Molding and Casting

I started out making a redesign of a logo of toyota company. I started modeling in Solidworks but after few hours of trial and error because i was trying to insert in the logo as a picture. I had rage-quit the software about 4 times in the process and I'm sure my hardware suffered a beating or two.It gives you the impression it does.I imagine that on a bigger scale you would need more sides.

I designed a Toyota logo by inserting a picture in solidworks

I sketched the picture and extruded it

I transfered the dxf files to vcarve which is the language that communicates to shopbot and had to set tools and paths

I started maching the mould by shopbot

Doing the machining of the mould with Shopbpt

In the first place i milled inside but later i found that it won't give me the right mould that i wanted so i had to mill outside.

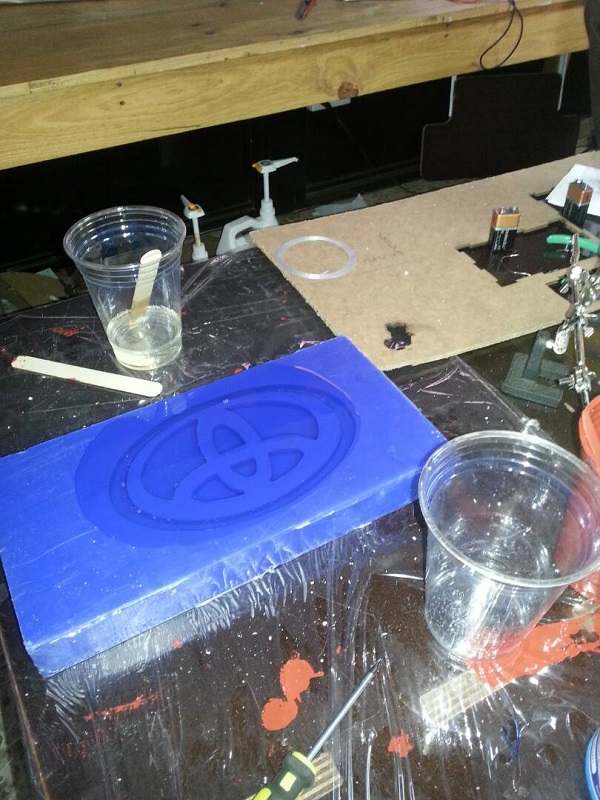

On Moulding and Casting

DXF files

DXF files