Computer-Controlled Machining

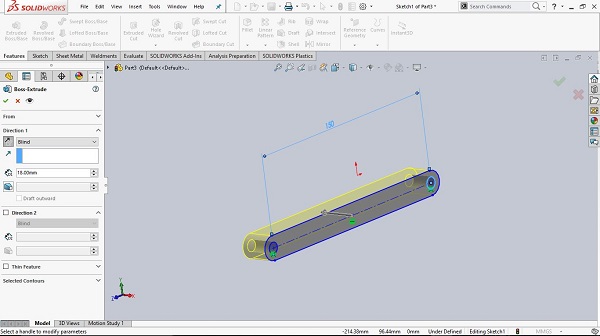

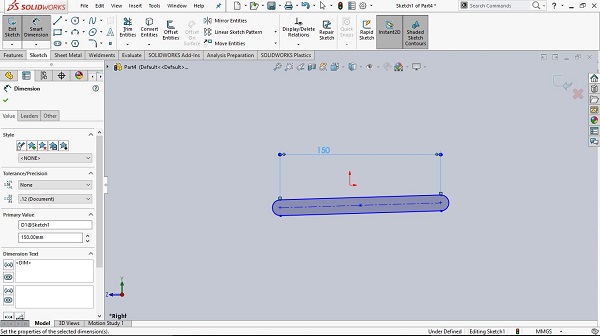

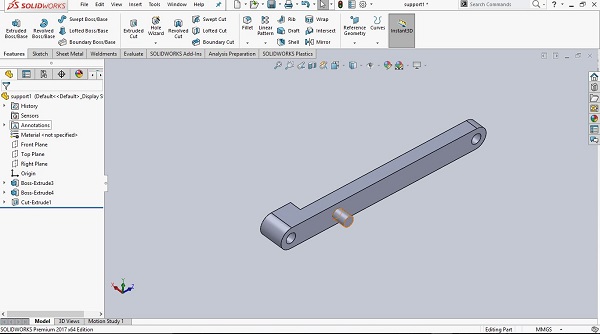

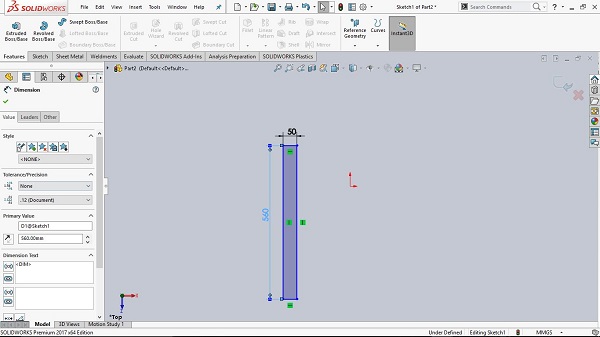

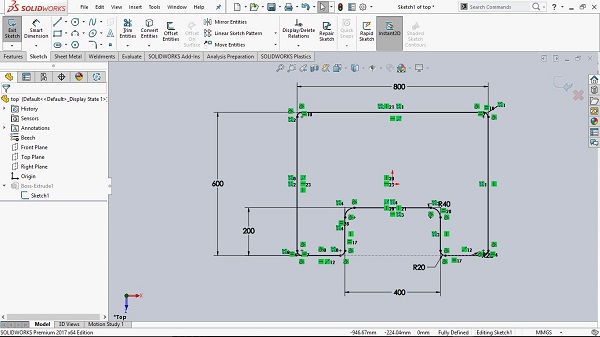

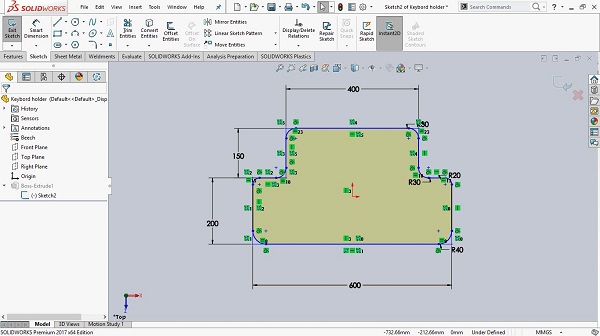

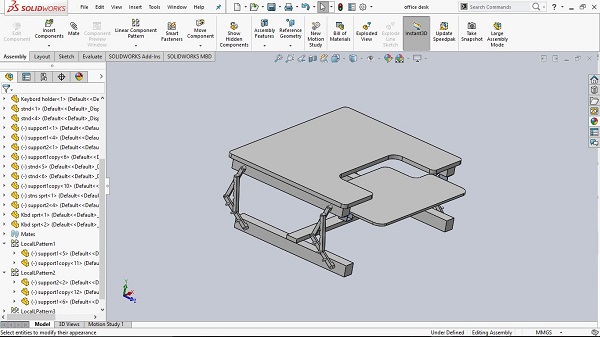

Since many people these days have problems with their backs due to over working will sitting, i decided to design a standing office desk, i did the design with solidworks and used the shopbot for cutting the material.

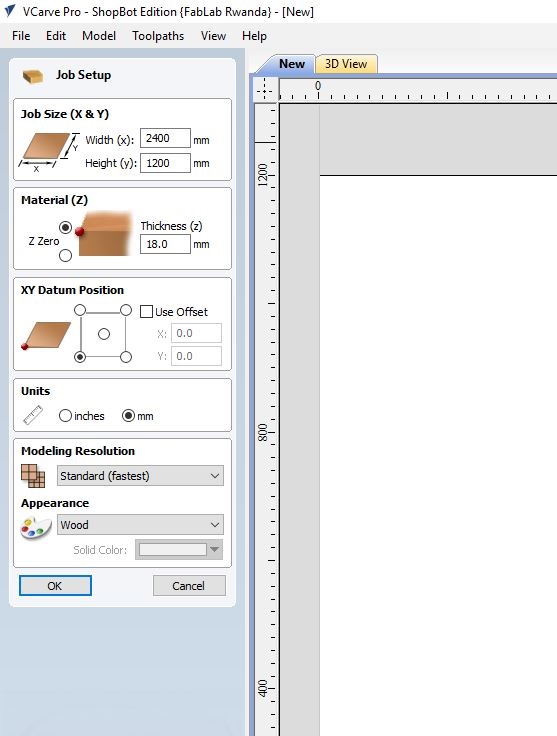

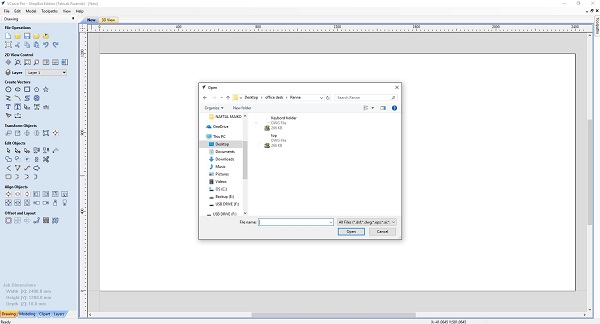

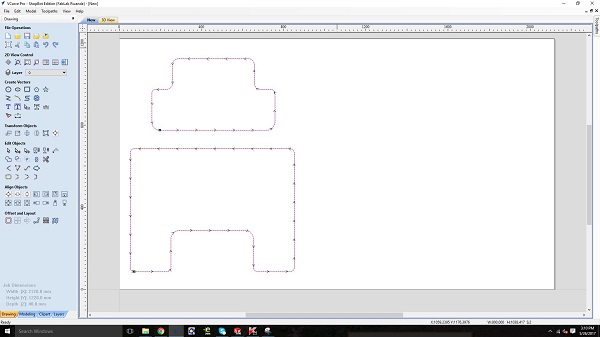

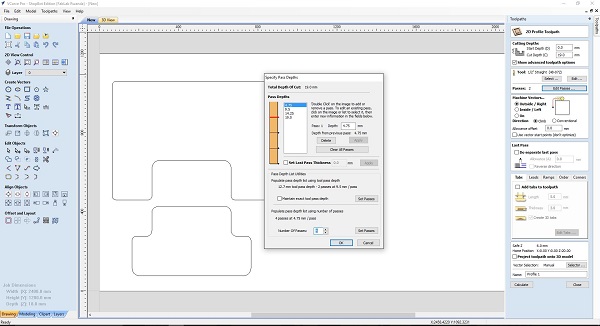

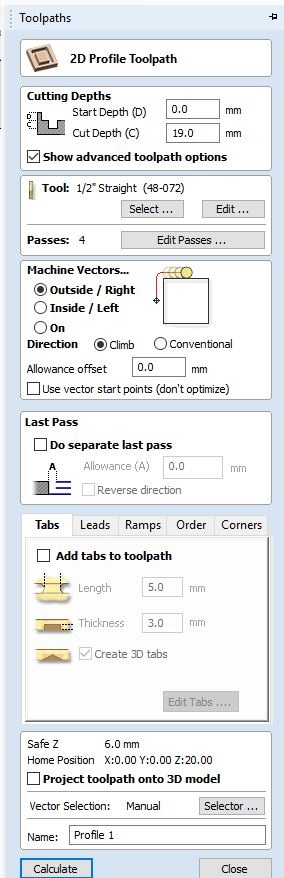

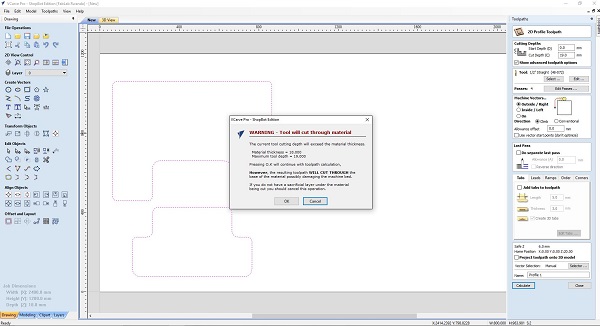

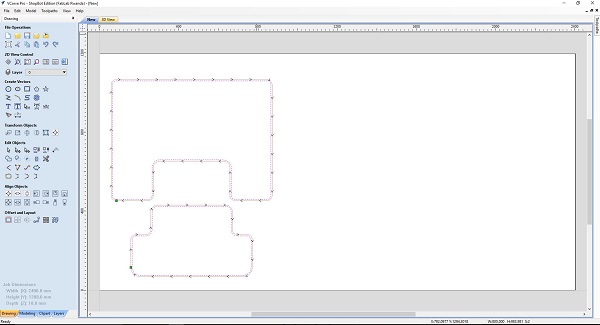

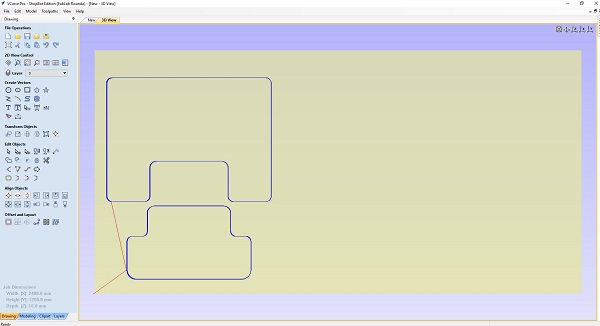

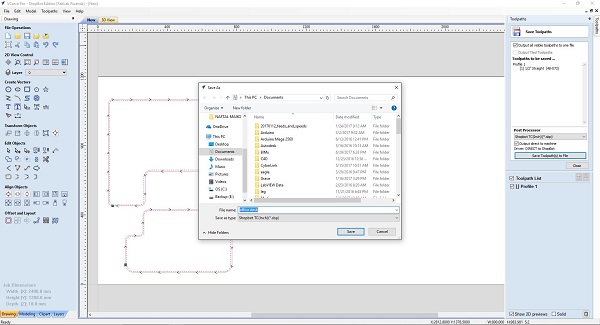

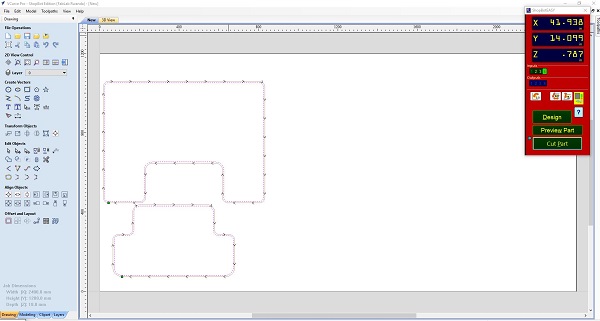

I uploaded the files from Solidworks, saved as DWG so that Vcarve a software used by shopbot may understand the model that i designed in solidworks.

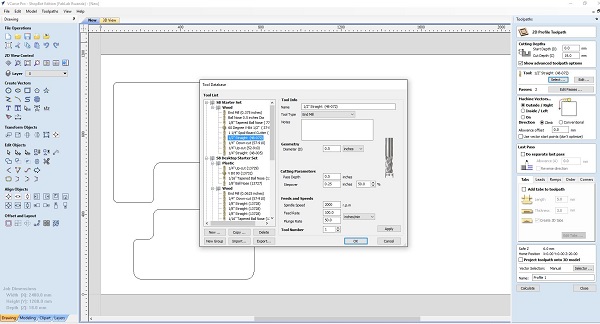

After doing the design i had to use the shopbot to cut the parts before assembling it

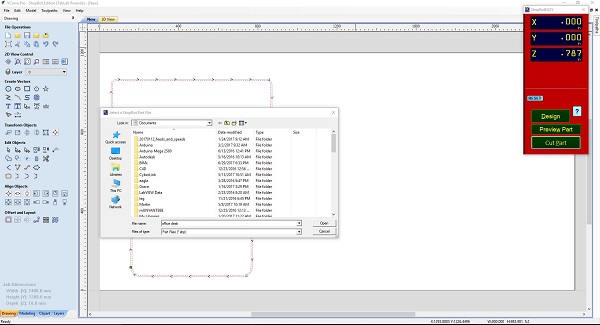

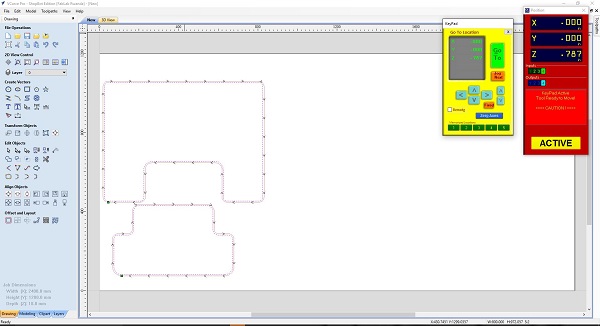

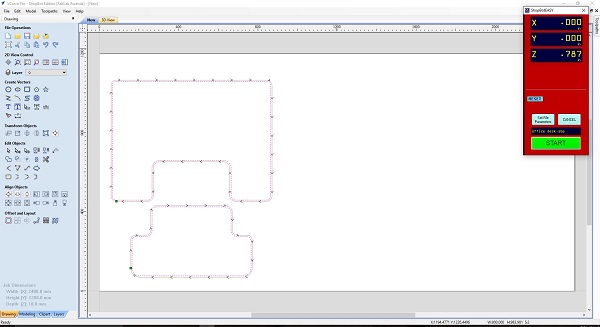

For this process after saving toolpath the shopbot GUI software lunch itself automaticaly and open the file but before start cutting you have to set origin point on my self X and Y origin i used axis navigation controll on computer interefence and for z is some how automatic because i used zeroing plate for this setting and now i can start cutting process

Download Office desk stl