Mechanical design,Machine Design

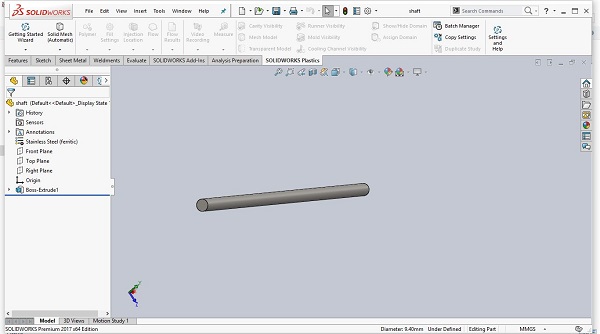

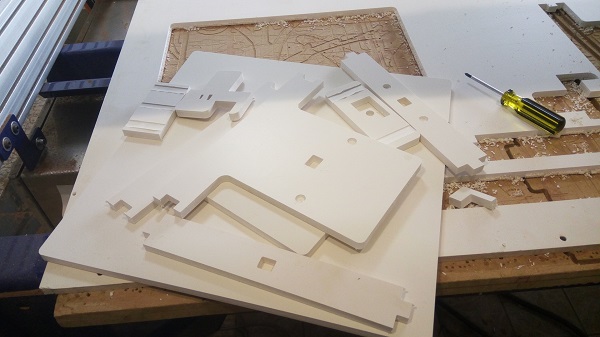

On this project I mainly focused on the mechanical design aspects, with the help and tips of my project mates. Together with Serge we made a summary of our work, taken from the group page. First thing that I did was to build a rough 3D model in Solidworks, as shown in the pictures below. Starting from there, we prototyped a physical model with the ShopBot in order to get a feeling for the size and the structural strenght of the model.

The electronics and programming of this machine was made by lambert RULINDANA

Technical analysis