Machine Design

I called for a meeting to decide what to be done in the machine.

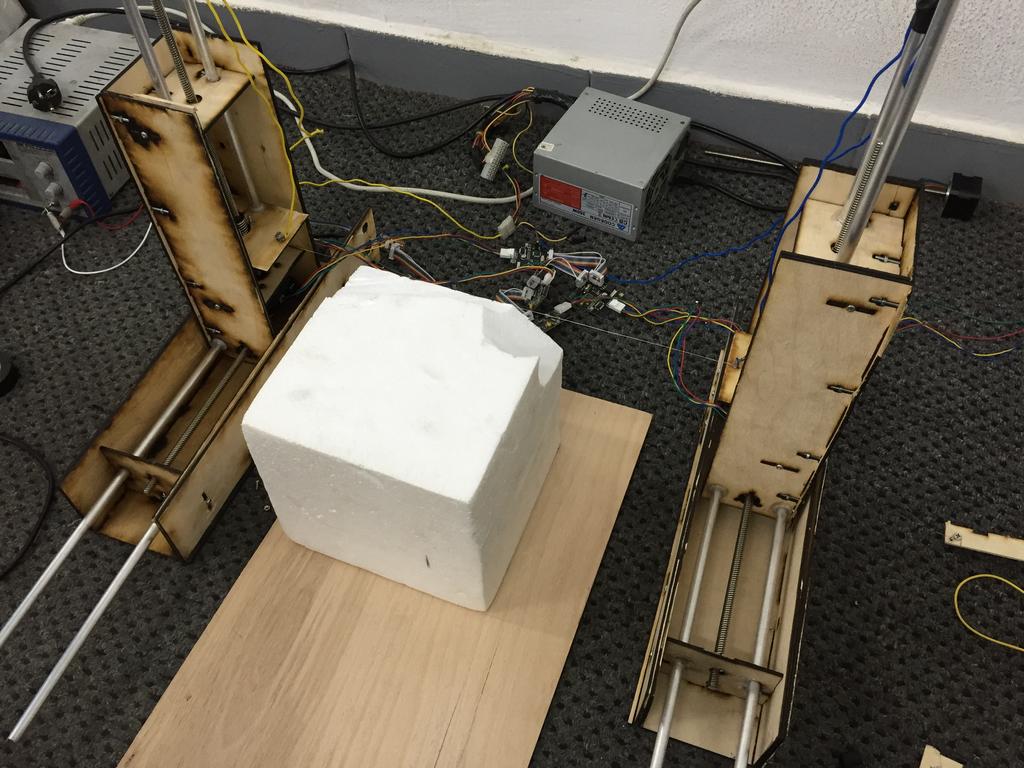

We decided to make a foam cutter using gestalt system. And we split into teams.

I handled the CAD and helped with the assembly and operations.

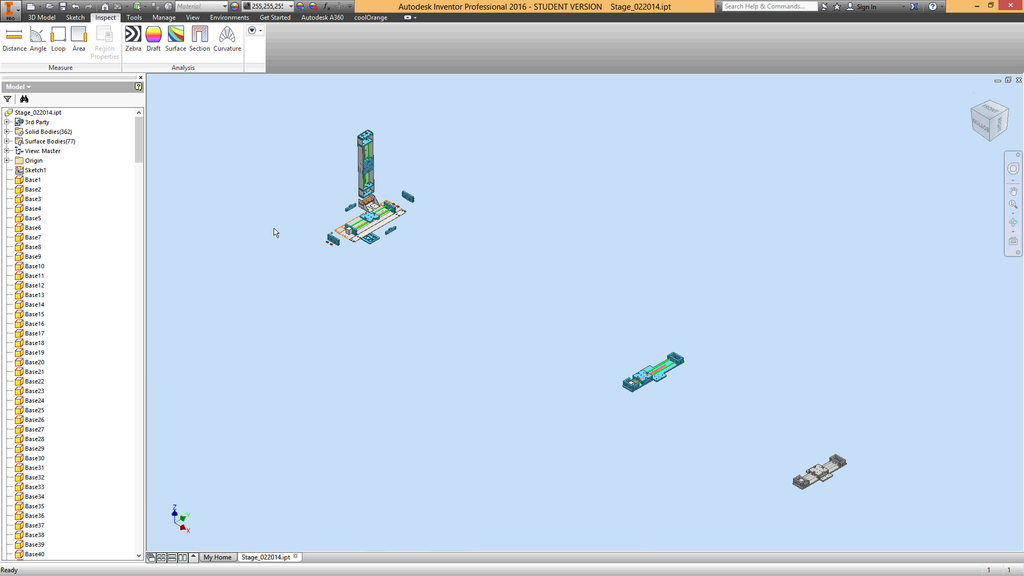

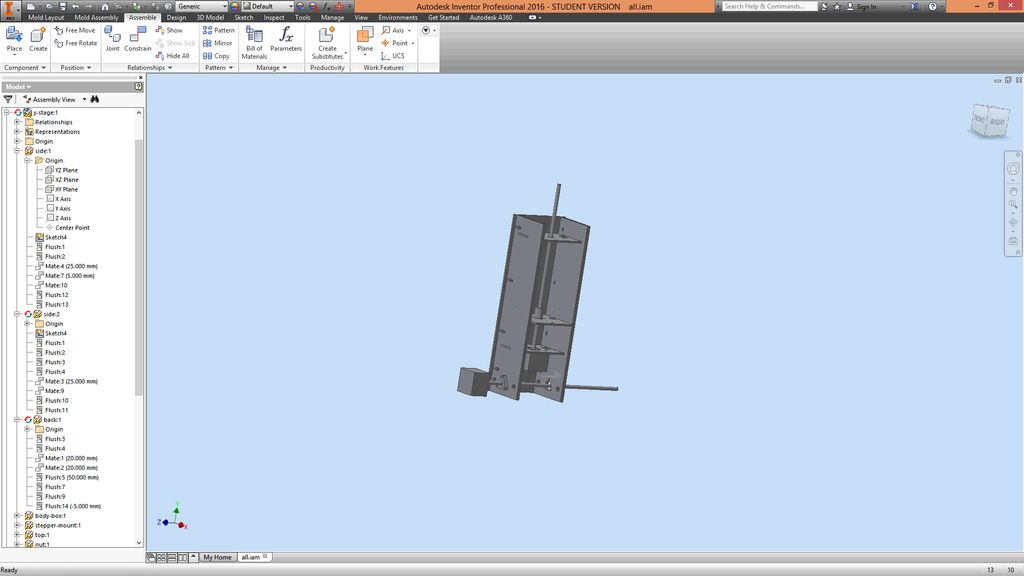

So I designed the CAD for the X and Y stages

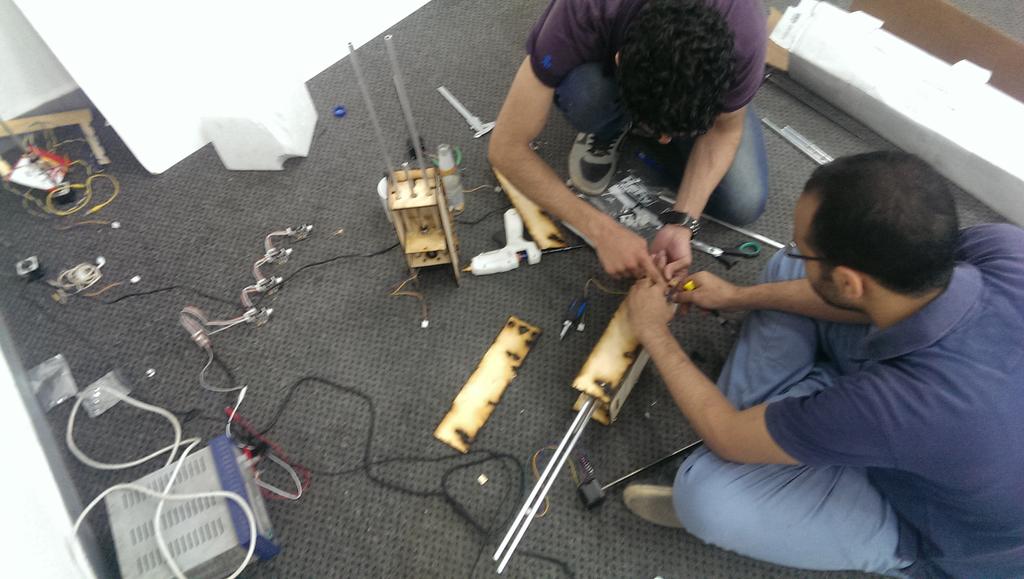

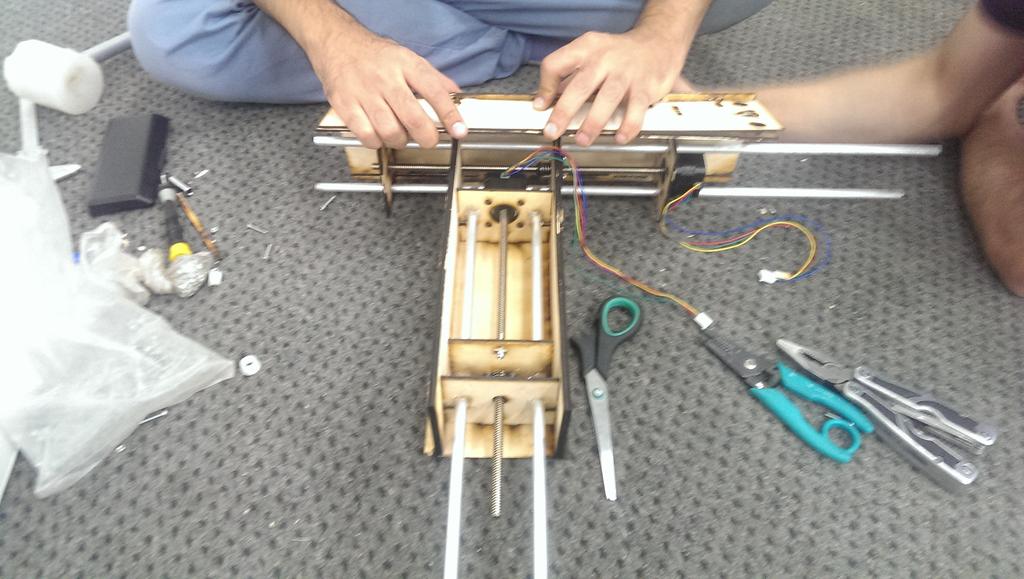

Then I tested the parts for fitting and I helped the team with the assembly the machine.

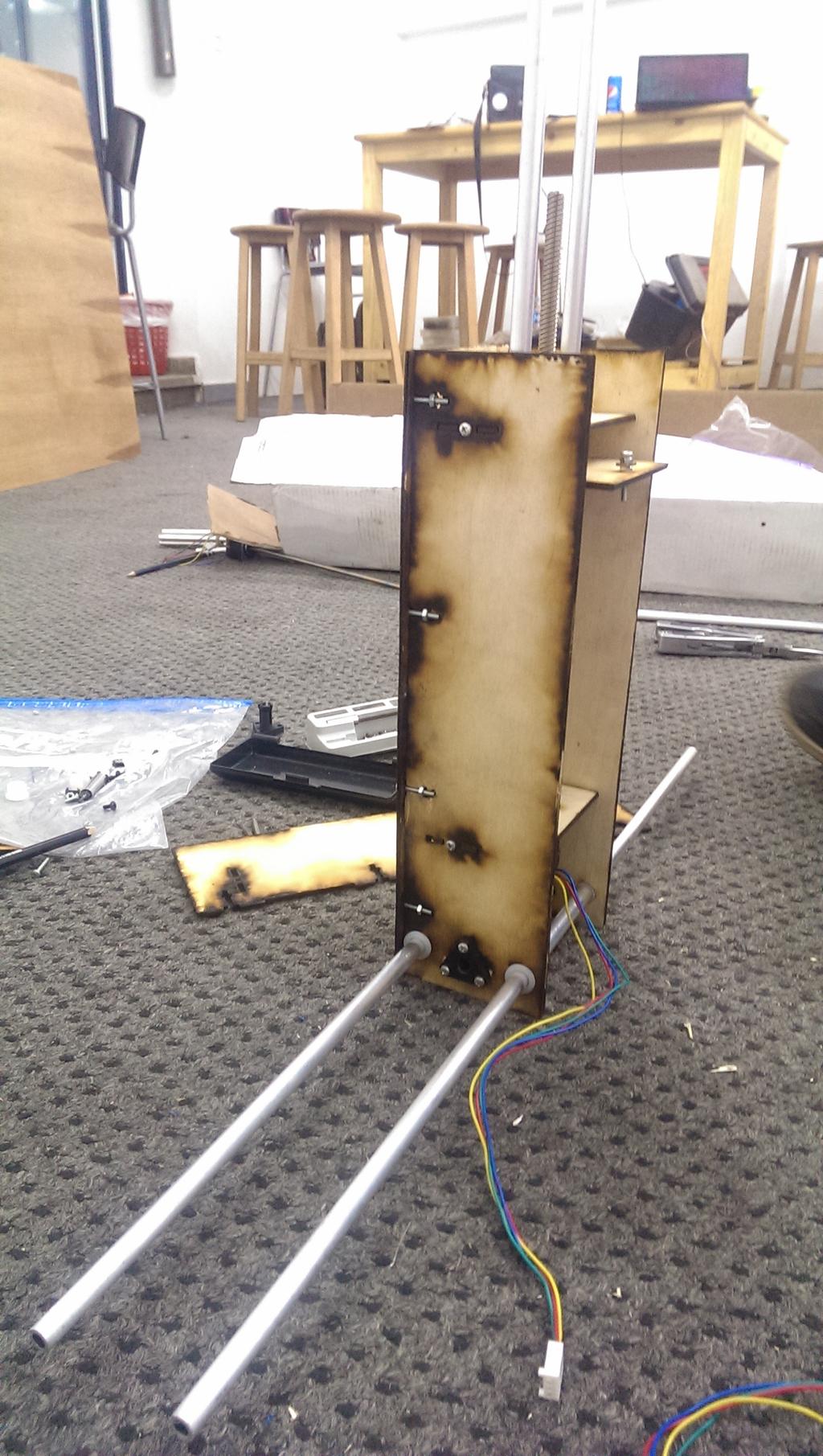

We had an issue with the laser cutter in the lab that the laser stops every approximately 1 minute which mad the students responsible for the cutting pause it for half a minute then resume which made some of the parts not completely cut and over-burnt.

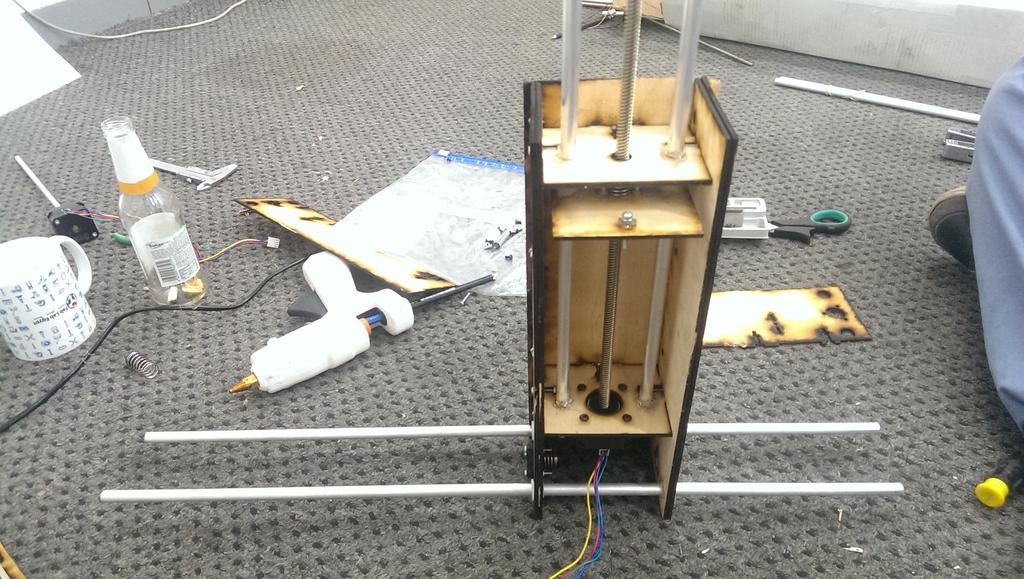

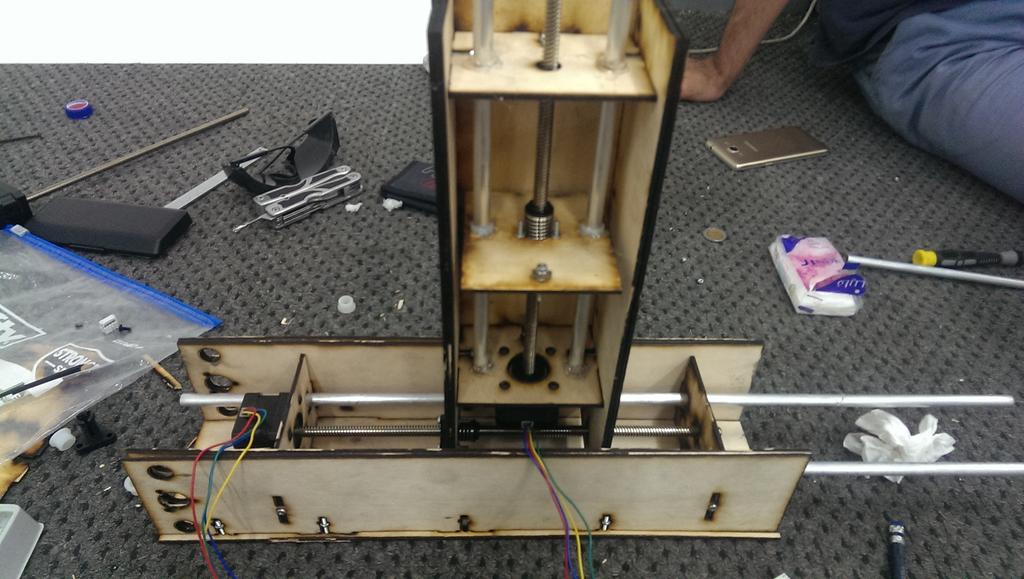

We assembled the Y-axis and tested it

Then we assembled the X-axis and tested their combined movement

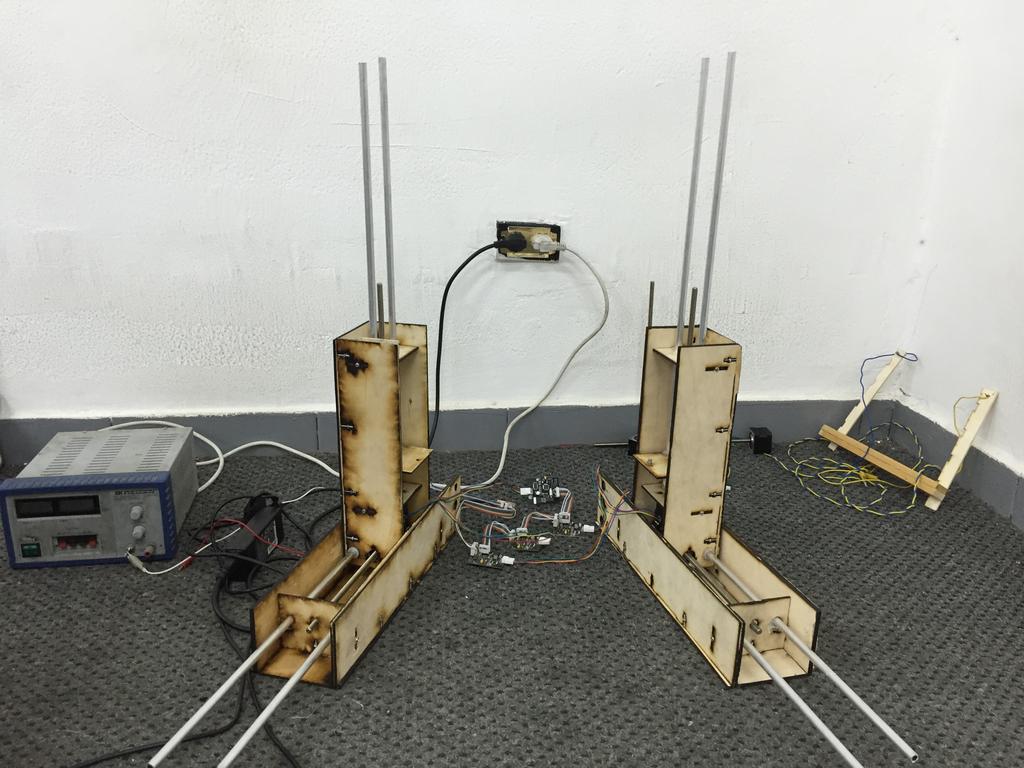

We then assembled the other x and y stages and tested their synchronized movement.

Then we started cutting after fixing the foam block