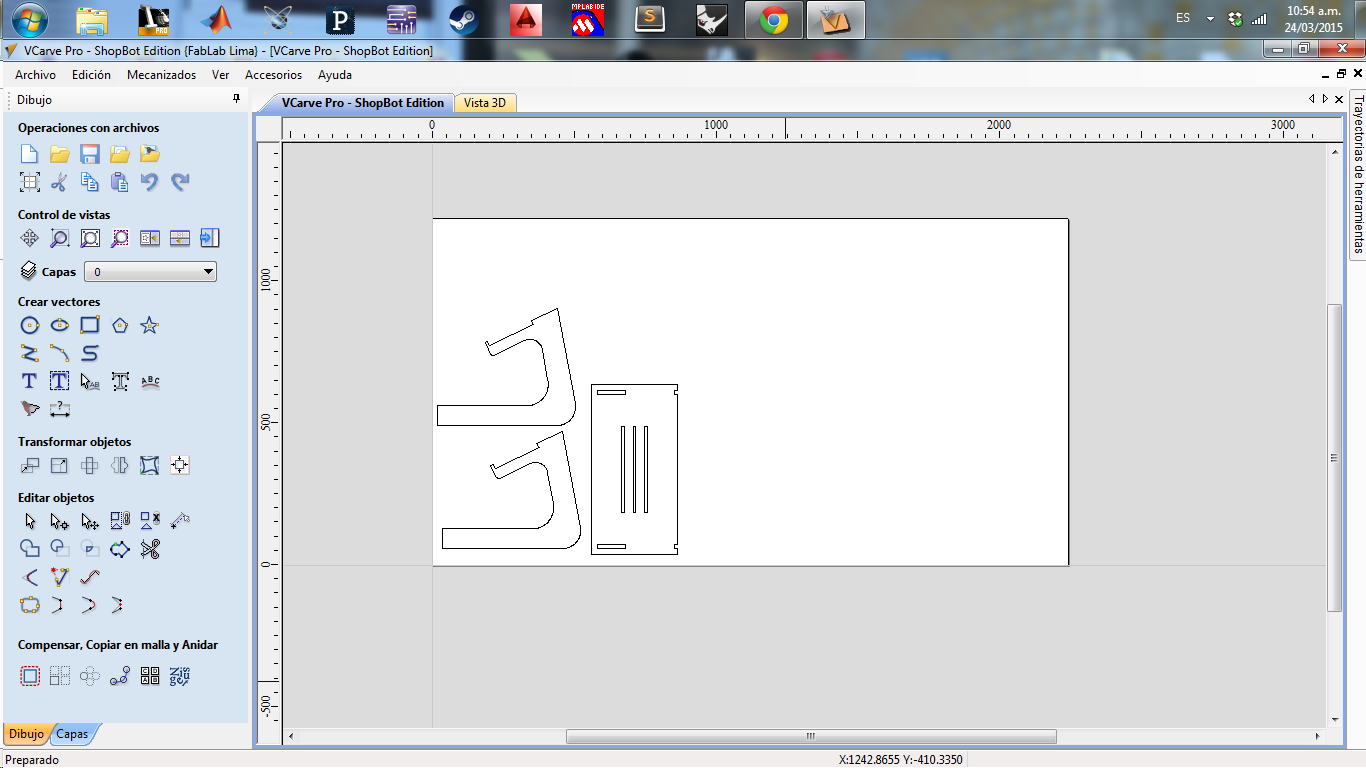

I import DXF files on VCARVE PRO software and I verify that all vectors are closed

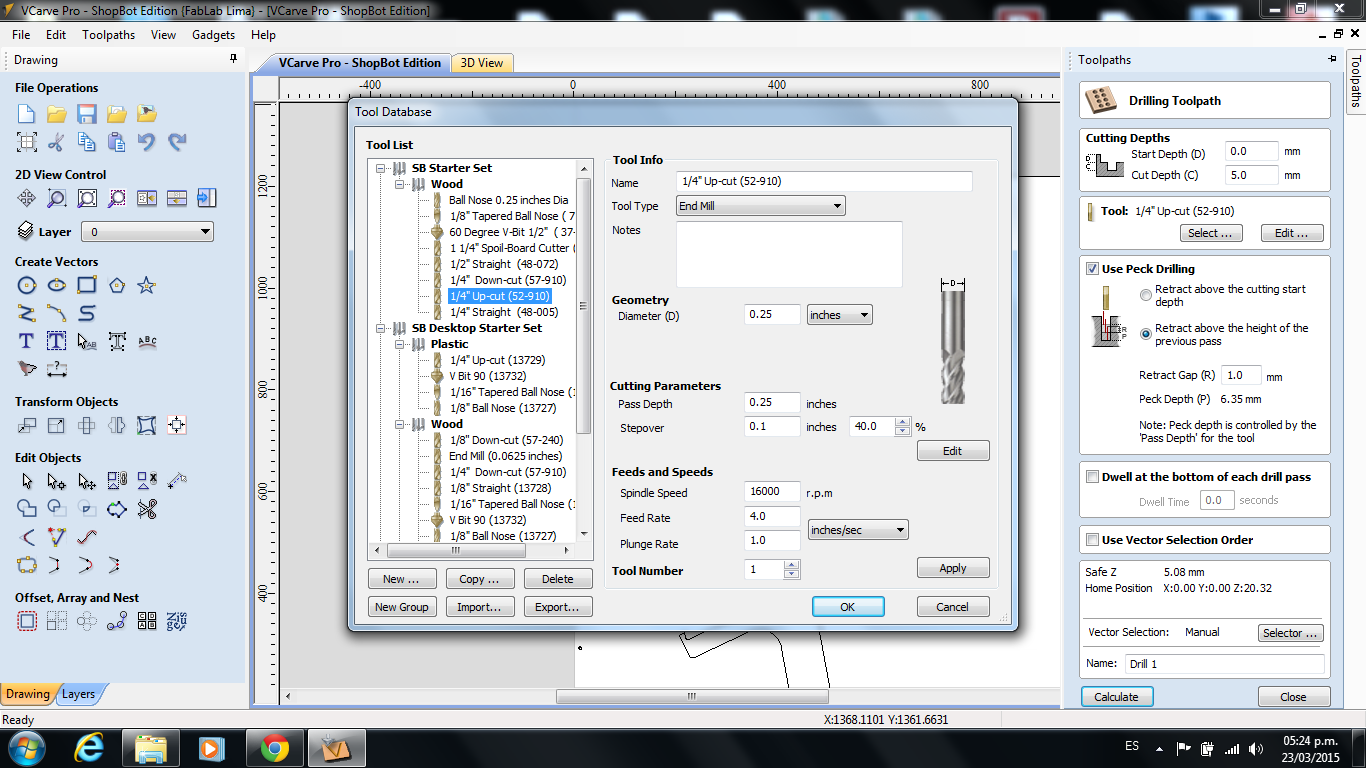

I choose the correct end mill and verify all the correct configurations, I take note of RPM "16000" then I calculate chipload parameter, first I configurate drill then perfil

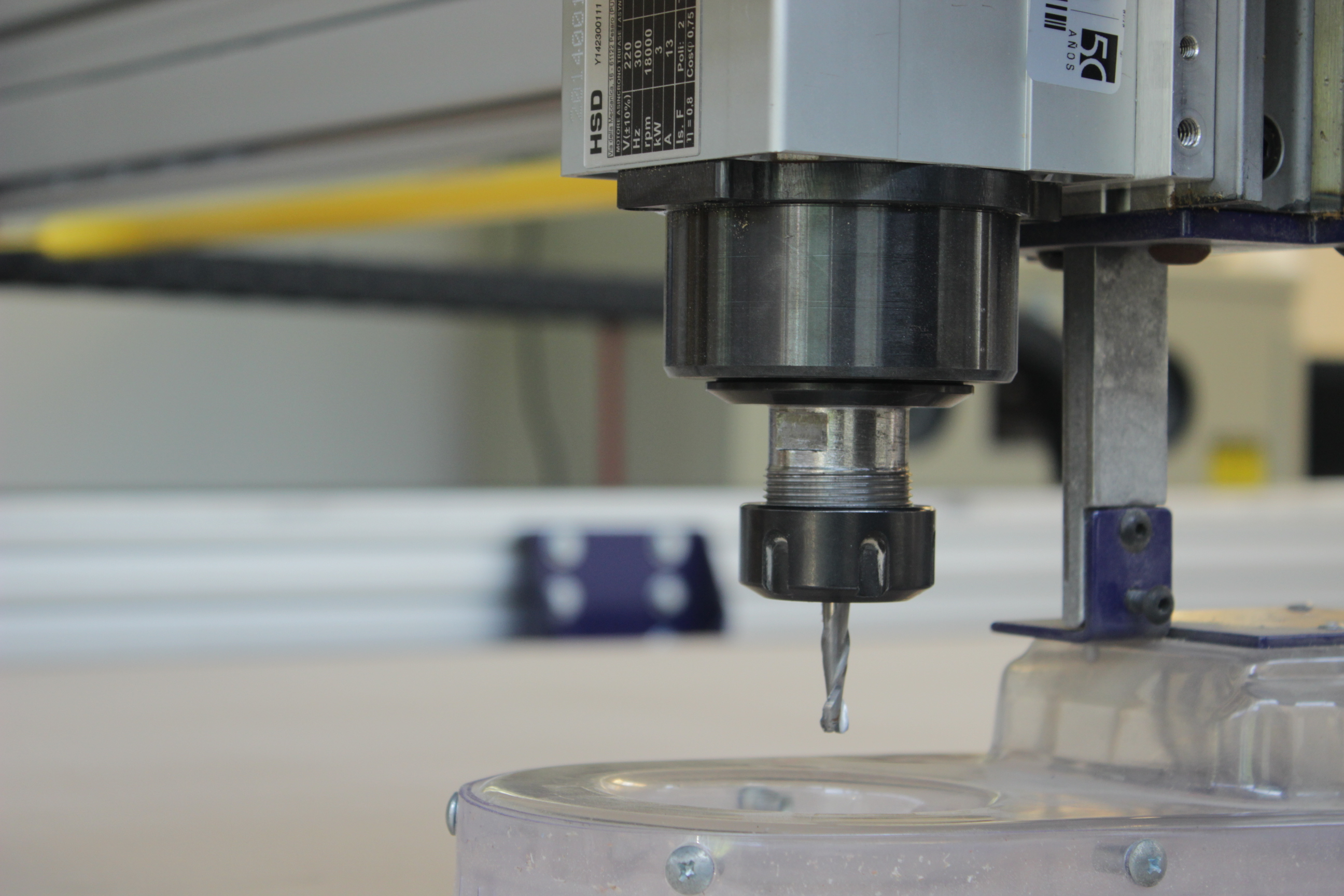

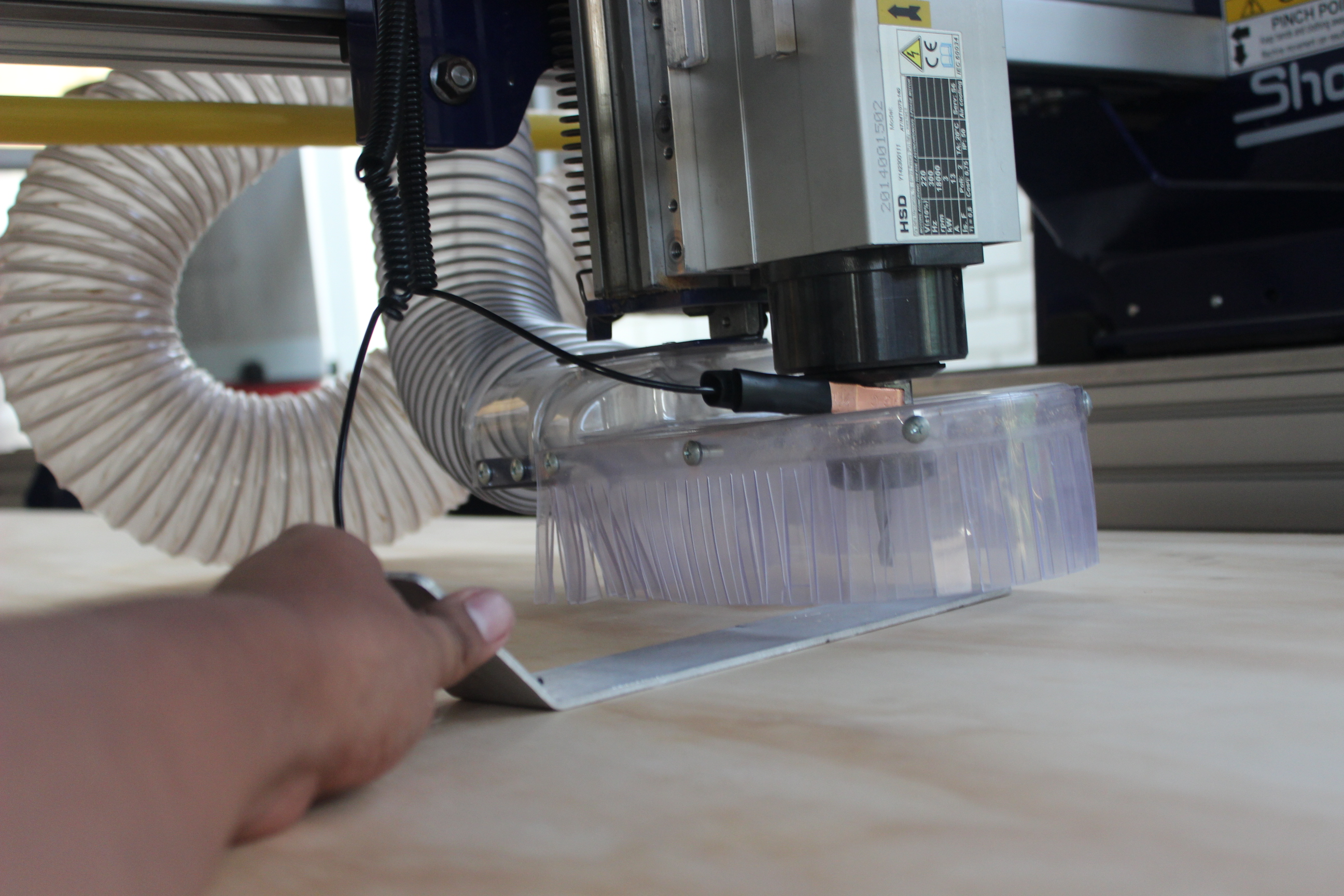

I put plywood on the shopbot, then I prepare the machine

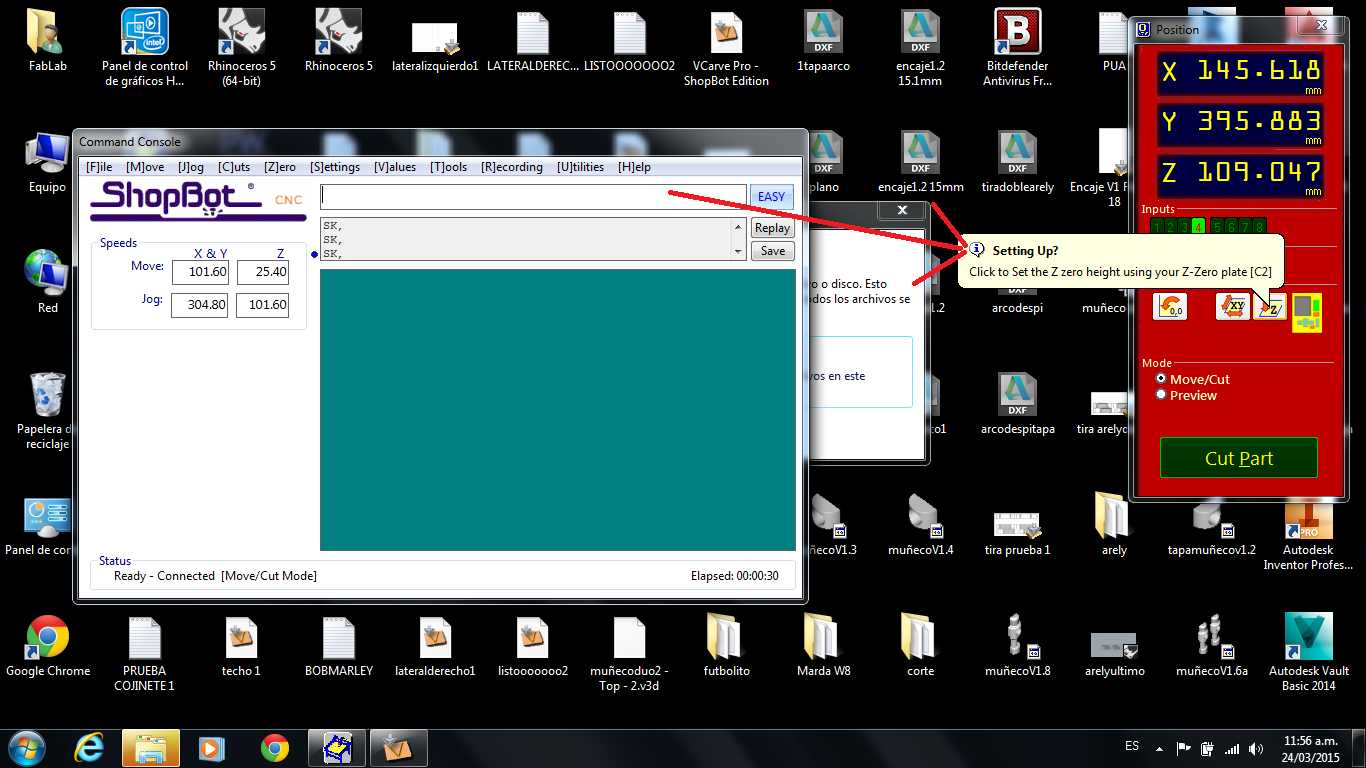

first I calibrate the Z axis

after that I calibrate the X/Y axis

then I can send my curt configuration

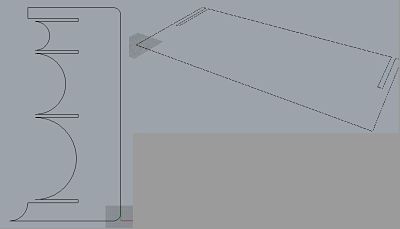

After learning the whole process of manufacture with shopbot, I designed and built a bigger piece of furniture that will serve to save materials and objects within the FabLab

I designed 2 pieces, They will double to build the full furniture.

These pieces were also designed in AutodeskInventor