Computer-controlled Cutting

For this assignment, I've designed a press-fit construction kit inspired from something I used to play with when I was a child.

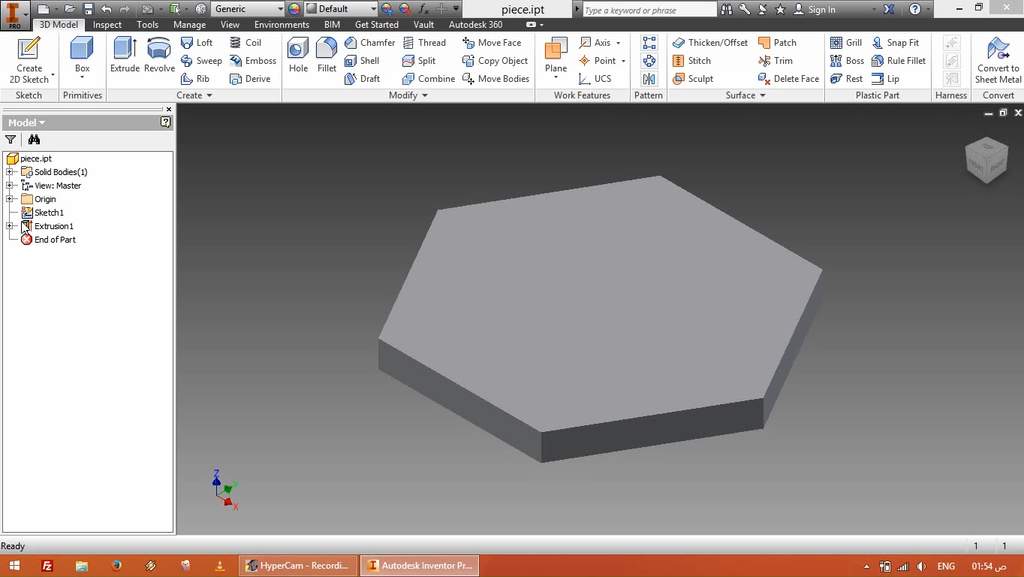

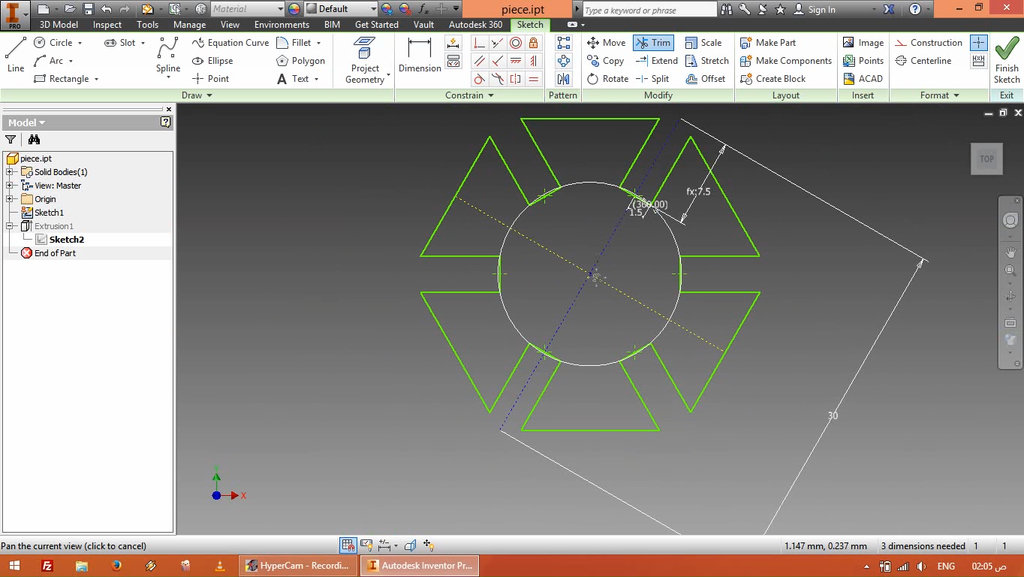

Designing in Autodesk Inventor

I started by 6-sided polygon and extruded it by 3mm (The thickens of the plywood we use)

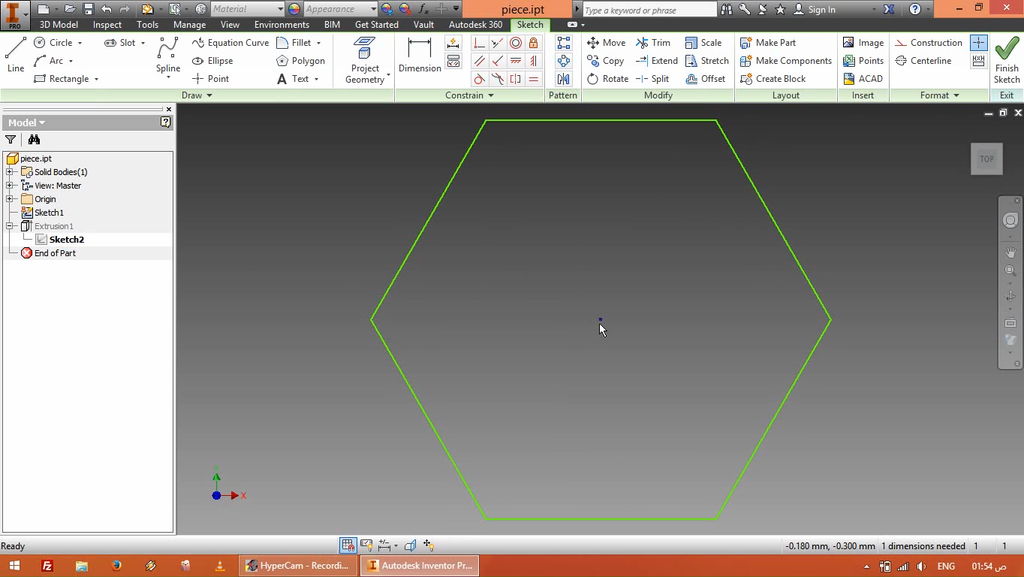

Added a construction line

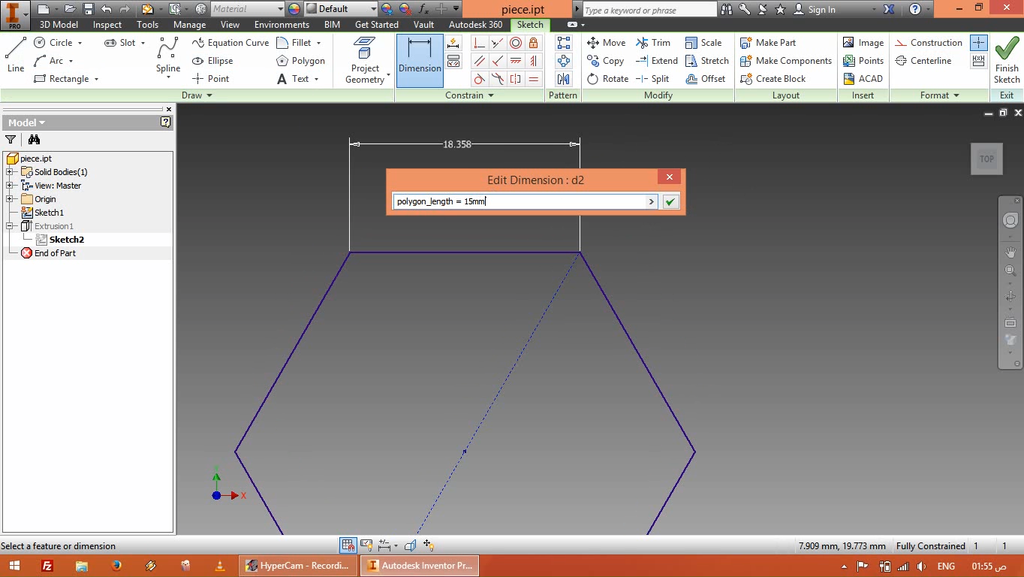

Set a polygon length dimension

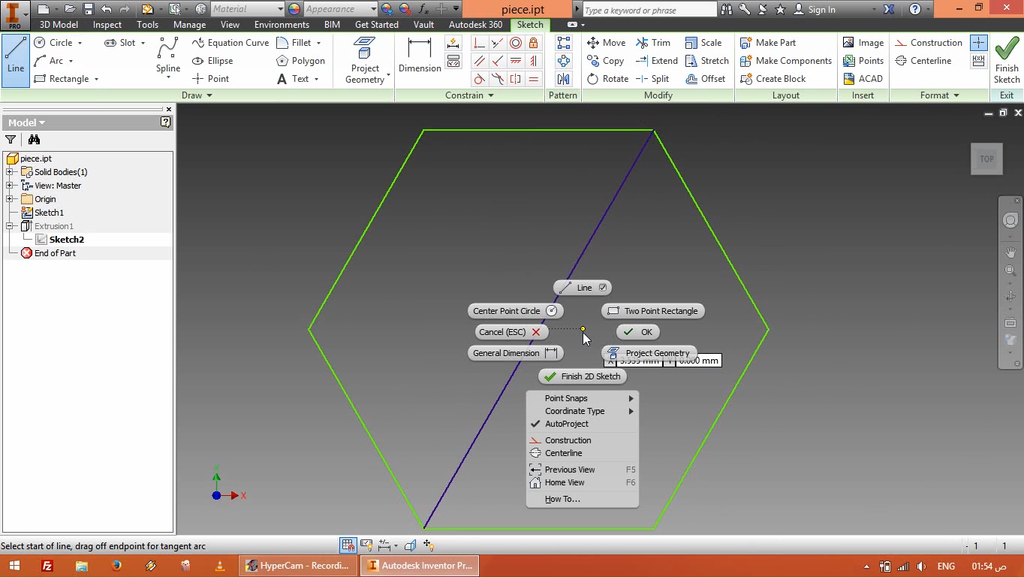

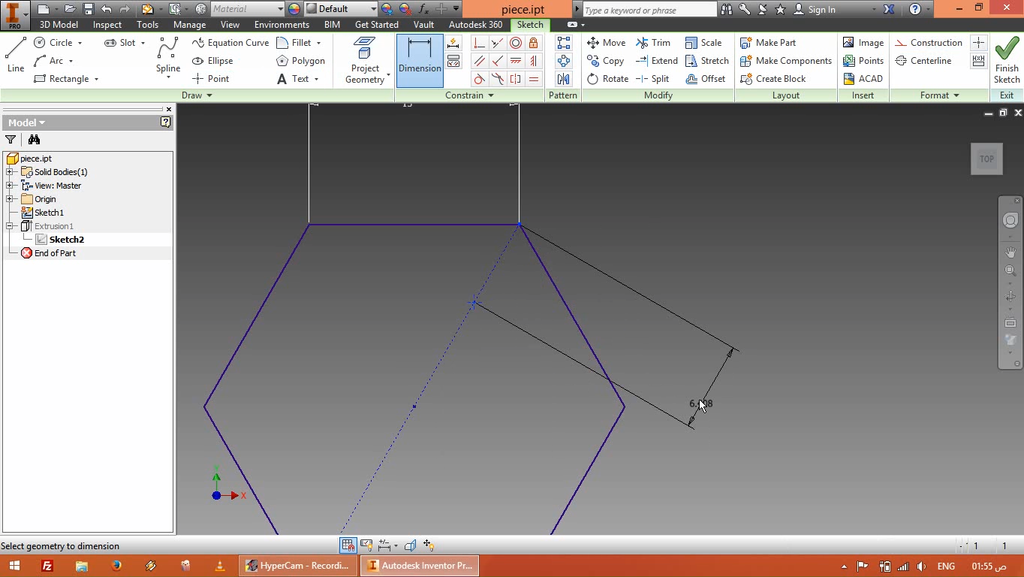

Create a point on the construction line and set a dimention for it.

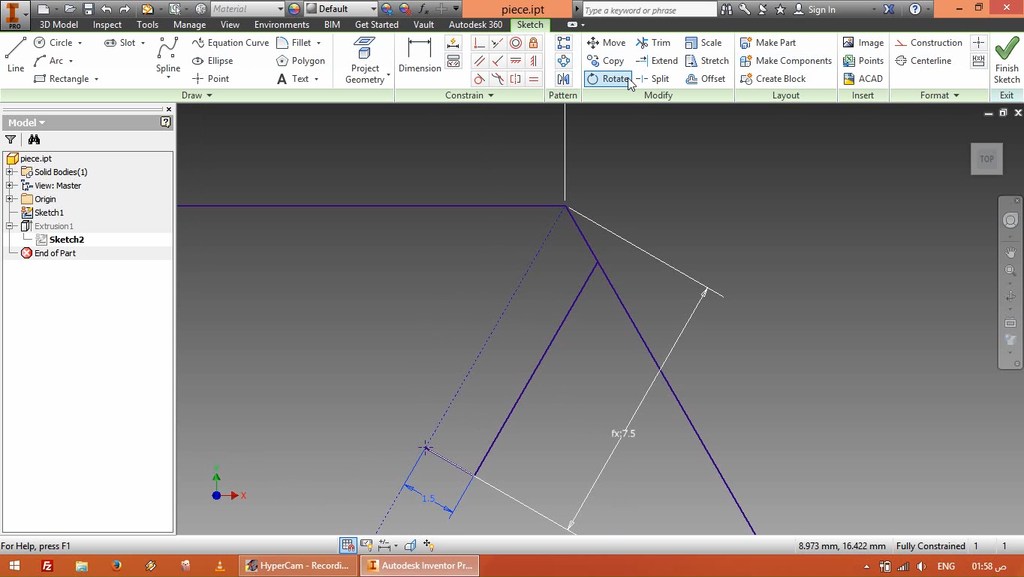

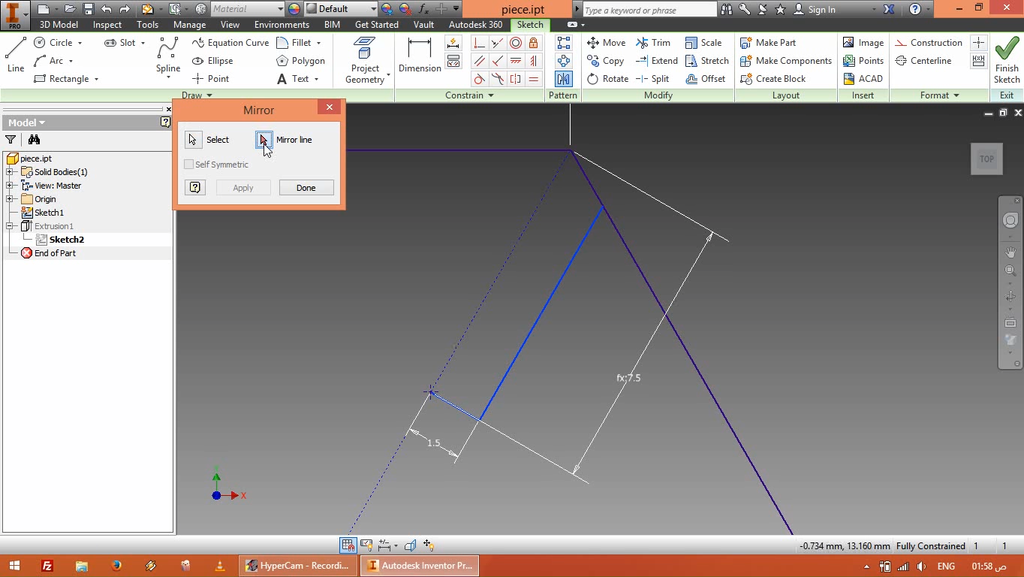

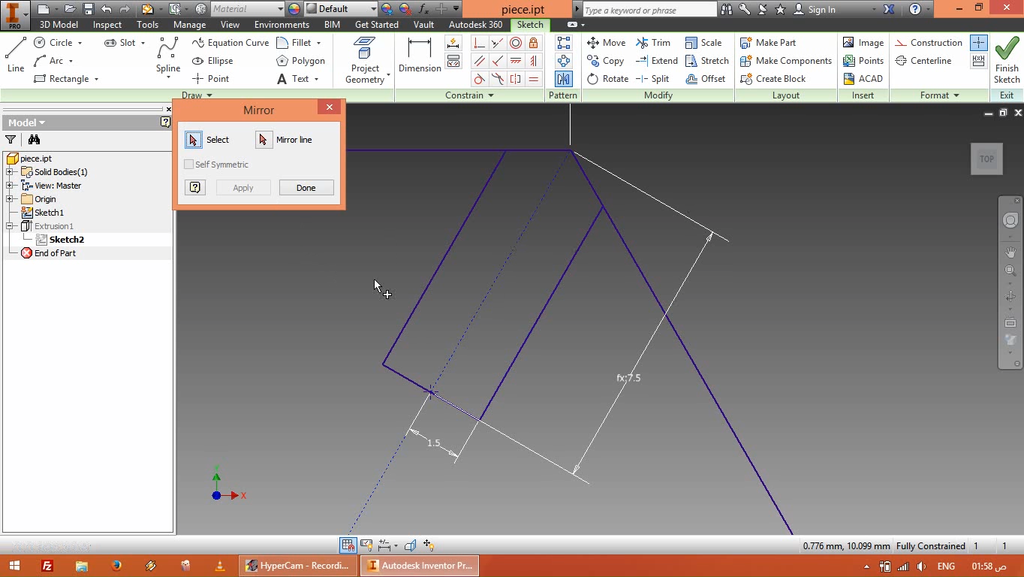

Create lines for half the slot and mirror it

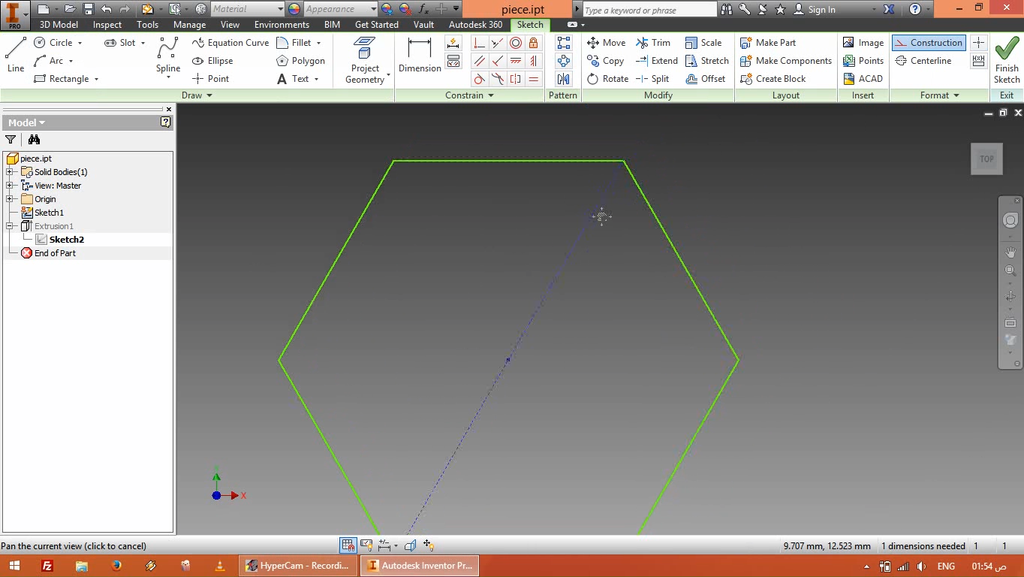

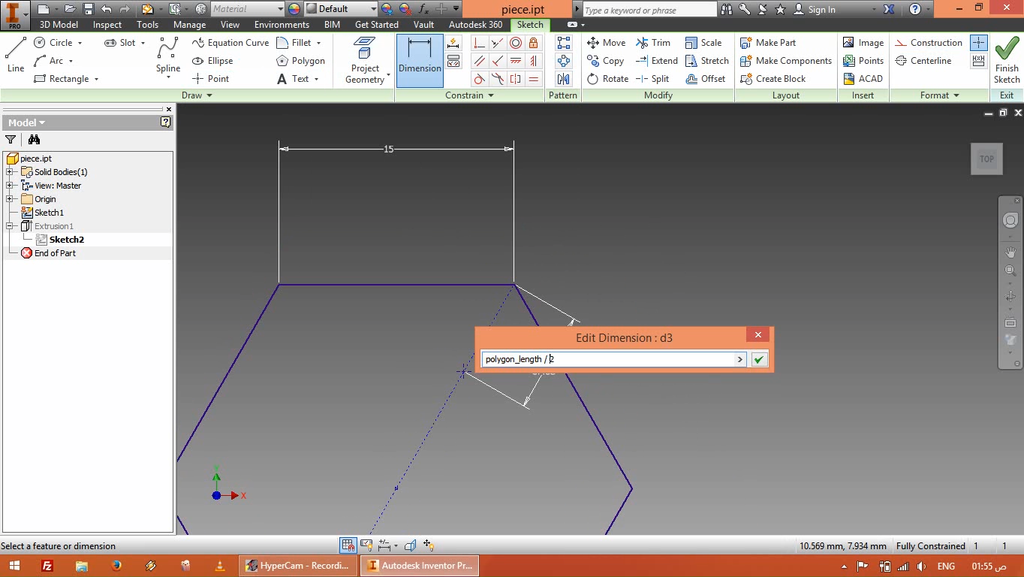

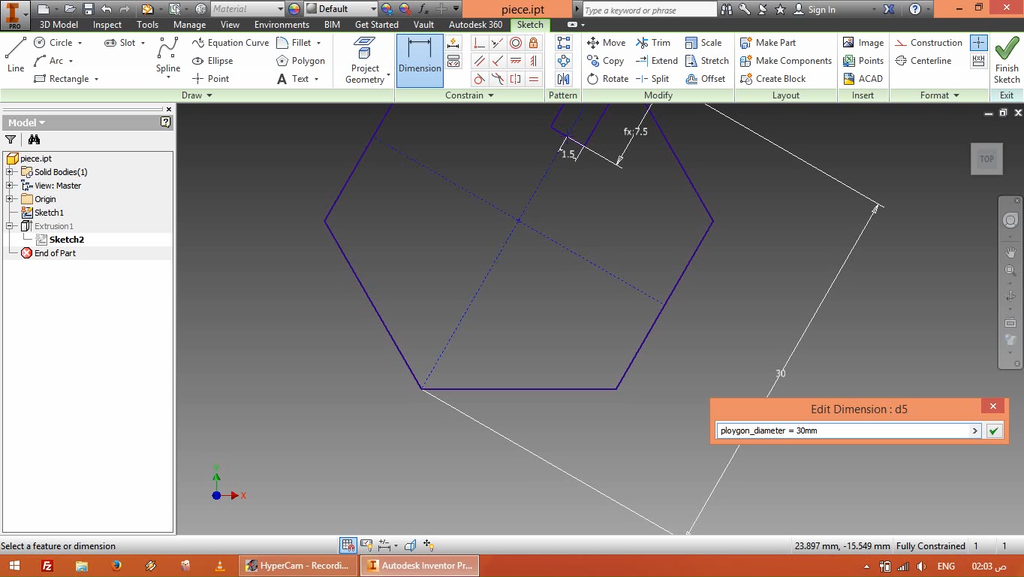

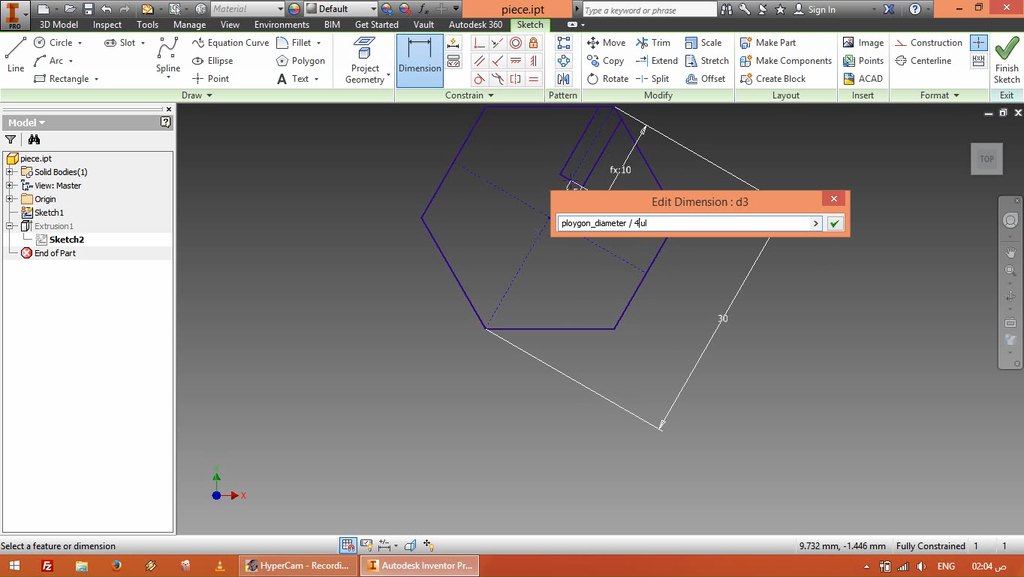

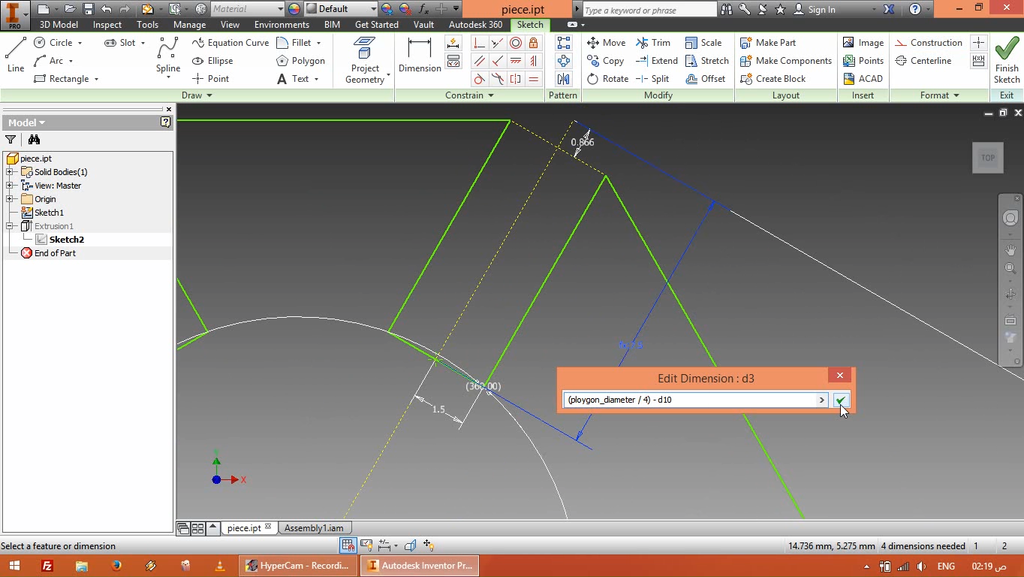

Create a construction line for polygon diameter and set a dimension for it then set the depth of the slot to be 1/4 of the diameter.

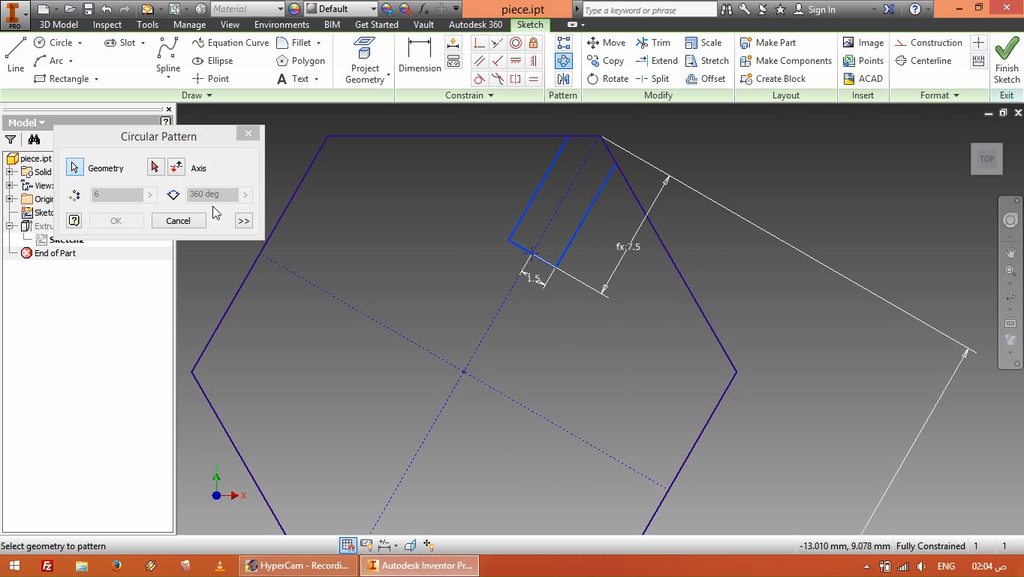

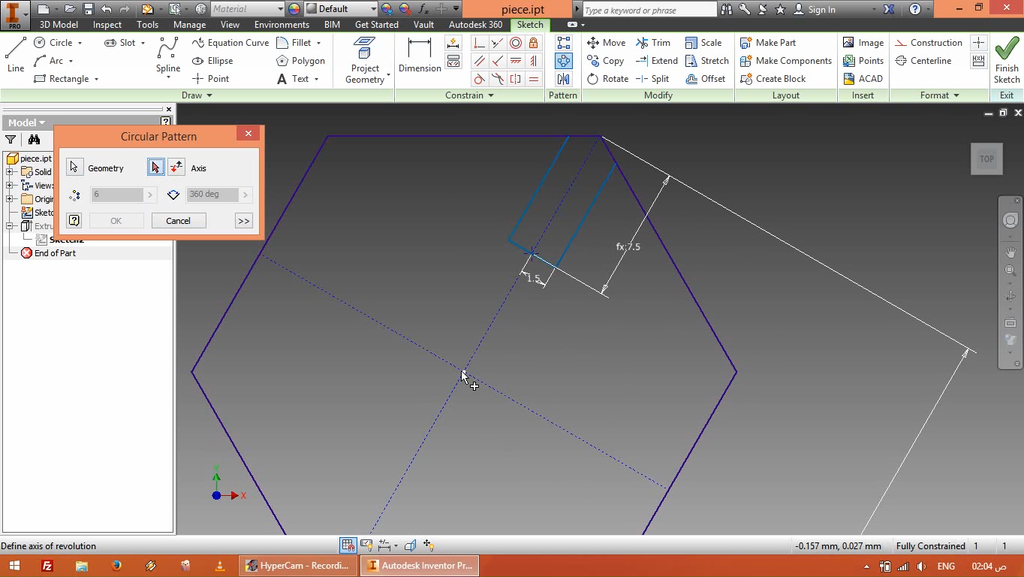

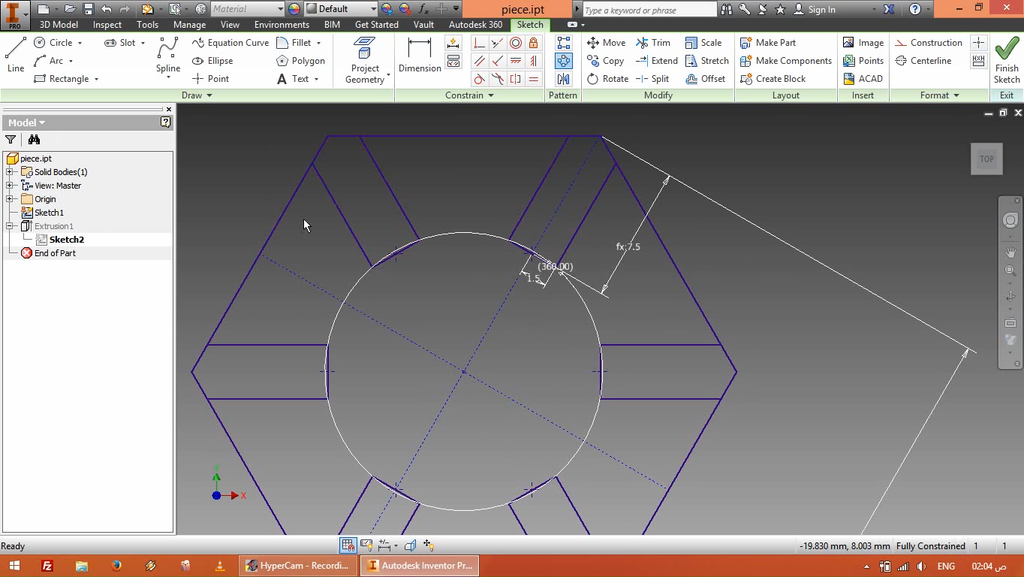

Selecting the lines for the slot and create a circular pattern around the midpoint

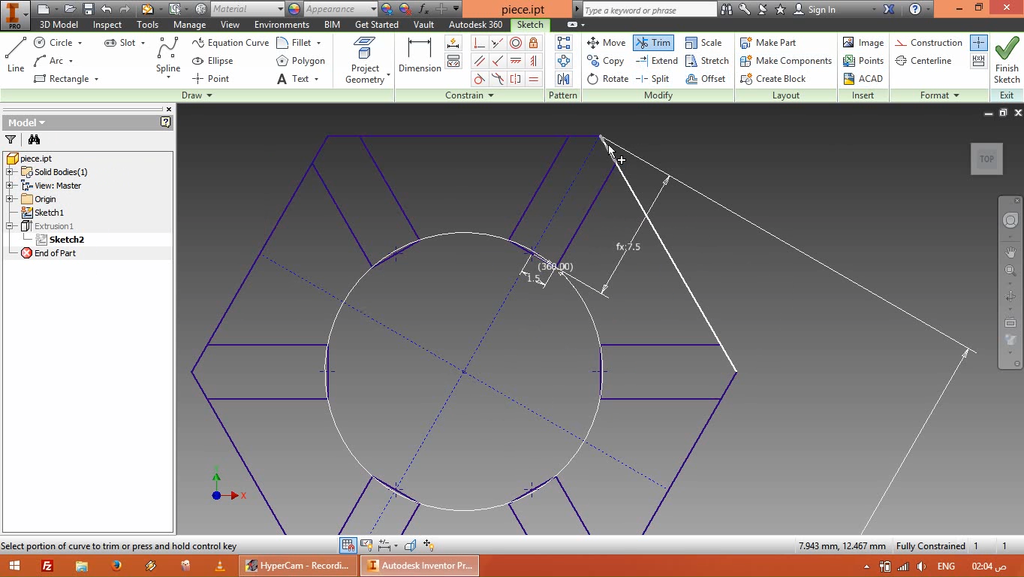

Trimming the lines

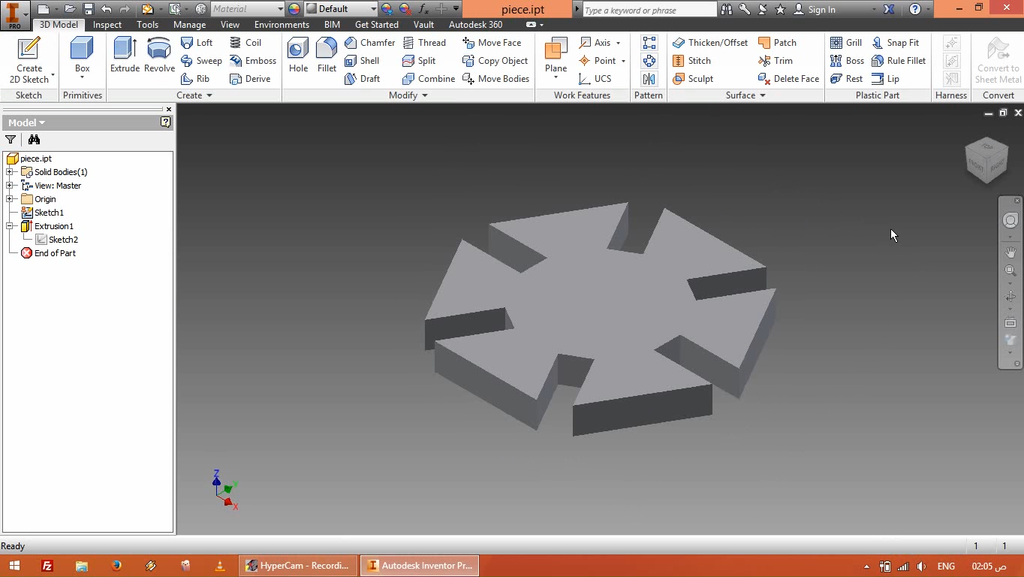

The finished piece

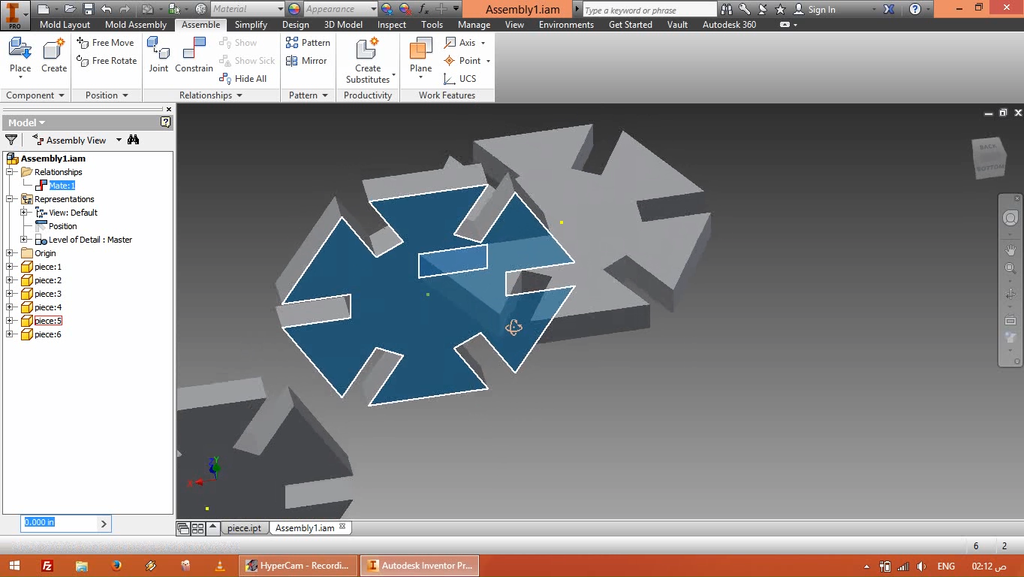

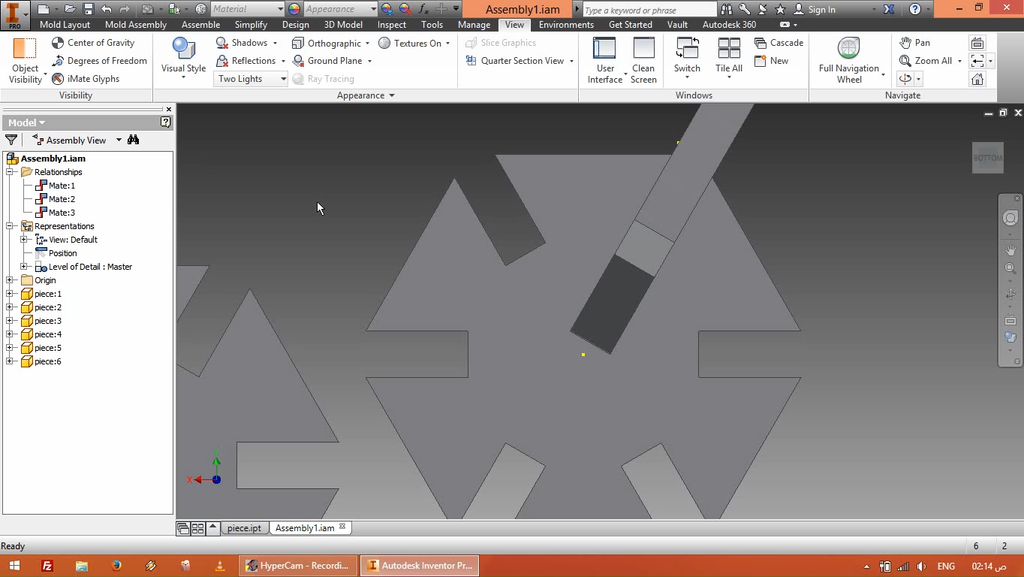

Assembly

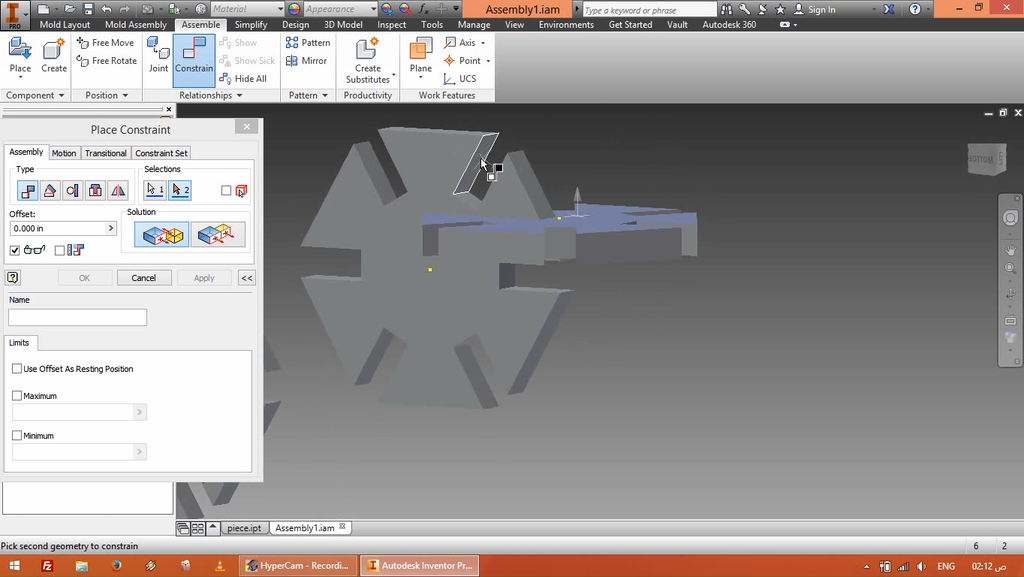

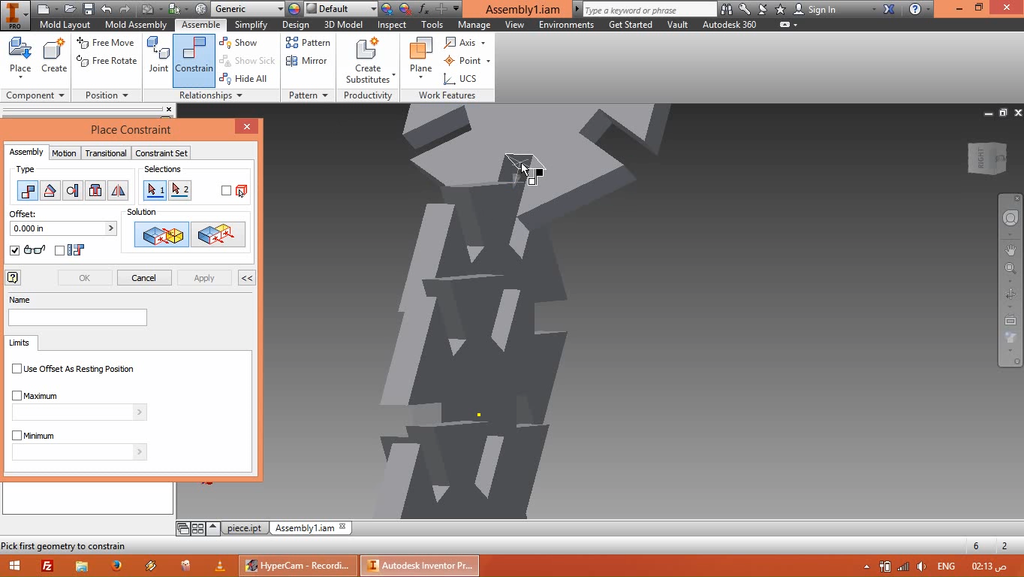

Creating constrains to test the fitting of pieces

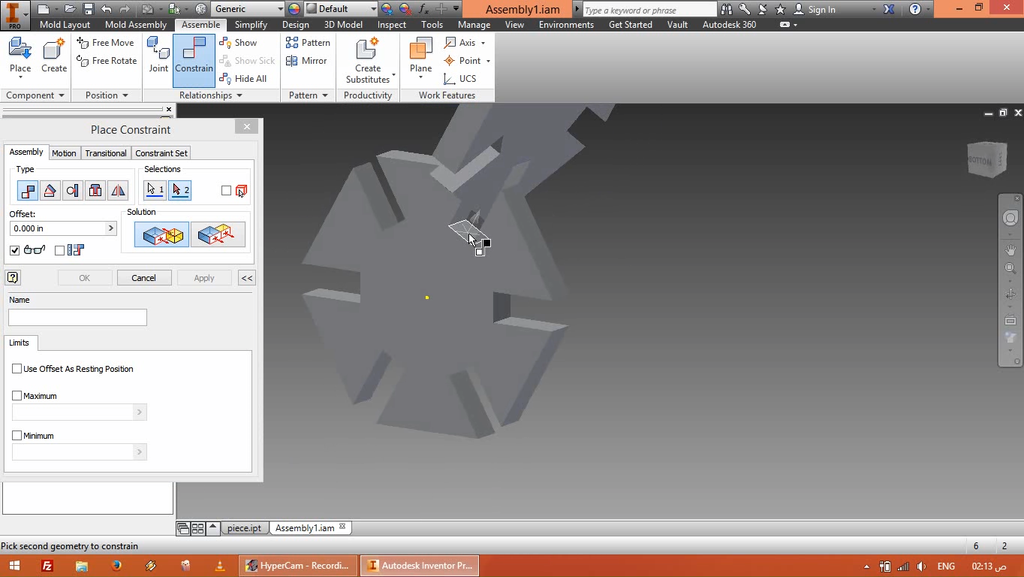

After inspection, I found out that the slot need to be more shallow so that all the pieces can fit together .So, I resized it by creating a reference point and resetting the dimension.

Multiple pieces assembled

Preparing file for laser cutting

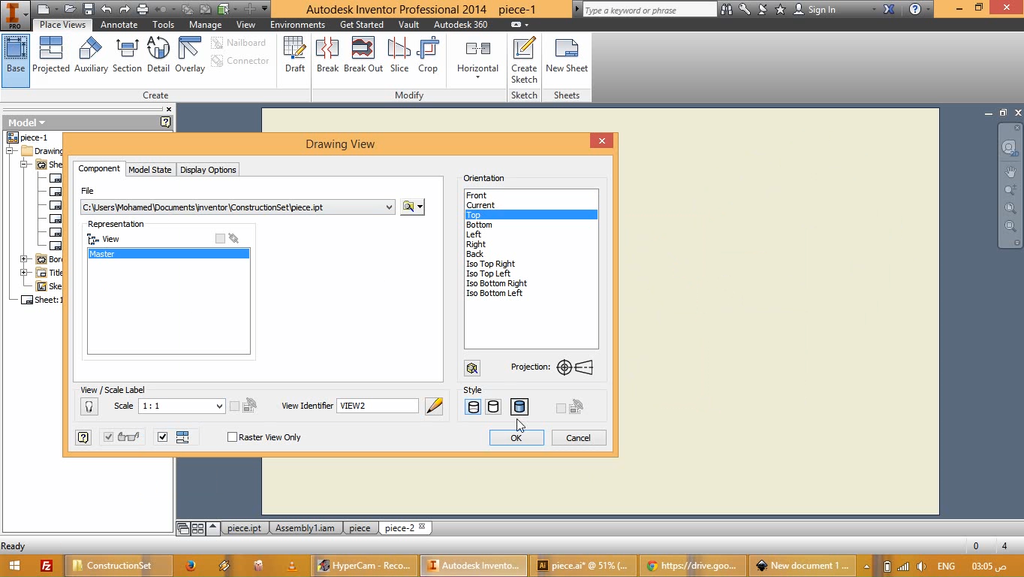

Creating a drawing in Autodesk

When creating a drawing views, I set the orientation to to Top and scale to 1:1

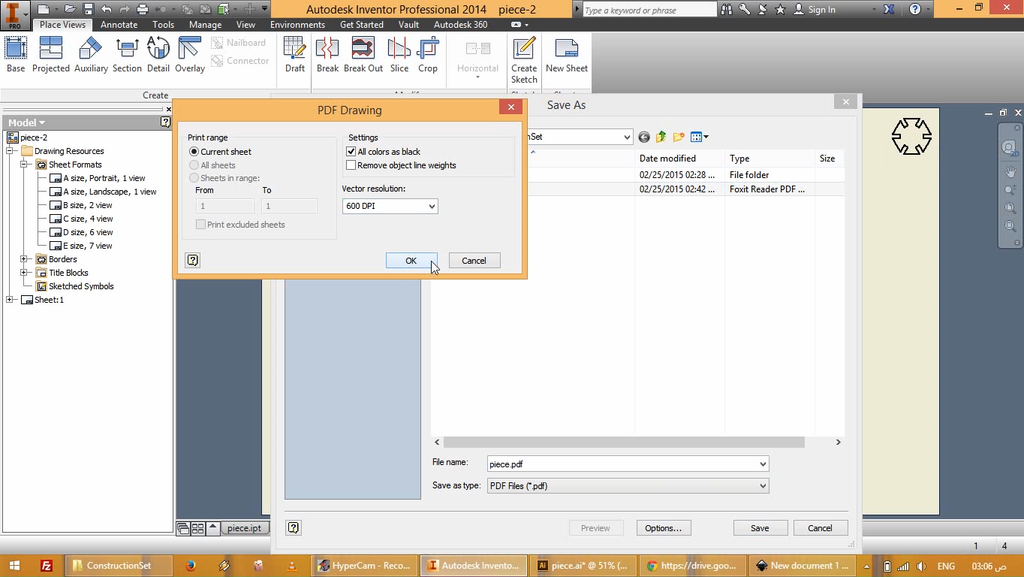

Export drawing as PDF

When exporting the drawing I set the DPI to 600

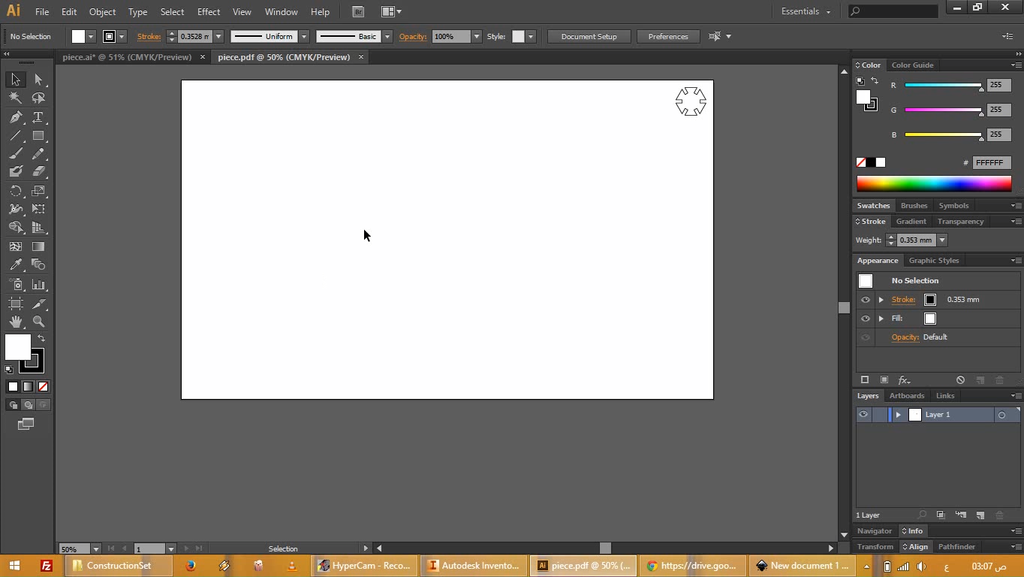

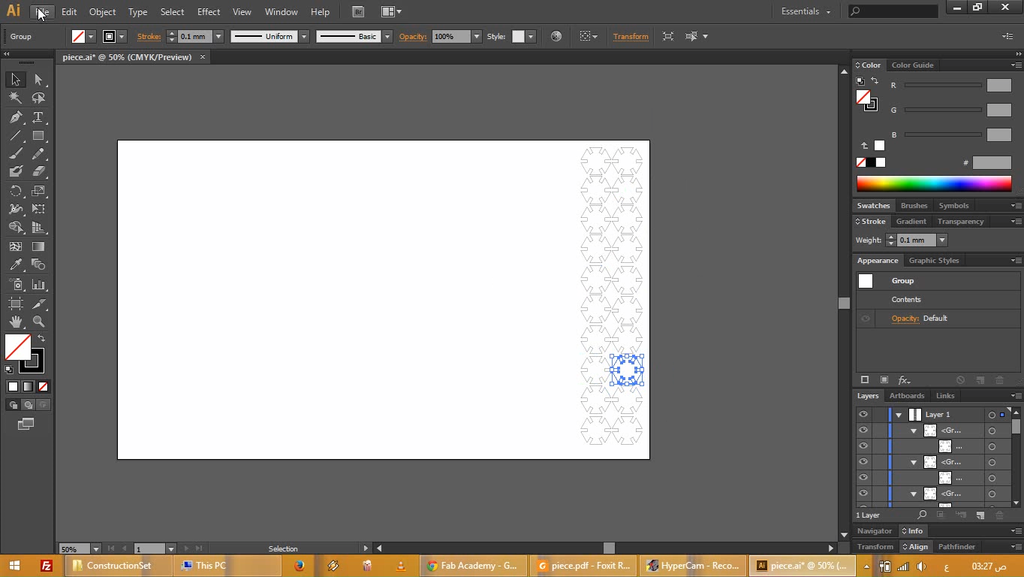

Importing the PDF into illustrator

I've exported the file into Adobe Illustrator to repeat the part.

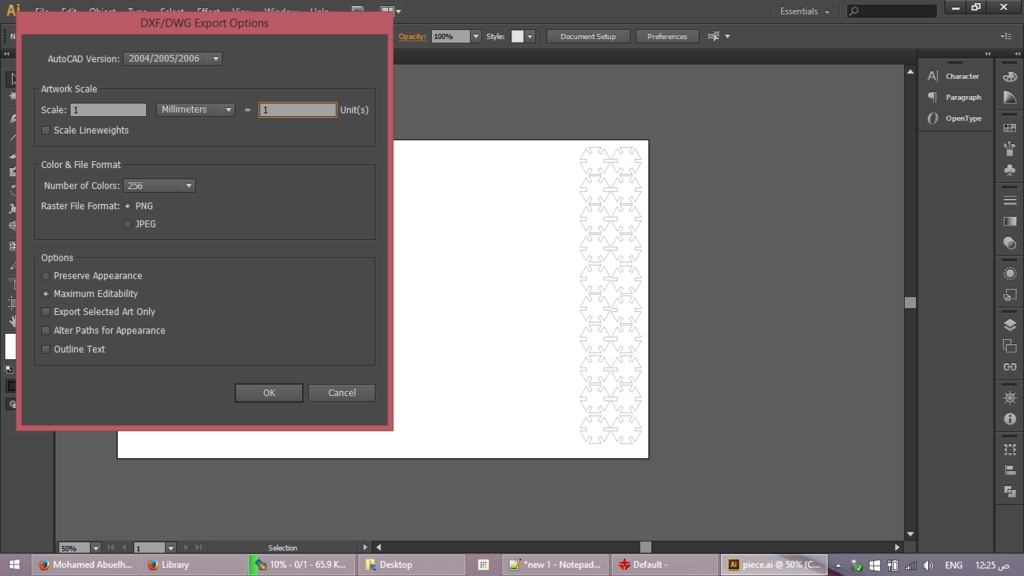

Export as DXF

In order to keep the dimensions, I set every 1 pixel to be 1 unit in the DXF export Options dialog.

Laser cutting

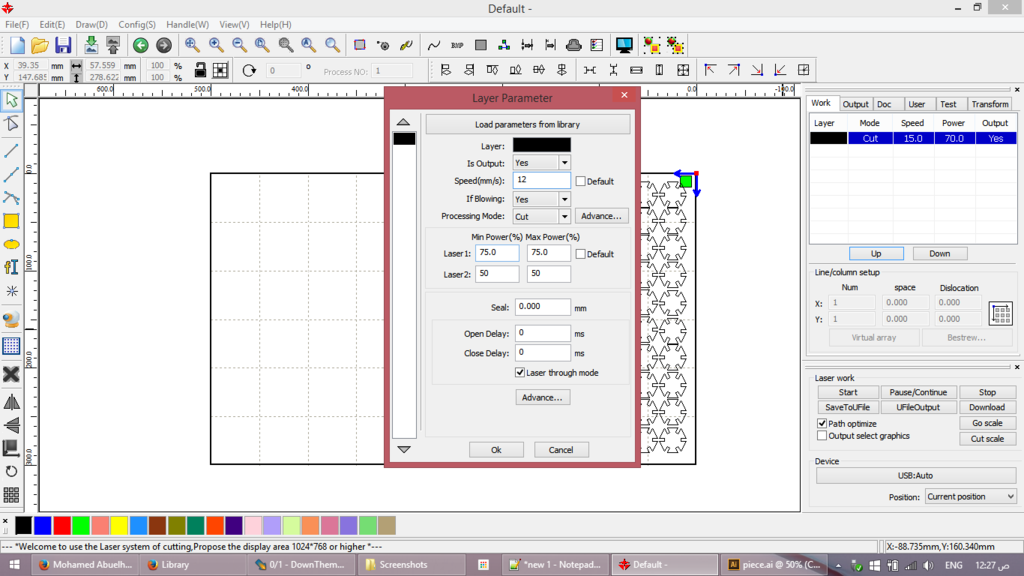

At Fab Lab Egypt we have a Morn laser cutter which uses Laser Works to work. I had Laser Works V6 installed so I opened it to prepare the file to be sent to the machine.

I chose File->import and browsed to the location of the DXF file which loaded the prices in the middle which I then moved to the top right corner.

I set the values to be 12mm/s and min and max power for the laser to be 75 as these are the values I found to work with cutting the 3mm plywood we had at the lab.

Then to set the cutting parameters, I double clicked the black layer in the "Work" panel to display its option.

I set the values to be 12mm/s and min and max power for the laser to be 75 as these are the values I found to work with cutting the 3mm plywood we had at the lab.

Then I hit OK the Start to start the cutting process.

Here is the output